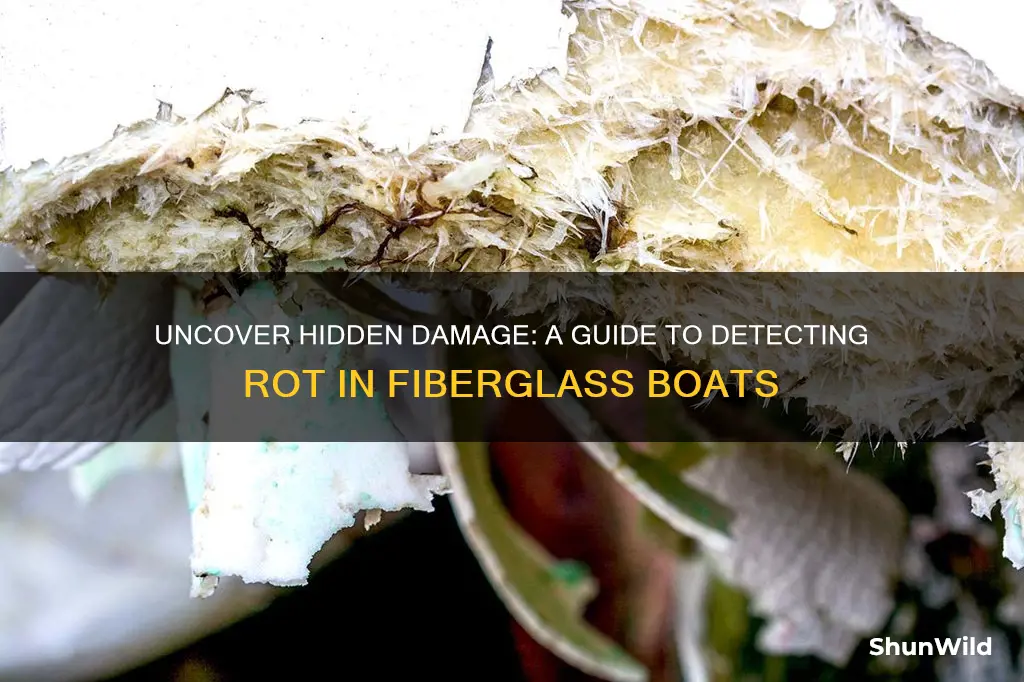

Checking for rot in a fiberglass boat is essential for maintaining its structural integrity and longevity. Rot, often caused by moisture and mold, can weaken the boat's hull and lead to costly repairs. This guide will provide a step-by-step process to inspect your boat for signs of rot, ensuring you can catch and address any issues early on. From understanding the common areas affected to using the right tools and techniques, you'll learn how to thoroughly examine your boat's fiberglass for any signs of decay.

What You'll Learn

- Visual Inspection: Look for discolored or soft spots on the hull

- Moisture Detection: Use a moisture meter to identify wet areas

- Structural Integrity: Check for warped or damaged components

- Gelcoat Condition: Inspect for chalking or fading gelcoat finish

- Repair Techniques: Learn methods for filling and sanding small holes

Visual Inspection: Look for discolored or soft spots on the hull

A visual inspection is a crucial step in identifying rot in a fiberglass boat, as it allows you to detect early signs of deterioration that might not be immediately apparent through other methods. When examining the hull, look for any discolored areas, which could indicate the presence of rot or water damage. These discolors can range from subtle changes in hue to more pronounced stains or marks. Soft spots on the hull are another critical indicator of potential rot. These soft areas might feel spongy or squishy when pressed, and they can be a result of water absorption and subsequent decay of the fiberglass material.

Start by thoroughly cleaning the hull to ensure a clear view. Use a mild detergent and water solution to wash the surface, removing any dirt, grime, or old paint that might obscure potential issues. Pay close attention to areas that are more susceptible to damage, such as the waterline, where the hull meets the transom, and the areas around access panels and through-hulls. These spots are often more prone to moisture accumulation and, consequently, rot.

Look for any changes in the texture of the fiberglass. Rot can cause the material to become brittle and crumbly, leading to a noticeable difference in the feel of the surface compared to unaffected areas. You might also notice a change in the color of the fiberglass, with affected areas appearing more faded or discolored. Keep an eye out for any signs of mold or mildew, as these can be indicators of underlying rot and should be addressed promptly.

In addition to visual cues, be mindful of any unusual odors that might accompany the discolored or soft spots. A musty or mildewy smell is often a strong indicator of water damage and potential rot. If you notice any of these issues, it's essential to investigate further and consider more comprehensive checks, such as using a moisture meter or cutting into the affected areas to assess the extent of the damage.

