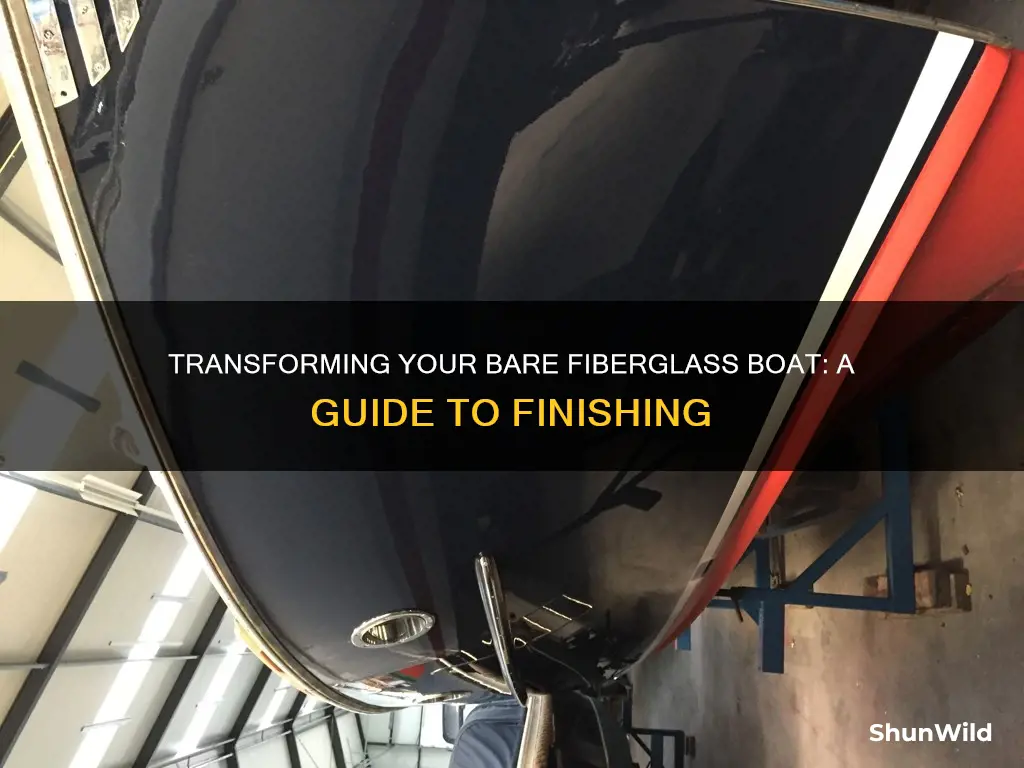

Finishing a bare fiberglass boat can be a rewarding project for any boat owner or DIY enthusiast. Whether you're restoring an old vessel or building a custom one, the process involves several key steps to ensure a durable and aesthetically pleasing result. From preparing the surface to choosing the right materials and techniques, each phase is crucial to achieving a professional finish. This guide will provide an overview of the essential steps, including surface preparation, choosing the right paint or gelcoat, and applying the finish to create a sleek and long-lasting boat.

What You'll Learn

- Prepare the Hull: Clean, sand, and etch the surface for optimal bonding

- Choose the Right Resin: Select a suitable epoxy or polyester resin for strength

- Apply Gelcoat: Use gelcoat to protect and enhance the boat's finish

- Sand and Smooth: Regularly sand and smooth the surface for a professional look

- Finish with Paint: Apply marine-grade paint for durability and aesthetics

Prepare the Hull: Clean, sand, and etch the surface for optimal bonding

Preparing the hull of a bare fiberglass boat is a crucial step in the finishing process, as it ensures optimal bonding and a smooth, durable finish. Here's a detailed guide on how to tackle this task:

Cleaning the Hull: Begin by thoroughly cleaning the entire surface of the boat. This initial step is essential to remove any dirt, grime, or old paint that might hinder the bonding process. Use a mild detergent or a specialized marine cleaner, ensuring you follow the manufacturer's instructions. Rinse the boat thoroughly with water to eliminate any residue. For hard-to-reach areas, consider using a pressure washer, but be cautious to avoid damaging the fiberglass.

