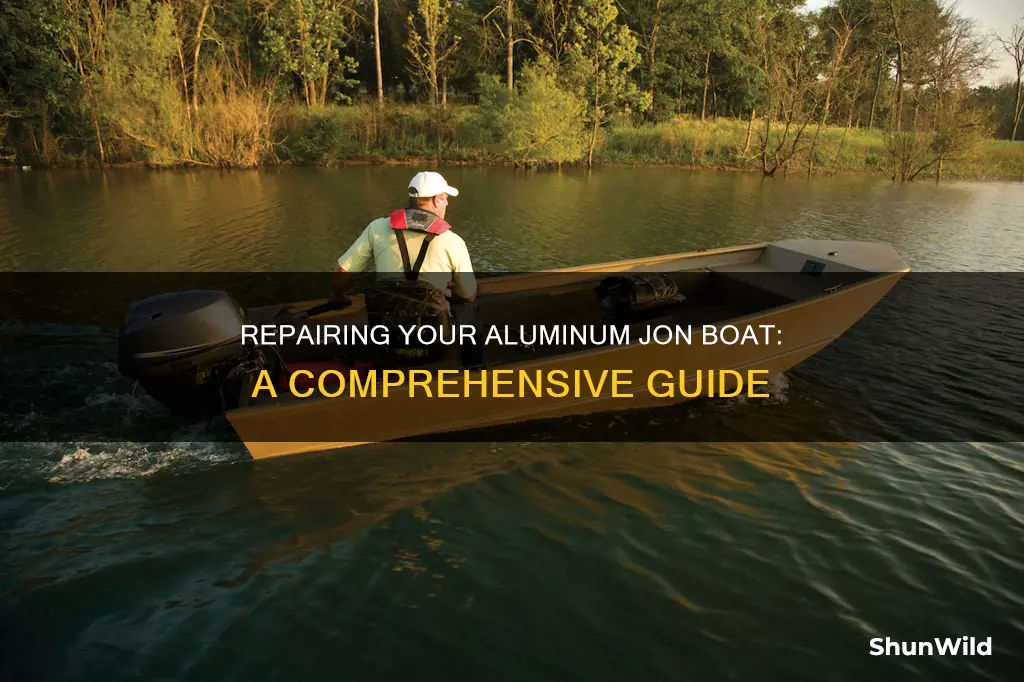

Repairing an aluminum Jon boat can be a challenging task, especially if you're dealing with cracks, holes, or damaged panels. While some repairs can be done by boat owners themselves, more extensive damage may require professional assistance. One of the key challenges in repairing aluminum is that it work hardens when bent, and improper handling can lead to further distortion or irreparable damage. For larger repairs, techniques such as hydraulic jack pressure and heat treatment are employed to straighten and reshape the metal. Smaller holes and cracks can often be addressed with epoxy putty, fiberglass resin, or welding.

What You'll Learn

Fixing a hole in an aluminum boat

Tools and Materials

You will need an aluminum boat repair kit, which includes epoxy or putty, a stainless steel brush, and easy-to-follow instructions. Other tools you will need include a soft-headed hammer, a hydraulic jack, and a propane torch. Additionally, you should have some marine primer and paint, such as Krylon, in the colour of your choice, as well as acetone for cleaning.

Preparation

Before beginning the repair, it is important to prepare the area around the hole. Clean the area with acetone to remove any oil or grease. This step is crucial as any residue will affect the adhesion of the repair material. Use the stainless steel brush from your kit to further clean and prepare the surface. Ensure the area is completely dry before proceeding.

Repair Process

Now, you are ready to start repairing the hole. If the hole is in a rivet or seam, you can follow the instructions in your repair kit to seal it. For larger holes, you can use epoxy putty or a similar product, such as JB Weld, to fill and patch the hole. Start by hammering the area flat to close the hole as much as possible. Then, apply the epoxy putty to both the interior and exterior sides of the hole, smoothing it out to create a watertight seal. If the hole is a crack, remember to drill small holes at each end to prevent the crack from spreading.

Once the epoxy has cured, you can sand the area smooth and apply a primer. After the primer has dried, you can paint the boat with your chosen colour. And that's it! You've successfully repaired the hole in your aluminum boat.

