Building an aluminium foil boat is a great activity for kids to learn about engineering, buoyancy, and density. To make the best boat, you'll need to consider its size and shape, as these factors will determine how much weight it can carry and how well it floats. Cut and fold aluminium foil into a boat shape, making sure to create a strong structure with no leaks. Test your boat's buoyancy by placing it in water and adding weight, such as pennies, one by one until it sinks. Repeat this process with different boat designs to find the one that holds the most weight. You can also experiment with different materials and liquids to further explore the concepts of density and buoyancy.

| Characteristics | Values |

|---|---|

| Materials | Aluminum foil, tape, pennies, water, container, scissors |

| Boat Design | Two squares of foil, one twice the size of the other, folded into the same boat shape |

| Boat Construction | Foil squares folded into boat hulls, with finishing touches to ensure no leaks, using tape if necessary, and flattening the bottoms |

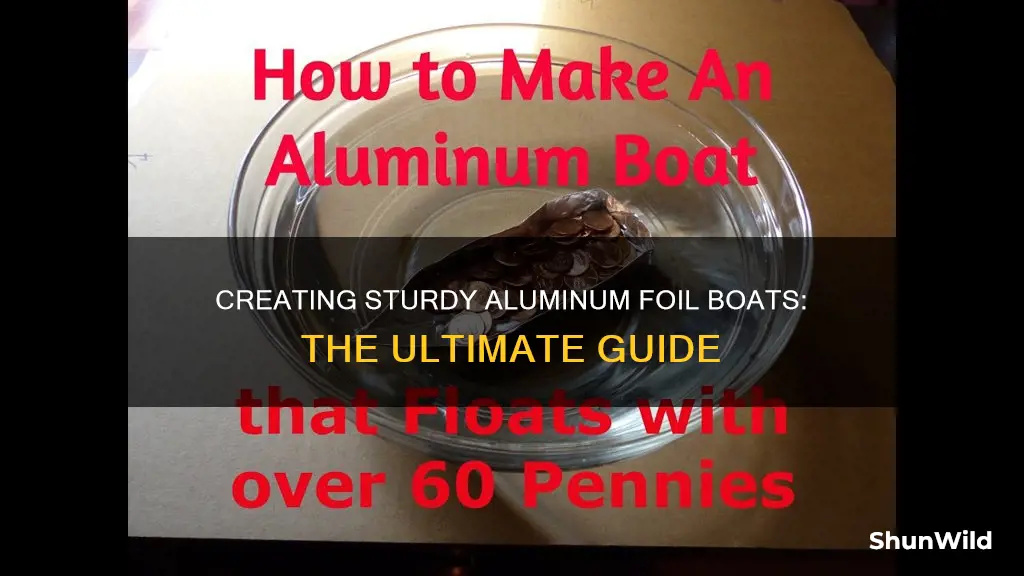

| Testing Method | Place boat in water, add pennies one by one until it sinks, counting the number of pennies |

| Variables | Boat size, boat shape, weight distribution, speed of penny addition |

What You'll Learn

Cut and fold foil into a boat shape

To cut and fold foil into a boat shape, you can start by cutting the foil into a square. You can use scissors or carefully tear the foil to do this. The size of the square can be of your choosing, and you don't need to be exact. You can always make another boat that is bigger or smaller.

Next, you will fold the edges of the foil to form a boat shape. You can try out different shapes and types of boats. You could even draw pictures of boats before you start building to help guide your design.

If you want to make a bigger boat, you can use a plastic bowl as a mould. Cut or tear a piece of aluminium foil that is slightly larger than the bowl. Then, wrap the foil around the bowl, tucking it in over the edge. Press down firmly to mould the foil to the bowl's shape. Gently unwrap the bowl and remove it from the foil, then fold the edges that were inside the bowl back in to strengthen the walls of the boat. Repeat this process to make multiple boats of a similar size.

Once you have your boat shape, you can make finishing touches to ensure it doesn't have any leaks. Use a little tape to make it stronger if needed, and flatten the bottom of the boat. Check that the rim is the same height all the way around the edge of the boat.

Marvin's Age in Fresh Off the Boat Explored

You may want to see also

Test its buoyancy

Once you've built your boat, it's time to test its buoyancy. This is a crucial stage in the process as it will determine whether your boat floats and how much weight it can carry. Here's a step-by-step guide to testing the buoyancy of your aluminium foil boat:

- Prepare your testing area by filling a container with water. You can use a bucket, tub, sink, dish pan or even a bath if you're making a larger boat. Ensure you have enough water in the container to allow the boats to sink. Place your container on a towel to soak up any spillages.

- Carefully place your aluminium foil boat in the water. If it floats, well done!

- Now for the exciting part: start adding pennies (or other coins) one by one into the boat. Balance the load as you add the pennies to prevent the boat from tipping.

- Continue adding pennies until your boat finally sinks. You may be surprised by how many pennies it can hold!

- Remove the sunken boat from the water and place it on a rag or paper towel, along with the pennies.

- Count the number of pennies the boat supported before sinking (don't include the penny that sank the boat).

- Repeat this process with any other boats you've made, using only dry pennies.

- Compare the results to see if the larger boat could support more pennies than the smaller one.

- You can also experiment with different types of coins, such as nickels, dimes or quarters, or even international coins.

- Try testing your boats in different liquids, such as oil or vinegar, to see how many pennies it takes to sink them.

By testing the buoyancy of your aluminium foil boats, you're learning about basic engineering and experimentation. You'll observe how the shape and size of the boat affect its ability to float, and you'll understand the concept of density and buoyancy in a fun and hands-on way.

