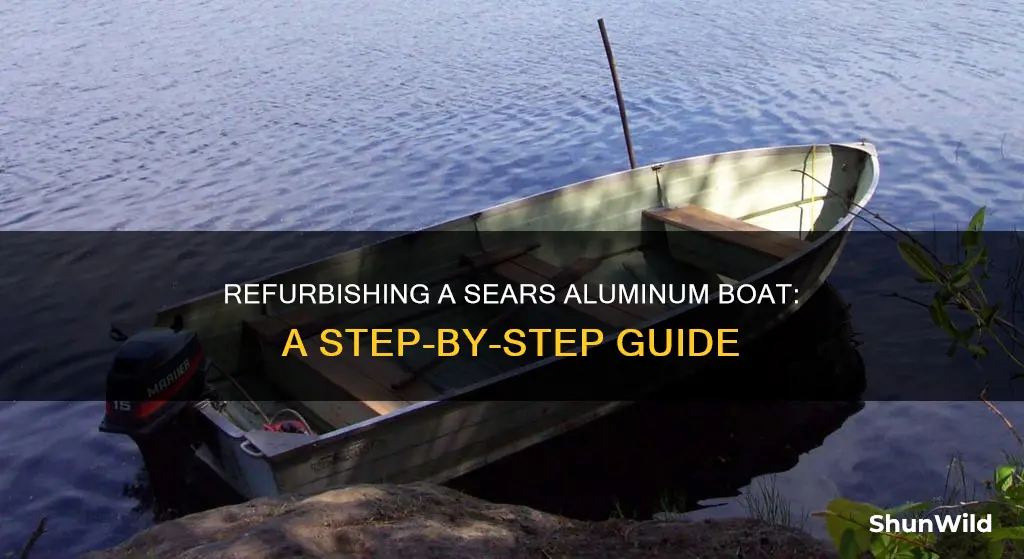

Refurbishing a 12-foot Sears aluminum boat is a challenging task that requires careful planning and execution. The restoration process involves several steps, from deconstruction and cleaning to polishing and protection. One of the critical aspects of the project is addressing the issues with the transom, which is often found to be rotten or damaged in older boats. This includes reinforcing the transom with additional layers of marine-glued plywood, ensuring it can withstand the weight and usage of the boat. The use of Flex Seal and paint is also recommended to seal the seams and protect the aluminum from corrosion. Additionally, it is important to pay attention to the rivets, replacing any that are missing or damaged, as well as cleaning and inspecting the hull seams for leaks. The restoration process also involves refurbishing or replacing the seats, ensuring they are securely installed and can withstand the weight of passengers. Finally, the choice of cleaning products and safety gear, such as gloves and goggles, is essential for a successful and safe restoration project.

What You'll Learn

Cleaning the hull seams

To refurbish a 12-foot Sears aluminum boat, one of the steps is to clean and check the hull seams. Here is a detailed, step-by-step guide on how to do this:

Firstly, you will need to gather the right tools and materials. In this case, you will need to borrow or buy a pressure washer.

Once you have the necessary equipment, start by cleaning the boat inside and out. Pay particular attention to the seams, and spray hard at them to check for leaks. It is important to take your time with this step, as you want to ensure that the boat is watertight before moving on.

In the case of the boat in this example, the stern seams seemed suspect. Given the age of the boat, the owner decided to seal all the seams and rivets. This is a good idea if you are refurbishing an old boat, as it will help to ensure that it is watertight and prevent future leaks.

To seal the seams, you can use a product like Flex Seal, which is designed to create a waterproof barrier. Paint the Flex Seal onto the seams and rivets, making sure to follow the manufacturer's instructions. You may also want to consider using a primer before applying the Flex Seal, to help it adhere better.

After sealing the seams, you will need to address any breaches in the hull. In the example boat, the owner used JB Weld to repair a breach above the waterline. Once the repair is complete, you can paint over the shiny spots with a metal primer.

Finally, to protect the hull and improve performance, apply a coating to the bottom of the boat. In the example, the owner used a spray-on pickup truck bedliner, which can reduce drag and improve the boat's efficiency in the water.

By following these steps, you can ensure that the hull seams of your 12-foot Sears aluminum boat are clean, sealed, and protected, which will help to extend the lifespan of your boat.

The Luxury Yacht Never Enough: Who Owns This Floating Palace?

