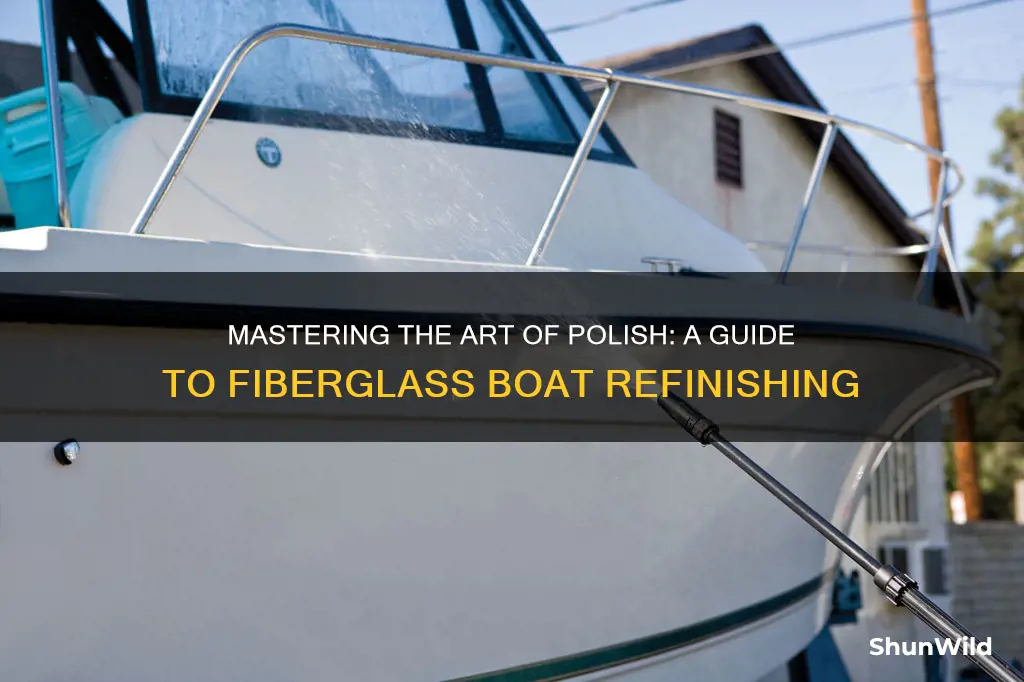

Cutting, polishing, and maintaining a fiberglass boat requires careful attention to detail and the right techniques to ensure a smooth and glossy finish. This guide will provide a step-by-step process for achieving a professional-looking boat with a polished fiberglass surface. From selecting the appropriate tools and materials to understanding the proper techniques for cutting and polishing, this guide will cover all the essential aspects to help boat owners and enthusiasts achieve a stunning and durable finish on their fiberglass vessel.

What You'll Learn

- Preparation: Clean and prepare the boat's surface for sanding, removing dirt and old polish

- Sanding Techniques: Use various grits of sandpaper to achieve a smooth, even finish

- Polishing Process: Apply a high-quality polish to enhance shine and protect the fiberglass

- Buffering: Use a buffer to create a smooth, glossy surface, ensuring a professional look

- Maintenance: Regular maintenance keeps the boat's finish in top condition, preventing damage

Preparation: Clean and prepare the boat's surface for sanding, removing dirt and old polish

Before you begin the process of cutting and polishing your fiberglass boat, it's crucial to ensure that the surface is clean and prepared properly. This initial step is often overlooked but is essential for achieving a smooth and professional finish. Here's a detailed guide on how to prepare the boat's surface for the sanding and polishing process:

Cleaning the Boat's Surface: Start by giving your boat a thorough cleaning. Use a mild detergent or a specialized boat cleaner to remove any dirt, grime, or old polish that has accumulated over time. You can use a soft brush or a sponge to scrub the surface gently, ensuring you cover all areas, including the hull, deck, and any accessories. Rinse the boat thoroughly with water to remove any soap residue, ensuring the surface is completely clean.

