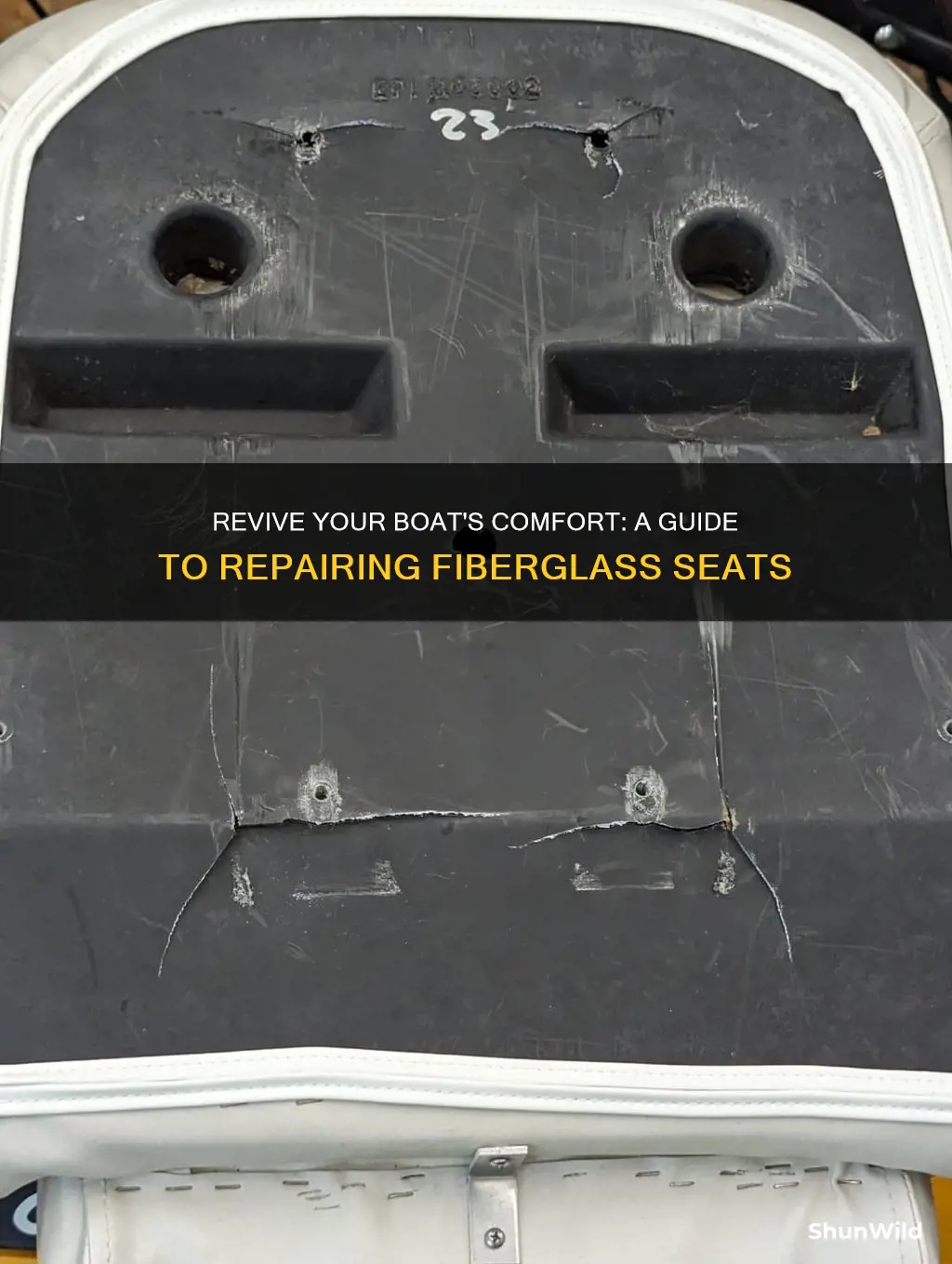

Repairing a fiberglass boat seat can seem daunting, but with the right tools and techniques, it's a manageable task. Whether you're dealing with a cracked or damaged seat, the process involves cleaning the area, applying a suitable filler or resin, and then sanding and painting to restore the seat's original appearance. This guide will provide step-by-step instructions on how to tackle this project, ensuring your boat seat is as good as new in no time.

What You'll Learn

- Prepare Materials: Gather tools and supplies: sandpaper, epoxy, filler, primer, and paint

- Clean Surface: Remove dirt, old paint, and debris with a scrub brush and cleaner

- Fill Cracks: Use marine-grade filler to repair holes and cracks, following manufacturer's instructions

- Sand Smooth: Smooth the surface with fine-grit sandpaper, ensuring a level and even finish

- Paint and Finish: Apply marine paint and clear coat for protection and a professional look

Prepare Materials: Gather tools and supplies: sandpaper, epoxy, filler, primer, and paint

Before you begin the repair process, it's crucial to gather all the necessary tools and materials to ensure a smooth and effective restoration of your boat seat. Here's a step-by-step guide on preparing the materials:

Sandpaper: Start by selecting the appropriate sandpaper for your project. Fine-grit sandpaper, typically in the range of 400 to 600 grit, is ideal for fiberglass repairs. This grit level will help you smooth out any imperfections and prepare the surface for further work. You can find various types of sandpaper, including aluminum oxide or silicon carbide, which are commonly used for fiberglass. Ensure you have enough sandpaper to cover the entire damaged area, and consider keeping a few extra sheets for touch-ups.