You may want to see also

Sealing the outside

Identify Leaks:

Before you begin sealing, it's important to identify the source of any leaks. Dry the boat thoroughly and inspect for leaks, paying close attention to seams and rivets, as these are common areas for water ingress. However, don't assume that leaks will only occur at these points; check the entire boat for any signs of water entry.

Prepare the Aluminum Surface:

Once you've identified the areas that need attention, it's time to prepare the aluminum surface for sealing. Use a dedicated aluminum boat cleaner to thoroughly clean the areas you'll be working on. Ensure that the boat is completely dry before proceeding to the next step, as you'll need a smooth and clean surface to work with.

Choose the Right Sealant:

When selecting a sealant, opt for a product specifically designed for use on metal surfaces. Look for sealants that adhere well to metals, such as Life-Calk or acid-free Silicone Rubber Sealant, which won't corrode the aluminum.

Apply the Sealant:

When applying the sealant, don't be shy. It's better to apply too much than too little. You can always scrape off any excess once the sealant has cured. Follow the directions on your chosen sealant's packaging for proper application techniques and curing times.

Cure and Inspect:

After applying the sealant, follow the manufacturer's instructions for curing. This usually involves leaving the boat undisturbed overnight. Once the sealant has cured, inspect the sealed areas and test them to ensure they are now waterproof.

Additional Tips:

- Always read the label of your chosen sealant to understand its specific application and adhesion properties.

- If you're sealing around rivets, consider using a product like 3M 5200, which is specifically designed for this purpose.

- If you're unable to flip the boat over, consider using a two-part epoxy paint that can be rolled on from underneath.

- For a slicker surface that aids in loading and unloading the boat, consider a coating like Gator Glide or Wetlander.

Remember, sealing the outside of your aluminum boat is essential to prevent leaks and protect the hull. Take your time, choose the right products, and follow the instructions carefully for a successful refurbishment.

Waterproof Your Boat: Wax and TLO Guide

You may want to see also

Repairing the transom and seats

To repair the transom and seats of a 12-seater aluminum boat, you'll need to assess the damage and determine the necessary repairs. Here's a step-by-step guide to help you through the process:

Transom Repair:

- Inspect the transom for damage: Check the entire transom structure, including the wood, aluminum, and hardware, for any signs of rot, corrosion, or looseness.

- Disassemble the transom: Remove the motor, steering, fuel hardware, and any other components attached to the transom. This will give you clear access to the transom shell.

- Clean and prepare the transom shell: Clean out any old, rotted material from the shell. You may need to drill out and replace rivets or screws that are damaged or corroded.

- Choose a replacement transom option: You can consider a pre-welded aluminum replacement transom, a plywood and fiberglass transom, or a pour-in-style transom. Each option has its pros and cons, so choose the one that best suits your skills, budget, and the boat's needs.

- Install the new transom: Follow the instructions for your chosen replacement transom option. Ensure all measurements are accurate, and seal and bolt the new transom securely into place.

Seat Repair:

- Inspect the seats: Check the aluminum bench seats for any signs of damage or weakness. Pay close attention to the pop rivets that hold the seats in place, as these can come loose over time.

- Reinforce or replace rivets: If the rivets are loose or missing, you may need to replace them. Use a rivet gun and rubber sealant to secure the seats firmly in place. Ensure the areas around the rivet holes are flat, and the holes are not wallowed out.

- Repair or replace the plywood: If the plywood seats have eroded or weakened, you may need to replace them. Cut new plywood to size, prime and paint it, and install it onto the aluminum thwarts.

- Reinforce the seat ends: To prevent future failures, reinforce the ends of the seats from below. You can use pressure-treated wood cut at the right angle and screwed into place inside the thwarts.

- Maintain and protect the seats: Regularly clean and inspect the seats to prevent dirt and grime buildup. Protect the seats from sun exposure by using a boat seat cover when they're not in use.

Remember to take your time, work patiently, and seek professional advice or assistance if you're unsure about any aspect of the repair process.

Connecting Power to Fishfinders: Stratos Bass Boat Guide

You may want to see also

Removing rust and corrosion

Understanding Corrosion

Before embarking on the refurbishment process, it is essential to understand the different types of corrosion that can affect aluminum boats. The three main types of oxidation that can impact your aluminum hull are galvanic corrosion, electrolysis, and crevice corrosion. Galvanic corrosion occurs when aluminum comes into contact with dissimilar metals in an electrolyte solution, such as saltwater or freshwater. Electrolysis is caused by potential current (AC or DC) between two different objects, often due to stray electrical current in the water. Crevice corrosion occurs when moisture is trapped in cracks or crevices, leading to a breakdown of the passive film protecting the aluminum.