Removing Old Polish: If your boat has an existing polish or wax, it's important to remove it before sanding. Old polish can create a layer that hinders the sanding process and may not allow for a smooth finish. Use a specialized polish remover or a strong solvent, applying it to the surface and letting it sit for a few minutes to dissolve the old polish. Then, use a scraper or a plastic scraper tool to carefully remove the old polish, being mindful not to scratch the fiberglass.

Sanding Preparation: After cleaning and removing the old polish, the surface is ready for sanding. Start with a coarse-grit sandpaper (e.g., 80-grit) to remove any remaining imperfections and roughen the surface slightly. Work in small sections, sanding carefully and following the direction of the fiberglass weave. Once you've smoothed the surface with the coarse grit, progress to a finer grit (e.g., 120-grit) to refine the texture and prepare the surface for polishing.

Ensuring a Smooth Surface: The goal of this preparation step is to create a smooth, even surface that is free from dirt, old polish, and imperfections. Proper preparation will make the subsequent cutting and polishing processes more effective and efficient, resulting in a high-quality finish. Take your time with this step, as it sets the foundation for the rest of the project.

Boat Speed Tracker: Instant Insights for Your Water Adventures

You may want to see also

Sanding Techniques: Use various grits of sandpaper to achieve a smooth, even finish

When it comes to sanding a fiberglass boat, using the right techniques and tools is crucial to achieving a smooth and professional finish. One of the key aspects of this process is understanding the various grits of sandpaper and how to utilize them effectively. Here's a detailed guide on sanding techniques to help you master the art of polishing your fiberglass vessel:

Understanding Sandpaper Grits:

Sandpaper comes in a wide range of grit sizes, typically measured in numbers (e.g., 40, 60, 80, 120, etc.). The lower the number, the coarser the grit, and the higher the number, the finer the grit. For fiberglass, you'll want to start with a coarse grit and gradually move to finer grits for a smooth surface. Common grits used for fiberglass sanding include 40, 60, 80, 120, 180, and 220.

Starting with Coarse Grit:

Begin the sanding process by using a coarse grit sandpaper, such as 40 or 60. This initial step helps to quickly remove any old paint, gelcoat, or imperfections from the fiberglass surface. Work in small sections, applying gentle pressure and using smooth, circular motions. Remember, the goal is to create a uniform surface, so take your time and be thorough. After sanding with the coarse grit, inspect the surface to identify any remaining imperfections or uneven areas.

Progressing to Finer Grits:

Once you've addressed the major issues, it's time to refine the surface. Move to a finer grit sandpaper, such as 80 or 120. This step will help to create a smoother and more even finish. Finer grits are excellent for blending and preparing the surface for the next steps in the polishing process. Continue sanding in the same manner, ensuring that you follow the direction of the fiberglass weave. Avoid excessive pressure, as it can lead to scratches or damage to the gelcoat.

Achieving a Smooth Finish:

For an exceptionally smooth and glossy finish, consider using a finer grit, like 180 or 220. These grits will help to eliminate any remaining imperfections and create a smooth surface ready for polishing. Take your time and be meticulous in this stage, as it will greatly impact the final appearance of your boat. After sanding with the finest grit, wipe away any dust or debris using a clean cloth to ensure a clean surface for the next steps.

Tips for Success:

- Always sand with the direction of the fiberglass weave to avoid creating visible scratches.

- Work in small sections to maintain control and ensure an even finish.

- Keep your sandpaper clean by regularly removing dust and debris to maintain its effectiveness.

- Inspect the surface frequently to identify any areas that require additional sanding.

- Consider using a sanding block or pad for consistent pressure and a more controlled sanding action.

Mastering sanding techniques is an essential skill in the process of cutting and polishing a fiberglass boat. By understanding the various grits and applying them correctly, you'll achieve a smooth, professional finish that will make your boat look its best. Remember, patience and attention to detail are key to success in this process.

