Cutting speaker holes in an aluminium boat can be a daunting task, but with the right tools and precautions, it is certainly achievable. The first step is to measure the size of the speakers and mark the desired location on the boat. It is important to ensure that there are no wires or fuel lines behind the marked area to avoid any accidental damage. Covering the area with masking tape or painter's tape will help protect the gel coat and prevent chipping. The next step is to choose the appropriate tool for cutting. Options include a jigsaw with a fine blade, a RotoZip or Dremel tool with a fiberglass or tile bit, a carbide grit hole saw, or a die grinder with a spindle sanding drum. When using power tools, it is crucial to work slowly and carefully to avoid injury and maintain control. For larger holes, a hole saw or a plunge router with an MDF template can be used. It is recommended to start drilling in reverse to prevent chipping and cracking of the gel coat. After the holes are cut, it is important to smooth the edges to prevent spider cracks.

| Characteristics | Values |

|---|---|

| Tools | Rotozip, Dremel, Jig saw, Drill, Oscillating tool, Air saw, Diamond-coated hole saw, Flap wheel, Die grinder, Reciprocating air saw, Sanding drum wheel, Trim router, Multi-purpose cutting bit, Flexible attachment, Shop vac, Saber saw, Hole cutting tool, Cutting blade, Circle cutter, Carbide grit hole saw |

| Techniques | Use masking tape, Make a template, Drill in reverse, Use a shop vac, Drill slowly, Use a variable-speed drill, Chamfer the edge of the hole, Use painter's tape, Drill a centred pilot hole, Use a plunge router, Use an MDF template, Use a wood plug, Use a wood insert |

What You'll Learn

Using a Rotozip saw with a fiberglass bit

Before you begin, it is important to plan the location of the speaker holes carefully. Check for clearance behind the area where you will be cutting and make sure there are no wires or fuel lines in the way. Mark the center of the desired hole with a grease pen or marker.

Next, apply masking tape to the surface beyond the circumference of the hole. This will help prevent scratches and chipping of the gel coat during the cutting process. It is also recommended to cover the surrounding area with a tarp or drop cloth to catch any debris.

