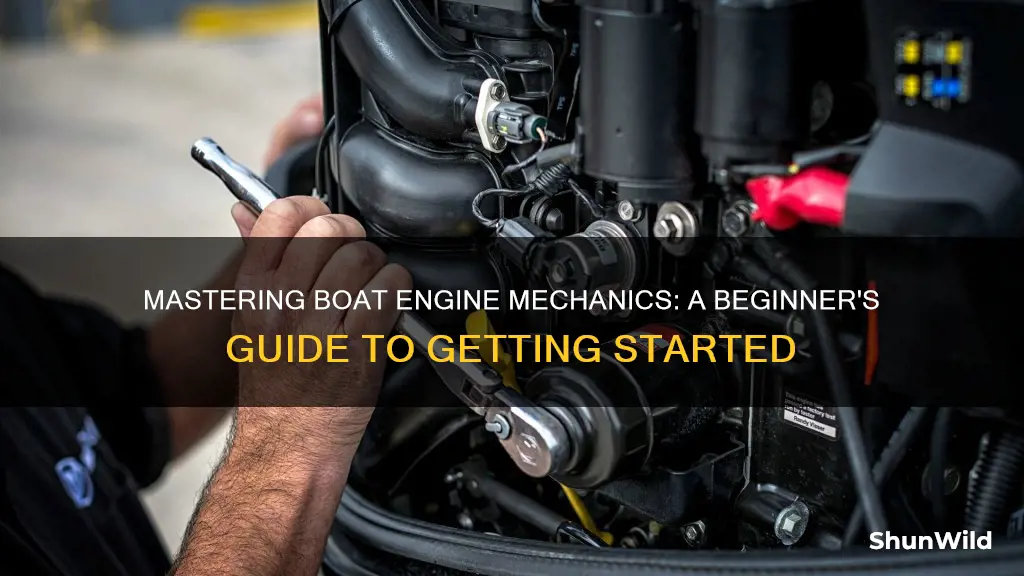

Learning to work on boat engines can be a rewarding and exciting endeavor for anyone interested in marine mechanics. Whether you're a boating enthusiast or a professional looking to expand your skills, understanding the intricacies of boat engine maintenance and repair is essential. This guide will provide a comprehensive overview of the process, covering the basics of engine mechanics, troubleshooting common issues, and best practices for maintenance. From understanding the different types of boat engines to mastering the art of engine diagnostics, you'll gain the knowledge and confidence to tackle a wide range of engine-related tasks.

What You'll Learn

- Engine Basics: Understand core components, functions, and maintenance needs

- Fuel Systems: Learn about fuel injection, carburetors, and proper fuel management

- Cooling Systems: Explore cooling methods, radiators, and preventing overheating

- Electrical Systems: Master wiring, batteries, and troubleshooting electrical issues

- Troubleshooting: Identify common issues, use diagnostic tools, and perform basic repairs

Engine Basics: Understand core components, functions, and maintenance needs

To begin your journey into understanding boat engine mechanics, it's crucial to familiarize yourself with the core components and their functions. Boat engines, typically gasoline or diesel, are intricate systems that power your vessel. Here's a breakdown of the essential parts and their roles:

Engine Block: This is the heart of the engine, a solid or cast metal structure that houses the internal combustion process. It contains the cylinders, where the magic happens, and is where the fuel and air mixture is ignited, creating power. The block is designed to withstand immense pressure and temperatures, ensuring the engine's longevity.

Cylinders: These are the chambers within the engine block where the combustion process occurs. Each cylinder has a piston that moves up and down, converting the energy from the combustion into mechanical motion. The number of cylinders can vary, but common configurations include in-line (e.g., 4-cylinder) and V-shaped (e.g., V8) arrangements.

Piston: A piston is a critical component that moves within the cylinder, transferring the force generated by the combustion process. It has a ring seal that prevents leakage of the fuel-air mixture and engine oil. As the piston moves, it drives the crankshaft, which converts the reciprocating motion into rotational energy.

Crankshaft: This component is responsible for converting the piston's linear motion into rotational motion. It is typically connected to the pistons via connecting rods. The crankshaft's rotation is what ultimately powers the boat's propeller, enabling movement.

Valvetrain: The valvetrain system controls the intake and exhaust of air and fuel into and out of the cylinders. It consists of valves (intake and exhaust), camshafts, and timing components. The camshafts open and close the valves at precise timings, ensuring efficient combustion and exhaust.