Sandblasting (Optional): For a more aggressive preparation, consider sandblasting, especially if the boat's surface is heavily oxidized or has a thick layer of old paint. Sandblasting uses high-pressure air and abrasive material to create a smooth, uniform surface. This method can remove old finishes and prepare the hull for the new coating. Ensure you wear appropriate protective gear, including a respirator, when sandblasting.

Etching the Fiberglass: Etching is a chemical process that roughens the surface of the fiberglass, creating a microscopic texture that promotes better adhesion. This step is particularly important when applying a gelcoat or paint. You can use a specialized etching compound or a solution of water and a strong acid. Follow the product instructions carefully, as etching can be hazardous if not done correctly. After etching, rinse the boat thoroughly and allow it to dry completely.

Sanding: After cleaning and etching, it's time to sand the hull. Use fine-grit sandpaper (600-1200 grit) to create a smooth surface. Start with a larger area and gradually work your way to smaller, more intricate sections. Ensure you sand with the grain of the fiberglass to avoid scratching the surface. Remove any dust or debris with a damp cloth, and re-etch the hull if necessary, especially in areas where the sandpaper has removed the etching compound.

By following these steps, you'll create a clean, smooth, and etched surface, ready for the next phase of finishing your bare fiberglass boat. This preparation is key to ensuring a long-lasting and aesthetically pleasing result.

Crafting a Custom Dragon Boat Paddle Bag

You may want to see also

Choose the Right Resin: Select a suitable epoxy or polyester resin for strength

When it comes to finishing a bare fiberglass boat, choosing the right resin is a critical step to ensure the strength and durability of the repair or customization. Epoxy and polyester resins are the most commonly used resins for this purpose, each offering unique advantages.

Epoxy resins are renowned for their exceptional strength and hardness. They form a strong, durable bond when mixed with a hardener, creating a rigid and impact-resistant structure. This type of resin is ideal for structural repairs, as it can withstand the stresses and strains of the boat's environment. Epoxy resins are also known for their ability to fill and bridge gaps, making them perfect for repairing holes or cracks in the fiberglass. However, it's important to note that epoxy resins can be more challenging to work with due to their longer curing time and the need for precise mixing ratios.

On the other hand, polyester resins offer a more flexible approach. They are lighter and easier to apply, making them suitable for cosmetic repairs and fairing. Polyester resins provide a smooth finish and are often used for creating a seamless surface over the fiberglass. While they may not offer the same level of strength as epoxy, they are more forgiving during the application process and can be easily blended with fiberglass cloth for reinforcement. This resin is a popular choice for beginners due to its user-friendly nature.

The choice between epoxy and polyester resins depends on the specific requirements of your project. For structural repairs and maximum strength, epoxy resins are the preferred option. They provide excellent bonding and can handle the rigors of marine environments. However, for cosmetic enhancements or when working with larger areas, polyester resins can be a better choice due to their ease of use and flexibility.

It is essential to consider the environmental conditions your boat will be exposed to. If the boat will be used in harsh marine conditions, epoxy resins might be the safer choice due to their superior strength. Additionally, the availability and cost of the resins should also be taken into account, as some resins may require specialized equipment or additional materials for application. Always ensure that you follow the manufacturer's instructions for mixing and application to achieve the best results.

Boat Racing in Rhode Island: An Active Season?

You may want to see also

Apply Gelcoat: Use gelcoat to protect and enhance the boat's finish

Applying gelcoat is a crucial step in finishing a bare fiberglass boat, as it provides a protective layer and enhances the boat's overall appearance. Gelcoat is a resin-based material that is applied to the surface of the fiberglass, filling in any imperfections and creating a smooth, durable finish. Here's a step-by-step guide on how to apply gelcoat effectively:

Preparation: Before applying gelcoat, ensure that the fiberglass surface is clean, dry, and free from any contaminants. Remove any old gelcoat, paint, or debris using a sharp blade or a fiberglass scraper. It's essential to have a smooth and clean base for the gelcoat to adhere properly. Additionally, prepare the gelcoat by mixing it according to the manufacturer's instructions. Typically, gelcoat is mixed with a hardener, creating a thick, pourable consistency.