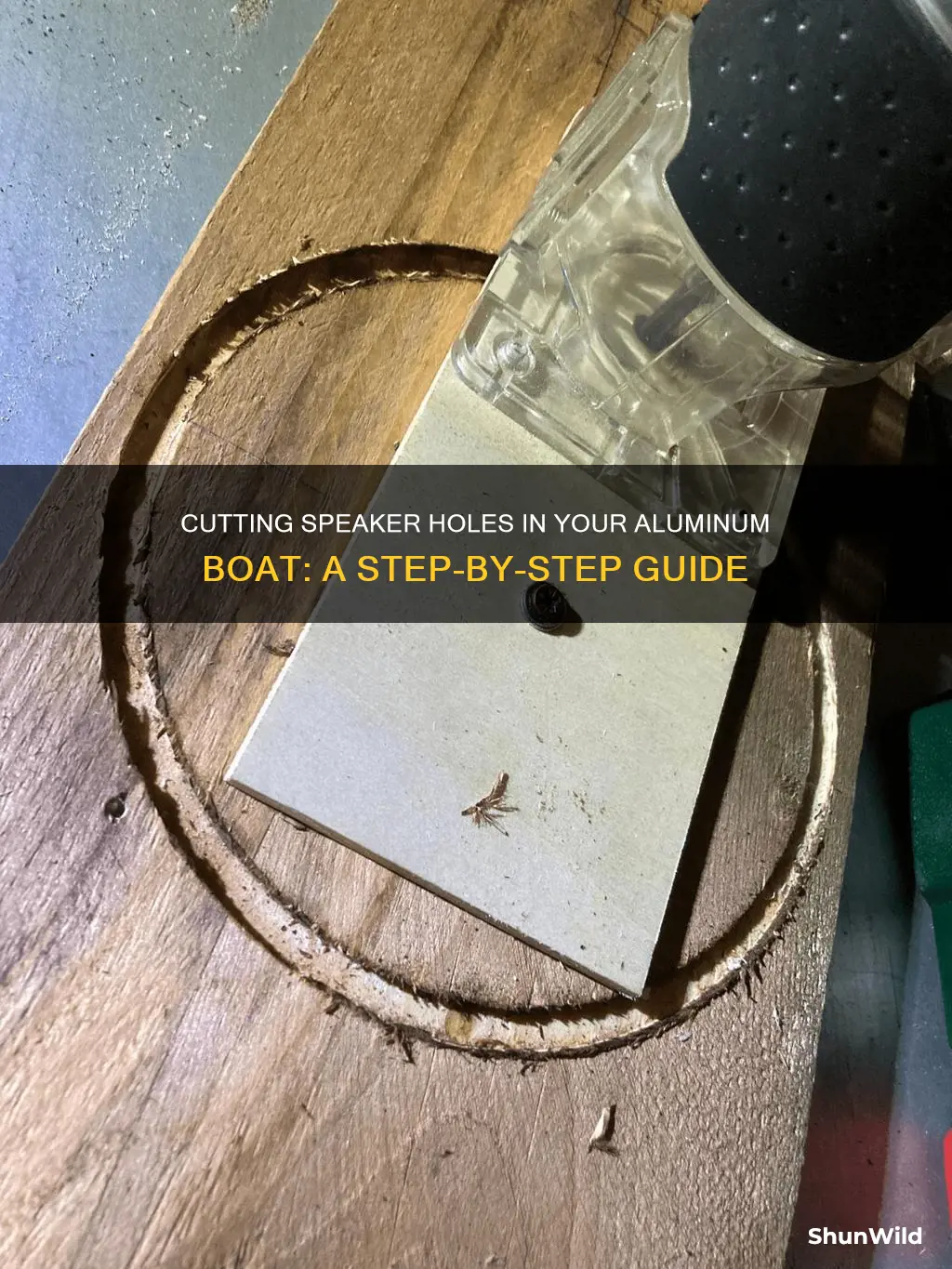

Now you are ready to start cutting. Drill a 1/2-inch pilot hole in the center of the marked area. This will serve as a guide for your Rotozip saw. Attach the fiberglass bit to your Rotozip saw and start cutting along the marked circumference of the hole. It is important to go slow and maintain a firm, steady hand to avoid the tool "taking off". Keep your shop vacuum nearby to suck up any fiberglass dust created during the cutting process.

Take your time and work your way around the marked circumference until you have cut through the entire area. Once you have finished cutting, slowly peel off the masking tape to reveal a clean, precise hole.

Finally, you can install your speakers by drilling mounting holes and using screws or bolts to secure them in place. Make sure to use a countersink bit to prevent cracking of the gel coat. And that's it! You have successfully cut speaker holes in your aluminum boat using a Rotozip saw with a fiberglass bit.

Boat Ramps in New Jersey: Permits Required or Not?

You may want to see also

Using a jigsaw with a fine blade

Using a jigsaw to cut speaker holes in an aluminium boat requires careful preparation and execution. Here is a step-by-step guide:

First, ensure you have the right tools and materials. You will need a jigsaw with a fine blade, a drill, masking tape, a pen or marker, and safety gear, including gloves and eye protection. The fine blade is crucial as it will enable a clean cut and reduce the risk of chipping or scratching the aluminium surface.

Next, mark the cut-out area. Using a pen or marker, carefully outline the shape and size of the speaker hole on the aluminium surface. This will serve as a guide for your cutting. It is essential to double-check your measurements and speaker size before marking to avoid mistakes.

Once marked, cover the surrounding area with masking tape. This will help protect the aluminium surface from scratches and any gel coat from chipping. Make sure to press down the tape firmly, especially along the cutting line, to create a barrier between the jigsaw foot and the aluminium.

Now, you are ready to start cutting. Drill a 1/2-inch hole inside the marked area to insert the jigsaw blade. Start the cut slowly and carefully, following your marked outline. It is crucial to take your time and not rush this step to achieve a clean and precise cut. Remember to wear your safety gear, including gloves and eye protection, throughout the process.

As you cut, be mindful of the pressure you apply and the speed at which you work. Applying too much pressure or going too fast can cause the blade to bind or break, resulting in an uneven cut or damage to the aluminium. Take your time, and let the jigsaw do the work for you.

Finally, once you have completed the cut, remove the masking tape and inspect your work. If necessary, use a file or sandpaper to smooth out any rough edges. Ensure there are no sharp edges or burrs that could pose a safety hazard.

Malibu Boats: Engine Options and Performance Insights

You may want to see also

Using a Dremel with a roto-zip blade

Step 1: Prepare the Work Area

Before you start cutting, it's important to prepare your work area. Make sure you have a clear and well-lit space to work in, and lay out all the tools and materials you will need. Put on safety gear, including eye protection and gloves, to protect yourself from any debris or sharp edges.

Step 2: Measure and Mark the Speaker Hole

Carefully measure the size of the speaker you will be installing and mark the hole accordingly. It's important to be precise at this stage to ensure a perfect fit. You can use a template or a compass to mark the circle, and make sure the speaker will be mounted securely and won't interfere with any underlying wires or fuel lines.

Step 3: Choose the Right Bit

For cutting holes in aluminium, it's recommended to use a bit designed specifically for soft metals. Look for a bit with a scraping action rather than a digging action, as this will help prevent the Dremel from grabbing and reduce the risk of leaving rough edges. A fiberglass bit can also be used, but avoid using a regular bit as it may not give you the desired results.

Step 4: Start Cutting

When you're ready to start cutting, make sure your Dremel is set to a slower speed to avoid generating excessive heat. Start by drilling a pilot hole in the centre of the marked circle. This will give you a starting point for your Roto-Zip blade. Take your time and work steadily, allowing the tool to do the work. Remember that aluminium is a soft metal, so you don't need to apply a lot of pressure.

Step 5: Finish the Edges

Once you've cut out the speaker hole, you can use a sanding wheel attachment on your Dremel to smooth out any rough edges. This will help ensure a clean and professional finish.