Remember, early detection is key to preventing further damage and costly repairs. By conducting a thorough visual inspection, you can identify rot in its initial stages and take appropriate measures to preserve the integrity of your fiberglass boat.

The Ultimate Guide to Spooling Cable onto Boat Winches

You may want to see also

Moisture Detection: Use a moisture meter to identify wet areas

Checking for moisture and potential rot in a fiberglass boat is a critical step in maintaining its structural integrity and longevity. One effective method to identify hidden wet areas is by using a moisture meter, a tool specifically designed for this purpose. Here's a detailed guide on how to utilize this technique:

Start by ensuring the boat is clean and dry. Moisture meters work best on surfaces free from dirt, grime, and water. Remove any visible water or condensation from the boat's interior and exterior. This step is crucial to get accurate readings.

Hold the moisture meter against the surface of the fiberglass. The meter will emit a small electrical signal that is absorbed by the material. The device then measures the electrical resistance of the fiberglass, which is directly related to the moisture content. A higher resistance indicates a lower moisture level, while a lower resistance suggests higher moisture absorption.

Pay close attention to areas that are more susceptible to moisture accumulation, such as the bilge, engine compartments, and below deck areas. These spots are often challenging to inspect visually and may hide signs of rot. Use the moisture meter to scan these regions thoroughly, moving the tool across the surface to cover a wide area.

Take note of any areas with consistently low resistance readings, indicating high moisture levels. These spots are prime candidates for further investigation and potential repair. It's essential to act promptly when moisture is detected to prevent further damage and the spread of rot.

Remember, the moisture meter is a valuable tool for identifying wet areas, but it should be used in conjunction with other inspection methods. Visual inspections, feel tests, and the use of a stethoscope to listen for hollow sounds can also aid in a comprehensive assessment of the boat's condition. By combining these techniques, you can effectively detect and address rot in your fiberglass boat.

Boat Registration Numbers: Louisiana's Unique Identification System Explained

You may want to see also

Structural Integrity: Check for warped or damaged components

When inspecting a fiberglass boat for structural integrity, it's crucial to pay close attention to the condition of its components. One of the most common issues to look out for is warping or damage that could compromise the boat's strength and safety. Here's a step-by-step guide to help you identify potential problems:

Start by examining the boat's hull. Look for any visible signs of warping, such as bends or twists in the fiberglass. These can often be found along the waterline, where the hull meets the keel. Use a straight edge or a long ruler to check for any deviations from a straight line. Even slight warping can affect the boat's stability and performance. If you notice any warping, it's essential to have it assessed by a professional to determine the extent of the damage and the necessary repairs.

Next, inspect the boat's interior. Check for any signs of water damage, especially in areas where the hull meets the cabin or deck. Look for soft spots, discolored areas, or a musty smell, which could indicate the presence of rot. Pay attention to the condition of the interior panels, seats, and bulkheads. Warped or damaged components can lead to structural issues, making the boat unsafe for navigation. If you find any warped or damaged parts, carefully document the problem areas for further evaluation.

The boat's deck is another critical area to inspect. Look for any signs of warping or damage, especially around the gunwales and along the edges of the deck. Check for cracks, delaminations, or soft spots that might indicate rot. These issues can weaken the boat's structure and affect its overall integrity. If you notice any problems, it's crucial to address them promptly to prevent further damage.

Additionally, don't forget to inspect the boat's fasteners and hardware. Check for any loose or missing screws, bolts, or other fasteners that could lead to structural issues. Ensure that all hardware is tight and secure, as this plays a vital role in maintaining the boat's structural integrity.

Remember, regular maintenance and inspections are key to preserving the longevity and safety of your fiberglass boat. By carefully examining the boat's structure, you can identify potential issues early on and take the necessary steps to ensure its structural integrity remains intact.

Repairing a Leaking Boat Float: A Step-by-Step Guide

You may want to see also

Gelcoat Condition: Inspect for chalking or fading gelcoat finish

When it comes to maintaining and inspecting a fiberglass boat, one crucial aspect is the condition of the gelcoat. Gelcoat is a protective layer applied to the fiberglass hull, providing a smooth, durable finish that protects the underlying structure from UV rays, chemicals, and other environmental factors. Over time, however, gelcoat can deteriorate, leading to various issues, including chalking and fading.

Chalking is a common problem that occurs when the gelcoat begins to break down, releasing tiny particles of calcium carbonate, which then accumulate on the surface. This chalky residue can be easily noticed as a white, powdery substance on the boat's exterior. It is often more prominent in areas exposed to sunlight, such as the bow, sides, and deck. Chalking can be a sign of UV damage, as the intense sunlight causes the gelcoat to degrade, leading to a loss of its protective properties.

