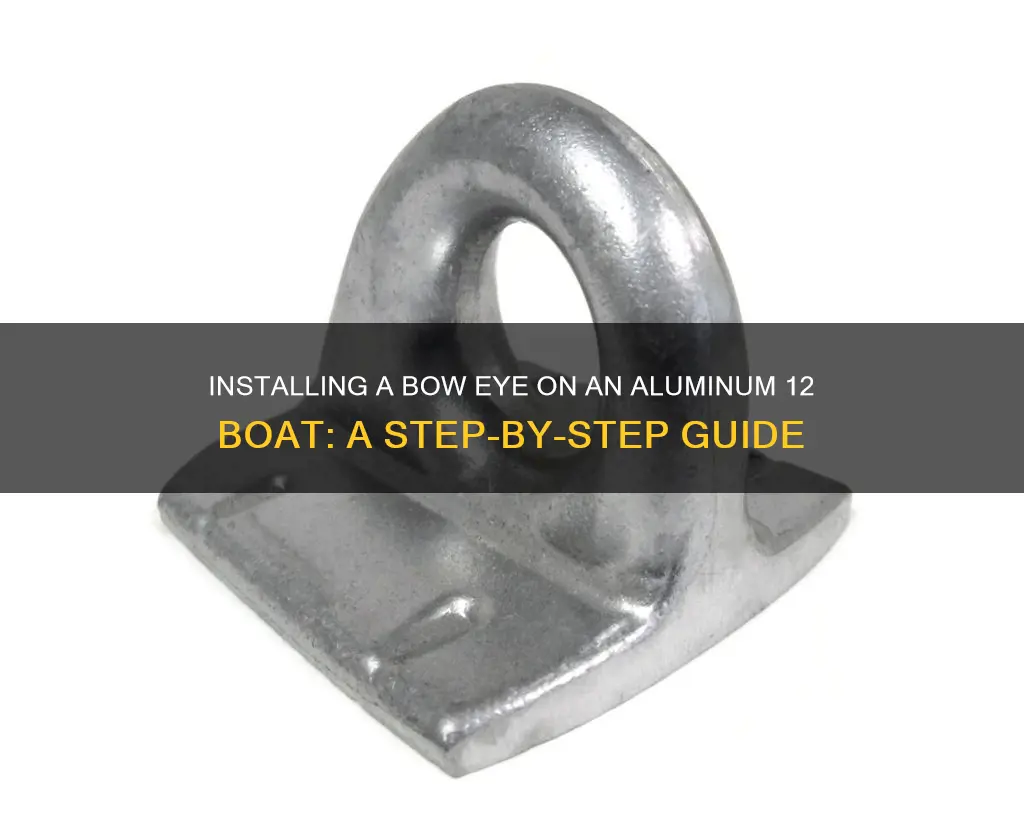

Installing a bow eye on an aluminium boat is a straightforward process. The bow eye is a crucial component for securing the front of the boat to a trailer. While some boats may not come with a bow eye, it is possible to add one as an aftermarket installation. The process involves drilling holes in the boat's hull and securing the bow eye with bolts and a backing piece. The backing piece can be made from wood, plastic, or aluminium, and it helps to distribute the force and prevent the bow eye from pulling through the hull. When installing a bow eye, it is important to consider the height and alignment to ensure easy loading and reduce hull stress. Additionally, sealing the holes and backing piece with epoxy or resin can enhance the strength and durability of the installation.

What You'll Learn

Drilling the holes for the bow eye

Before you begin drilling, it is important to select the appropriate location for the bow eye. Choose a spot on the prow seam, preferably at a point where the hull is doubled, to provide additional strength. Consider the height of the trailer winch and aim for a straight pull to ease loading and reduce hull stress. Keep in mind that the bow eye should be installed lower than the winch roller or stop.

Once you have identified the ideal location, it's time to gather the necessary tools and materials. You will need a drill, a drill bit of the appropriate size (matching your bow eye bolt size), safety goggles, and work gloves for protection. It is also recommended to have a helper assist you during the drilling process.

