Owning a boat is a dream for many, but it can also be a lot of work. One common issue that boat owners may encounter is holes in the aluminum hull. While this may seem like a daunting problem, there are several ways to fix these holes and get your boat back in the water. In this article, we will explore different methods for repairing aluminum boat holes, from welding to epoxy putty, and provide step-by-step guidance on how to tackle this repair project with confidence.

What You'll Learn

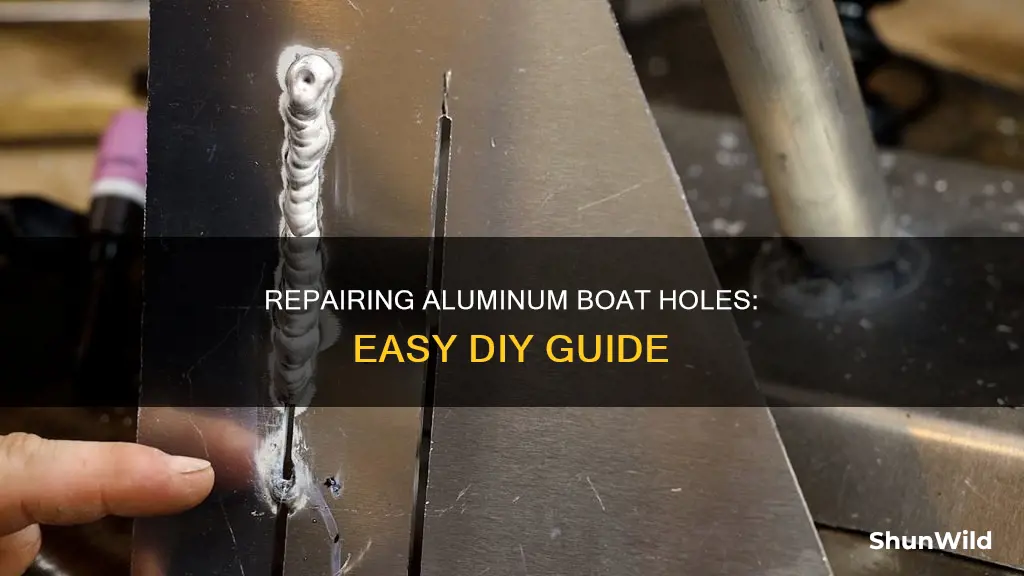

Welding holes

Welding is the best way to fix a hole in an aluminium boat, but it can be expensive and inaccessible for some. If you can weld, or know someone who can, this is the best way to fix a hole. If you don't want to weld, or can't access the service, there are other ways to fix a hole, but they are only temporary solutions.

Aluminium boats are popular because they are durable, sturdy, affordable and lightweight. However, they do require specific maintenance and repairs. Aluminium is a tricky metal to weld because it dissipates heat quickly, so it's important to use the right tools and techniques.

Choosing the Right Welding Equipment

To weld aluminium, you will need a MIG or TIG welder to ensure a stable wire feed and reduce the risk of contamination. Always use a welder designed specifically for aluminium to achieve solid, clean welds.

Preparing the Aluminium Surface

Before welding, the aluminium surface must be thoroughly cleaned to remove any dirt, grease or oxide layers. Use a stainless steel brush designed for aluminium, and clean the surface immediately before welding to ensure a clean weld pool and to prevent contamination.

Controlling Heat Input

Aluminium heats up and cools down quickly, so it's important to control the heat input with short welds and allow the metal to cool between passes. Preheating the aluminium slightly can also help manage the heat flow and create more consistent welds.

Choosing the Right Filler Material

The filler rod or wire should match the base material of the boat to ensure compatibility and strength. For most marine-grade aluminium, 5356 and 4043 filler materials are commonly used. Check the specifications of your boat and choose a matching filler.

Welding in the Right Environment

Environmental factors can affect the quality of the weld, so it is best to weld in a clean, controlled environment. If welding outdoors, use a portable welding shelter to protect the work area from wind, dust and moisture.

Practicing Proper Technique

Mastering the technique of aluminium welding is key to achieving strong and durable welds. Maintain a consistent travel speed to ensure even heat distribution and practice steady hand movements, keeping a close watch on the weld pool. Use a push technique when welding, as this helps keep the shielding gas in the weld pool and reduces the risk of contamination.

Boat Rental Business: Getting Started and Growing Fast

You may want to see also

Epoxy putty

- Prepare the area: If the hole is in an accessible location, you can hammer the area flat to close the hole as much as possible. If the hole is a crack, drill a small hole at each end to prevent the crack from spreading. Then, sand or grind the area to smooth it out and clean it with an acetone solvent.

- Mix the epoxy putty: Epoxy putty usually comes in two parts, a resin, and a hardener. Roll equal parts of each together until you get a uniform colour.

- Apply the putty: Press and smooth the mixed epoxy putty into the hole and the surrounding area. If possible, apply the putty from both sides of the hole.

- Let it cure: Epoxy putty usually takes several hours to cure. Follow the instructions on the packaging for the specific cure time.

- Finish with paint (optional): Once the putty has cured, you can apply paint to match the colour of your boat and to provide additional protection.

