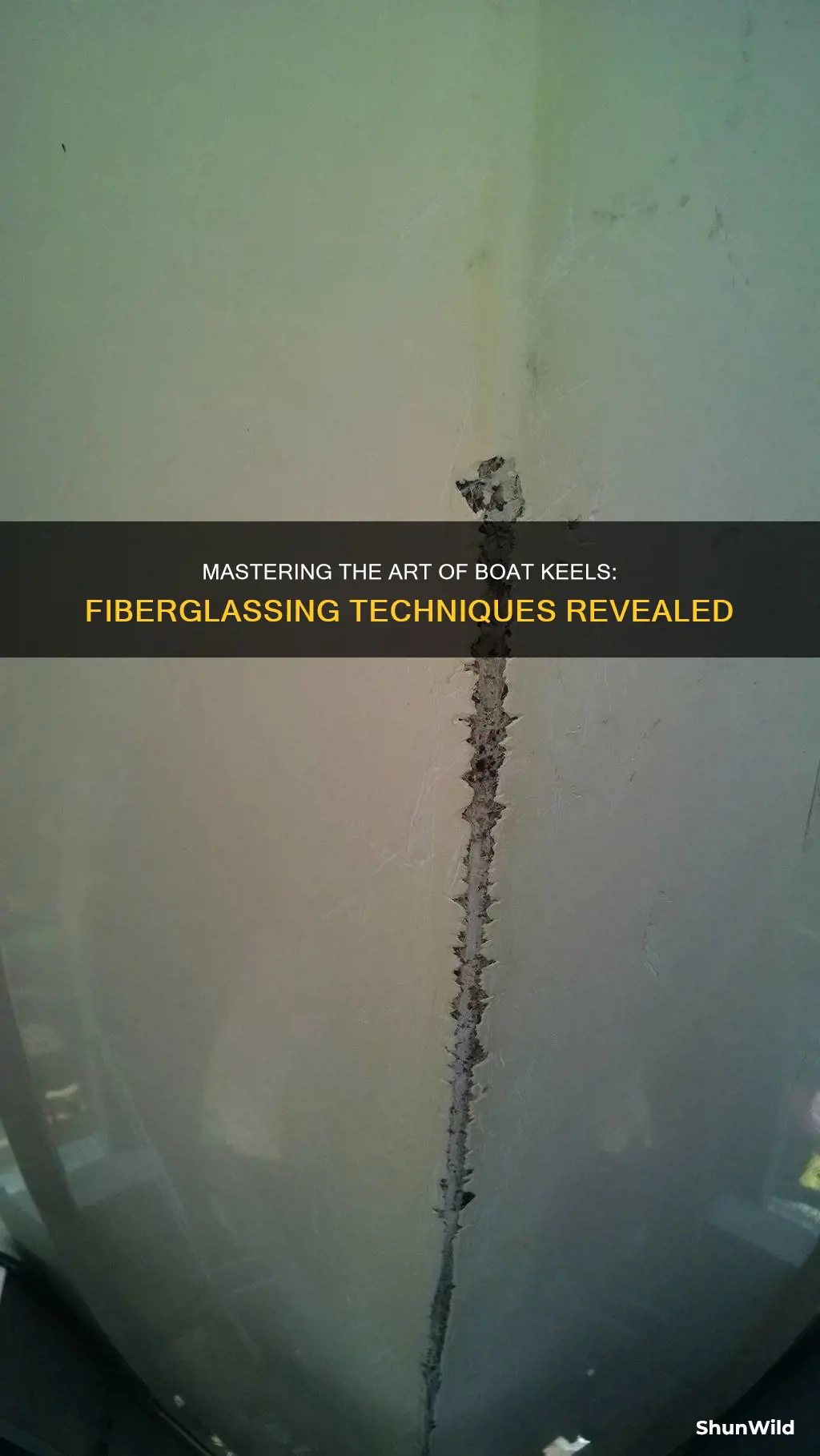

Fiberglassing a boat keel is a crucial process for enhancing the boat's performance and durability. It involves applying a layer of fiberglass to the keel, which is the underwater part of the boat that provides stability and support. This process requires careful preparation, including cleaning the keel surface, ensuring it is free of contaminants, and using the right materials and techniques to create a strong, seamless bond. The goal is to create a smooth, durable surface that not only protects the boat's structure but also improves its handling and overall performance on the water. This guide will provide a step-by-step approach to achieving a professional-quality fiberglass keel.

