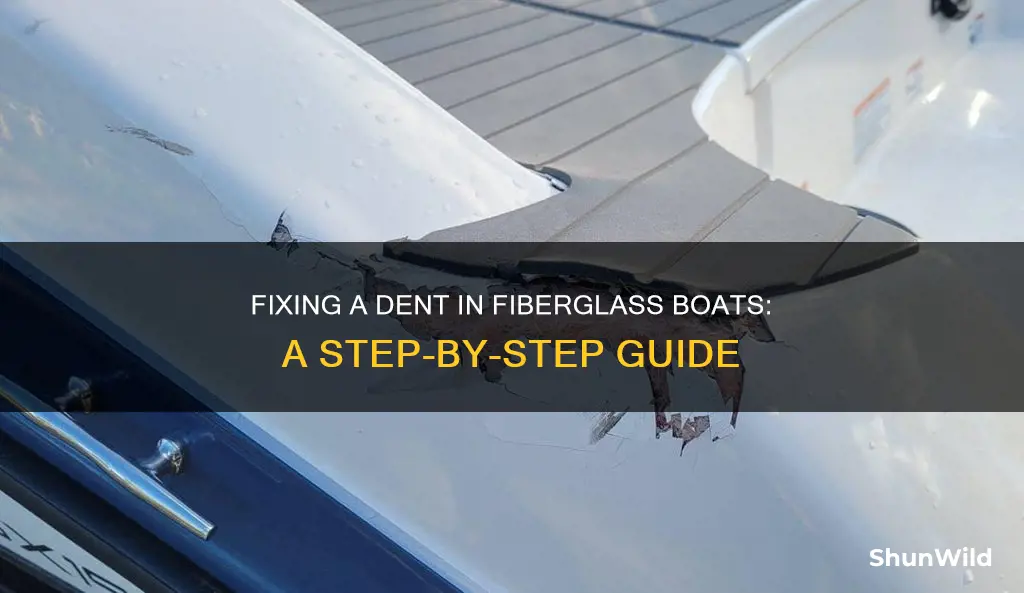

Fixing a dent in a fiberglass boat can seem daunting, but with the right approach, it's a manageable task. The key is to act quickly to prevent further damage. Start by assessing the extent of the dent and ensuring the boat is dry and stable. Gather the necessary tools, including a fiberglass repair kit, a putty knife, and a heat gun. Begin by cleaning the area around the dent to remove any dirt or debris. Then, carefully fill the dent with a fiberglass repair compound, following the manufacturer's instructions. Smooth the surface with a putty knife and allow it to cure. Finally, sand the repair area and apply a fiberglass cloth to reinforce the bond. With patience and attention to detail, you can restore your boat's smooth finish.

What You'll Learn

- Identify the Dent: Inspect the damage, noting its size, shape, and location

- Prepare the Surface: Clean the area, ensuring it's free of dirt and debris

- Choose a Filling Material: Select a suitable filler for fiberglass, matching the color

- Apply Filler: Fill the dent, following the manufacturer's instructions for drying time

- Sand and Smooth: Gently sand the filled area, then smooth it with fine-grit sandpaper

Identify the Dent: Inspect the damage, noting its size, shape, and location

When dealing with a dent in a fiberglass boat, the first step is to thoroughly inspect the damage to understand the extent of the issue. This initial assessment is crucial as it guides your repair strategy. Start by carefully examining the affected area with the naked eye. Look for any visible signs of damage, such as a visible indentation or a change in the surface texture. Note the size, shape, and depth of the dent. Measure the width and length of the dent to get an idea of its dimensions. A smaller dent might be easier to repair, while a larger one could require more extensive work.

Pay close attention to the location of the dent as well. Is it on the hull, deck, or any other component of the boat? The accessibility and visibility of the repair area will vary depending on its location. For instance, a dent on the bottom of the hull might require more intricate work due to limited access. Understanding the shape of the dent is also essential. Is it a simple indentation or a more complex, irregular shape? This information will help you decide on the appropriate repair method.

Use a flashlight or a mirror to get a better view of the damage, especially if the dent is not immediately visible. Shine the light at different angles to identify any hidden scratches or imperfections. This step ensures that you have a comprehensive understanding of the damage before proceeding with the repair. Remember, a thorough inspection at this stage will make the repair process more efficient and effective.