Step 6: Clean Up

After you've finished cutting and sanding, be sure to clean up the work area. Use a shop vac to remove any debris or metal shavings, and wipe down the area with a damp cloth to remove any remaining dust.

By following these steps and using a Dremel with a Roto-Zip blade, you can cut speaker holes in your aluminium boat efficiently and effectively. Remember always to work safely and take your time to achieve the best results.

Putting a Boat on a Roof Rack: Step-by-Step Guide

You may want to see also

Using a hole saw in reverse

Step 1: Prepare the Work Area

Before you start, make sure you have all the necessary tools and safety equipment. This includes a hole saw, a drill, a sharp bit, safety goggles, gloves, and ear protection. It is also recommended to work in a well-ventilated area to avoid inhaling any debris or fumes. Cover the surrounding area with a tarp or drop cloth to catch any metal shavings and make clean-up easier.

Step 2: Measure and Mark the Hole

Determine the size of the speaker you will be installing and mark the centre of the hole with a centre-punch. You can also use masking tape to mark the hole and prevent scratches or chipping on the boat's surface. Measure and mark the hole carefully to ensure the speaker fits snugly.

Step 3: Drill a Pilot Hole

Drill a small pilot hole at the centre of your marked circle. This will guide the hole saw and help it stay on course. Drill slowly and carefully to maintain control. Make sure the pilot hole is the same size as the hole saw's arbor drill.

Step 4: Start Cutting in Reverse

Attach the hole saw to your drill and start cutting in reverse. This technique will help prevent chipping and cracking of the gel coat and create a clean cut. Hold the drill firmly and let the speed of the drill do the work. Do not apply too much pressure as it can destroy the teeth of the hole saw.

Step 5: Switch to Forward

Once you have established a clean cut and feel comfortable, switch the drill to forward. This will allow you to cut faster and complete the hole more efficiently. Remember to retract the hole saw frequently to clear waste and prevent overload.

Step 6: Finish the Hole

As you approach the end of the cut, go around and finish the hole from the other side to prevent tear-out and achieve a clean hole on both sides. You can also place a "backer" board behind the hole to support the material and prevent flex.

Additional Tips:

- Always wear safety gear, including goggles, gloves, and ear protection, when using power tools.

- Use a sharp hole saw bit to ensure clean and efficient cutting.

- Consider using a drill with an additional handle for better control.

- Be mindful of what's behind the hole you're drilling to avoid damaging wires or pipes.

- If cutting through metal, use cutting oil to cool the saw and the workpiece, reducing heat and abrasion.

- For large holes, consider scoring the surface with the hole saw first, then bore smaller holes around the circle to keep the saw cooler and reduce binding.

Boat Registration in Illinois: Where to Pay?

You may want to see also

Using a Dremel with a tile-cutting bit

Step 1: Prepare the Work Area

Before you start cutting, it's important to prepare the work area. Make sure you have a clear and well-lit workspace to work in. Cover any surrounding areas with plastic sheets to protect them from dust and debris. Put on safety goggles and a respirator mask to protect yourself from dust and debris.

Step 2: Choose the Right Dremel Bit

For cutting speaker holes in aluminium, you'll need to use a diamond tile-cutting bit with your Dremel tool. The specific bit you'll need will depend on the type of cut you want to make. For straight cuts, use the #545 diamond wheel blade. For irregular cuts, such as circles, use the #562 tile bit.

Step 3: Mark the Cut Line

Use a permanent marker to mark the cut line on the aluminium surface. If you're cutting a circle, you can use a compass to draw a perfect circle. Make sure the line is clearly visible and easy to follow.

Step 4: Secure the Workpiece

If possible, clamp the aluminium sheet or workpiece to a workbench to keep it stable while you're cutting. This will help you make a clean and precise cut.

Step 5: Start Cutting

Turn on your Dremel tool and gently plunge the tile-cutting bit into the aluminium at the starting point of your cut line. Apply gentle pressure and let the Dremel do the work. Slowly guide the tool along the cut line, following your marked path.

Step 6: Take Your Time

Cutting through aluminium can take time, so be patient and don't rush the process. Let the Dremel tool do the cutting, and only apply enough pressure to move the bit forward. Pushing too hard can wear out the bit prematurely.

Step 7: Stop at the End of the Cut Line

When you reach the end of the cut line, stop cutting and carefully pull the Dremel tool out of the hole. If you need to make additional cuts, plunge the tool again at the starting point of the next cut line.

Step 8: Clean Up

Once you've finished cutting, remove the plastic coverings and wipe down the area to clean up any remaining dust or debris.

Fixing Your Boat's Speed: Repairing the Speedometer Housing

You may want to see also

Frequently asked questions

The best tools to cut speaker holes in an aluminium boat are a RotoZip, Dremel, jigsaw, or a hole saw.

To prevent chipping when cutting speaker holes, it is recommended to use painter's tape, masking tape, or blue tape over the area. You should also drill a small pilot hole to get the blade started and run the drill in reverse until you go through the gel coat.

When using a jigsaw to cut speaker holes, it is recommended to use a carbide blade or a fine blade with sharp teeth.