Inspect for Corrosion

Start by thoroughly inspecting your boat for signs of corrosion. Pay close attention to areas where different metals are in contact, such as stainless-steel fittings or screws in the aluminum hull. Look for pitting, flaking, paint blistering, or spalling of the aluminum structure. Check for corrosion in critical areas such as the green wire (grounding wire), fuel shut-off valve, shift and throttle cables, and navigation light sensor.

Clean and Wash the Boat

Use a pressure washer to clean the boat inside and out, paying close attention to the hull seams and rivets. Spray hard at the seams to check for leaks and seal them if necessary. It is important to clean and rinse your boat thoroughly, especially if it has been used in saltwater, as salt residue can accelerate corrosion.

Repair and Replace Corroded Parts

If you notice any corroded parts, such as bolts, screws, or fittings, remove them and replace them with new ones. In some cases, you may need to cut away severely corroded sections of the aluminum hull and weld or patch in new pieces. Ensure that all replacement parts are designed for use with aluminum and follow the manufacturer's instructions for installation.

Isolate Dissimilar Metals

To prevent future galvanic corrosion, isolate dissimilar metals from direct contact with each other. For example, if you have stainless-steel fittings or screws in an aluminum hull, use nylon isolators or other isolating materials to create a barrier between the two metals. This will disrupt the galvanic couple that leads to corrosion.

Protect with Sacrificial Anodes

Install sacrificial anodes, such as zinc or aluminum anodes, on the boat's hull and any accessories prone to corrosion. These anodes will corrode instead of the aluminum, providing a layer of protection. However, be careful not to overuse zinc anodes, as too many can cause a crust to form and render them ineffective.

Seal and Paint

After making the necessary repairs and replacements, seal all seams, rivets, and hardware with a suitable sealant, such as Flex Seal. This will help prevent water ingress and reduce the risk of corrosion. Finally, apply a coat of paint designed for use with aluminum to further protect the surface and improve the appearance of your boat.

Remember to consult a professional boat repair specialist if you are unsure about any steps or encounter significant corrosion or damage.

How Much Is a 1978 Ranger Bass Boat Worth?

You may want to see also

Testing for leaks

First, ensure your boat is on dry land. Then, fill it up with water. If there is a significant leak, you will spot it immediately. If not, wait for a few hours. To make the test more effective, you can add food colouring to the water, making any leaks easier to spot.

If you don't find any leaks but suspect there might be some, check the drain plug seal and the livewell pump, as these are common sources of leaks that can be challenging to identify.

Common Leakage Spots:

Transducer screw holes are one of the most common places for leaks to occur. So, pay close attention to these areas when inspecting your boat.

Temporary Fixes:

If you're in a pinch and need a temporary solution, some forum users suggest using products like JB Weld or silicone. However, these are not long-lasting fixes and may not hold up in choppy waters.

Permanent Repairs:

For a more permanent solution, you have several options:

- Replace the broken part: If the damage is limited to a few small cracks or holes, you can simply replace the affected parts. Sand the area to clear any dirt, ensure it's fully dry, and then apply a sealant.

- Re-riveting: If the problem is widespread, you may need to re-rivet the entire boat. This can be costly and time-consuming, so consider consulting a professional for this job.

- Sealant: Apply a sealant like Flex Seal, Marine Adhesive Sealant, or an epoxy solution. Remember to follow the manufacturer's instructions, especially when it comes to preparation and curing time.

Tips:

- When using epoxy, you may need a heat gun to melt it and force it through the gaps.

- Always seal your boat from the outside. Sealing from the inside can leave water within the seams, and the pressure will push the seals out.

- If you're sealing rivets, coat the inside of the seams and follow the manufacturer's instructions closely.

Remember, fixing leaks on your Sears aluminum boat can range from simple to complex. If you're unsure, don't hesitate to consult a professional to ensure the job is done correctly and safely.

Repairing Scuffed Boat Stickers: A Step-by-Step Guide

You may want to see also

Frequently asked questions

The first step is to deconstruct the boat to identify the areas that need work. This includes checking the motor, transom, seats, hull seams, and rivets.

Basic safety materials such as gloves and goggles are essential. Other materials include an aluminum cleaner, power buffer, and release for removing adhesives from metals.

Yes, it is recommended to use multi-tasking products and equipment to reduce work time. Additionally, cleaning the boat first and sealing it from the outside can make the process easier and more effective.