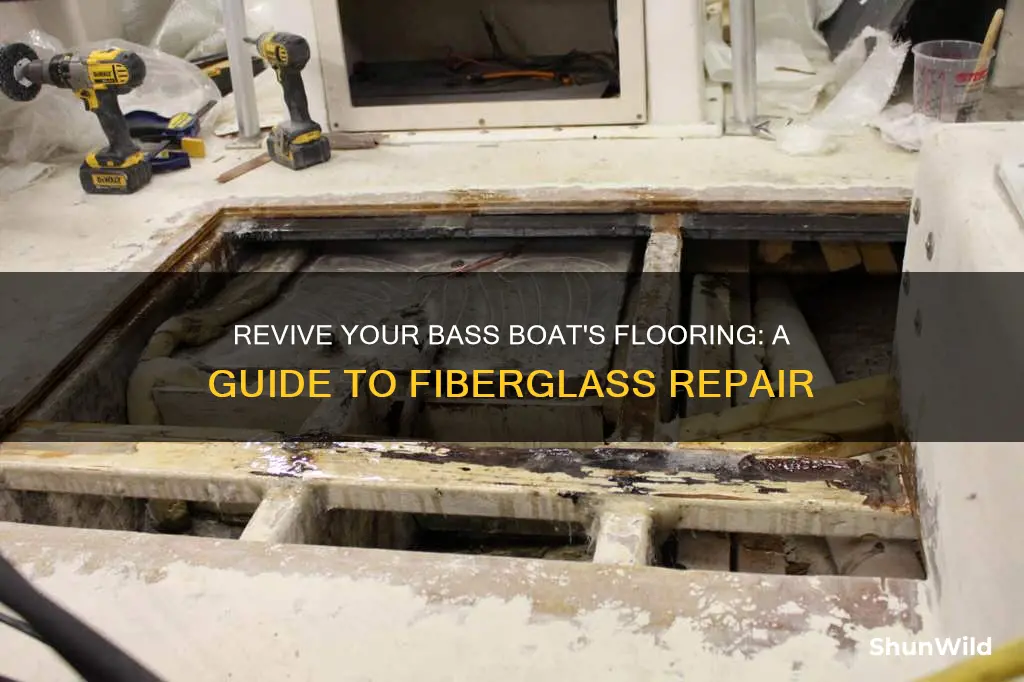

Repairing a fiberglass bass boat floor can be a challenging task, but with the right tools and techniques, it is definitely achievable. This guide will provide a step-by-step approach to help you restore the integrity and functionality of your boat's floor. From identifying the damage to choosing the appropriate materials and tools, we'll cover the entire process, ensuring you have the knowledge to tackle this project with confidence. Whether you're dealing with small holes, cracks, or a completely damaged section, this guide will offer practical solutions to get your boat back in top shape.

| Characteristics | Values |

|---|---|

| Materials Needed | Fiberglass repair kit, epoxy resin, hardener, fiberglass cloth, tape, sandpaper, primer, paint, cleaning supplies, gloves, mask, safety goggles |

| Preparation | Clean the damaged area thoroughly. Remove any loose fibers or debris. Ensure the surface is dry and free of contaminants. |

| Filling the Hole | Mix the epoxy resin and hardener according to the manufacturer's instructions. Fill the hole with the epoxy mixture, ensuring it's level with the surrounding surface. |

| Sanding and Smoothing | Allow the epoxy to cure partially. Then, sand the filled area to create a smooth surface. Remove any excess material and ensure a level finish. |

| Reinforcement | Apply a layer of fiberglass cloth over the repaired area. Secure it with tape or clamps. This provides additional strength and structural integrity. |

| Sanding and Priming | After the fiberglass has cured, sand the surface again to remove any imperfections. Clean the area and apply a suitable primer to prepare for painting. |

| Painting | Choose a marine-grade paint suitable for fiberglass. Apply multiple thin coats, allowing each layer to dry before applying the next. |

| Drying and Curing | Follow the paint manufacturer's instructions for drying and curing times. Ensure the boat is in a well-ventilated area during this process. |

| Testing and Inspection | Once cured, test the repaired area for strength and durability. Inspect the entire boat floor to ensure no other issues require attention. |

| Maintenance | Regularly clean and maintain the boat floor to prevent further damage. Use marine-safe cleaning products and avoid harsh chemicals. |

