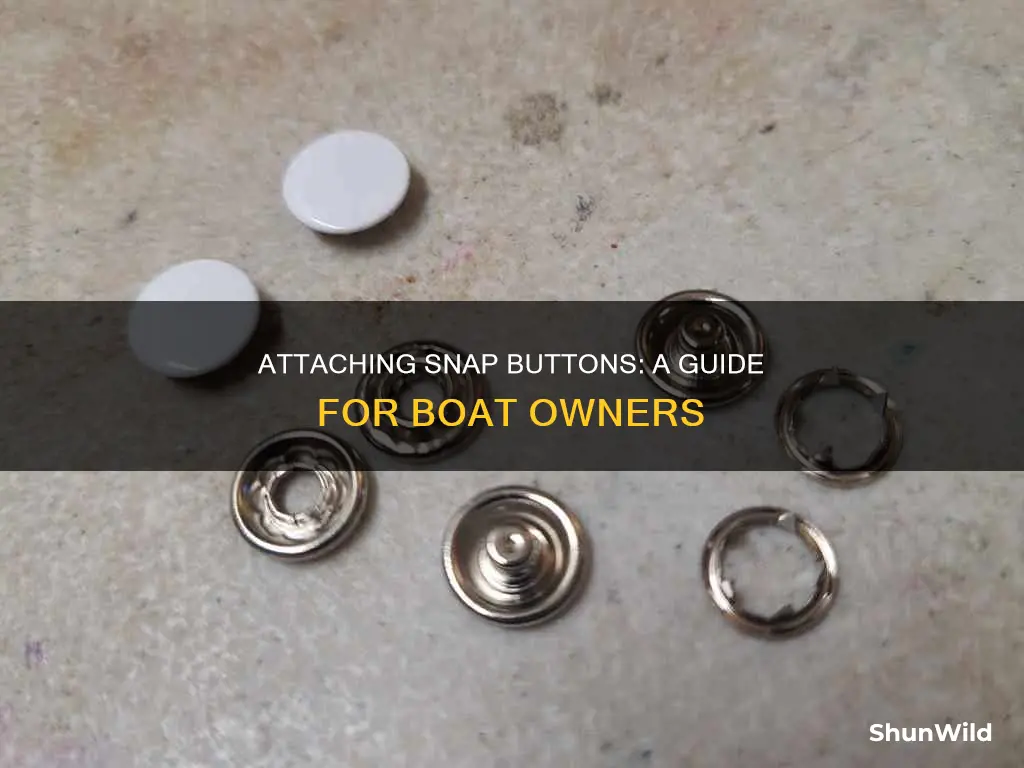

Putting snap buttons on a boat is a straightforward task that can be done at home with a few tools. The most common snaps used on boats are glove button fasteners or durable-type snaps, consisting of a button and socket that form the female snap, and an eyelet and stud that form the male snap. There are two types of snap buttons: spring snaps and ring snaps. Spring snaps are gentler on fabric and look great from all sides when installed, while ring snaps are good for heavy-duty applications but don't look as nice. Before installing snap buttons, it is important to determine the location of each snap and mark it with a pencil. The process of installing spring snaps involves using a snap setting tool to attach the cap and socket, and then the stud and post. For ring snaps, the process is similar, but a wider setting tool is not required as there is no post or stud to install.

| Characteristics | Values |

|---|---|

| Types of snap buttons | Spring snaps and ring snaps |

| Best type of snap button | Spring snaps |

| Where to buy snap buttons | Gold Star Tools |

| Snap button parts | Button cap with socket, stud with corresponding post |

| Snap setting tool for cap and socket | Narrower end |

| Snap setting tool for stud and post | Wider end with indent at the bottom |

| Installation order | Cap and socket first, then stud and post |

| Marking snap location | Pencil |

| Making holes in fabric | Awl or hole punch |

| Installation tool | Hammer |

| Preventing damage to fabric | Interfacing any area you will be applying snaps to |

| Snap replacement | Screw-in snap stud replacement kit |

| Snap installation system | SnapRite® System |

What You'll Learn

Choosing the right snap button type

- Application and Functionality: Snap buttons can be used for various applications, from clothing and bags to more heavy-duty uses like boat covers and upholstery. Consider the intended use and choose a snap button type that can withstand the expected stress and environmental conditions.

- Material and Durability: Snap buttons come in different materials, including metal and plastic. Metal snap buttons, such as those made from stainless steel or nickel-plated brass, are typically more durable and suitable for harsh environments. Plastic snap buttons are often used for home sewing and craft projects.