Ventless Washer-Dryers: Efficient On-Boat Laundry Solution?

You may want to see also

Prepare the Surface: Clean the area, ensuring it's free of dirt and debris

Before you begin the process of repairing a dent in your fiberglass boat, it's crucial to ensure that the surface is clean and free of any contaminants. This initial step is often overlooked but is essential for a successful repair. Start by thoroughly cleaning the dented area using a mild detergent and warm water. You can use a soft-bristled brush or a sponge to gently scrub the surface, removing any dirt, grime, or old paint that might be present. Pay close attention to the edges of the dent, as these areas may have accumulated more debris over time. Rinse the cleaned area thoroughly with clean water to ensure no soap residue remains.

Once the area is dry, use a fine-grit sandpaper (600-grit or higher) to gently smooth the surface. This step helps to create a uniform texture and ensures that the filler material will adhere properly. Be careful not to apply too much pressure, as you don't want to further damage the fiberglass. After sanding, wipe the area with a clean cloth to remove any dust and prepare the surface for the next step.

If the dent is particularly deep or the fiberglass has been compromised, you might need to use a specialized fiberglass repair kit. These kits often include a primer and a filler compound designed to bond with fiberglass. Follow the manufacturer's instructions for application, ensuring that the surface is clean and dry before applying the primer. Allow the primer to dry completely, then apply the filler compound, being mindful of the specific techniques recommended for your boat's material.

In summary, preparing the surface of your fiberglass boat for a dent repair is a critical process. It involves a thorough cleaning to remove dirt and debris, followed by sanding to create a smooth, uniform surface. For more severe damage, consider using a specialized repair kit to ensure a strong bond and a seamless finish. This meticulous preparation will set the foundation for a successful and long-lasting repair.

Boat Dock Railings: How High Should They Be?

You may want to see also

Choose a Filling Material: Select a suitable filler for fiberglass, matching the color

When it comes to repairing a dent in a fiberglass boat, selecting the right filling material is crucial for a successful and discreet repair. Fiberglass is a composite material that requires a specific approach to filling and finishing to ensure the structural integrity and aesthetic appeal of the boat. Here's a guide on choosing the appropriate filler to match the color of your fiberglass:

Understanding Fiberglass Structure: Fiberglass is composed of a matrix of resin and fibers, often glass fibers. The surface of the fiberglass can vary, ranging from smooth and glossy to textured and grainy. This unique structure requires a filler that can adhere well to the material and blend seamlessly.

Color Matching: The key to a successful repair is matching the color of the filler to the surrounding fiberglass. Fiberglass can come in various colors, and the filler should complement the boat's finish. You can use color charts or samples provided by the manufacturer or a reputable marine supply store to find a matching color. If you don't have access to these resources, a professional marine painter can advise on the closest match.

Types of Fillers: There are several types of fillers available for fiberglass repairs:

- Epoxy Fillers: These are two-part epoxy systems that provide excellent adhesion and strength. They are available in various colors, allowing for precise color matching. Epoxy fillers are versatile and can be used for both small and large repairs.

- Polyester Fillers: Polyester resins are another popular choice, offering good adhesion and flexibility. They are typically less expensive than epoxy systems and come in a wide range of colors. Polyester fillers are easy to work with and can be sanded and blended to match the surrounding surface.

- Spray Fillers: For larger areas, spray fillers can be applied for a smooth finish. These fillers are available in various colors and can be sprayed onto the dent, creating a seamless repair.

Application and Mixing: Once you've chosen the appropriate filler, follow the manufacturer's instructions for mixing and application. Proper mixing ensures the filler's consistency and adhesion. Apply the filler to the dent, using a putty knife or a similar tool to create a smooth and even surface. Allow the filler to cure according to the manufacturer's guidelines, and then sand it to match the surrounding fiberglass.

Remember, the goal is to restore the boat's original appearance, so take the time to match the color accurately. With the right filler and careful application, you can effectively repair a dent in your fiberglass boat, ensuring its structural integrity and maintaining its beauty.

Moving Your Boat Battery: A Step-by-Step Guide

You may want to see also

Apply Filler: Fill the dent, following the manufacturer's instructions for drying time

When repairing a dent in a fiberglass boat, applying filler is a crucial step to restore the structure's integrity and appearance. Here's a detailed guide on how to effectively fill the dent:

Step 1: Prepare the Area

Before applying filler, ensure the dented area is clean and free from debris. Use a fine-grit sandpaper to gently sand the surface, removing any loose fibers or contaminants. This step ensures better adhesion of the filler material.

