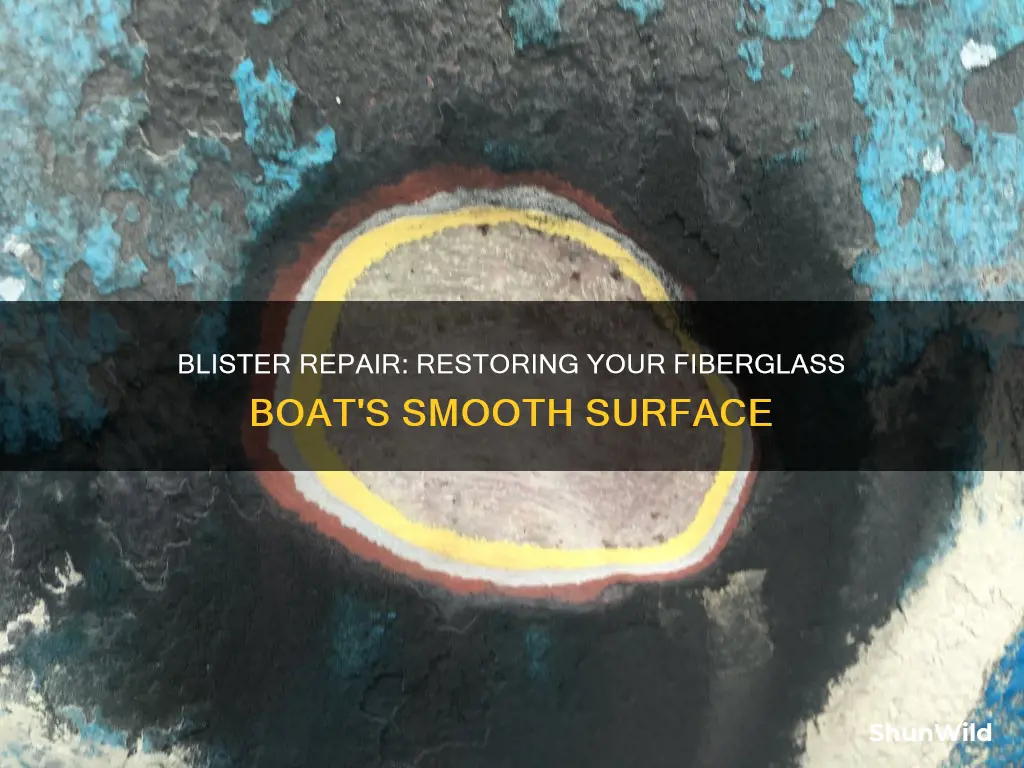

Fiberglass blister boats are popular for their lightweight and efficient design, but they can be prone to developing blisters, which are small bubbles or imperfections on the surface. Repairing these blisters is essential to maintain the boat's structural integrity and appearance. This guide will provide a step-by-step process for effectively repairing fiberglass blister boats, ensuring they remain in top condition for years to come.

What You'll Learn

- Identify Blister: Inspect boat for raised, bubbly areas on fiberglass surface

- Clean and Prepare: Remove dirt and old repair attempts with a scraper and cleaner

- Patch with Resin: Use a suitable epoxy resin to create a new layer over the blister

- Reinforce with Fabric: Apply a fiberglass cloth or tape to strengthen the repair area

- Sand and Finish: Smooth the repair with sandpaper and apply a protective coating

Identify Blister: Inspect boat for raised, bubbly areas on fiberglass surface

When it comes to identifying blisters on a fiberglass boat, a thorough inspection is key. Blisters are essentially raised, bubbly areas on the surface of the fiberglass, often caused by trapped air or moisture beneath the gelcoat layer. These blisters can be a sign of potential structural issues and should be addressed promptly to prevent further damage. Here's a step-by-step guide to help you identify and assess blisters:

Start by thoroughly examining the entire boat's exterior. Look for any areas where the fiberglass surface appears raised or distorted. Blisters can vary in size, ranging from small, pin-sized bubbles to larger, more prominent areas. Pay close attention to the gelcoat, which is the clear outer layer of the fiberglass. Blisters often form beneath the gelcoat, causing it to bulge upwards. Use your fingers or a soft-bristled brush to gently press on the suspected blister areas. If you feel a firm, raised surface, it's likely a blister.

Look for patterns in the blister distribution. Blisters can occur randomly, but they may also indicate a specific issue. For example, if you notice multiple blisters in a linear pattern, it could suggest a problem with the boat's construction or a previous repair attempt. Keep an eye out for any discoloration or changes in the texture of the fiberglass around the blisters. Moisture absorption can lead to discolored or soft spots, indicating potential water intrusion.