- Appearance and Aesthetics: Snap buttons can also be selected based on their visual appeal. Spring snaps, for example, are known for their gentler effect on fabric and their professional, ready-to-wear appearance. Ring snaps, on the other hand, are good for heavy-duty applications but may not look as neat, especially when the buttons are undone.

- Installation Process: The installation process for snap buttons can vary. Some types, like press studs, have two parts and can be sewn on like buttons. Others, like rivet studs, come with three or four parts and require special riveting tools for installation. Consider your tools and level of expertise when making a selection.

- Size and Compatibility: Snap buttons come in various sizes, and it's important to choose the right size for your project. For boat covers, standard sizes such as 3/8" or 15mm are commonly used. Ensure that the snap buttons you choose are compatible with the fabric or material you're working with.

- Directional Fasteners: If you're working with boat covers, consider using directional fasteners, which are designed to stay snapped even at sharp angles. Examples include pull-the-dot snaps, curtain fasteners (or twist fasteners), and lift-the-dot snaps. These fasteners can be tricky to use but provide added security in challenging conditions.

Boat Paint and Lacquer: What's the Difference?

You may want to see also

Buying snap buttons

When buying snap buttons, it's important to consider the type of snap button, the material, the quantity, and the required tools for installation. Here are some detailed guidelines for purchasing snap buttons:

Types of Snap Buttons:

There are two common types of snap buttons: spring snaps and ring snaps. Spring snaps are generally preferred as they are gentler on fabric and have a more professional, ready-to-wear appearance. Ring snaps are suitable for heavy-duty applications but may not look as aesthetically pleasing.

Material:

The material of the snap buttons is crucial for durability and corrosion resistance. Look for snap buttons made from stainless steel or nickel-plated brass. Stainless steel is known for its strength and ability to hold its finish, while nickel-plated brass provides added durability in harsh environments. Avoid plain brass snap buttons as they are more susceptible to corrosion.

Quantity:

Determine the number of snap buttons needed for your project. Snap buttons are typically sold in kits or sets, ranging from a few pieces to over a hundred. Consider the scope of your project and purchase accordingly. It's always a good idea to have a few extra snap buttons on hand in case of future repairs or replacements.

Installation Tools:

When purchasing snap buttons, ensure that the kit includes the necessary installation tools. Most kits come with a snap setting tool, but it's important to verify. Additionally, you may need other tools such as a hammer, an anvil, an awl, or a hole punch to create holes in the fabric. Some kits may also include a button installation tool, which can be handy for repairs.

Where to Buy:

Snap buttons can be purchased online or at local fabric stores. Online retailers like Amazon offer a wide variety of snap button kits, including those specifically designed for boat covers. Specialty stores like Gold Star Tools are also a great source for high-quality snap buttons and installation tools.

When buying snap buttons, consider the type, material, quantity, and necessary installation tools. By following these guidelines, you'll be able to make an informed purchase decision and ensure a successful snap button installation project.

Mastering the Tahoe Boat: A Beginner's Guide to Smooth Sailing

You may want to see also

Installing spring snap buttons

Tools and Materials

- Spring snap buttons (including button caps, sockets, studs, and posts)

- Snap setting tools (a small circular anvil and two different snap setting tools, one narrower and one wider with an indent at the bottom)

- Hammer

- Awl (optional, but useful for making holes)

- Metal hole punch

- Pencil

Step-by-Step Guide

- Determine where you will locate the snap and mark the location with a pencil.

- Make a hole in the fabric with the hole punch or awl.

- Insert the button cap post into the hole, ensuring the cap is located on the outside of the garment.

- Place the spring socket on the cap post, then place the base of the cap inside the indent of the anvil so the socket is facing up.

- Place the end of the narrower tool through the socket and align it with the post, ensuring everything is lined up straight.

- Hammer the setting tool a few times to flatten out and lock the cap post against the inside of the socket.

- Install all your caps and sockets before moving on to the next step.

- Close the fly placket and use a pencil to mark the location for the corresponding stud and post on the other side of the fabric.

- Use an awl or the hole punch to make room for the stud post, which is wider than the cap post.

- Place the stud on top of the post, ensuring the part with the longer post is against the wrong side of the fabric and the part that looks like a little bowler hat is on the right side.

- Place the base of the post on top of the anvil.

- Use the wider setting tool with the indent at the bottom, and align the indent with the stud.

