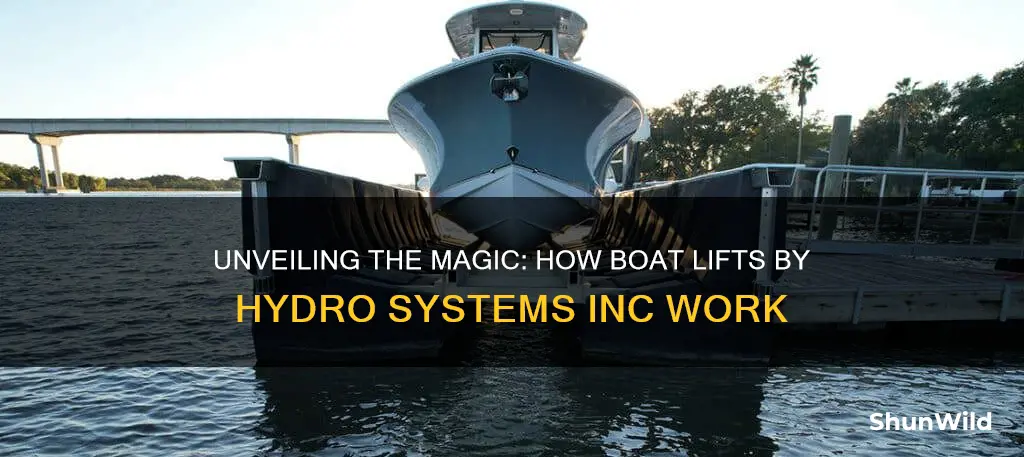

Boat lifts by Hydro Systems Inc. are innovative mechanical systems designed to efficiently and safely raise and lower boats between different water levels. These lifts utilize a combination of hydraulic and mechanical components to provide a smooth and controlled movement. The system typically consists of a lift platform, a hydraulic pump, and a control panel. When activated, the hydraulic pump activates a series of pistons, which extend and retract the lift platform, allowing boats to be raised or lowered. This mechanism ensures precise control over the boat's position, making it a reliable and efficient solution for managing water levels and boat transportation in various aquatic environments.

What You'll Learn

- Hydraulic Systems: Utilizes pressurized fluid to lift boats vertically

- Piston Mechanism: Linear motion is achieved through reciprocating pistons

- Control Panels: Operate lift via buttons, switches, and automated controls

- Safety Features: Includes sensors and interlocks to prevent accidents

- Maintenance: Regular checks ensure optimal performance and longevity

Hydraulic Systems: Utilizes pressurized fluid to lift boats vertically

Hydraulic systems are an innovative and efficient solution for vertical boat lifting, offering a precise and controlled mechanism to move vessels between different water levels. These systems operate by utilizing the power of pressurized fluid, typically oil, to generate the necessary force for lifting. The process begins with a pump that creates pressure within a sealed hydraulic circuit, pushing the fluid through various components.

At the heart of the system is a hydraulic cylinder, a key component that provides the lifting action. This cylinder contains a piston, which is connected to the boat's mooring system or a supporting structure. When pressurized fluid is directed into the cylinder, it extends the piston, creating a lifting force. The pressure is carefully controlled to ensure smooth and gradual movement, allowing for precise boat positioning.

The design of the hydraulic system is crucial for its functionality. It involves a network of pipes, valves, and control mechanisms that direct the fluid's flow. These components work together to regulate pressure, control speed, and ensure the system's overall safety. By using a series of check valves and pressure relief valves, the system can prevent overloading and maintain stability during the lifting process.

One of the significant advantages of hydraulic boat lifts is their ability to handle heavy loads with ease. The pressurized fluid provides a powerful lifting force, capable of moving large boats or vessels with minimal effort. This makes hydraulic systems ideal for applications where traditional mechanical methods might struggle, such as in narrow channels or areas with limited space.

Furthermore, these systems offer excellent control and precision. Operators can adjust the pressure and flow rate to fine-tune the lifting process, ensuring the boat is lifted smoothly and securely. This level of control is particularly beneficial in busy marinas or harbors, where synchronized and controlled boat movements are essential to prevent accidents and maintain efficient operations.

Understanding Boat Engine Overheating: Common Causes and Solutions

You may want to see also

Piston Mechanism: Linear motion is achieved through reciprocating pistons

The piston mechanism is a fundamental component of boat lifts designed by Hydro Systems Inc., offering a precise and controlled method for achieving linear motion. This system utilizes reciprocating pistons to move boats vertically along a lift shaft, ensuring a smooth and efficient operation. Here's a detailed explanation of how this mechanism operates:

Within the lift shaft, a series of pistons are strategically positioned and connected to a common piston rod. These pistons are typically made of durable materials such as aluminum or steel, designed to withstand the forces involved in the lifting process. The piston rod, often a sturdy metal rod, acts as the connecting element, transferring the motion from the power source to the pistons. When the lift is activated, the power source, which could be an electric motor or a hydraulic pump, initiates the reciprocating motion of the piston rod.