Understanding the Mechanics: How Blocks Operate on Crab Boats

You may want to see also

Polishing Process: Apply a high-quality polish to enhance shine and protect the fiberglass

The polishing process is a crucial step in maintaining and enhancing the appearance of a fiberglass boat. It involves applying a high-quality polish to restore and protect the surface, ensuring a deep, glossy finish. Here's a detailed guide on how to achieve a professional-looking polish:

Start by ensuring the boat's surface is clean and free from any dirt or grime. Use a mild detergent and a soft cloth to gently clean the fiberglass. Rinse thoroughly and allow the surface to dry completely. This initial step is essential as it ensures the polish adheres properly and creates a smooth base for the final finish.

Once the surface is dry, it's time to apply the polish. Choose a high-quality marine polish specifically designed for fiberglass. These polishes are typically available in spray or liquid form. Follow the manufacturer's instructions for application. For spraying, ensure an even coat, avoiding any drips or uneven coverage. For liquids, use a clean cloth or a polishing pad to apply in a circular motion, covering the entire surface. Allow the polish to dry as per the product's guidelines, which is usually a few minutes.

After the polish has dried, inspect the surface for any imperfections or areas that require additional attention. Use a soft cloth to gently buff the polish, removing any excess and creating a smooth, glossy finish. This step ensures a professional-grade shine and highlights the beauty of the fiberglass. Remember to work in small sections to maintain control and avoid over-polishing.

For optimal results, repeat the polishing process regularly, especially after any maintenance or repair work. This routine maintenance will help preserve the boat's finish and protect the fiberglass from UV damage and environmental factors. With consistent care, your fiberglass boat will maintain its stunning appearance for years.

Islands Near Santorini: A Boater's Paradise

You may want to see also

Buffering: Use a buffer to create a smooth, glossy surface, ensuring a professional look

Buffering is an essential step in the process of cutting and polishing a fiberglass boat to achieve a smooth, glossy finish. This technique is particularly useful for creating a professional-looking surface that enhances the boat's overall appearance and value. Here's a detailed guide on how to effectively use a buffer for this task:

Step-by-Step Buffering Process:

- Preparation: Ensure that the fiberglass surface is clean and free from any dirt or debris. Use a mild detergent and water solution to wash the boat, and then thoroughly rinse and dry it. This step is crucial to avoid any contamination that could affect the buffering process.

- Choose the Right Buffer: Select a buffer that is suitable for fiberglass. A dual-action buffer is commonly recommended as it provides a balance between speed and control. The buffer should have a variable speed setting to allow for adjustment based on the surface's condition. Different sizes of buffers are available, and a smaller, more compact buffer is ideal for working in tight spaces and hard-to-reach areas.

- Apply the Buffering Compound: Use a high-quality polishing compound designed for fiberglass. This compound is typically applied in a thin layer to the surface. Start with a lower speed setting on the buffer and gently glide the tool over the surface in a straight, even motion. Apply light pressure to avoid marring the finish. Work in small sections to maintain control and ensure an even application.

- Buffing Technique: As you move the buffer, you'll notice the surface starting to shine and become smoother. Continue this process, gradually increasing the speed of the buffer for a more aggressive cut. This step helps to remove any remaining imperfections and prepares the surface for the final polish. Remember to always work in the direction of the fiber direction to avoid creating a hazy or cloudy appearance.

- Final Polish: Once you've completed the buffering process, you'll have a smooth and glossy surface. Apply a high-quality polish designed for fiberglass to enhance the shine and protect the finish. This final step ensures that your boat's exterior looks pristine and professional.

By following these steps and using a buffer effectively, you can achieve a stunning, high-gloss finish on your fiberglass boat, elevating its appearance and overall value. This process requires patience and attention to detail, but the results will undoubtedly impress.