Using epoxy putty to repair holes in an aluminium boat is a straightforward process. However, it is important to follow the instructions carefully and ensure the area is properly prepared for the best results.

Boat Battery Basics: What to Run on Your Starting Battery

You may want to see also

JB Weld

To repair a hole with JB Weld, start by cleaning the area with a wire wheel on a drill until you reach the bare aluminium. Next, slice off a pebble-sized piece of JB Weld and knead it until it becomes one colour. Stick the putty onto the hole and flatten it a bit, then repeat the process on the inside of the hole. After it starts to set, use a moistened finger to smooth it down and ensure the edges adhere well. This will harden enough in 5 minutes for the boat to be put in the water. You can then choose to either end the repair here or sand it down and paint over it.

Overall, JB Weld is a good option for repairing small holes in aluminium boats, especially for those who want a quick, budget-friendly solution.

Sailing Surf Boats: A Unique Water Adventure

You may want to see also

Marine sealants

Firstly, you will need to prepare the area to ensure a good seal. Clean the area with acetone and then roughen the surfaces with sandpaper. You can also use a coarse 3M Roloc Bristle Disc to remove paint and create a larger bonding surface area. It is important to clean the area again with acetone after sanding to ensure the area is ready for bonding.

There are several types of marine sealants that can be used to fix holes in an aluminium boat. Epoxy putty, such as JB Weld, is a popular choice and can be found at auto parts stores or home improvement stores. It is important to follow the instructions on the packaging and combine the two parts of the epoxy until they are a uniform colour. You can then press and smooth the putty into the hole, and if the hole is a crack, it is recommended to drill small holes at each end to prevent the crack from spreading.

Another option is to use a marine-grade epoxy resin, such as G/flex Epoxy, and a patch of fiberglass cloth to cover the hole. Cut a piece of fiberglass cloth that is slightly larger than the hole and wet it with the epoxy resin. Apply the epoxy to the area around the hole and then place the patch over the hole, smoothing it out to remove any air bubbles. Let the patch cure overnight and then sand the edges to remove any roughness. You can then apply a fairing compound to smooth out the repair.

Additionally, there are marine sealants available in a tube, such as marine silicone, which can be used to seal old screw holes. Simply apply the sealant to the screw threads and insert the screws into the holes. This will create a strong seal and prevent leaks.

It is important to note that while marine sealants can provide a strong and durable repair, they may not be a permanent solution for larger holes. In some cases, welding may be necessary to ensure a long-lasting repair.

Installing a Jack Plate: A Step-by-Step Guide for Boat Owners

You may want to see also

Marine-Tex putty

Marine-Tex is a heavy-duty structural epoxy putty that can be used to repair aluminium boats. It is a versatile compound that can be used to fill, bond and rebuild wood, fibreglass, ceramic, glass, metal, masonry and even many plastics. It is manufactured to meet the harsh demands of the marine environment.

To use Marine-Tex to repair a hole in an aluminium boat, first ensure the area is well-ventilated and you are wearing protective gloves and eyewear. Then, follow these steps:

- Clean the area around the hole with a rag and soapy water to remove any dirt or oil. Ensure the surface is completely dry.

- Sand the area around the hole and use acetone or lacquer thinner to remove any remaining grit and improve adhesion.

- Mix the Marine-Tex resin and hardener thoroughly on a flat surface, such as wood or cardboard, using a putty stick or hard plastic squeegee. The ratio should be 5 parts resin to 1 part hardener by volume (or 6.3 grams of resin to 1 gram of hardener by weight).

- Apply the mixed Marine-Tex to the hole, ensuring it is spread evenly and filling the hole completely.

- Allow the putty to cure for 24 hours at a constant temperature of 72°F (22°C). Do not apply in temperatures below 55°F (13°C).

- Once cured, sand the repaired area with fine-grit sandpaper until smooth.

- Apply a coat of primer followed by marine-grade paint to match the colour of your boat.

Marine-Tex is an effective way to repair small holes in aluminium boats, providing a strong and watertight seal.

A Boat, a Bird, and a Brush: Sailing into Art

You may want to see also

Frequently asked questions

The best way to fix a hole in an aluminium boat is to take it to a weld shop and have it welded. If you are unable to do this, small holes can be fixed with epoxy putty. Ensure the area is hammered flat, then sand or grind the area and clean with acetone solvent. Mix the two-part, marine-grade epoxy putty, by rolling equal parts of A and B together until it is a uniform colour. Press and smooth the putty into the hole and surrounding area, from both sides if possible. If the hole is a crack, you should drill a small hole at each end to prevent the crack from spreading.

You can use Marine JB weld, marine silicone, or radiator repair sticks. Clean the area with brakeclean and scotchbrite prior to filling the holes.

Keep an eye on the pinholes as you may have some corrosion problems starting.

If the holes are from screws or rivets, you can simply replace the screws or rivets. If the holes are in different places, the best solution is to have them filled by a welder.

Flex seal spray works best for this kind of repair. Spray it inside and out, and spray it really thick on the keel guard to seal unseen voids.