As the piston rod moves, it extends and retracts, causing the connected pistons to move in a linear fashion. This linear motion is crucial for the vertical movement of the boats. The pistons are carefully arranged in a way that their movement is synchronized, ensuring that the lift operates smoothly and predictably. Each piston's stroke is designed to match the specific requirements of the lift, allowing for precise control over the boat's position.

The key to the piston mechanism's efficiency lies in its ability to convert the reciprocating motion of the piston rod into linear motion. This is achieved through a series of carefully designed seals and guides that prevent leakage and ensure smooth movement. These seals and guides are critical in maintaining the lift's performance and safety, as they prevent any potential leaks of hydraulic fluid, which could lead to system malfunctions.

In operation, the lift's power source drives the piston rod, causing the pistons to extend and retract in a controlled manner. This linear motion is then transferred to the boat, allowing it to be raised or lowered as needed. The piston mechanism's design ensures that the boat's movement is smooth and steady, providing a reliable and efficient boat-lifting solution.

General Dynamics Electric Boat: Who Owns This Groton Giant?

You may want to see also

Control Panels: Operate lift via buttons, switches, and automated controls

Control panels play a crucial role in the operation of boat lifts, especially those designed by Hydro Systems Inc. These panels are the central command centers that allow users to control and monitor the lift's functions, ensuring smooth and efficient operation. The design and functionality of these control panels can vary depending on the specific lift model and its intended use.

When it comes to operating a boat lift via control panels, users are typically presented with a range of options and controls. These controls often include buttons, switches, and automated mechanisms that enable precise management of the lift's movement. For instance, a user might find a series of buttons labeled with different functions such as 'Up', 'Down', 'Stop', and 'Emergency Stop'. These buttons are strategically placed for easy access and provide a quick way to initiate the lift's movement.

Switches, often in the form of toggle or slide switches, can be used to adjust settings and parameters. These switches might control factors like water flow, lift speed, or even the lift's position. For example, a user could adjust the lift's speed by sliding a switch to a higher or lower position, allowing for a more customized and controlled ascent or descent.

Automated controls are another essential feature of these panels. These controls can include sensors, timers, and microprocessors that enable the lift to operate without direct human intervention. For instance, an automated control system might be programmed to raise the lift at specific times of the day when water levels are optimal, ensuring a smooth and efficient operation. This automation also enhances safety by reducing the risk of human error.

In addition to these controls, modern boat lifts often incorporate digital displays and indicators. These displays provide real-time information about the lift's status, such as current position, water level, and any error codes. This visual feedback allows operators to make informed decisions and quickly respond to any issues that may arise. The combination of buttons, switches, and automated controls, along with digital displays, ensures that boat lift operators have a comprehensive and user-friendly interface to manage the lift's functions effectively.

The Disappearance of Show Boat: Why It's No Longer Performed

You may want to see also

Safety Features: Includes sensors and interlocks to prevent accidents

Boat lifts designed by Hydro Systems Inc. incorporate a range of safety features to ensure the operation is secure and accident-free. These safety mechanisms are crucial, especially in environments where boats and other watercraft are frequently lifted and lowered. One of the primary safety measures is an array of sensors that monitor various parameters during the lifting process. These sensors are strategically placed to detect potential issues and provide real-time data to the control system. For instance, load cells are used to measure the weight of the boat, ensuring it does not exceed the lift's capacity. This prevents overloading, which could lead to structural damage or even failure of the lift mechanism. Additionally, proximity sensors are employed to detect the presence of obstacles or foreign objects in the lift's path, allowing for immediate adjustments to avoid collisions.

Interlocks are another critical component of the safety system. These interlocks are designed to prevent the lift from operating in unsafe conditions. For example, a mechanical interlock might be used to ensure that the lift gates are fully closed before the lifting process begins, preventing accidental operation. Electrical interlocks, on the other hand, monitor the power supply and can shut down the system if there is a malfunction or a power surge. This dual-safety approach ensures that even if one interlock fails, the other can activate to prevent accidents.

The sensors and interlocks work in conjunction with the lift's control panel, which acts as the central command center. This panel displays critical information, such as sensor readings and interlock status, allowing operators to make informed decisions. In the event of a sensor failure or interlock activation, the control panel will provide visual and auditory alerts, prompting the operator to take immediate action. This could include initiating a manual override, if available, to bring the lift to a safe position or shutting down the system entirely.

