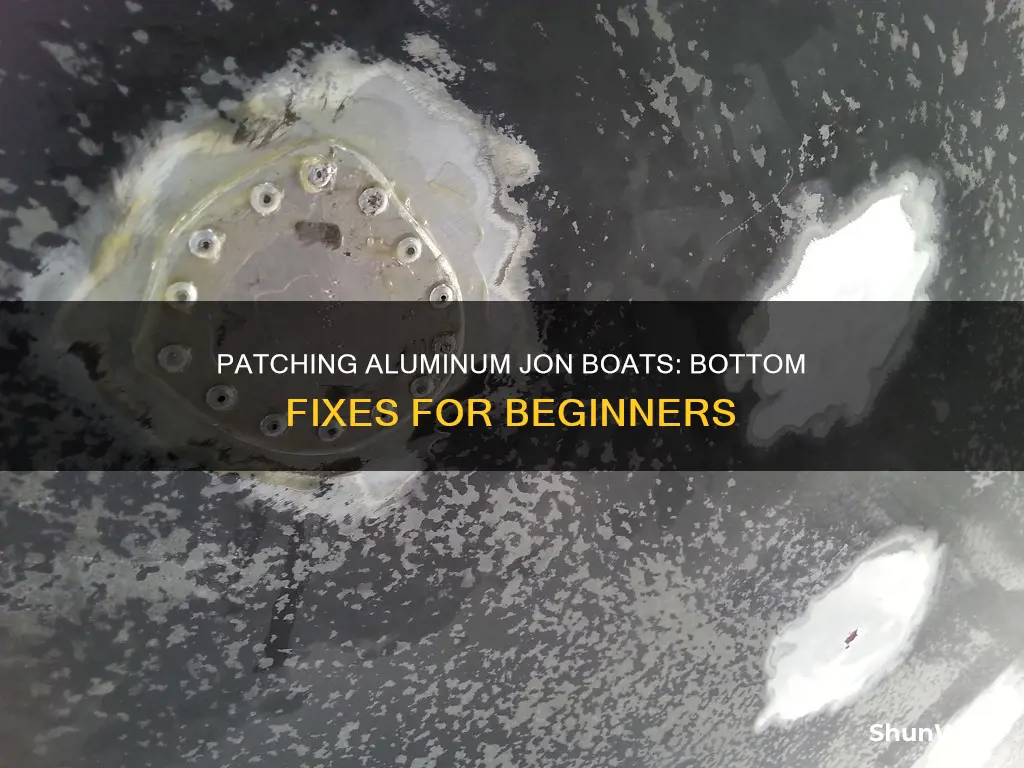

Owning a boat is a dream for many, but it also comes with its own set of challenges. One of the most common issues faced by boat owners is dealing with holes and tears in the hull, which can lead to leaks and affect the boat's performance. In this article, we will explore the various methods and materials available to patch an aluminum jon boat bottom, ensuring that your vessel remains seaworthy and safe for your adventures on the water.

| Characteristics | Values |

|---|---|

| Hole size | Small, big, 2-inch long, 5-inch long, thumb-sized |

| Repair material | Epoxy putty, JB Weld, fiberglass cloth, 3M Marine Adhesive/Sealant, 3M 5200, 3M 4000UV sealant, G Flex, Marine Tex, MarineWeld, SteelFlex, Marine-grade epoxy putty, PC 11, PC Metal, Marine Tex, JB Weld Steelstik, Hy-Poxy H-450 Alumbond, Hy-Poxy H-455 Alumfast, Epoxy, Weld |

| Repair method | Welding, drilling and deburring, patching, filling, sealing, riveting, grinding, sanding, painting, coating, smoothing, buffing, cleaning, hammering, popping, gluing, chiselling, breaking |

| Tools | Wire wheel, acetone, drill, screwdriver, ball pien hammer, paintbrush, sharp grit, small grit, prick punch, center punch, chisel, wire brush, sandpaper, angle grinder, Bondo spreader, gloves, marine tex, fiberglass cloth, 3M marine adhesive/sealant, JB Weld, 5200, PC 11, PC Metal, epoxy putty, JB Weld Steelstik, Hy-Poxy H-450 Alumbond, Hy-Poxy H-455 Alumfast, Bondo, Marine Tex, SteelFlex, 3M 4000UV sealant, G Flex, drill, wire brush, sharp chisel, prick punch, center punch, pop rivets, 3M5200, 3M 4000UV sealant, 5200, 400, 5700, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, 3M4000UV sealant, 5200, 400, 5700, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 5200, 3M5200, SteelFlex, epoxy, glue gun, heat gun, acetone solvent, two-part epoxy putty, two-part marine-grade epoxy putty, fiberglass resin, fiberglass fiber, glue, Bondo, TIG welder, wire wool, cloth, sandpaper, marine sealant, MarineWeld, Flex Seal Tape, Flex Tape, Marine Tex, 3M 520, 3M4000UV, 52 |