Epoxy: Epoxy is a vital component for bonding and strengthening the fiberglass. Choose a two-part epoxy system, which typically consists of a resin and a hardener. Follow the manufacturer's instructions for mixing ratios and application techniques. Having the right amount of epoxy is essential, so measure carefully according to the size of your repair. It's a good idea to have some extra epoxy on hand in case you need to make additional passes.

Filler: Fiberglass filler is used to fill any gaps, holes, or imperfections in the seat. Select a filler that is compatible with fiberglass, such as epoxy-based or polyester-based filler. Again, measure the amount needed based on the size of the repair. Practice applying the filler on a test surface to get a feel for the process and ensure you have enough for the job.

Primer and Paint: Priming and painting are essential steps to ensure a professional finish. Start with a fiberglass primer, which will create a suitable surface for the paint. Choose a primer that complements the epoxy you used. After priming, apply your chosen paint color. Opt for marine-grade paint, which is designed to withstand the harsh marine environment. Ensure you have enough paint to cover the entire seat, considering any additional coats you might need for a smooth finish.

By gathering these materials in advance, you'll be well-prepared to tackle the repair process and restore your boat seat to its original glory. Remember to follow the instructions provided with each product for the best results.

Bay Boats: Saltwater and Freshwater Versatility Explored

You may want to see also

Clean Surface: Remove dirt, old paint, and debris with a scrub brush and cleaner

Before you begin the repair process, it's crucial to ensure that the surface of the boat seat is clean and free from any contaminants. This step is often overlooked but is essential for a successful restoration. Start by thoroughly cleaning the entire area, paying close attention to any areas where old paint or stains might have accumulated. Use a stiff-bristled scrub brush to gently remove dirt and debris. Work in small sections to avoid overwhelming yourself and to ensure a thorough clean.

For stubborn stains or paint buildup, you may need to use a specialized cleaner designed for marine applications. These cleaners are typically safe for use on fiberglass and can be applied directly to the affected areas. Allow the cleaner to sit for a few minutes to penetrate and loosen the old paint or stains before scrubbing again. This process ensures that you're not just moving the dirt around but actually removing it from the surface.

Once you've scrubbed the entire seat, rinse the area thoroughly with clean water to remove any remaining dirt and cleaner. Ensure that no residue is left behind, as this could interfere with the bonding process during the repair. Use a garden hose or a pressure washer (if available) to ensure a thorough rinse.

After rinsing, inspect the surface to ensure it's clean and ready for the next step. If there are any remaining stains or paint residue, repeat the scrubbing process until the surface is completely clean. This attention to detail will ensure a strong bond between the old and new materials during the repair, making the final result more durable and long-lasting.

Remember, taking the time to properly clean the surface is a critical step that will pay off in the long run, ensuring a successful and long-lasting repair for your fiberglass boat seat.

Bass Boat Hulls: Understanding the Design and Functionality

You may want to see also

Fill Cracks: Use marine-grade filler to repair holes and cracks, following manufacturer's instructions

When it comes to restoring the comfort and aesthetics of your fiberglass boat seat, filling cracks and holes is a crucial step in the repair process. Here's a detailed guide on how to effectively tackle this task using marine-grade filler:

Step 1: Preparation

Before you begin, ensure the boat seat is clean and dry. Remove any loose debris or dirt from the crack or hole using a soft brush or cloth. This step is essential to create a clean surface for the filler. If the damage is extensive, consider using a marine-grade primer to ensure better adhesion.

Step 2: Choose the Right Filler

Marine-grade filler is specifically designed for use in marine environments and offers excellent resistance to UV rays, saltwater, and other harsh conditions. Select a filler that matches the color of your boat seat as closely as possible. This will help maintain the original appearance. Common types of marine-grade filler include epoxy-based and polyurethane-based options, each with its own advantages.

Step 3: Application

Follow the manufacturer's instructions carefully for the chosen filler. Typically, you'll mix the filler with a hardener or catalyst to create a paste-like consistency. Here's a general process:

- Load the filler into a disposable syringe or a small container for easier application.

- Inject or spread the filler into the crack or hole, ensuring it is fully filled. You might need to use a putty knife or a similar tool to shape and smooth the filler.

- Allow the filler to set partially, following the manufacturer's guidelines for the initial setting time. This will make it easier to sand and shape later.

- Once partially set, use fine-grit sandpaper (e.g., 400-grit) to smooth the filler's surface, creating a level and even finish.

