Fixing cracks in fiberglass on a boat requires careful attention to ensure the repair is durable and long-lasting. The process typically involves cleaning the damaged area, applying a suitable filler or resin, and then carefully smoothing and sanding the repair to match the surrounding surface. This guide will provide a step-by-step approach to effectively repair these cracks, ensuring your boat remains safe and aesthetically pleasing.

What You'll Learn

- Identify the Type of Crack: Inspect the crack to determine if it's a hairline, surface, or structural issue

- Prepare the Surface: Clean the area, remove debris, and ensure a smooth, dry surface for repair

- Choose the Right Filler: Select a suitable fiberglass filler that matches the boat's material and color

- Apply the Filler: Follow manufacturer instructions for mixing and applying the filler, ensuring even coverage

- Sand and Smooth: After curing, sand the filled area to match the surrounding surface, then prime and paint

Identify the Type of Crack: Inspect the crack to determine if it's a hairline, surface, or structural issue

When dealing with cracks in fiberglass on a boat, the first crucial step is to identify the type of crack you're facing. This classification will significantly influence the repair approach and the materials required. Here's a detailed guide on how to determine the nature of the crack:

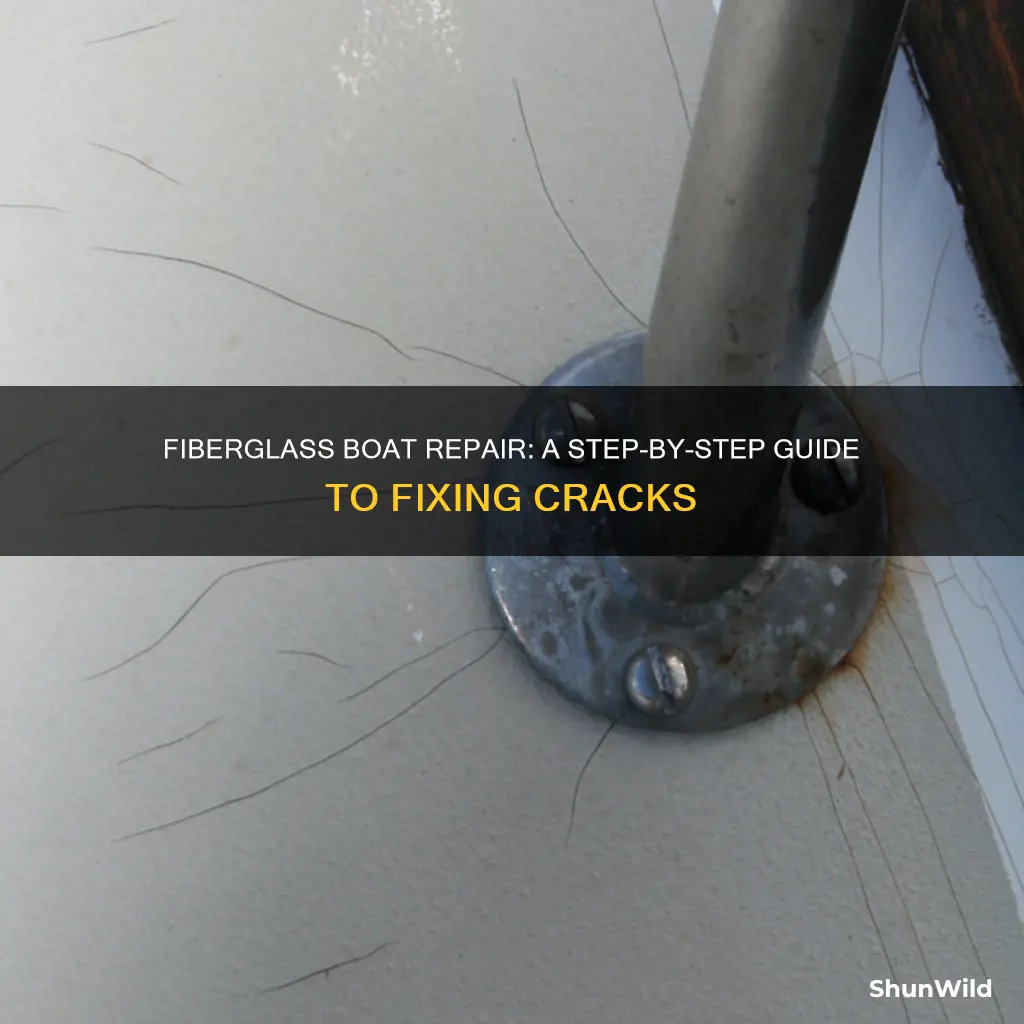

- Hairline Cracks: These are the most common and least concerning type of crack. Hairline cracks are typically thin, almost invisible to the naked eye, and often appear as fine lines or small fissures. They are usually caused by minor stress or impact and are not deep enough to penetrate the entire thickness of the fiberglass. If you can't see the crack with the naked eye, it's likely a hairline issue. To confirm, you can use a magnifying glass or a flashlight to inspect the area closely. These cracks are generally not structural and can often be repaired with a simple filling and sanding process.

- Surface Cracks: These cracks are more visible and can be felt or seen with the naked eye. They are usually caused by more significant impacts or stress, such as collision damage or frequent movement in rough waters. Surface cracks may extend deeper into the fiberglass, but they are still limited to the outer layer. Inspect the crack carefully to ensure it doesn't penetrate the gelcoat or the underlying layers. These cracks might require a more extensive repair, including sanding, filling, and possibly re-gelcoating the affected area.