What You'll Learn

- Prepare the Keel: Clean, sand, and etch the keel surface for optimal bonding

- Choose the Right Fiberglass: Select a suitable resin and cloth for the job

- Lay Up Technique: Apply layers of cloth and resin, ensuring proper overlap and wetting

- Reinforcement Methods: Use glass tape or mats for added strength and durability

- Cure and Finish: Allow adequate curing time and sand for a smooth, professional finish

Prepare the Keel: Clean, sand, and etch the keel surface for optimal bonding

Preparing the keel for fiberglassing is a crucial step to ensure a strong and durable bond between the material and the boat's structure. Here's a detailed guide on how to get this right:

Cleaning the Keel: Begin by thoroughly cleaning the keel surface. This step is essential to remove any dirt, grease, or old paint that could interfere with the bonding process. Use a mild detergent and a soft brush to scrub the entire area, ensuring you reach all the nooks and crannies. Rinse the keel with water to remove any residue and allow it to dry completely in a well-ventilated area.

Sandblasting or Sanding: Depending on the condition of the keel, you might need to employ a more aggressive technique like sandblasting or heavy-duty sanding. This process helps create a rough surface, providing an ideal texture for the fiberglass to adhere to. If sandblasting is not an option, use a power sander with a fine-grit sandpaper (around 120-180 grit) to carefully sand the entire keel surface. Be cautious not to damage the underlying structure during this process.

Etching the Surface: Etching is a chemical process that further prepares the keel for bonding. It involves applying a mild acid solution to the sanded surface, which reacts with the metal or existing paint, creating a microscopic roughness. This step ensures that the fiberglass will have a better grip and will not slip off over time. You can use a commercial etching solution or create a DIY mixture with hydrochloric acid and water. Follow the instructions on the etching product carefully, as improper use can damage the boat's structure.

After cleaning, sanding, and etching, the keel should be ready for the fiberglass application. This preparation process is vital to guarantee a long-lasting and secure bond, ensuring the boat's structural integrity and performance. Remember, taking the time to properly prepare the keel will pay off in the long run, as it will prevent potential issues and provide a solid foundation for your fiberglass work.

Mastering Speaker Installation: Tips for Cutting Fiberglass for Boat Speakers

You may want to see also

Choose the Right Fiberglass: Select a suitable resin and cloth for the job

When it comes to fiberglassing a boat keel, selecting the right materials is crucial for a successful and durable repair. The choice of resin and cloth will significantly impact the strength, flexibility, and overall performance of the composite. Here's a guide to help you make the right selection:

Resin Selection:

- Choose a resin system that is specifically designed for marine applications. Epoxy resins are commonly used due to their excellent bonding properties and resistance to water absorption. Look for resins that offer good adhesion to the substrate (in this case, the boat's existing structure) and have a suitable working time for your project.

- Consider the type of reinforcement you plan to use. If you're working with a smooth surface, a low-viscosity resin might be ideal for easy application. For more complex shapes or thick layers, a higher-viscosity resin will provide better control and prevent sagging.

- Check the resin's cure time and temperature requirements. Some resins cure faster at higher temperatures, while others may require specific curing agents for optimal performance. Ensure you follow the manufacturer's instructions for mixing and application.

Fiberglass Cloth:

- Select a cloth that complements the chosen resin. Glass fiber cloth, typically available in various weights (ounces), is a popular choice for boat repairs. The weight determines the cloth's strength and flexibility. Heavier cloth (e.g., 6 or 8 oz) provides more structural support, while lighter cloth (4 oz or less) offers flexibility and is suitable for contouring around curves.

- Consider the weave pattern of the cloth. A random weave is common for boat repairs as it provides good coverage and strength in multiple directions. For areas requiring extra reinforcement, consider using a unidirectional cloth (e.g., 0° or 90° weave) to create a stiffer composite.