Application Technique: Start by applying a thin layer of gelcoat using a suitable tool, such as a roller or a brush. Work in small sections to avoid lap lines, which can be difficult to blend later. Apply the gelcoat evenly, ensuring complete coverage of the fiberglass surface. Pay attention to any areas that may have been damaged or require extra protection, such as gelcoat lines or areas with visible imperfections. Use a putty knife or a similar tool to smooth out any ripples or uneven surfaces. Allow the initial coat to flash off (harden slightly) before adding additional layers.

Building Up the Finish: Gelcoat is typically applied in multiple thin layers to achieve a high-quality finish. After the first coat, wait for the recommended time before applying the next layer. This process is called "building up" the gelcoat and helps to create a smooth, glossy surface. Each subsequent layer should be applied in the same manner, ensuring that the previous layer is fully cured before adding more. Take your time and be patient, as rushing the process may result in an uneven or flawed finish.

Sanding and Buffing: Once you've applied the desired number of gelcoat layers, allow sufficient curing time. After curing, inspect the surface and sand it gently with fine-grit sandpaper to remove any imperfections. This step helps to create a smooth base for the final finish. Buff the surface with a high-quality buffer and a polishing compound to achieve a glossy and durable finish. This process will enhance the boat's appearance and provide an additional layer of protection.

Curing and Maintenance: Proper curing is essential for the gelcoat to set and harden effectively. Follow the manufacturer's guidelines for curing times, which may vary depending on the gelcoat type and environmental conditions. Regularly clean and maintain the gelcoat surface to ensure its longevity. Use marine-grade cleaners and avoid harsh chemicals that could damage the gelcoat.

By following these steps and taking the time to apply gelcoat correctly, you can transform a bare fiberglass boat into a stunning and protected vessel. Gelcoat not only adds a professional finish but also provides essential protection against UV rays, chemicals, and general wear and tear.

The Skull Boat: A Unique Watercraft Experience

You may want to see also

Sand and Smooth: Regularly sand and smooth the surface for a professional look

When it comes to finishing a bare fiberglass boat, one of the most crucial steps is sanding and smoothing the surface to achieve a professional and polished look. This process involves removing any imperfections, such as scratches, bumps, or manufacturing defects, and creating a smooth and even finish. Here's a detailed guide on how to master this technique:

Start by selecting the appropriate sandpaper. For fiberglass, it's recommended to use a fine-grit sandpaper, typically ranging from 400 to 600 grit. This grit range provides a balanced combination of aggressiveness and finesse, allowing you to remove surface imperfections without causing excessive damage to the fiberglass. Coarse grits (e.g., 120-180 grit) are ideal for initial preparation, while finer grits (400-600) are used for refining and achieving a smooth surface.

Before beginning the sanding process, ensure that the boat's surface is clean and free of any debris. Use a mild detergent or a specialized fiberglass cleaner to wash the surface, ensuring no residue remains. Rinse thoroughly and allow the surface to dry completely. This step is essential as any dirt or residue can affect the sanding outcome and may lead to uneven results.

Begin sanding with light pressure, using circular motions and overlapping strokes. Start with the coarser grit sandpaper to remove any visible imperfections and create a rough surface. Work in small sections, gradually moving across the boat's surface. As you progress, switch to finer grit sandpaper to refine the surface and achieve a smoother finish. Take your time and be patient, as thorough sanding is key to a professional-looking result.

After completing the sanding process, it's time to smooth the surface. This step involves removing any remaining sand marks and creating a seamless finish. Use a high-quality compound or a specialized fiberglass filler to fill in any minor imperfections and create a smooth base. Apply the compound carefully, following the manufacturer's instructions, and allow it to cure according to the product's guidelines. Once cured, gently sand the filled areas with a fine-grit paper to ensure a seamless transition.

Regularly inspecting and maintaining the sanding process is essential. Periodically check the surface for any high spots or uneven areas and re-sand as needed. This ensures a consistent and professional finish. Additionally, consider using a polishing compound to enhance the surface's shine and protect the fiberglass. With practice and attention to detail, you'll master the art of sanding and smoothing, transforming your bare fiberglass boat into a stunning masterpiece.

Exploring Painted Rocks: Boat Ride Necessary?