While this guide provides a general repair process, always refer to the instructions in your chosen repair kit as the steps may vary depending on the products used.

Exploring Rivers with Pedal Boats: Is It Possible?

You may want to see also

Repairing cracks in an aluminum boat

To repair cracks in an aluminium boat, you can use a welder to seal the crack. This is a recommended method, as it will likely be a longer-lasting solution than other forms of repair. Before welding, clean the area down to bare aluminium so that the welder can make a good, clean weld.

If welding is not an option, you can use an epoxy putty such as JB Weld, or a two-part, marine-grade epoxy putty like Marine Tex. Ensure you prepare the area first by hammering the crack flat, then sand or grind the area and clean with an acetone solvent. You can then press and smooth the putty into the crack and the surrounding area, from both sides if possible. Apply a second layer of putty on the outside of the crack and smooth it out. Once cured, sand it down and prime and paint the repaired area.

Another option is to use a product like Cabela's Aluminium Boat Patch or Gluvit, which can be applied with a heat gun.

For small cracks, you can also use a product like 3M's "5200" polyurethane sealant.

Fresh Off the Boat: Producer's Dark Harassment Secrets

You may want to see also

Sealing leaking rivets in an aluminum boat

Sealing leaking rivets in an aluminium boat is an important step in boat restoration. Here is a detailed, step-by-step guide:

Firstly, identify the leaky rivets. This may involve flipping the hull and filling it with water to test for leaks. While this method is not 100% reliable, it is a common practice. An alternative is to take the boat to a pond or lake, with all the usual gear, to simulate real-world conditions and identify leaks more accurately.

Once the leaky rivets have been identified, the next step is to decide between repairing or replacing them. Some people suggest that the best fix is to replace the rivets by drilling out the old ones and installing new ones, ensuring a good seal by cleaning and straightening the surface. This method can be time-consuming but is often more reliable than simply sealing the rivets.

If you decide to seal the rivets instead of replacing them, there are several products you can use. One option is to use a product like Gluvit on the inside of the rivets, followed by an exterior treatment such as West Systems G-Flex, which is specifically designed for boat repairs and sealing loose, leaky rivets. Another product that can be used is thin or medium super glue, which is wicked into the leaking rivets. A paint-on product like Flex Seal is also an option, though it may not provide the best surface for paint to adhere to.

In conclusion, sealing leaking rivets in an aluminium boat can be done in several ways, depending on your preferences and the condition of your boat. Taking the time to identify leaks properly and choose the right products will ensure a successful repair.

Tommy Hilfiger Boat Shoes: Materials and Craftsmanship

You may want to see also

Straightening aluminum sheet panels

To straighten aluminium sheet panels on an aluminium Jon boat, you will need to address any dents or warping. Here is a step-by-step guide:

Step 1: Assess the Damage

Before beginning any repairs, it is important to inspect the aluminium sheet panels thoroughly and identify the areas that require straightening. Look for dents, creases, or warped sections. Take note of the extent of the damage, as this will influence the repair process.

Step 2: Prepare the Work Area

Ensure you have a clean and flat surface to work on. If possible, place the aluminium sheet panels on a workbench or a sturdy table. Gather the necessary tools and materials, including hammers, mallets, blocks of wood, clamps, and a heat source such as a torch or heat gun.

Step 3: Use Heat to Relax the Metal

In some cases, applying heat to the damaged area can help relax the metal and make it more pliable. Use a torch or heat gun to carefully heat the dented or warped sections of the aluminium sheet panels. Be cautious not to overheat the metal, as this can weaken its structural integrity.

Step 4: Apply Controlled Force

Once the metal is heated, you can attempt to straighten it by applying controlled force. Use a mallet or a flat-faced hammer to gently tap the reverse side of the dent, working your way towards the edge. Support the metal with a block of wood to prevent further deformation. This technique is particularly useful for minor dents and creases.

Step 5: Clamp and Support

For more severe warping or larger dents, clamping may be necessary. Use C-clamps or bar clamps to hold the aluminium sheet panels in place, applying even pressure to straighten the metal. Ensure the clamps are secure and tight enough to effect gradual change.