Launching a Boat: FAQs for Beginners

You may want to see also

Calculate the boat's volume

To calculate the volume of your aluminium foil boat, you will need to take some measurements. If your boat has a simple shape, such as a rectangular prism, you can measure the length, width, and height of the hull and multiply these dimensions together to get its volume. However, if your boat has an irregular shape, you will need to measure the volume piece-wise and then add these volumes together. For any areas of the hull that are curved or angled, you can use triangles to approximate their volume.

Another method to calculate the volume of your boat is to fill it with dry rice and then transfer the rice to a measuring cup. This method may be easier for boats with irregular shapes or for those who do not have the tools to measure the dimensions of their boat.

Once you have calculated the volume of your boat, you can use this information to determine the density of the boat and how much weight it can carry before sinking. To do this, divide the weight of the boat by its volume. This will give you the boat's density, which can then be compared to the density of water to determine its buoyancy.

Additionally, you can use the concept of displacement to calculate the maximum weight your boat can carry. By measuring the volume of water displaced by your boat, you can determine how much water it would take to fill it and, consequently, the mass that would cause it to sink. This can be calculated using Archimedes's principle, which states that the buoyant force on an object is equal to the weight of the fluid displaced by the object.

Finally, it is important to note that the weight your boat can carry will also depend on its shape and stability. A well-designed boat with a stable shape may be able to carry more weight without sinking, even if it has a smaller volume.

Should You Repair or Replace an Aging Boat?

You may want to see also

Experiment with different shapes

The shape of an aluminum foil boat plays a crucial role in its ability to float and carry weight. By experimenting with different shapes, you can discover which designs are more stable, buoyant, and capable of holding more weight. Start by cutting several uniform squares of aluminum foil. You can make the squares as small as 4 inches by 4 inches or go up to 12 inches by 12 inches for larger boats. These squares will serve as the base for your boat shapes.

One basic shape to try is the rectangular prism or canoe shape. Cut two squares of aluminum foil, with one square having dimensions twice as large as the other. For example, make one square 12 inches by 12 inches and the other 6 inches by 6 inches. Fold these squares into boat hulls with two pointed ends, resembling canoes. Make sure the hulls are leak-free and use tape sparingly to reinforce them if needed. Flatten the bottoms of the hulls and ensure the rims are of uniform height.

Another shape to experiment with is the flat-bottomed boat. These boats are designed to sit higher in the water, reducing the amount of water they need to push aside. As a result, they experience less friction with the water, allowing them to travel faster and making them suitable for shallow waters. However, their higher center of gravity can make them less stable in rough seas. To create a flat-bottomed boat, you can use a small cup or bowl to mold the hull of your aluminum foil boat. This will give it a consistent shape. Secure the shape with clear adhesive tape, using as little tape as possible to keep the boat lightweight.

Once you've crafted your boats, it's time to test their performance. Fill a bathtub or large tub with water and gently place each boat on the water's surface. Start adding weight to the boats, one penny at a time, balancing the load evenly to prevent tipping. Keep track of how many pennies each boat can hold before it sinks. By testing different shapes, you can determine which designs are more successful in carrying weight.

Additionally, pay attention to how the boats behave during the experiment. Observe if they change shape, spring a leak, or lean in a particular direction as weight is added. This will provide valuable insights into the stability and buoyancy of different shapes. Remember to use dry pennies for accurate results, as wet pennies can affect buoyancy calculations.

Bleeding a Diesel Boat Engine: Step-by-Step Guide

You may want to see also

Compare with other materials

Aluminum foil boats are a fun and educational activity for people of all ages. The objective is to create a boat that can hold as much weight as possible before sinking. While aluminum foil is a great material for this activity, other materials such as clay can also be used for building boats.

Aluminum foil is a versatile material that can be easily folded and shaped into various boat designs. It is lightweight, buoyant, and strong enough to hold a considerable amount of weight. The size and shape of an aluminum foil boat play a crucial role in determining how much weight it can carry. By experimenting with different shapes, such as canoes, squares, or rectangles, individuals can observe how these variations impact the boat's performance.

Clay, on the other hand, offers a different set of advantages and disadvantages. While it may not be as readily available as aluminum foil, clay provides a unique opportunity to explore boat-building with a malleable material. Clay boats can be moulded into various shapes, allowing for creative designs. However, clay is denser than aluminum foil, which affects its buoyancy. Clay boats may require larger volumes to achieve the same level of buoyancy as aluminum foil boats.

Another material that can be used for boat-building is paper. Paper boats are easy to construct and can be made from readily available materials such as printer paper or construction paper. The advantage of paper boats is that they are lightweight and can be quickly prototyped. However, paper is more susceptible to water damage and may not hold up as well under heavier loads compared to aluminum foil or clay.

In conclusion, while aluminum foil boats offer a great balance of strength, buoyancy, and ease of construction, other materials such as clay and paper provide alternative avenues for exploration. Each material has its own unique properties that influence the design and performance of the boat. By experimenting with different materials, individuals can gain a deeper understanding of the underlying principles of buoyancy, density, and boat design.

The Best Sailboats for Ocean Exploration and Adventures

You may want to see also

Frequently asked questions

You will need aluminum foil, a container of water, and pennies or other coins to test the boat's buoyancy. You may also want to use scissors, tape, and a rag or paper towels.

The shape of the boat is important for its buoyancy. A shape with lots of empty space, such as a boat with a large hull, will be better at floating as it can push more water out of the way, creating a bigger buoyancy force.

Cut a square of aluminum foil and fold the edges to form a boat shape. You can experiment with different shapes and sizes to find the best design. Make sure there are no leaks and that the boat has a flat bottom.

This will depend on the size and shape of the boat. You can test this by adding pennies or other coins one-by-one until the boat sinks.