Repairing Riveted Aluminum Boats: A Comprehensive Guide

You may want to see also

Maintenance: Regular maintenance keeps the boat's finish in top condition, preventing damage

Regular maintenance is crucial for preserving the appearance and structural integrity of a fiberglass boat. The process of maintaining a boat's finish involves several key steps to ensure it remains in optimal condition and protects against potential damage. Here's a comprehensive guide to achieving this:

Cleaning and Detailing: Start by thoroughly cleaning the entire boat, both above and below the waterline. Use a mild detergent or a specialized boat cleaner to remove dirt, grime, and any accumulated saltwater or marine growth. Pay close attention to the hull, deck, and all accessible surfaces. For a thorough clean, consider using a power washer or a high-pressure hose to remove stubborn stains and salt deposits. After cleaning, rinse the boat thoroughly to eliminate any soap residue.

Polishing and Waxing: Fiberglass surfaces benefit from regular polishing and waxing to restore their shine and protect against UV damage. Use a high-quality fiberglass polish designed for marine applications. Apply the polish generously to the entire hull and deck, following the manufacturer's instructions. Allow the polish to dry and then buff it to a high shine. For added protection, consider applying a marine-grade wax after polishing. This step will create a protective barrier, preventing scratches and maintaining the boat's finish.

Inspecting for Damage: Regular maintenance also involves inspecting the boat for any signs of damage or wear. Check for cracks, chips, or delamination in the fiberglass, especially in areas prone to impact or stress, such as the bow and stern. Inspect the gelcoat for fading or discoloration, as this can indicate UV damage. Look for any signs of corrosion on metal components, such as the propeller or hardware. Address any issues promptly to prevent further damage.

Protecting Against Marine Elements: Fiberglass boats are susceptible to the elements, so it's essential to take preventive measures. Apply a marine-grade antifouling paint to the hull if necessary, especially if the boat is kept in saltwater for extended periods. This will inhibit the growth of barnacles and algae. Regularly check and clean the boat's anchor and lines to prevent the buildup of marine organisms. Additionally, consider using a marine-safe cover to protect the boat when not in use, especially during harsh weather conditions.

By implementing these maintenance practices, boat owners can ensure that their fiberglass vessels remain in excellent condition, with a pristine finish that withstands the test of time and the marine environment. Regular care and attention will ultimately save time and money by preventing costly repairs and replacements.

The Ziegfeld Touch: Show Boat's Legacy

You may want to see also

Frequently asked questions

Fiberglass is a versatile material that can be cut and shaped using various tools. A common method is to use a sharp utility knife or a fiberglass cutter, which is a specialized tool with a sharp blade designed for cutting fiberglass. It's important to use a sharp blade to ensure clean cuts and to avoid damaging the fiberglass. Always wear safety gear, including gloves and eye protection, when cutting.

After cutting or shaping the fiberglass, it's essential to smooth out any rough edges and restore the surface's shine. You can use a fine-grit sandpaper (e.g., 600-grit or higher) to gently sand the area, removing any sharp edges and creating a smooth finish. Follow this with a polishing compound or a fiberglass filler to further enhance the surface and prepare it for painting or further customization.

Yes, there are several products designed specifically for fiberglass maintenance and restoration. For cutting, you can use a fiberglass cutter or a sharp knife with a protective guard to ensure safety. For polishing, a good-quality fiberglass filler or a polishing compound designed for marine applications will help restore the surface's luster. These products are typically available at marine supply stores or online.

While regular sandpaper can be used for initial sanding to remove old paint or rough surfaces, it is not ideal for cutting or fine polishing fiberglass. Regular sandpaper may not provide the precision needed for clean cuts and can leave a rough texture. Instead, opt for fine-grit sandpaper and specialized fiberglass cutting and polishing tools for the best results.

When dealing with intricate shapes or curves, it's crucial to use a steady hand and a sharp, precise tool. Consider using a small utility knife or a fiberglass cutter with a thin blade to carefully cut along the curves. For polishing, a small, soft-bristled brush or a polishing pad can help reach tight spaces and ensure a smooth finish without damaging the fiberglass.