What You'll Learn

- Assess Damage: Inspect floor for holes, tears, or delamination

- Prepare Surface: Clean, sand, and etch for better adhesion

- Choose Repair Material: Select a suitable epoxy or fiberglass resin

- Apply Repair: Follow steps for filling, smoothing, and curing

- Finish and Seal: Sand, paint, and apply a protective coating

Assess Damage: Inspect floor for holes, tears, or delamination

When assessing the damage to your fiberglass bass boat floor, a thorough inspection is crucial to determine the extent of the repairs needed. Start by carefully examining the entire floor surface for any visible signs of damage. Look for holes, tears, or any areas where the fiberglass has delaminated or separated from the underlying structure. These issues can often be identified by feeling the surface with your hands or using a tool to probe gently. Pay close attention to areas near the boat's edges, as these spots are more susceptible to damage from waves, rocks, or other obstacles.

Holes and tears in the fiberglass can vary in size and depth. Small holes might be easily repairable, while larger ones could require more extensive work. Tears, on the other hand, may indicate a more significant issue, especially if they are accompanied by delamination. Delamination occurs when the fiberglass layers separate, creating a bubbly or raised appearance on the surface. This condition can weaken the structural integrity of the floor and should be addressed promptly.

To inspect for delamination, use a bright light or a flashlight to shine it across the floor from different angles. This will help you identify any areas where the light reflects off the air pockets between the fiberglass layers. Delaminated areas will appear as shiny, raised spots. Additionally, feel the surface with your hands to detect any soft or spongy spots, which could indicate delamination.

If you find any holes, tears, or delamination, it's essential to measure their dimensions accurately. This information will guide your repair process, ensuring you use the right amount of material and technique. For holes, you might need to fill them with a suitable fiberglass repair compound or resin, depending on their size and location. Tears may require re-glassing the affected area, while delamination might need to be addressed by carefully removing the damaged layers and re-laying the fiberglass.

Remember, a thorough assessment is the first step towards successful fiberglass floor repairs. By carefully inspecting for holes, tears, and delamination, you can pinpoint the specific areas that require attention and choose the appropriate repair methods accordingly.

Gary Muehlberger's Boat: A Fateful Twist of Fate

You may want to see also

Prepare Surface: Clean, sand, and etch for better adhesion

Preparing the surface of a fiberglass bass boat floor is a crucial step in ensuring a successful repair. This process involves cleaning, sanding, and etching the existing material to create a rough, textured surface that will promote better adhesion of the new repair material. Here's a detailed guide on how to achieve this:

Cleaning the Surface: Begin by thoroughly cleaning the damaged area of the boat floor. Use a mild detergent or a specialized boat cleaner to remove any dirt, grime, or old repair materials. Rinse the area with clean water to ensure no residue remains. It's important to work quickly, as fiberglass can be sensitive to moisture, and prolonged exposure to water can weaken the material. After cleaning, inspect the surface for any remaining debris or contaminants and ensure it is completely dry before proceeding.

Sanding the Fiberglass: Once the surface is clean, it's time to sand the fiberglass. Use a fine-grit sandpaper (around 400-600 grit) to create a smooth, even texture. Start by gently sanding the entire damaged area, following the direction of the fiberglass weave. This process helps to remove any smooth or shiny spots, ensuring that the new material will have a better surface to bond to. Take your time and be careful not to apply too much pressure, as excessive force can damage the fiberglass. After sanding, wipe away any dust or debris with a damp cloth to prepare the surface for the next step.

Etching the Fiberglass: Etching is a process that roughens the surface of the fiberglass, making it more receptive to adhesives and repair materials. You can use a variety of etching solutions, such as a diluted vinegar and water mixture or a specialized fiberglass etch. Follow the instructions on the etching product carefully. Typically, you'll apply the etch to the sanded area, let it sit for a specified time, and then rinse it off. This process should leave a slightly textured surface. If you're using a vinegar solution, you might notice a slight fizzing reaction, which is normal. Ensure the area is completely dry before moving on to the next step.