- Ensure the cloth is compatible with the resin. Some resins may require specific cloth types or treatments to ensure proper bonding. Always refer to the resin manufacturer's guidelines for compatible materials.

When sourcing your materials, it's essential to obtain high-quality products from reputable suppliers. This ensures you have the right tools and substances to create a strong and long-lasting bond between the resin and the boat's structure. Remember, proper preparation and attention to detail will contribute to a successful fiberglass repair.

Best Boat Wax: Shine and Protection

You may want to see also

Lay Up Technique: Apply layers of cloth and resin, ensuring proper overlap and wetting

The lay-up technique is a fundamental process in fiberglass boat construction, especially when it comes to reinforcing the keel. This method involves carefully applying layers of cloth (fibreglass) and resin to create a strong, lightweight structure. Here's a step-by-step guide to mastering this technique:

Preparation: Before you begin, ensure you have all the necessary materials, including the appropriate type of fibreglass cloth (usually a woven glass cloth), the chosen resin system, and a catalyst to initiate the curing process. Prepare your workspace by laying down a flat surface, preferably a dedicated work area or a tarp, to protect your surroundings. Gather all the tools you'll need, such as a brush, roller, gloves, and safety gear.

Applying the First Layer: Start by cutting the fibreglass cloth into manageable pieces slightly larger than the area you intend to cover. This allows for better coverage and overlap. Begin with a base layer, applying the resin to the cloth and then carefully laying it over the keel area. Ensure the cloth is smooth and taut, with no wrinkles or bubbles. Use a brush or roller to wet the cloth evenly, making sure the resin penetrates the fabric. Allow the first layer to set slightly, following the resin manufacturer's instructions for curing time.

Layering and Overlap: The key to a strong layup is in the layering and overlapping process. Cut additional pieces of fibreglass cloth, slightly overlapping the previous layer. Apply resin to each new piece, ensuring it's well-saturated. Carefully lay the new cloth over the previous layer, maintaining the overlap. Continue this process, adding more layers, until you've covered the desired area. Each layer should be slightly wetter than the previous one to ensure proper bonding. Take care to avoid air bubbles by gently smoothing the cloth with a wet blade or a damp cloth.

Ensuring Proper Wetting: Proper wetting is critical to a successful layup. Use a brush or roller to apply the resin, ensuring it's evenly distributed and fully penetrates the fibreglass cloth. Overlap the layers, but be mindful not to overload the resin, as this can lead to bleeding and affect the finish. After each layer, inspect the work and make any necessary adjustments to ensure a smooth, bubble-free surface.

Curing and Finishing: Once you've completed the layup, allow sufficient time for the resin to cure according to the manufacturer's guidelines. This process might require patience, as the curing time can vary depending on the resin type and environmental conditions. After curing, inspect the work for any imperfections and make any final touch-ups. Properly cured and laid-up fibreglass provides excellent structural integrity and protection for the boat's keel.

Winterizing a Direct Drive Boat: A Step-by-Step Guide

You may want to see also

Reinforcement Methods: Use glass tape or mats for added strength and durability

When it comes to reinforcing a boat's keel with fiberglass, using glass tape or mats is a crucial step to ensure the structure's strength and longevity. This method is particularly effective in areas that require additional support, such as the keel itself, as it provides a strong, lightweight layer that can withstand the rigors of marine environments.

Glass tape, also known as glass cloth or weave, is a versatile material that can be easily cut and shaped to fit the specific contours of your boat's keel. It is typically made from a fine mesh of glass fibers, which, when combined with a resin matrix, creates a rigid yet flexible material. The tape is applied in layers, overlapping each other slightly to create a strong, continuous surface. This layering technique is essential as it provides structural integrity and helps distribute stress evenly across the keel.

To begin the reinforcement process, ensure that the surface of the keel is clean and free of any debris or old fiberglass. Prepare the area by applying a suitable primer or bonding agent to create a strong adhesion base for the glass tape. Start by laying the tape in a direction that complements the natural grain of the wood or existing fiberglass, typically in a crisscross pattern. This technique, known as 'biasing', adds strength in multiple directions, making the structure more resistant to twisting and bending forces.