Take note of the boat's history and usage. Blisters can be more prevalent in boats that have been exposed to harsh marine environments, frequent temperature fluctuations, or those that have experienced impact damage. Older boats may also be more susceptible due to the natural degradation of materials over time. If you're unsure about the cause, consider consulting with a marine repair specialist who can provide expert advice.

Remember, early detection is crucial for successful repair. Once you've identified blisters, take appropriate measures to address the underlying cause and prevent further damage to your fiberglass boat.

Bass Pro Shop: Boat Trailers and More

You may want to see also

Clean and Prepare: Remove dirt and old repair attempts with a scraper and cleaner

Before you begin the repair process, it's crucial to thoroughly clean and prepare the fiberglass surface. This step ensures that any existing dirt, grime, or previous repair attempts are removed, providing a clean slate for the new fix. Start by inspecting the blister area and identifying any loose or damaged fiberglass. Use a sharp scraper to carefully remove any flaking or cracked material, ensuring you don't damage the underlying gelcoat. Work gently and methodically, scraping in a straight line and avoiding any circular motions that might create new imperfections.

Once the initial scraping is complete, it's time to clean the area. You can use a mild detergent mixed with water to create a soapy solution. Apply this mixture to the blister, ensuring it covers the entire affected area. Let it sit for a few minutes to allow the soap to penetrate and loosen any remaining dirt or old repair residue. Then, use a stiff-bristled brush to scrub the area vigorously, removing any stubborn grime. Rinse the area thoroughly with clean water to eliminate any soap residue.

For a more thorough clean, consider using a fiberglass cleaner or a specialized gelcoat cleaner. These products are designed to cut through grease, oil, and other contaminants that might be present. Apply the cleaner to the blister and let it sit for the recommended time, which is usually a few minutes. This allows the cleaner to work its way into the surface, breaking down any stubborn deposits. After the specified time, scrub the area again with a brush, then rinse it thoroughly.

After cleaning, inspect the surface to ensure it is free from any dirt, grime, or old repair attempts. If there are any remaining traces of previous work, use the scraper again to remove them. Be cautious not to go too deep, as you don't want to create new imperfections or damage the gelcoat. The goal is to create a smooth, clean surface that is ready for the new repair.

Remember, taking the time to properly clean and prepare the fiberglass is essential for a successful repair. It ensures that the new material bonds effectively with the existing surface, leading to a stronger and more durable fix. This process might seem tedious, but it is a critical step that will pay off in the long run.

Staying Safe: Life Jackets Requirements for Boating Trips

You may want to see also

Patch with Resin: Use a suitable epoxy resin to create a new layer over the blister

When dealing with a fiberglass blister boat, a common issue that sailors and boat owners face is the need to repair blisters or delaminations. One effective method to address this problem is by patching with resin, specifically using a suitable epoxy resin. This technique involves creating a new layer over the damaged area to restore the boat's structural integrity and appearance. Here's a step-by-step guide to help you through the process:

Step 1: Prepare the Blister Area

Start by carefully inspecting the blister to assess its size and depth. Clean the affected area thoroughly, removing any dirt, debris, or loose fibers. Ensure the surface is smooth and free from contaminants. It is crucial to prepare the blister properly to ensure the resin adheres effectively. Consider using a fine-grit sandpaper to create a slightly textured surface, providing better grip for the resin.

Step 2: Choose the Right Epoxy Resin

Selecting the appropriate epoxy resin is vital for a successful repair. Opt for a two-part epoxy system, typically consisting of a resin and a hardener. Follow the manufacturer's instructions to mix the two parts in the correct ratio. Choose a resin that is compatible with fiberglass and offers good adhesion and strength. Consider the environmental conditions and temperature range when making your selection.

Step 3: Apply the Resin

Now, it's time to apply the epoxy resin. Start by brushing or rolling the resin onto the prepared blister area. Ensure an even and thin layer, avoiding any thick spots. Work quickly as epoxy resins cure relatively fast. If needed, use a heat gun or hairdryer to accelerate the curing process, but be cautious not to overheat the resin.

Step 4: Create a New Layer

Once the initial layer of resin is applied and cured, it's time to build up the damaged area. Carefully blend the new resin layer with the existing one, ensuring a smooth transition. You can use a putty knife or a similar tool to create a level surface and blend the edges seamlessly. This step is crucial to ensure the structural integrity of the boat and maintain its aesthetic appeal.

Step 5: Sanding and Finishing

After the resin has cured, inspect the patched area. If there are any rough spots or imperfections, gently sand them down using fine-grit sandpaper. Take care not to sand through the new layer. Once satisfied with the surface, you can further refine it by applying additional layers of resin and sanding between coats. This process will create a smooth and durable finish.

Remember, when working with epoxy resins, always follow safety precautions, such as wearing gloves and a respirator, and ensuring proper ventilation. With patience and attention to detail, you can successfully patch a fiberglass blister boat using this resin-based repair method.