By following these preparation steps, you'll create a solid foundation for your fiberglass bass boat floor repair. Proper surface preparation is key to ensuring the new material adheres effectively, resulting in a long-lasting and durable repair. Remember to work carefully and take your time with each step to achieve the best results.

The Art of Leveling a Boat Dock

You may want to see also

Choose Repair Material: Select a suitable epoxy or fiberglass resin

When it comes to repairing a fiberglass bass boat floor, choosing the right repair material is crucial for a successful and long-lasting fix. The primary goal is to restore the structural integrity of the boat and ensure it remains waterproof. For this task, epoxy resins and fiberglass are commonly used materials, each offering distinct advantages.

Epoxy resins are renowned for their exceptional bonding strength and durability. They form a strong, flexible bond when cured, making them ideal for structural repairs. When selecting an epoxy, consider the type suitable for marine environments. Marine-grade epoxies are formulated to withstand the harsh conditions of saltwater, UV radiation, and temperature fluctuations, ensuring the repair will last for years. These resins often come in two-part kits, requiring mixing before application, and they can be applied in various thicknesses to fill and shape the repair area.

Fiberglass resins, on the other hand, are excellent for creating a smooth, seamless surface. They are particularly useful when the damage is localized and can be used to build up or reinforce specific areas. Fiberglass resins are typically applied as a gelcoat or a woven cloth (mat) to create a strong, lightweight layer. This process can be more complex and time-consuming but results in a visually appealing and durable repair. When choosing a fiberglass resin, ensure it is compatible with the existing fiberglass structure and consider the type of reinforcement needed, such as woven or chopped strand mat.

The decision between epoxy and fiberglass resins depends on the nature of the damage and your specific requirements. For instance, if the floor has significant structural damage or needs to be reinforced, epoxy resins might be the better choice due to their strength. Conversely, if the goal is to create a smooth, cosmetic repair, fiberglass resins could provide a more aesthetically pleasing result.

In summary, selecting the appropriate repair material is a critical step in restoring a fiberglass bass boat floor. Epoxy resins offer strength and durability, while fiberglass resins excel at creating a seamless surface. Understanding the properties of each material will enable you to make an informed decision and ensure a successful repair.

The Boat Driving Experience: Who Said Let Me?

You may want to see also

Apply Repair: Follow steps for filling, smoothing, and curing

When repairing a fiberglass bass boat floor, the process of filling, smoothing, and curing is crucial to ensure a strong and durable fix. Here's a step-by-step guide to help you through this phase:

Step 1: Prepare the Repair Area

Start by cleaning the damaged area thoroughly. Remove any loose debris, dirt, or old filler material using a wire brush or a scraper. Ensure the surface is smooth and free from contaminants. This preparation step is essential for the new filler to adhere properly.

Step 2: Choose the Right Filler Material

Select a suitable fiberglass repair filler that is compatible with your boat's material. There are various types available, such as epoxy-based or polyester-based fillers. Follow the manufacturer's instructions for the specific product you choose. Consider the size and depth of the repair; for larger areas, you might need a heavier-duty filler, while smaller, shallower repairs can be addressed with a lighter option.

Step 3: Apply the Filler

Put on protective gear, including gloves and a dust mask, to avoid inhaling any fumes. Mix the filler according to the package instructions, ensuring it is in the correct consistency for easy application. Use a putty knife or a similar tool to apply the filler to the prepared area. Start from the center and work outward, creating a smooth, even surface. Be generous with the filler to ensure the repair is thick enough to provide structural integrity.

Step 4: Smooth and Shape the Repair

Once the filler is applied, you'll need to smooth it out. Use a putty knife or a fiberglass smoothing tool to level the surface. Work quickly but gently to avoid trapping air bubbles. You can also use a heat gun or hairdryer to warm the filler slightly, making it more pliable and easier to shape. Ensure the repair is flush with the surrounding fiberglass, creating a seamless appearance.