Start by marking the drill points on the prow seam. Use a ruler or measuring tape to ensure the holes are evenly spaced and aligned. Put on your safety goggles and gloves, and position yourself comfortably near the drilling area. Hold the drill firmly and start drilling at low speed, applying gentle pressure. Gradually increase the speed and pressure as you create the hole. Take your time and be cautious to avoid drilling all the way through the boat. Drill to a depth that matches the length of your bow eye bolts.

After drilling the holes, it is essential to deburr and clean the area. Use a deburring tool or a file to remove any sharp edges or burrs that may have formed during drilling. Wipe the area clean with a cloth, ensuring no metal shavings or debris remain.

Finally, before installing the bow eye, apply a marine-grade sealant or epoxy to the holes and the surrounding area. This will help create a watertight seal and prevent corrosion. Follow the instructions on the sealant or epoxy packaging for proper application and curing times.

By carefully following these steps, you can effectively drill the holes for the bow eye on your aluminum 12-boat, ensuring a secure and long-lasting installation. Remember to take your time, wear appropriate safety gear, and seek assistance if needed.

Firefighters' Boat: Still Missing, Search Continues

You may want to see also

Choosing the right backing material

When choosing the right backing material for your bow eye installation, there are several factors to consider. The backing material plays a crucial role in reinforcing the bow eye and ensuring the strength and durability of the installation. Here are some detailed guidelines and considerations to help you make an informed decision:

Compatibility with Boat Material:

Start by considering the compatibility of the backing material with your aluminum boat. Since you have an aluminum boat, it is essential to choose a backing material that works well with this metal. Some options include stainless steel, galvanized iron, or another type of aluminum piece.

Load Distribution:

The backing material should effectively distribute the load exerted on the bow eye. This is crucial to prevent excessive stress on the boat's hull and to ensure the longevity of the installation. Consider using a material that can be shaped to match the contour of your boat's "V"-shaped bow. For example, plywood or Starboard material can be laminated and shaped to fit the "V" shape, providing a strong and rot-resistant backing.

Strength and Durability:

Opt for backing materials that offer strength and durability. For instance, stainless steel, aluminum, or galvanized iron are known for their strength and resistance to corrosion. Additionally, consider using a bedding material, such as epoxy or marine-grade sealants, between the bow eye and the hull to prevent water ingress and acidification, which can weaken the backing material over time.

Ease of Installation:

Choose a backing material that is relatively easy to work with and install. For example, plywood or epoxy putty can be shaped and molded to fit the "V" shape of the bow, making them good choices for a DIY installation.

Maintenance and Replacement:

Consider the long-term maintenance and replacement needs of the backing material. Opt for materials that are readily available and easy to source, should you need to replace or repair them in the future. Additionally, some backing materials may require periodic maintenance, such as checking for loosening or corrosion, so choose something that aligns with your maintenance capabilities and schedule.

In summary, when choosing the right backing material for your bow eye installation on an aluminum boat, prioritize compatibility, load distribution, strength, and durability. Opt for materials like stainless steel, aluminum, or plywood that can be shaped to match your boat's contour and provide effective reinforcement. Don't forget to use bedding materials to prevent water ingress, and always follow best practices for marine installations to ensure a safe and long-lasting solution.

Marine Batteries: Charging Process and Boat Maintenance

You may want to see also

Ensuring the bow eye is correctly aligned

First, select the ideal location for the bow eye on the bow of your boat. It is important to choose a structural point that can withstand the forces exerted on the bow eye during towing and anchoring. Make sure to consider the design and construction of your boat when selecting this location.

Once you have identified the correct position, use a measuring tape to mark the centre point for the installation. This will ensure that the bow eye is aligned correctly. Use a level to double-check that the marked centre point is level.

Next, use the appropriate drill bit to carefully drill a pilot hole at the marked location. This will help guide your drilling and ensure that the holes for the bow eye are drilled in the correct location. Take your time with this step to avoid making any mistakes.

Now, you can insert the bolts or screws that will secure the bow eye in place. Make sure they are the correct length and made from marine-grade stainless steel to prevent corrosion. Tighten them securely, but be careful not to over-tighten as this could damage the threads or the bow eye itself.

Finally, double-check the installation for stability and integrity. Ensure that the bow eye is level and firmly attached to the boat. Test the strength of the installation by applying force to the bow eye and checking for any movement or weakness.