Transom Replacement: A Step-by-Step Guide for Boat Owners

You may want to see also

Reinforce with Fabric: Apply a fiberglass cloth or tape to strengthen the repair area

When dealing with a fiberglass blister repair, reinforcing the affected area with fabric is a crucial step to ensure a strong and durable fix. This method provides additional strength and stability to the repair, making it less likely to fail in the future. Here's a step-by-step guide on how to effectively reinforce the blister with fabric:

Step 1: Prepare the Repair Area

Start by cleaning the blister area thoroughly. Remove any dirt, old filler, or debris using a wire brush or a scraper. Ensure the surface is smooth and free from contaminants. This preparation step is essential to create a strong bond between the new fabric and the existing fiberglass.

Step 2: Choose the Right Fabric

Select a fiberglass cloth or tape that is appropriate for the size and shape of the blister. For small repairs, a fine-woven fiberglass cloth (also known as a 'glass cloth') is commonly used. It provides a smooth surface for bonding. If the blister is larger, consider using a fiberglass tape, which is typically more flexible and can conform to curved areas. Ensure the fabric is compatible with the type of fiberglass used in your boat.

Step 3: Apply the Fabric

Cut the fabric slightly larger than the repair area to allow for overlap. Start by laying the fabric over the prepared surface, ensuring it is centered and aligned properly. Use a small amount of epoxy resin or a specialized fiberglass repair adhesive to coat the fabric. This adhesive will act as a bond between the fabric and the existing fiberglass. Apply a thin, even layer, being careful not to use too much, as it can lead to sagging or wrinkling.

Step 4: Wet the Fabric

After applying the adhesive, wet the fabric with a spray bottle filled with water. This process is known as 'wetting out' the glass. It helps to create a strong bond and ensures the fabric lays flat without wrinkles. Smooth out any air bubbles or creases with your hands or a plastic scraper. Take your time with this step to achieve a professional finish.

Step 5: Add Additional Layers (Optional)

For larger or more complex repairs, consider adding multiple layers of fabric. This can be done by overlapping the fabric and wetting it out in the same manner. Each additional layer will further strengthen the repair. However, be mindful of the weight and structural integrity of the boat, especially if the blister is near the waterline.

Step 6: Finish with a Coat of Resin

Once the fabric is properly bonded and wet, apply a final coat of epoxy resin over the entire repair area. This will provide a protective layer and enhance the strength of the repair. Allow the resin to cure according to the manufacturer's instructions before handling or testing the boat.

Reinforcing a fiberglass blister with fabric is a practical and effective repair technique. By following these steps, you can ensure a strong and long-lasting fix, restoring the structural integrity of your boat. Remember, proper preparation and attention to detail are key to a successful repair.

Bass Boat Carpet: Choose the Best for Your Boat

You may want to see also

Sand and Finish: Smooth the repair with sandpaper and apply a protective coating

When it comes to repairing a fiberglass blister boat, the process of sanding and finishing is crucial to ensure a seamless and durable repair. Here's a step-by-step guide to help you achieve a smooth and professional finish:

Start by carefully inspecting the damaged area and ensuring that the repair is stable and secure. Use a fine-grit sandpaper (e.g., 400-grit) to gently sand the blister and surrounding area. This initial sanding helps to create a smooth surface and prepares the fiberglass for the next steps. Take your time and be gentle to avoid further damaging the boat's structure. Work in small sections and follow the direction of the fiberglass weave to ensure an even finish.

Once the sanding is complete, it's time to smooth out any rough patches. Apply a small amount of fiberglass repair compound or putty to the sanded area, ensuring it is slightly thicker than the surrounding surface. Use a putty knife to spread the compound evenly, creating a level and smooth finish. Allow the compound to cure according to the manufacturer's instructions, which may involve a second application and sanding for a truly seamless repair.

After the compound has cured, lightly sand the area once more with fine-grit sandpaper to create a smooth transition between the repair and the original fiberglass. This step ensures that the repair blends seamlessly with the boat's surface. For an even more refined finish, consider using a power sander with a fine-grit disc, being cautious not to damage the surrounding fiberglass.

Finally, to protect the repair and enhance the boat's appearance, apply a suitable protective coating. This could be a clear fiberglass gelcoat or a specialized marine paint, depending on your preference and the boat's overall design. Follow the manufacturer's instructions for application, ensuring an even and thin coat. This final step not only protects the repair but also adds a professional touch to the boat's finish.

Remember, patience and attention to detail are key during this process. Take your time with each step, and don't rush the sanding and finishing stages. With careful execution, you'll be able to restore your fiberglass blister boat to its original glory.

Boat Shoes: Worth the Investment?

You may want to see also