- Structural Cracks: Structural cracks are the most severe and should be addressed with the utmost urgency. These cracks extend through multiple layers of the fiberglass and can compromise the boat's integrity. They are often caused by significant structural damage, such as a collision or severe impact. Structural cracks may be visible from the outside, but they can also be hidden beneath the surface. If you suspect a structural issue, it's essential to seek professional help immediately. Attempting to repair structural damage without proper expertise can be dangerous and may lead to further complications.

To identify the type of crack, start by examining the crack's appearance and texture. Feel the surface around the crack to assess its depth. Then, use a flashlight or a magnifying glass to get a closer look. If the crack is hairline, you might not see it without magnification. For surface and structural cracks, ensure they don't extend through the gelcoat or multiple layers of fiberglass. Remember, proper identification is the first step towards an effective repair strategy.

Finding the Right Boat Surveyor: A Comprehensive Guide

You may want to see also

Prepare the Surface: Clean the area, remove debris, and ensure a smooth, dry surface for repair

When preparing the surface of your boat's fiberglass for repair, it's crucial to follow a meticulous process to ensure a successful and long-lasting fix. Start by thoroughly cleaning the area around the cracks. Use a mild detergent or dish soap mixed with warm water to remove any dirt, grime, or old repair materials. This step is essential as it ensures that the new filler material will adhere properly to the existing surface. Rinse the area thoroughly with clean water to eliminate any soap residue.

Once the cleaning is complete, inspect the surface for any remaining debris or contaminants. Use a soft-bristled brush or a small tool to gently remove any loose particles or sharp edges that might hinder the bonding process. Ensure that the surface is completely dry before proceeding. Moisture on the fiberglass can interfere with the adhesion of the repair materials.

The next critical step is to smooth out the area around the cracks. Fiberglass can be somewhat porous, and any imperfections or rough spots should be addressed. Use fine-grit sandpaper (600-1200 grit) to gently sand the area, creating a smooth and even surface. Be careful not to apply too much pressure, as this can damage the fiberglass. After sanding, wipe away any dust or debris with a damp cloth to ensure a clean and smooth base for the repair.

Before applying any repair materials, it's essential to ensure the surface is dry and free of any moisture. Use a hairdryer on a low setting to accelerate the drying process if necessary. This step is vital to prevent any water-based repair materials from curing improperly. By taking the time to thoroughly prepare the surface, you'll create a solid foundation for your fiberglass repair, ensuring a strong and durable bond.