Step 6: Annealing Process

If the above methods are ineffective, you may need to anneal the aluminium. Annealing involves heating the metal to a specific temperature to alter its physical properties, making it more malleable. Consult an aluminium alloy chart to determine the appropriate annealing temperature for your specific alloy. Use a soap coating, as suggested by one source, to help gauge the temperature: apply the soap and heat the metal until the soap begins to turn black.

Step 7: Quenching and Straightening

After annealing, quickly quench the metal by plunging it into cold water or using a wet rag. This rapid cooling process will help straighten the aluminium. Be cautious, as this technique can sometimes lead to differential stretching and cause the metal to pull back.

Step 8: Final Adjustments

Once the major straightening is complete, make any necessary final adjustments. Use a deadblow mallet to gently tap the surface and fine-tune the evenness of the sheet. You can also try placing heavy weights on the panel for an extended period to encourage further straightening.

Remember to exercise caution when working with metal, and always prioritise your safety. Wear appropriate protective gear, including gloves and eye protection, when handling tools and equipment.

Best Cambridge Spots to Watch the Boat Race

You may want to see also

Painting an aluminum boat

Prepare the Boat:

Firstly, find a suitable workspace. Look for a well-ventilated and lit area, protected from the elements, to ensure the paint job is consistent. Cover your entire workspace with paper or plastic sheets to prevent paint stains. Elevate the boat for easier access during painting. You can use sawhorses to support the boat, preferably with the inside facing upwards initially.

Sand the Boat:

Sanding is crucial for a smooth and even paint finish. Use 40 or 80-grit sandpaper, starting with the interior, and then flipping the boat over to sand the exterior. If there was old carpet inside, ensure you sand away all the glue to prevent paint adhesion issues. This step will likely leave small scratches on the aluminum, which is normal.

Clean the Boat:

After sanding, thoroughly clean the boat to remove any debris from the sanding process. Use soap, a brush with stiff bristles, and a bucket of water to scrub the boat. Rinse the boat completely with a power spray nozzle or a hose, and let it air dry.

Prime the Boat:

Priming is essential to help the paint adhere to the aluminum surface. Look for a self-etching primer suitable for metal surfaces. You can use an oil-based primer and mix in a paint thinner to help it penetrate small cracks in the boat. Apply the primer in a thin, even layer to the interior of the boat, ensuring you get into all the cracks and corners. You can use a paint sprayer, roller, or brush for application. Allow the primer to dry for several hours, or preferably overnight, before proceeding to the exterior.

Paint the Boat:

Select a water-resistant paint in the colour of your choice. Apply the first coat to half of the boat, let it dry, and then turn the boat over to paint the other side. Depending on the desired finish, you may need to apply a second coat for better coverage and protection. Use a brush for corners and hard-to-reach areas. Allow the paint to dry completely before proceeding to the next step.

Apply a Clear Coat (Optional):

Applying a clear coat will provide extra protection from scratches and the elements. Simply spray, roll, or brush it on the boat, just like the paint. This step will ensure your aluminum boat looks pristine for years to come.

Always remember to wear the proper safety gear, including a respirator, when working with paint, and ensure adequate ventilation during the process.

Boat Registration Renewal: Currency Exchange Made Easy

You may want to see also

Frequently asked questions

You can repair a small hole in an aluminum Jon boat using epoxy putty, JB Weld, or fiberglass resin. First, hammer the area flat to close the hole as much as possible. Then, sand or grind the area and clean with an acetone solvent. Finally, apply the epoxy putty, JB Weld, or fiberglass resin to the hole and the surrounding area, following the product instructions.

To repair a crack in an aluminum Jon boat, you can use a product like JB Weld or epoxy putty to seal the leak. However, for a more permanent solution, it is recommended to have the crack welded by a professional. Before welding, the area must be cleaned and prepared, and the aluminum must be straightened using heat treatment to relax the molecules and prevent cracking.

To repair leaking rivets in an aluminum Jon boat, you can use an aluminum boat repair kit, which typically includes epoxy sticks and a stainless steel brush for surface preparation. Follow the instructions provided with the kit to properly seal the leaking rivets.