Fading of the gelcoat finish is another indicator of its deterioration. The vibrant colors and glossy appearance of a new gelcoat can fade over time due to prolonged sun exposure and environmental factors. This fading is not just an aesthetic concern but also a sign of potential damage. As the gelcoat fades, it becomes more susceptible to further degradation and may eventually lead to the exposure of the underlying fiberglass, which can result in more serious issues.

To inspect your boat for chalking and fading gelcoat, start by thoroughly cleaning the surface to remove any loose chalk. Use a mild detergent and a soft brush to gently scrub the affected areas. Pay close attention to areas that receive the most sunlight, as these are more prone to chalking and fading. After cleaning, examine the gelcoat closely for any signs of chalking or discoloration. Look for white powdery deposits or areas where the color has become dull and faded.

If you notice significant chalking or fading, it is essential to take action promptly. Consider applying a gelcoat repair kit or a specialized gelcoat restoration product to restore the finish. These products can help rejuvenate the gelcoat, reducing chalking and improving its overall appearance. Regular maintenance and inspections will ensure that your fiberglass boat remains in optimal condition, providing long-lasting protection and preserving its value.

Army of Thieves: Boat's Identity Unveiled

You may want to see also

Repair Techniques: Learn methods for filling and sanding small holes

When it comes to repairing small holes in a fiberglass boat, the process involves several steps to ensure a seamless and durable fix. Here's a detailed guide on the techniques you can employ:

Filling the Hole:

- Preparation: Start by cleaning the area around the hole. Remove any debris, dirt, or loose fibers using a wire brush or a small scraper. Ensure the surface is smooth and free from contaminants.

- Primer Selection: Choose an appropriate primer designed for fiberglass. This step is crucial as it provides a base for the filler and ensures proper adhesion. Apply the primer to the prepared area, following the manufacturer's instructions for drying time.

- Filler Application: Use a two-part epoxy filler or a fiberglass repair kit specifically formulated for small holes. Mix the components according to the package instructions, ensuring a consistent consistency. Fill the hole, pressing the filler into all gaps and crevices. You can use a putty knife or a small spatula for this step. Allow the filler to cure according to the product's guidelines, which may involve multiple layers and drying times.

- Smoothing and Fairing: Once the filler is cured, sand it gently with fine-grit sandpaper (e.g., 400-grit) to create a smooth surface. Remove any excess filler and blend it seamlessly with the surrounding area. This step requires patience to achieve a level and smooth finish.

Sanding and Finishing:

After filling the hole, the sanding process is essential to prepare the surface for further repairs or painting.

- Intermediate Sanding: Use slightly coarser sandpaper (e.g., 320-grit) to remove any imperfections and create a slightly textured surface. This step helps the final finish adhere better.

- Fine Sanding: Switch to a finer grit (e.g., 600-grit) for a smoother finish. Sand in the direction of the fiber layup to avoid fiber exposure. Ensure the surface is free from any debris or residue.

- Final Touches: For an even smoother finish, consider using a power sander or a fine-grit sandpaper block. This step is optional but can enhance the overall appearance of the repair.

Remember, when working with fiberglass, it's crucial to work in a well-ventilated area and wear appropriate protective gear, including gloves and a respirator. Practice these techniques in a controlled environment before attempting repairs on your boat to gain confidence and skill.

Understanding Boat Propulsion: Tunnel Drive Explained

You may want to see also

Frequently asked questions

Checking for rot in a fiberglass boat requires a thorough inspection. Start by visually examining the boat's surface for any signs of discolouration, soft spots, or delamination. Look for areas where the gelcoat (the outer layer) may be peeling or bubbling, as this could indicate underlying damage. Pay close attention to areas that are more susceptible to rot, such as the hull bottom, stringers, and compartments. If you notice any suspicious areas, use a sharp tool to gently probe the surface; if it feels soft or compresses easily, it may indicate rot.

Yes, having the right tools can make the process easier. A sharp, thin tool like a utility knife or a specialized marine inspection tool can help you probe the surface without causing further damage. You can also use a flashlight to illuminate the boat's interior and hard-to-see areas. Additionally, consider using a moisture meter, which can detect the presence of water or moisture within the fiberglass, indicating potential rot.

If you find any signs of rot, it's crucial to take immediate action. Start by cleaning the affected area to remove any dirt or debris. Then, depending on the severity, you may need to repair or replace the damaged section. For minor rot, you can use a fiberglass repair kit to fill and sand the area. However, for more extensive damage, it's best to consult a professional marine repair specialist who can provide the necessary expertise and materials to ensure a proper and safe repair.