Cooling System: Boat engines generate a significant amount of heat, so a cooling system is essential. This system typically uses a liquid coolant that absorbs heat from the engine block and dissipates it through a radiator. Regular maintenance, such as checking coolant levels and replacing it periodically, is vital to prevent overheating.

Fuel System: Efficient fuel delivery is critical to engine performance. The fuel system includes the fuel tank, fuel pump, injectors or carburetor, and fuel lines. The pump ensures a consistent fuel supply, and the injectors or carburetor mixes the fuel with air and delivers it to the cylinders.

Understanding these core components and their functions is the first step in learning how to work on boat engines. Each part plays a unique role, and regular maintenance and care are essential to keep the engine running smoothly and reliably.

Open Boat's Most Likely Sentence

You may want to see also

Fuel Systems: Learn about fuel injection, carburetors, and proper fuel management

When it comes to working on boat engines, understanding the fuel system is crucial. This system is responsible for delivering the right amount of fuel to the engine, ensuring optimal performance and efficiency. There are two primary methods of fuel delivery: fuel injection and carburetors, each with its own advantages and considerations.

Fuel Injection:

Fuel injection systems have become increasingly popular in modern boats due to their precision and reliability. In this system, fuel is injected directly into the engine's cylinders, ensuring a precise mixture of air and fuel. The process involves a fuel pump that delivers fuel at a controlled pressure to the injectors. These injectors then spray the fuel into the combustion chamber, creating a more efficient and powerful burn. One of the key benefits of fuel injection is its ability to provide a consistent fuel-air mixture, even under varying load conditions. This results in improved performance, reduced emissions, and better fuel economy. When working on a fuel-injected engine, it's essential to understand the electronic control unit (ECU) that manages the fuel injection process. This includes learning how to diagnose and troubleshoot issues related to the ECU, such as sensor failures or wiring problems.

Carburetors:

Carburetors, on the other hand, are mechanical devices that mix air and fuel in a controlled manner. They are simpler in design compared to fuel injection systems. A carburetor uses a series of valves and jets to meter the fuel, creating a combustible mixture with the incoming air. Carburetors are often found in older boat engines and require precise adjustments to ensure optimal performance. Learning how to adjust the carburetor's idle, acceleration, and main jets is crucial. These adjustments control the fuel-air mixture at different engine speeds, ensuring smooth operation and efficient fuel consumption. It's important to note that carburetors are more susceptible to contamination and require regular cleaning to maintain their effectiveness.

Fuel Management:

Proper fuel management is essential to keep your boat engine running smoothly and efficiently. This includes understanding the basics of fuel storage, handling, and maintenance. Firstly, ensure that your fuel tank is clean and free of contaminants. Regularly check and replace the fuel filter to prevent debris from entering the system. It's also crucial to monitor the fuel levels and add the appropriate grade of fuel, as some engines require specific types of fuel (e.g., ethanol-free or marine-grade gasoline). Additionally, learn about fuel stabilization techniques, especially for long-term storage, to prevent fuel degradation.

By grasping the fundamentals of fuel injection, carburetors, and fuel management, you'll be well-equipped to handle various boat engine issues. These systems require regular maintenance and adjustments to ensure optimal performance and longevity. Remember, each boat engine may have unique characteristics, so it's essential to consult the manufacturer's guidelines and seek professional advice when needed.

Understanding Third-Party Boat Insurance Coverage and Benefits

You may want to see also

Cooling Systems: Explore cooling methods, radiators, and preventing overheating

When it comes to boat engines, effective cooling is crucial to ensure optimal performance and prevent overheating, which can lead to costly repairs or even engine failure. Understanding the cooling systems and methods employed in boats is essential for anyone looking to work on these powerful machines. Here's an overview of cooling systems, radiators, and strategies to maintain a healthy engine temperature.

Cooling Methods:

Boat engines often utilize various cooling techniques to maintain optimal operating temperatures. One common method is liquid cooling, where a coolant fluid, typically a mixture of water and antifreeze, circulates through the engine block and absorbs heat. This heated coolant then passes through a radiator, which is a vital component in the cooling system. The radiator dissipates heat into the surrounding air, effectively cooling the coolant and preventing the engine from overheating. Another approach is air cooling, where the engine block is designed to draw cool air directly over the hot components, often facilitated by fans or natural airflow.