You may want to see also

Finish with Paint: Apply marine-grade paint for durability and aesthetics

Finishing a bare fiberglass boat with paint is a crucial step to enhance its appearance and protect the underlying material. Marine-grade paint is specifically formulated to withstand the harsh conditions of the marine environment, making it an ideal choice for this project. Here's a step-by-step guide on how to achieve a professional-looking finish:

Surface Preparation: Before applying any paint, ensure the fiberglass surface is clean, smooth, and free from contaminants. Start by thoroughly cleaning the boat with a mild detergent and water solution to remove any dirt or grime. Rinse the surface and allow it to dry completely. Inspect the fiberglass for any imperfections, such as small holes or scratches, and fill them with a suitable fiberglass filler or putty. Smooth out the surface with a fine-grit sandpaper, ensuring a uniform texture. This preparation step is vital to guarantee proper paint adhesion.

Priming the Surface: Priming is an essential step to create a bond between the fiberglass and the paint. Use a marine-grade primer specifically designed for fiberglass. Apply the primer evenly across the entire surface, following the manufacturer's instructions for drying time between coats. Priming helps to ensure a smooth finish and improves the overall durability of the paint job.

Choosing the Right Marine Paint: Select a marine-grade paint that is compatible with fiberglass. Acrylic or epoxy-based paints are excellent choices for their durability and resistance to UV rays. Consider the color and finish you desire; marine paints come in various colors and sheens, allowing you to customize the look of your boat. Ensure you have the necessary painting equipment, including brushes, rollers, and spray guns, to apply the paint efficiently.

Application Technique: Start painting in a well-ventilated area or outdoors on a day with minimal wind. Begin with a thin coat, following the recommended thickness specified by the paint manufacturer. Allow the first coat to dry, then sand it lightly with a damp cloth to remove any brush marks. Apply subsequent coats, ensuring complete coverage and a smooth finish. Take your time and be meticulous with each layer to achieve a professional result.

Drying and Curing: Allow ample time for the paint to dry and cure between coats. Follow the paint manufacturer's guidelines for drying times. Avoid exposing the painted boat to harsh weather conditions or direct sunlight during this period. Once the final coat is applied and fully cured, your fiberglass boat will have a stunning finish that not only looks great but also provides long-lasting protection against the elements.

Painting Aluminum Boat Railing: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Before applying any paint or coatings, it's crucial to properly prepare the fiberglass surface. Start by thoroughly cleaning the boat with a mild detergent and water solution to remove any dirt, grime, or old paint residues. Use a non-abrasive cleaner to avoid scratching the surface. After cleaning, inspect the boat for any damage, such as cracks or holes, and repair them accordingly. You can use a fiberglass repair kit to fill in any imperfections and ensure a smooth surface.

For fiberglass boats, it's recommended to use marine-grade paint specifically designed for this material. Epoxy-based paints are a popular choice as they provide excellent adhesion and durability. Look for paints that are UV-resistant and offer protection against the harsh marine environment. Two-part epoxy systems are often preferred as they provide a strong bond and a smooth finish.

Cracking can be a concern when finishing fiberglass, especially during the application of paint or gelcoat. To minimize this risk, ensure that the surface is properly prepared and any existing damage is repaired. Apply a fiberglass primer to create a smooth base and improve adhesion. Use a flexible paint or gelcoat that can accommodate minor surface movements without cracking. Additionally, avoid rapid temperature changes during the finishing process, as this can stress the material.

Gelcoat is a crucial component in the finishing process of a fiberglass boat, providing a protective layer and enhancing the appearance. Start by ensuring the fiberglass surface is clean, dry, and free of any contaminants. Apply a thin layer of gelcoat using a spreader or brush, following the manufacturer's instructions for proper technique. Allow the gelcoat to flash off slightly before applying subsequent layers to avoid trapping air bubbles. Multiple thin coats are better than a single thick layer to achieve a smooth finish.

Proper maintenance is essential to preserve the finish and protect the investment. Regularly clean the boat with a mild soap and water solution to remove dirt and salt buildup. Avoid using abrasive cleaners or scrub brushes that can damage the surface. Inspect the boat periodically for any signs of damage, such as small scratches or minor imperfections, and address them promptly. Keep the boat covered when not in use to shield it from UV rays and harsh weather conditions.