Step 2: Choose the Right Filler

Select a filler specifically designed for fiberglass repairs. There are various types available, such as epoxy-based or polyester-based fillers. Follow the manufacturer's recommendations to choose the appropriate product for your boat's material.

Step 3: Apply the Filler

Carefully follow the instructions provided by the filler manufacturer. Typically, you'll apply a thin layer of filler to the dented area, ensuring it is level with the surrounding surface. Use a putty knife or a similar tool to spread the filler evenly, creating a smooth and consistent finish.

Step 4: Allow for Drying

One of the most critical aspects of the process is patience. After applying the filler, allow it to dry completely according to the manufacturer's instructions. Drying times can vary depending on the product and environmental factors. Ensure the area is not disturbed or exposed to moisture during this period.

Step 5: Sand and Smoothen

Once the filler is fully dried, inspect the repaired area. If the surface is not smooth, gently sand it with a finer grit sandpaper until it matches the surrounding fiberglass. This step ensures a seamless blend between the repaired area and the rest of the boat's structure.

Remember, taking the time to follow the manufacturer's guidelines for drying times is essential for a successful repair. Rushing this process might lead to an uneven or weak repair. With proper application and patience, you can effectively fill and restore the dent in your fiberglass boat.

Painting Boat Seats: A Step-by-Step Guide

You may want to see also

Sand and Smooth: Gently sand the filled area, then smooth it with fine-grit sandpaper

When it comes to repairing a dent in a fiberglass boat, the process of sanding and smoothing is an essential step to ensure a seamless finish. Here's a detailed guide on how to achieve a smooth and professional-looking repair:

Start by ensuring the area around the dent is clean and free of any debris. Use a mild detergent and water solution to wash the surface, and then gently dry it with a soft cloth. This step is crucial to create a clean base for the repair process. Once the area is dry, carefully apply the filler material you've chosen (as per the initial research on fixing dents). Use a putty knife to spread the filler evenly, following the contour of the dent. Allow the filler to dry completely, which may take several hours depending on the product used.

After the filler has set, it's time to sand the filled area. Begin with a coarse-grit sandpaper (e.g., 120-grit) to remove any rough edges and blend the filler into the surrounding surface. Work in small sections, gently sanding the filler until it is flush with the boat's surface. Be patient and take your time during this process to avoid any uneven textures. Once the coarse sanding is complete, progress to a finer-grit sandpaper (e.g., 220-grit) to refine the surface further. This step will help create a smooth transition between the repaired area and the original fiberglass.

For the final sanding stage, use an even finer-grit sandpaper, such as 320-grit or higher. This will result in a very smooth and almost mirror-like surface. Continue sanding in the same gentle, circular motions, ensuring the filler is completely blended in. After this step, the repaired area should feel and look seamless.

Finally, to complete the process, use fine-grit sandpaper (e.g., 400-grit or higher) to achieve an incredibly smooth finish. This fine sanding will help prepare the surface for any further steps, such as painting or polishing. Always work with the sandpaper in a gentle, even manner to avoid any scratches or imperfections.

Exploring the Black Pearl: A Pirate Ship Legend

You may want to see also

Frequently asked questions

For minor dents, you can use a fiberglass repair kit. These kits typically include a filler compound and a hardening agent. Clean the dented area, apply the filler, and smooth it out with a putty knife. Once it's dry, sand it down and paint over it to match the surrounding surface.

For more significant damage, it's recommended to seek professional help. A marine repair specialist can use techniques like fiberglass repair, which involves cutting out the damaged area, laying up new fiberglass, and bonding it to the existing structure. This process requires skill and experience to ensure a strong and durable repair.

While it might seem like a quick fix, using a hammer to pop a dent can cause more harm than good. It can lead to further damage, cracking, or even structural issues. It's best to avoid this method and opt for a proper repair technique to ensure the integrity of the boat's structure.

Yes, you can use marine-grade putty or a temporary filler to camouflage the dent. These products can be rubbed and shaped to match the surrounding surface. However, this is a temporary measure and a proper repair should be done as soon as possible to prevent further deterioration.