Step 4: Final Touches

After sanding, inspect the repaired area. If there are any visible imperfections or gaps, carefully reapply more filler and repeat the sanding process until you achieve a seamless blend with the surrounding surface. Allow sufficient time for the filler to cure completely, following the manufacturer's instructions.

Remember, practice makes perfect. If you're new to this process, consider starting with a small, inconspicuous area to get a feel for the technique. With patience and attention to detail, you can effectively fill cracks and holes, restoring your fiberglass boat seat to its original glory.

Boat Donation Organizations: Finding the Best One

You may want to see also

Sand Smooth: Smooth the surface with fine-grit sandpaper, ensuring a level and even finish

Before you begin the repair process, it's crucial to ensure you have the right tools and materials. Fine-grit sandpaper is essential for this step, as it will help you achieve a smooth and even surface. Start by laying the sandpaper on a flat surface and gently rubbing it over the damaged area of the boat seat. Apply even pressure to avoid any uneven spots. Work in small sections to maintain control and precision. If you encounter any stubborn rough patches, you may need to go over them multiple times until the surface is consistently smooth.

The goal is to remove any imperfections and create a seamless transition between the repaired area and the surrounding seat. Remember to sand with the grain of the fiberglass to avoid creating new scratches. Once you've covered the entire damaged area, inspect the surface to ensure it's smooth and level. If there are any remaining rough spots, re-sand them gently until you achieve the desired finish.

After sanding, it's a good idea to wipe down the entire seat with a damp cloth to remove any dust and ensure a clean surface for the next step. This process might require patience and a keen eye for detail, but it's an essential part of restoring the boat seat's original appearance.

Unveiling the Speed Limits: How Fast Can Fishing Boats Go?

You may want to see also

Paint and Finish: Apply marine paint and clear coat for protection and a professional look

When it comes to restoring the appearance and durability of your fiberglass boat seat, applying marine paint and a clear coat is an excellent solution. This process not only rejuvenates the seat's finish but also provides essential protection against the harsh marine environment. Here's a step-by-step guide to help you achieve a professional-looking result:

Preparation: Begin by thoroughly cleaning the seat surface. Remove any dirt, grime, or old paint using a mild detergent and a soft brush. Rinse the area with water and ensure it is completely dry before proceeding. It's crucial to start with a clean and smooth surface for optimal paint adhesion. Consider using a fine-grit sandpaper to gently smooth out any rough spots or imperfections on the fiberglass. This step will create a seamless base for the new paint.

Priming (Optional but Recommended): Priming the fiberglass surface is an essential step to ensure the paint adheres properly. Choose a marine-grade primer suitable for fiberglass. Apply a thin, even coat using a small brush or a spray gun, following the manufacturer's instructions. Allow the primer to dry completely before proceeding to the next step. Priming will enhance the paint's durability and provide a more professional finish.

Painting: Select a marine paint that is specifically designed for outdoor use and resistant to UV rays and water. Marine paint comes in various colors, so choose one that matches your desired finish. Apply the paint in thin, even coats using a brush or a spray gun. Start with a base coat and allow it to dry before applying subsequent coats. Multiple thin coats will provide better coverage and a smoother finish compared to a single thick coat. Ensure you follow the paint manufacturer's guidelines for drying times between coats.

Clear Coat Application: After the paint has dried, it's time to add the final touch with a clear coat. Marine clear coat provides additional protection and a high-gloss or satin finish. Apply the clear coat using a brush or a spray gun, ensuring an even layer. Allow it to dry thoroughly, and then apply a second coat if desired for added protection and depth. The clear coat will not only enhance the appearance of the seat but also protect the paint from fading and UV damage.

Final Touches: Once the clear coat is fully cured, inspect the seat for any minor imperfections. You can touch up any areas with a small brush or a touch-up paint pen. Ensure all edges and corners are well-defined. Consider adding a protective seat cover or cushion to enhance comfort and further protect the newly painted seat. With these steps, your fiberglass boat seat will not only look brand new but will also be well-protected against the marine environment.

Protecting Wood Boat Seats: Finishing Touches for Marine Craft

You may want to see also

Frequently asked questions

For minor tears, you can use a fiberglass repair kit specifically designed for marine applications. These kits typically include a resin, hardener, and a cloth or tape to reinforce the damaged area. Clean the tear, apply the resin and hardener, and then lay the cloth over the repair area. After it dries, sand it smooth and paint it to match the seat's color.

To fill holes, you can use a two-part epoxy or a marine-grade filler. Clean the area around the hole, ensuring it's free of debris. Mix the epoxy or filler according to the manufacturer's instructions and apply it to the hole, building up the surface slightly above the original level. Once it's dry, sand it smooth and consider painting or covering it with a marine-grade fabric to match the seat.

While spray cans can be used for temporary repairs, they are not ideal for a permanent solution. Spray-on products may not adhere as strongly to fiberglass as a traditional repair method. For a more durable fix, it's recommended to use a repair kit or a two-part epoxy, ensuring a proper bond and a longer-lasting result.