Radiators:

Radiators are the heart of the cooling system, responsible for transferring heat from the engine to the surrounding environment. They are typically made of aluminum or copper and are designed with a series of fins and tubes. As the coolant flows through the radiator, the fins increase the surface area, allowing for efficient heat exchange with the air. Proper radiator maintenance is crucial; regular cleaning to remove debris and ensuring the radiator is securely mounted to facilitate optimal airflow are essential practices.

Overheating Prevention:

Preventing overheating is a critical aspect of boat engine maintenance. Here are some key strategies:

- Coolant Maintenance: Regularly check and top up the coolant to ensure the engine is adequately protected. The coolant should be checked for contamination and replaced if necessary. Maintaining the correct coolant level is vital, as an empty reservoir can lead to engine damage.

- Coolant Type: Using the manufacturer-recommended coolant type is essential. Different coolants have varying properties, and using the wrong type can lead to engine corrosion or reduced efficiency.

- Thermostat Inspection: The engine's thermostat regulates coolant flow and temperature. Inspecting and testing the thermostat ensures it opens and closes correctly, allowing for proper cooling.

- Engine Maintenance: Regular engine maintenance, including cleaning and inspecting all cooling system components, is crucial. This includes checking for leaks, ensuring proper fan operation, and verifying that all hoses and pipes are intact and securely connected.

- Monitor Engine Temperature: Keep a close eye on the engine temperature gauge during operation. If the temperature rises rapidly or exceeds safe limits, take immediate action by slowing down the engine or seeking a safe haven to prevent damage.

Understanding the cooling system's intricacies and implementing these preventive measures will contribute to the longevity and reliable performance of your boat engine. It is always recommended to consult the boat's manual or seek professional advice for specific engine requirements and maintenance procedures.

Budapest's Public Boat Transport: Where to Board?

You may want to see also

Electrical Systems: Master wiring, batteries, and troubleshooting electrical issues

Learning to work on boat engines, especially focusing on electrical systems, is a valuable skill for any boat owner or enthusiast. Electrical systems are the backbone of a boat's functionality, powering everything from navigation equipment to lighting and engine controls. Understanding wiring, batteries, and troubleshooting electrical issues is crucial for ensuring your boat runs smoothly and safely. Here's a comprehensive guide to help you get started:

Understanding the Basics of Boat Electrical Systems:

Begin by familiarizing yourself with the fundamental components of a boat's electrical system. This includes the main battery, alternator, fuses, circuit breakers, and various sensors. Each component plays a vital role in ensuring the boat's electrical supply is stable and reliable. The main battery is the power source, while the alternator recharges it while the engine is running. Fuses and circuit breakers protect the system from overcurrent, preventing potential fires and damage. Sensors monitor various engine parameters, providing critical data for engine management.

Wiring and Connections:

Boat wiring can be complex, with numerous cables and connections. Start by learning the different types of wiring used, such as thhn (thinner heat-resistant wire) and marine-grade wire, which is designed to withstand the marine environment. Understand the color-coding of wires, as this can help in identifying their functions. For example, black wires often represent power, while white wires might be used for grounding. Learn the proper way to connect wires, ensuring tight and secure terminations to prevent loose connections that can cause issues. Practice soldering and crimping techniques to make professional-grade connections.

Battery Maintenance and Troubleshooting:

Batteries are the heart of a boat's electrical system, providing the initial power boost when the engine starts. Learn how to check and maintain batteries, including testing their voltage and capacity. Regularly cleaning battery terminals and ensuring they are securely connected is essential. In the event of a battery issue, such as a short circuit or corrosion, you should be able to identify and rectify the problem. Understanding battery charging systems and how to troubleshoot charging issues is also crucial, as it ensures your batteries stay healthy and have a long lifespan.

Troubleshooting Electrical Issues:

When dealing with electrical problems, a systematic approach is necessary. Start by identifying the specific issue, whether it's a faulty gauge, a non-functional light, or a complete power loss. Check for blown fuses or tripped circuit breakers, and replace or reset them if necessary. Use a multimeter to test for continuity, voltage, and resistance, helping you pinpoint the problem area. Learn to read electrical diagrams and schematics to understand the wiring layout and potential trouble spots. Practice soldering and desoldering techniques to make repairs without causing further damage.

Safety and Best Practices:

Working on electrical systems requires a strong emphasis on safety. Always ensure the boat is properly grounded and that you are following all safety protocols. Wear appropriate personal protective equipment, such as insulated gloves and safety goggles, to protect yourself from electrical shocks and burns. When making repairs, double-check your work to avoid causing further issues. Keep your workspace clean and organized to prevent accidents. Stay updated with the latest marine electrical technology and best practices to ensure you are working with the most current methods and tools.