Step 5: Allow for Curing

Follow the manufacturer's instructions for curing time. Typically, you'll need to cover the repair with a clear coat or a specialized fiberglass cloth to protect it during the curing process. This step is vital to ensure the filler sets properly and gains its full strength. Avoid any pressure or heavy use of the boat during this time to prevent damage to the repair.

Step 6: Finish and Sand

After the filler has cured, inspect the repair. If there are any rough spots or imperfections, gently sand them down using fine-grit sandpaper. This step will create a smooth transition between the repair and the original fiberglass surface. Take your time during this process to avoid removing too much material.

Remember, patience and attention to detail are key during the filling and smoothing process. Properly curing the filler will result in a strong and long-lasting repair.

Boat Delivery to Your Winnipesaukee Dock: Easy Summer Sailing

You may want to see also

Finish and Seal: Sand, paint, and apply a protective coating

Before you begin the finishing process, ensure the fiberglass floor is thoroughly cleaned and free of any debris. Use a mild detergent and a soft brush to scrub the surface, removing any dirt or old paint residue. Rinse the area with clean water and allow it to dry completely. This step is crucial to ensure proper adhesion of the new finish.

Sand the fiberglass floor to create a smooth and even surface. Start with a coarse-grit sandpaper (around 120-grit) to remove any imperfections and rough spots. Gradually switch to finer grits (180-grit and above) to achieve a smooth finish. Work in small sections, using gentle, circular motions to avoid creating new scratches. After sanding, wipe away the dust with a tack cloth or a damp cloth to prepare the surface for painting.

Choose a suitable paint for your fiberglass boat floor. Epoxy-based paints are commonly used for their durability and resistance to chemicals and UV rays. Ensure the paint is specifically designed for marine environments and can withstand the conditions of a bass boat. Apply the paint in thin, even coats, allowing sufficient drying time between each layer. Follow the manufacturer's instructions for the best results.

Once the paint is dry, it's time to apply a protective coating. This step is essential to enhance the durability and longevity of the repair. Consider using a marine-grade clear coat or a specialized fiberglass repair resin. These coatings provide an additional layer of protection against water, chemicals, and UV damage. Apply the coating evenly, ensuring full coverage, and allow it to cure according to the manufacturer's guidelines.

Finally, inspect the repaired area to ensure a high-quality finish. Check for any imperfections, such as uneven paint or missed spots, and address them promptly. With proper care and maintenance, the sealed and painted fiberglass floor will provide a long-lasting solution for your bass boat's interior. Remember to follow safety precautions when working with chemicals and always wear appropriate protective gear.

Las Vegas Boat Launch: Platform Location and Directions

You may want to see also

Frequently asked questions

Repairing a small hole in the fiberglass floor can be done with a simple process. First, clean the area around the hole to remove any dirt or debris. Then, fill the hole with a fiberglass repair kit, which typically includes a resin and a hardener. Mix the two components according to the kit's instructions and apply the mixture into the hole, ensuring it's level with the surrounding surface. After it dries, sand the filled area and apply a fiberglass cloth or tape to reinforce it. Finally, paint or gelcoat the repaired section to match the boat's finish.

Cracked fiberglass floor panels can be repaired by following these steps. Start by removing the damaged panel carefully to avoid any further damage. Then, clean the area and apply a fiberglass repair kit as mentioned above. Once the repair is dry, use a fiberglass cloth or tape to reinforce the area. After that, you can either re-install the panel or use a gelcoat to fill the crack and create a smooth surface. It's important to ensure the repair is strong enough to handle the boat's weight.

Yes, you can use a fiberglass repair kit for larger tears or holes, but it might require some additional steps and materials. For larger repairs, it's recommended to use a fiberglass cloth or tape to reinforce the area before applying the repair kit. You may also need to cut out the damaged section and replace it with a new piece of fiberglass, ensuring it's properly bonded. Always follow the instructions of the repair kit and consider seeking guidance from a professional or experienced boat repairer for complex repairs.