What You'll Learn

Clean the area around the hole with a wire brush or sandpaper

To patch a hole in an aluminium jon boat, it is important to clean the area around the hole thoroughly. This can be done with a wire brush or sandpaper. If you use sandpaper, make sure it is a small grit, as the metal is already thin and you don't want to remove too much of it. The goal is to get the metal around the hole back to its shiny, bare state. This will ensure that the patch adheres properly to the boat. Use a wire wheel on a drill to clean the holes and area down to bare aluminium. You can also use a wire brush or sandpaper to clean the area, but make sure to use a small grit to avoid removing too much metal. Once you have cleaned the area, you can move on to the next step of patching the hole.

It is important to note that some people recommend against using fibreglass cloth to patch holes in aluminium boats, as it can react with the aluminium and cause corrosion. Instead, consider using a product like JB Weld, Marine Tex, or 3M Marine Adhesive/Sealant to fill and seal the hole. These products will create a strong, watertight bond that can flex with the boat. Make sure to follow the instructions on the product you choose and clean the area thoroughly before applying the patch.

Operating a Skeeter Bass Boat Livewell: A Step-by-Step Guide

You may want to see also

Drill holes at the ends of cracks to prevent them from spreading

If you have cracks in the aluminum hull of your jon boat, it is important to act quickly to prevent them from spreading. Drilling holes at the ends of cracks is a crucial step in the repair process and will ensure that the damage does not worsen over time. Here is a detailed guide on how to properly drill these holes and some additional tips for repairing your boat:

Step-by-Step Guide to Drilling Holes at the Ends of Cracks:

- Clean the Area: Before you begin drilling, it is important to clean the aluminum surface thoroughly. Use a wire brush or sandpaper to remove any dirt, grease, or debris from the area around the cracks. You can also use a solvent like acetone to ensure the area is free of any oils that may hinder the repair process.

- Select the Correct Drill Bit: Choose a drill bit that is appropriate for the thickness of your aluminum hull. The bit should be just large enough to create a hole that will stop the crack from spreading. For thin aluminum, a small-sized bit is usually sufficient.

- Drill at a 90-Degree Angle: Position your drill bit perpendicular to the surface of the hull. This means drilling at a 90-degree angle to the aluminum. This will help ensure that the hole is straight and does not deviate from the intended path.

- Drill Slowly and with Caution: Start drilling at a slow speed and apply light pressure. Go slowly and with caution to avoid drilling all the way through the hull. You only need to drill enough to create a small hole at the end of the crack.

- Deburr the Holes: Once you have drilled the holes, use a deburring tool or a small file to remove any sharp edges or burrs that may have formed during drilling. This will help create a smooth finish and ensure that the repair patch adheres properly.

- Seal the Holes: After drilling and deburring, it is important to seal the holes to prevent water ingress. You can use an epoxy putty, such as JB Weld, to fill the holes and create a watertight seal. Smooth out the putty and ensure it adheres well to the surrounding area.

Additional Tips for Repairing Your Jon Boat:

- Rivet a Patch: As mentioned by several experienced boaters, riveting a patch over the repaired cracks can provide additional strength and peace of mind. Use a piece of aluminum at least .060 inches thick and seal it in place with rivets or stainless steel screws and nuts.

- Use Marine-Grade Products: When sealing holes and cracks, opt for marine-grade products like Marine Tex or 3M Marine Adhesive/Sealant. These are designed to withstand the unique challenges of a marine environment.

- Consider Welding: While welding can be expensive and challenging to find a skilled welder for thin aluminum, it is the most durable solution. Consider taking your boat to a weld shop for a professional repair that will last.

- Prepare the Surface: Before applying any patches or sealants, take the time to properly prepare the surface. This may include sandblasting or using a water/sand blaster to clean off paint, grime, and corrosion. A well-prepared surface will ensure that your repairs are long-lasting.

- Prevent Future Issues: To prevent cracks and holes from reappearing, consider coating your jon boat with a product like Gluvit or a specialized coating for aluminum boats. These coatings can provide added protection and help extend the life of your boat.