By focusing on these electrical system aspects, you'll gain the skills to tackle a wide range of boat engine issues. Remember, practice and hands-on experience are key to becoming proficient in this field.

The Estephan Boat Accident: A Survivor's Tale

You may want to see also

Troubleshooting: Identify common issues, use diagnostic tools, and perform basic repairs

When it comes to working on boat engines, troubleshooting is an essential skill to have. Being able to identify common issues and perform basic repairs can save you time and money, and ensure your vessel is always ready for the water. Here's a guide to help you get started:

Identifying Common Issues:

Start by familiarizing yourself with the different components of a boat engine and their functions. This includes the engine block, cylinders, pistons, valves, and the cooling and lubrication systems. Learn to recognize the signs of common problems, such as excessive oil consumption, strange noises, or reduced performance. For example, if you notice a significant drop in engine power, it could be due to clogged fuel filters, worn-out spark plugs, or a faulty fuel pump. Keep an eye out for leaks, especially from the engine block, head gaskets, or seals. These can indicate issues with the engine's integrity and may require immediate attention.

Using Diagnostic Tools:

Modern boat engines often come equipped with onboard diagnostic systems that can provide valuable insights into engine performance. These systems can detect and display error codes, which are essential for troubleshooting. Learn how to access and interpret these error codes. For instance, a code related to the 'Engine Control Module' (ECM) might indicate a problem with the engine's computer, while a code for the 'Crankshaft Position Sensor' suggests an issue with the engine's ability to start. Additionally, consider using handheld diagnostic tools, such as OBD-II scanners, which can read and clear error codes, helping you pinpoint the root cause of the problem.

Basic Repairs and Maintenance:

With a basic understanding of engine mechanics, you can perform simple repairs and maintenance tasks. Here are a few examples:

- Changing Engine Oil: Regular oil changes are crucial for engine longevity. Locate the oil drain plug and filter, and ensure you have the correct type of oil and filter for your engine.

- Spark Plug Replacement: Spark plugs play a vital role in ignition. Remove the old plugs and install new ones, ensuring you follow the manufacturer's specifications for torque and gap settings.

- Fuel System Maintenance: Check and replace fuel filters regularly to prevent contamination. Inspect the fuel lines for any cracks or leaks, and ensure the fuel pump is functioning correctly.

- Cooling System Checks: Inspect the engine's cooling system for any leaks or blockages. Check the coolant level and consider adding a coolant additive to prevent corrosion.

Remember, when performing repairs, always refer to the boat's manual for specific instructions and safety guidelines. It's also a good practice to keep a well-stocked toolbox with common tools and spare parts to handle minor issues promptly.

Black Legend Boat: Who Owns This Iconic Vessel?

You may want to see also

Frequently asked questions

Working on boat engines requires a combination of mechanical aptitude, technical knowledge, and practical experience. Basic understanding of engine mechanics, including engine types, fuel systems, cooling systems, and electrical components, is crucial. Additionally, familiarity with tools and equipment used in engine maintenance and repair is essential.

There are several ways to acquire the required technical knowledge. You can start by studying online resources, such as tutorials, videos, and forums, which provide valuable insights into engine operation and maintenance. Local community colleges or technical schools often offer marine engine courses, offering hands-on training and in-depth knowledge. Additionally, consulting manufacturer manuals and technical guides specific to your boat engine model is highly recommended.

Yes, several certifications and training programs are available for those interested in becoming boat engine mechanics. These programs often cover engine diagnostics, troubleshooting, repair techniques, and safety protocols. Reputable organizations like the National Marine Electronics Association (NMEA) and the Marine Mechanics Institute offer recognized certifications that can enhance your credibility and employability in the field.

The essential tools for boat engine maintenance include basic hand tools like wrenches, screwdrivers, and pliers. You may also require specialized tools such as torque wrenches, engine diagnostic scanners, and various types of measuring equipment. It's advisable to invest in a good-quality tool kit specifically designed for marine engine work, ensuring you have the necessary tools for various tasks.

Practical experience is invaluable in learning to work on boat engines. Start by assisting experienced mechanics or boat owners with routine maintenance tasks. You can also offer your services to local boat clubs or marinas, providing an opportunity to work on different engine models and gain hands-on experience. Additionally, consider volunteering at boat shows or marine events, where you can interact with professionals and learn from their expertise.