- Hammer the setting tool a few times to lock it on the post.

- Test each button to make sure they are correctly installed.

And that's it! You now know how to install spring snap buttons.

Clamping Boat Seats: The Easiest and Most Secure Way

You may want to see also

Installing ring snap buttons

Step 1: Gather the Required Tools and Materials

You will need ring snap buttons, a snap setting tool, an awl or a small circular anvil, and a hammer. The snap setting tool is crucial for installing the snap buttons, so ensure that it is the correct size and suitable for ring snaps.

Step 2: Prepare the Fabric

Determine the location of the snap button on the fabric and mark it with a pencil. Use the awl or hole punch to create a hole in the fabric at the marked location. Ensure the hole is big enough for the snap button post to fit through.

Step 3: Install the Cap and Socket

The cap is the plain outer part of the snap button, while the socket is the donut-shaped inner part that receives the stud. Insert the button cap post into the hole, with the cap on the outside of the fabric. Place the spring socket onto the cap post, ensuring it faces upwards.

Step 4: Use the Setting Tool and Hammer

Place the base of the cap inside the indent of the anvil, aligning the socket with the post. Place the end of the snap setting tool through the socket and hit it with the hammer to flatten the cap post, locking it against the inside of the socket. Repeat this process for all the caps and sockets.

Step 5: Install the Stud and Post

Close the fabric, such as a fly placket, to determine the location of the corresponding stud and post. Mark this location with a pencil. Use the awl or hole punch to create a hole for the stud post, ensuring it is placed on the correct side so that the buttons snap together correctly.

Step 6: Secure the Stud

Place the stud on top of the post, positioning it on the anvil. Use the wider setting tool with an indent at the bottom, aligning the indent with the stud. Hammer the setting tool to lock the stud onto the post.

Step 7: Test the Snap Buttons

Once all the snap buttons are installed, test each one to ensure they are correctly fastened and can snap together securely.

The River Styx: A Boat Tour Through Hell

You may want to see also

Removing old snap buttons

- Gather the necessary tools: You will need diagonal pliers and replacement snap buttons. Ensure that your pliers are clean to avoid soiling the fabric. It is also recommended to have a die to punch holes in the fabric, as well as fusible interfacing to reinforce the holes.

- Prepare the fabric: Before removing the old snap buttons, determine the exact placement of the new snap buttons. Mark the locations with a pencil. Having a clear plan will help ensure a neat removal process.

- Remove the snap button cap: Open the diagonal pliers as wide as possible and slide them under the snap button. Use your free hand to gently pull the fabric away from the snap as you do this. Start squeezing the pliers gently and gradually increase the pressure. The snap button will begin to curl up. Rotate the pliers to get them underneath all angles. Continue squeezing tighter until you hear a pop, and the top component comes off. Be careful as the component may fly off.

- Remove the snap button socket: After removing the cap, carefully wiggle out the bottom piece, taking care not to rip or distort the fabric. Discard these components as they cannot be reused.

- Prepare the fabric for new snap buttons: Use a die to punch holes in the fabric, especially if you are working with thick or heavy-duty fabric. Reinforce the holes by using fusible interfacing. This will help extend the life of the holes and provide a stronger base for the new snap buttons.

- Install the new snap buttons: Follow the instructions provided with your chosen snap button kit. Typically, you will need a snap setting tool and a hammer. Place the new snap button components in the correct positions, ensuring that the cap is on the outside of the garment. Use the snap setting tool and hammer to secure the components in place, following the specific instructions for your chosen snap button type (spring snaps or ring snaps).

Remember to take your time and work carefully to avoid damaging the fabric or misplacing the new snap buttons.

Exploring Iceland and Greenland: A Boat Voyage

You may want to see also

Frequently asked questions

There are two types of snap buttons: spring snaps and ring snaps. Spring snaps are gentler on fabric and look great from all sides when installed. Ring snaps are good for heavy-duty applications but don't look as nice.

You will need a snap setting tool, a small circular anvil, a hammer, and an awl or metal hole punch. You can buy snap button kits that include these tools, or you can buy the tools separately.

First, determine where you will locate the snap and mark the location. Make a hole in the fabric, insert the button cap post into the hole, and place the spring socket on the cap post. Place the base of the cap inside the indent of the anvil so the socket is facing up. Place the end of the narrower tool through the socket, ensuring everything is lined up straight, and hammer the setting tool a few times to lock it in place.