Boat Insurance: Geico's Towing Service and Its Limitations

You may want to see also

Choose the Right Filler: Select a suitable fiberglass filler that matches the boat's material and color

When it comes to repairing cracks in a boat's fiberglass hull or deck, choosing the right filler is crucial for a successful and long-lasting repair. The goal is to match the filler's properties to the boat's material and color as closely as possible to ensure a seamless and inconspicuous fix. Here's a guide to help you select the appropriate filler:

Understanding Fiberglass: Fiberglass is a composite material made of a resin matrix and reinforced with glass fibers. It is known for its strength, durability, and lightweight nature, making it a popular choice for boat construction. However, like any material, it can develop cracks over time due to various factors such as impact, UV exposure, or structural stress.

Types of Fillers: There are several types of fillers available for fiberglass repairs, each with its own advantages and considerations:

- Epoxy-Based Fillers: These fillers are a popular choice for fiberglass repairs due to their strong bonding capabilities. Epoxy resins create a durable and flexible bond, making them suitable for structural repairs. Look for epoxy fillers that are specifically formulated for marine environments, ensuring they can withstand the harsh conditions of the water.

- Polyester-Based Fillers: Polyester resins are another common option, offering a balance between strength and ease of use. They are generally less expensive and easier to apply compared to epoxy, but may not provide the same level of structural integrity. Choose a polyester filler that matches the color of your boat's fiberglass to ensure a discreet repair.

- Silicone-Based Fillers: Silicone resins are ideal for filling small cracks and providing a flexible repair. They are resistant to UV radiation and can withstand temperature changes, making them suitable for above-water applications. However, they may not be as strong as epoxy or polyester for structural repairs.

Matching the Filler to the Boat's Material: It is essential to select a filler that is compatible with the type of fiberglass used in your boat. Different manufacturers may use variations in their fiberglass formulations, so always refer to the boat's documentation or consult the original equipment manufacturer (OEM) for recommendations. Using a filler that is not compatible can lead to poor adhesion, reduced strength, or even deterioration of the fiberglass over time.

Color Matching: Achieving a seamless repair also involves matching the color of the filler to the surrounding fiberglass. Most filler manufacturers offer a range of colors to choose from. Select the color that best matches the boat's existing fiberglass. This ensures that the repair blends in and is less noticeable once completed. Some companies even provide color-matching services, allowing you to send a sample of the fiberglass for accurate color matching.

Application and Preparation: Before applying the filler, ensure that the crack is clean and free of any debris or old filler. Prepare the area by sanding it down to create a smooth surface for the filler to adhere to. Follow the manufacturer's instructions for mixing and applying the filler, ensuring you apply it evenly and in thin layers to avoid air bubbles. Allow sufficient time for each layer to cure before applying additional filler.

By carefully selecting a filler that matches the boat's material and color, you can ensure a professional-looking repair that will stand the test of time. Remember, proper preparation and attention to detail are key to a successful fiberglass repair.

Repairing Resin Shells: Restoring Your Boat's Exterior

You may want to see also

Apply the Filler: Follow manufacturer instructions for mixing and applying the filler, ensuring even coverage

When it comes to repairing cracks in fiberglass on a boat, one of the most effective methods is to use a specialized filler. This process requires careful preparation and attention to detail to ensure a successful repair. Here's a step-by-step guide on how to apply the filler:

Step 1: Prepare the Area

Before you begin, ensure the cracked area is clean and free of any debris or old filler. Use a sharp tool to carefully remove any loose fibers or debris around the crack. This step is crucial to ensure the filler adheres properly. If the crack is deep, consider using a fiberglass repair kit to create a smooth surface before applying the filler.

Step 2: Mix the Filler

Follow the instructions provided by the manufacturer of your chosen filler. Typically, you'll need to mix the filler with a hardener or catalyst to create a putty-like consistency. Use a clean, non-reactive container and follow the mixing ratio carefully. Over-mixing can lead to a sticky consistency, while under-mixing may result in a weak repair.