Furthermore, Hydro Systems Inc. often includes emergency stop buttons and manual release mechanisms as part of the safety features. These allow operators to quickly halt the lifting process in case of an emergency or if they notice any unusual behavior during operation. The design and placement of these safety elements are carefully considered to ensure they are easily accessible and do not interfere with the normal operation of the lift.

In summary, the safety features of boat lifts by Hydro Systems Inc. are comprehensive and designed to prevent accidents and protect both the equipment and those operating it. The combination of sensors, interlocks, and control panels ensures that the lifting process is secure, providing peace of mind to users and minimizing the risk of potential hazards.

Skiff Boat Driving: Tips and Tricks for Beginners

You may want to see also

Maintenance: Regular checks ensure optimal performance and longevity

Regular maintenance is crucial for the efficient and long-lasting operation of boat lifts by Hydro Systems Inc. These lifts utilize hydraulic systems to raise and lower boats, and proper care ensures their reliability and safety. Here's a detailed guide on how to maintain these lifts:

Routine Inspections: Implement a comprehensive inspection protocol for your boat lift. This should include checking all mechanical components, such as pumps, valves, and cylinders, for any signs of wear and tear. Inspect the hydraulic lines for cracks, leaks, or damage, as these can lead to system failure. Look for any unusual noises or vibrations during operation, which might indicate misalignment or worn-out parts. Regularly examine the control panel and electrical connections to ensure they are secure and functioning correctly.

Fluid Maintenance: The hydraulic system relies on clean and properly lubricated fluids to operate smoothly. Check the fluid levels regularly and top them up as needed. It is essential to use the manufacturer-recommended hydraulic fluid to maintain system performance. Periodically drain and replace the fluid to prevent contamination and ensure optimal efficiency. Keep an eye out for any fluid leaks and address them promptly to avoid damage to the lift and surrounding areas.

Electrical System Care: Boat lifts often feature sophisticated electrical systems. Inspect the wiring for any signs of corrosion or damage, especially in areas prone to moisture. Ensure all electrical connections are tight and secure. Test the batteries and consider replacing them annually or as recommended by the manufacturer to avoid unexpected power failures. Regularly clean the electrical components to prevent dust and debris buildup, which can cause overheating and performance issues.

Safety Checks: Safety is paramount with boat lifts. Conduct regular safety checks to ensure all security measures are in place. This includes verifying that emergency stop mechanisms are functional and that all safety switches are operational. Inspect the lift's travel limits and ensure they are set correctly to prevent overloading or damage. Regularly test the lift's operation at both the minimum and maximum travel positions to identify any potential issues.

Professional Servicing: While routine checks can be performed by operators, it is highly recommended to schedule periodic professional maintenance. Certified technicians can provide in-depth inspections, identify potential problems, and perform necessary repairs or replacements. They can also offer valuable advice on optimizing the lift's performance and extending its lifespan.

By adhering to a strict maintenance schedule, you can ensure that your Hydro Systems Inc. boat lift operates efficiently, safely, and for many years to come. Regular care and attention are key to avoiding costly repairs and unexpected breakdowns.

Teak Boat Painting: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Hydro Systems Inc.'s boat lifts utilize a unique hydraulic system to lift and lower boats. The process begins with a boat being positioned over the lift, where it is secured to a cradle or a platform. The lift then activates the hydraulic pump, which pressurizes the fluid, extending the lift arm and lifting the boat. This system provides precise control over the lifting and lowering process, ensuring a smooth and safe operation.

Hydraulic boat lifts offer several benefits. Firstly, they provide a smooth and quiet operation, making them ideal for residential areas or places where noise restrictions are in place. The hydraulic system also offers excellent control, allowing for precise adjustments to lift or lower boats at specific intervals. Additionally, these lifts can handle heavy loads and are designed to be durable, ensuring a long-lasting and reliable performance.

Yes, one of the key advantages of Hydro Systems Inc.'s boat lifts is their adaptability to various water levels. The hydraulic system allows for easy adjustments, enabling the lift to accommodate changes in water height. This feature is particularly useful for boaters who may experience varying water conditions, ensuring that their boats remain accessible regardless of the water level.

Proper maintenance is essential to ensure the longevity of the hydraulic boat lift. Regularly check the hydraulic fluid levels and top-up with the manufacturer's recommended fluid. Keep the lift clean and free from debris, especially after use in muddy or dirty water. It is also advisable to lubricate moving parts as per the maintenance schedule. Regularly inspecting the lift for any signs of wear and tear and addressing issues promptly will help maintain optimal performance.