Boat Registration Renewal: Florida's Rules and Requirements

You may want to see also

Use a sealant like 3M 5200 or 3M 4000UV

If you're looking to patch up an aluminum jon boat bottom, one method is to use a sealant like 3M 5200 or 3M 4000UV. Here's a step-by-step guide on how to do it:

Step 1: Clean the Boat Surface

Before applying any sealant, it's important to clean the aluminum surface thoroughly. Use a small grit sandpaper to sand and smooth out the area around the hole or tear. This will ensure that the sealant adheres properly to the boat. Make sure to remove any grease or oil from the surface with a solvent like acetone.

Step 2: Prepare the Sealant

Both 3M 5200 and 4000UV are moisture-curing sealants. This means they'll need to be kept away from moisture until you're ready to apply them. Once you're ready, cut the tip of the sealant tube and load it into a standard caulking gun.

Step 3: Apply the Sealant

With your caulking gun loaded, carefully apply the sealant to the hole or tear. Make sure to fill in any gaps or cracks completely. The 3M 5200 is a flexible polyurethane polymer, so you can use it to fill in any gaps and create a watertight seal. It's also a permanent solution, so you won't need to worry about reapplying it.

The 3M 4000UV, on the other hand, is a medium-strength sealant. It's designed to allow for disassembly, so you can use it to bond parts of your boat without worrying about damaging them when you need to make repairs in the future.

Step 4: Smooth and Cure

After applying the sealant, use a gloved finger to smooth out the surface. For the 3M 5200, you'll have about 48 hours before it reaches handling strength, so you'll have plenty of time to work with it. The 3M 4000UV, on the other hand, will start to become tacky in about 22 minutes, and it will typically cure completely in 24 hours.

Step 5: Painting (Optional)

If you wish to paint over the sealed area, you can do so with the 3M 4000UV sealant. It can be painted over with water-based paints immediately after application. Just make sure to mask off the area and remove the masking tape right after you're done painting.

By following these steps and using a high-quality sealant like 3M 5200 or 3M 4000UV, you can effectively patch up an aluminum jon boat bottom and get back out on the water!

Malibu Response Boat: What's Under the Hood?

You may want to see also

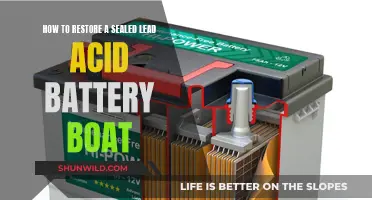

Apply a patch with JB Weld or Marine Tex

To apply a patch with JB Weld or Marine Tex, you must first clean the area around the hole. Use a wire wheel on a drill to clean the holes and the area around them down to bare aluminum. Next, use a small piece of the putty and flatten it onto the outside of the hole, then do the same on the inside. After it starts to set, use a moistened finger to smooth it down and make sure the edges adhere well. You can then sand it down and paint over it if you wish.

JB Weld is a good short-term solution, but it will not work long-term due to the flexing of the boat. For a more permanent solution, you can rivet a patch onto the boat, or use a product such as Marine Tex or 3M Marine Adhesive/Sealant with fiberglass cloth.

Boat Insurance in Georgia: What's the Law?

You may want to see also

Smooth the patch with a moistened finger

Once you have applied the JB Weld to the hole, you will need to smooth it down and make sure the edges adhere well. To do this, simply wet your finger and use it to smooth the putty. This will help to create a seamless finish and ensure that the repair blends in with the rest of the boat. It is important to act quickly, as the putty will start to harden within 5 minutes. However, this also means that you can put the boat in the water shortly after completing the repair.

If you are using a product like Marine Tex, you can also use a moistened finger to smooth it out. This will help to ensure that the repair is strong enough and can hold up to some flexing.

When using an epoxy putty, it is important to clean the repair area thoroughly before applying the putty. This includes sanding or grinding the area and cleaning it with an acetone solvent. This will help to ensure that the putty adheres properly and creates a strong, watertight seal.

After smoothing the patch, you may want to consider painting over it to create a more uniform appearance. This can also provide additional protection for the repair. However, be sure to follow the manufacturer's instructions for the putty or epoxy you are using, as some products may require additional steps or have specific curing times.

Staying Safe: Boat Distance from Military Vessels

You may want to see also

Frequently asked questions

Clean the area with a wire brush or wheel, sand/scuff, and clean again with a solvent such as acetone.

Epoxy putty, JB Weld, or fiberglass resin.

Mould the putty or resin into the hole and onto the surrounding area, and smooth it out. If the hole is a crack, drill a small hole at each end to stop the crack from spreading.

Seal the area with a product such as 3M 5200, 3M 4000UV, or PC 11.

Drill out the existing rivets, clean the area, and install new rivets with a rivet gun. Seal the rivets with 3M 5200 or 3M 4000UV.