Step 3: Apply the Filler

Take a small amount of the mixed filler and gently press it into the crack, ensuring it fills the entire gap. Use a putty knife or a similar tool to spread the filler evenly, creating a smooth and level surface. Take your time with this step to ensure a professional finish. Aim for a thickness of around 1/8 inch to 1/4 inch, depending on the depth of the crack.

Step 4: Smooth and Shape

Once the filler is applied, use a sharp tool to smooth the surface and create a seamless finish. Remove any excess filler and shape it to match the surrounding fiberglass. You can use a fine-grit sandpaper to gently smooth the area, ensuring it blends in with the original material.

Step 5: Allow it to Cure

Follow the manufacturer's instructions for curing time. Typically, you'll need to avoid any pressure or heavy use of the repaired area for a specified period. This allows the filler to set and bond effectively. Once cured, the filler will provide a strong and durable repair, restoring the structural integrity of the boat's fiberglass.

Remember, taking your time and following the manufacturer's guidelines will result in a successful and long-lasting repair. Proper preparation and attention to detail are key to ensuring the filler adheres and blends seamlessly with the existing fiberglass.

Installing a Boat Dock: A Comprehensive Guide

You may want to see also

Sand and Smooth: After curing, sand the filled area to match the surrounding surface, then prime and paint

After the repair process is complete and the filler has cured, it's crucial to ensure a seamless finish that blends seamlessly with the rest of the boat's surface. The first step in this process is sanding. You'll want to use fine-grit sandpaper, typically 400 or 600 grit, to gently smooth out the filled area. Start by lightly sanding the surface, removing any excess filler and creating a subtle texture that matches the surrounding fiberglass. Take your time and work in small sections to avoid over-sanding and damaging the gelcoat. Once you've achieved a smooth and even surface, wipe away any dust with a damp cloth to prepare the area for the next step.

Next, you'll need to prime the repaired area. Priming is essential to create a uniform base for the paint and ensure proper adhesion. Choose a marine-grade primer that is compatible with fiberglass. Apply the primer evenly using a small brush or a spray gun, ensuring complete coverage. Allow the primer to dry according to the manufacturer's instructions, which may take several hours or even overnight.

After priming, it's time to paint. Select a marine-grade paint that is designed for fiberglass surfaces. You can use a spray gun or a brush, depending on your preference and the desired finish. Apply the paint in thin, even coats, allowing each layer to dry before adding the next. This process ensures a smooth and professional-looking finish. Make sure to follow the paint manufacturer's guidelines for drying times between coats.

Once the paint is fully cured, you can admire your handiwork. The repaired crack should now be virtually invisible, seamlessly blending with the rest of the boat's surface. This process not only fixes the structural issue but also restores the boat's appearance, ensuring it looks as good as new. Remember, proper preparation and attention to detail are key to a successful repair, so take your time and be meticulous in each step.

Exploring Iceland and Norway: A Boat Voyage

You may want to see also

Frequently asked questions

For minor cracks, a simple solution is to use a fiberglass repair kit. These kits typically include a filler compound and a hardening agent. Clean the area, apply the filler, and smooth it out with a putty knife. Allow it to cure according to the kit's instructions, and then sand it to match the surrounding surface.

Boat fiberglass can crack due to various factors. Age and sun exposure can lead to degradation, making the material more prone to cracking. Impact damage from waves, anchors, or collisions can also cause fractures. Additionally, improper maintenance, such as neglecting to clean and protect the surface, may contribute to the issue.

No, regular wood filler is not suitable for fiberglass repairs. Wood filler is not designed to bond with fiberglass and may not provide a strong, durable repair. It's important to use products specifically formulated for fiberglass to ensure a proper and long-lasting fix.

Regular maintenance is key to preventing cracks. Keep the boat's surface clean and free of contaminants. Apply a suitable fiberglass protective coating or gelcoat to enhance durability and UV resistance. Additionally, be cautious during usage, avoiding sharp impacts and proper storage to minimize the risk of damage.