For an even stronger bond, consider using a specialized resin or bonding agent designed for fiberglass applications. This will create a more robust and durable reinforcement. After applying the tape, ensure that it is smooth and free of any wrinkles or creases, as these can lead to weak spots in the structure. Use a wet cloth or a specialized tool to gently smooth the tape, removing any air bubbles and ensuring a tight bond.

Glass mats, also known as glass cloth or weave, offer a similar reinforcement method but provide a more continuous and uniform surface. These mats are available in various sizes and weights, allowing for customization based on the specific requirements of your boat's keel. When using glass mats, follow a similar process as with tape, ensuring proper preparation of the surface and applying the mats in a way that complements the keel's natural grain.

By employing glass tape or mats, you are essentially adding a layer of protection and strength to your boat's keel, making it more resistant to wear and tear, corrosion, and the overall stresses of marine life. This reinforcement technique is a fundamental step in the fiberglassing process, ensuring that your boat's keel remains sturdy and reliable for years to come.

Dispose of Your Paddle Boat: A Step-by-Step Guide

You may want to see also

Cure and Finish: Allow adequate curing time and sand for a smooth, professional finish

The process of fiberglassing a boat keel requires careful attention to detail and patience, especially during the curing and finishing stages. Once the fiberglass layers are applied and the boat is ready for the final touches, it's crucial to allow sufficient curing time. This step is often overlooked, but it significantly impacts the overall quality and longevity of the repair.

Curing is a chemical reaction that occurs when the fiberglass resin and hardener are mixed and exposed to the right conditions. This reaction creates a strong, durable bond between the layers of fiberglass, forming a solid structure. Adequate curing time ensures that the resin fully sets, providing the necessary strength and flexibility to the boat's keel. It is essential to follow the manufacturer's instructions for the specific resin and hardener you are using, as curing times can vary. Typically, a minimum of 24 hours is required, but for optimal results, allowing 48 hours or more is recommended.

During this curing period, it's important to keep the boat in a controlled environment, away from direct sunlight and extreme temperatures. Heat and UV rays can accelerate the curing process but may also cause premature hardening, making it difficult to work with. If you need to accelerate the curing process, consider using a heat gun or a hairdryer on a low setting, ensuring you maintain a safe distance to avoid overheating the fiberglass.

After the curing period, inspect the boat's keel thoroughly. You should now be able to sand the surface without any soft or tacky areas. Start with a coarse-grit sandpaper (60-80 grit) to remove any excess resin and smooth out the surface. Gradually progress to finer grits (120-180 grit) for a smoother finish. Take your time with this process, as it is crucial to achieve a professional-looking surface.

Once you've sanded the entire surface, wipe away any dust or debris with a damp cloth. This step ensures that the final finish is clean and ready for the next stage. If you notice any imperfections or uneven areas, carefully re-sand them and repeat the process until you are satisfied with the result. Remember, a well-cured and properly finished fiberglass keel will not only enhance the boat's appearance but also contribute to its structural integrity.

Launching a Deep V Boat: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Fiberglassing, or fibreglassing, a boat keel is a process of applying a layer of fibreglass reinforcement to the bottom of the keel. This technique is commonly used to strengthen the structural integrity of the keel, especially in older boats or those that have experienced damage. It helps to prevent further deterioration and provides additional protection against wear and tear.

Before starting the fiberglassing process, ensure the keel is clean and free from any debris or old paint. Sand the surface to create a rough texture, allowing the fiberglass to adhere better. It's crucial to use a suitable primer to ensure proper bonding. Additionally, consider using a reinforcing material like carbon fiber or kevlar for added strength, especially if the keel has been compromised.

The process typically involves several steps. First, lay the fiberglass cloth over the prepared keel, ensuring full coverage. Use a resin-rich cloth for better bonding. Then, apply the appropriate amount of epoxy resin, following the manufacturer's instructions. Smooth out any bubbles and ensure a uniform layer. Finally, allow the resin to cure according to the product guidelines.

Yes, regular maintenance is essential to keep the fiberglassed keel in good condition. Inspect the keel periodically for any signs of damage or wear. Keep the fiberglass clean and free from grime, as it can affect its performance. Consider using a protective coating to enhance durability. Additionally, be cautious when using abrasive cleaning tools to avoid scratching the surface.