Remember, the correct alignment of the bow eye is crucial to the safety and functionality of your boat during towing and anchoring. Taking the time to ensure proper alignment will give you peace of mind and help protect your vessel.

Boat Registration Numbers: Where to Purchase and Display

You may want to see also

Sealing the bow eye with epoxy

Preparation

Before applying the epoxy, it's essential to prepare the aluminum surface. Start by cleaning it thoroughly to remove any dirt, debris, oxidation, or corrosion. Use a scuffing pad or sandpaper to scuff the surface until it's rough and a shiny, unoxidized layer is exposed. This process enhances the adhesion of the epoxy to the aluminum. Once you're satisfied with the surface profile, apply an aluminum etching product. These products further improve the aluminum's ability to adhere to the epoxy. Be sure to follow the manufacturer's instructions when using these products. Finally, rinse the surface with water and ensure it's completely dry before proceeding to the next step.

Mixing the Epoxy

Epoxy typically comes in two parts: the resin and the hardener. For optimal results, carefully measure and mix the two components according to the manufacturer's instructions. It's crucial to maintain the specified ratio of resin to hardener to ensure proper curing. You can use a calibrated epoxy pump or manually measure by weight or volume. Additionally, consider the temperature range specified for the epoxy, as it will affect the working time and curing process.

Applying the Epoxy

Once you have a well-mixed epoxy, it's time to apply it to the bow eye area. Use a brush, roller, syringe, or epoxy spreader to coat the area generously. Make sure to follow the manufacturer's recommendations for application techniques and thickness. Pay particular attention to the instructions regarding working time and curing time. The epoxy will need to cure for at least 24 hours, but ideally 48 hours, to reach its full strength. During this time, maintain the recommended temperature range to ensure proper curing.

Sanding and Finishing

After the epoxy has cured, you may need to sand the surface lightly to prepare it for the final finish. Clean the area with water to remove any residue or amine blush, a waxy substance that sometimes forms on the surface of cured epoxy. Once the surface is clean and smooth, you can apply a primer or paint to further protect the aluminum and give it a finished look.

Maintenance and Care

Epoxy is a durable and long-lasting solution for sealing the bow eye of your aluminum boat. However, proper maintenance is essential to ensure its longevity. Keep the sealed area clean and free of debris. Regularly inspect the epoxy for any signs of wear or damage. With the right care, your epoxy-sealed bow eye will provide reliable service for many years.

Rigging a Pond Sail Boat: A Beginner's Guide

You may want to see also

Tightening the bow eye

To tighten the bow eye on your aluminium boat, you will need to follow a few simple steps.

First, you will need to create a backing for the bow eye to distribute the pressure over a wider area inside the hull. You can use a small piece of wood, plastic, or aluminium for this. If you are using aluminium, you can preform it with a mallet and mandrel to fit the curve of the hull. Drill two holes through your backing piece, making sure they line up with the holes on the bow eye.

Next, you will need to drill straight through the prow of the boat at the desired height, making sure to seal the holes with epoxy to protect against water damage. Bed the backing piece in epoxy as well, and then insert the bow eye through the holes in the prow, securing it with the backing piece and tightening the nuts until the backing piece conforms to the curve of the prow.

Finally, back off the nuts and apply more epoxy to the threads of the bow eye. Snug the nuts down again, but avoid over-tightening. Allow the epoxy to cure, and your new bow eye will be ready to use!

Organizing Your Bass Boat: Tips for Efficient Storage

You may want to see also

Frequently asked questions

A bow eye is a feature on a boat that is used to secure the front of the boat to a trailer.

To install a bow eye on an aluminium 12 boat, you will need to drill holes in the front of the boat and attach a bow eye with bolts or U-bolts. You may also need to create a backing piece to distribute the pressure over a wider area inside the hull and prevent the bow eye from pulling through.

The backing piece for a bow eye installation can be made from wood, plastic, aluminium, or stainless steel.

You can use a dual-bolt or U-bolt bow eye for an aluminium 12 boat.

Yes, one potential issue is that if the bow eye is installed too low, it may contact the water in a chop, causing a large amount of spray.