Boat fuel gauges are essential instruments for monitoring fuel levels in watercraft, ensuring safe and efficient operation. Understanding how these gauges function is crucial for boaters to maintain their vessels effectively. The gauge operates by measuring the electrical current flowing through a fuel sender, which is connected to the fuel tank. This current varies based on the fuel level, with higher levels resulting in more current. The gauge then interprets this current to display the fuel level on a dial or digital screen, providing boaters with real-time information about their fuel reserves. This knowledge is vital for planning trips, avoiding fuel depletion, and ensuring the boat's engine remains healthy.

What You'll Learn

- Fuel Gauge Basics: Understanding the core function and types of fuel gauges

- Fuel Level Measurement: How gauges detect and display fuel volume

- Float Mechanism: The role of floats in measuring fuel height

- Send/Receive System: How electrical signals indicate fuel levels

- Calibration: Adjusting gauge accuracy for precise fuel readings

Fuel Gauge Basics: Understanding the core function and types of fuel gauges

A fuel gauge is an essential component in any vehicle, including boats, as it provides an accurate indication of the remaining fuel in the tank. Understanding how fuel gauges work is crucial for boaters to ensure they have enough fuel for their journeys and to avoid running out of gas in the middle of the water. The core function of a fuel gauge is to measure the amount of liquid in the fuel tank and display it to the driver or operator. This measurement is typically done through a combination of sensors and mechanical or electronic components.

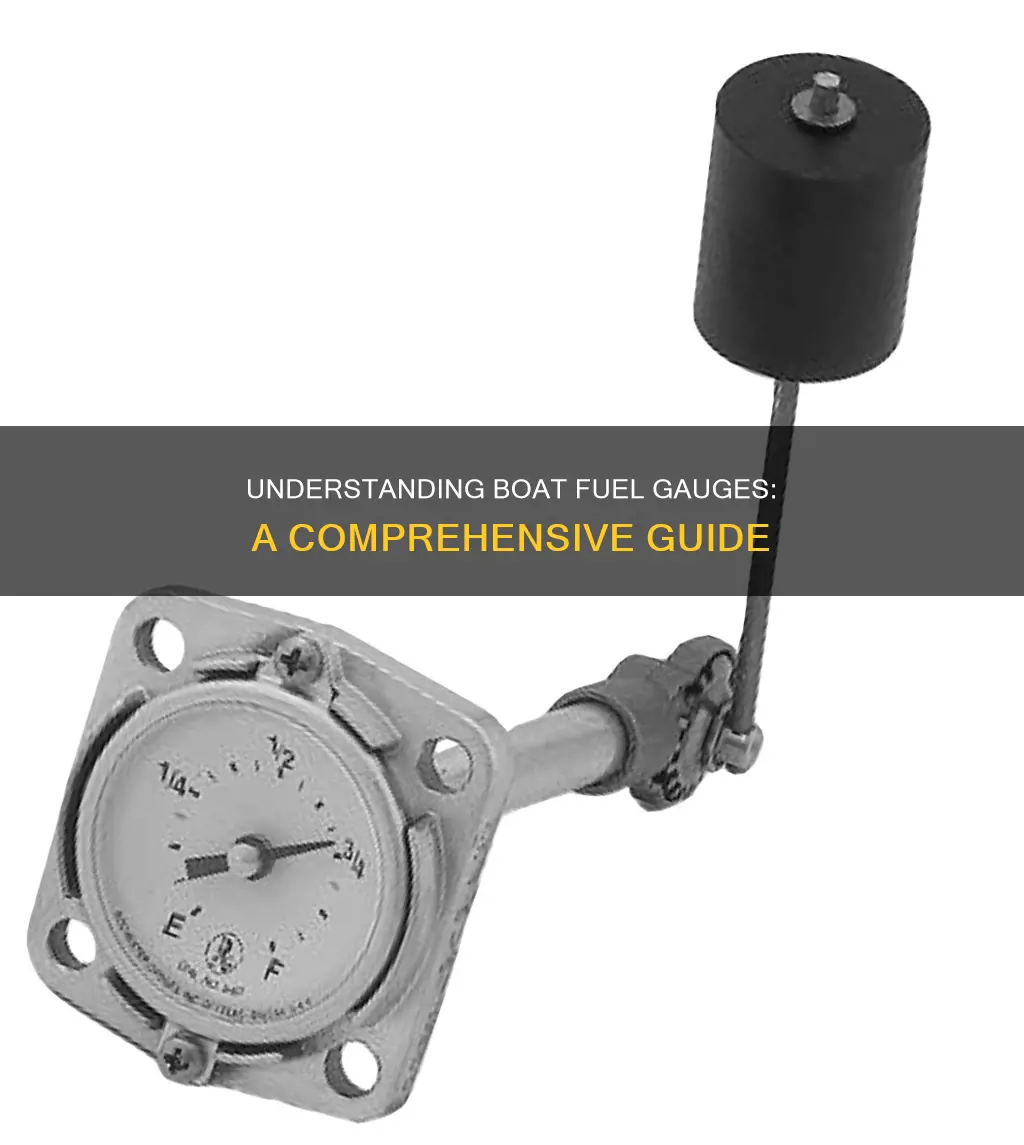

There are two primary types of fuel gauges commonly used in boats: mechanical and electronic. Mechanical fuel gauges use a float that rises and falls as the fuel level changes, which then moves a needle on a dial to indicate the fuel level. This traditional design has been used for many years and is still prevalent in older boats. The float is designed to be buoyant, so it floats on the fuel, and as the fuel level drops, the float descends, pulling the needle down accordingly. This method provides a visual representation of the fuel level, making it easy for boaters to estimate how much fuel is left.

Electronic fuel gauges, on the other hand, use sensors and electrical signals to measure the fuel level. These gauges often feature a digital display, providing a more precise and easy-to-read indication. They typically consist of a float or a pressure sensor that sends signals to the gauge's electronic control unit (ECU). The ECU then processes this data and displays the fuel level on a screen, often with additional information like the total fuel capacity and warning indicators for low fuel. Electronic gauges are more advanced and offer improved accuracy, especially in modern boats with complex fuel systems.

Both types of fuel gauges rely on the principle of measuring the fuel level relative to the tank's capacity. The gauge's sensitivity and accuracy are crucial factors in ensuring reliable fuel monitoring. For instance, a mechanical gauge's float must be properly calibrated to provide accurate readings. Similarly, electronic sensors need to be calibrated and maintained to function correctly. Regularly checking and calibrating the fuel gauge is essential to ensure its reliability and prevent potential issues during boating trips.

Understanding the mechanics and types of fuel gauges is fundamental for boaters to make informed decisions about their vessel's fuel management. By knowing how these gauges work, boaters can better estimate their fuel consumption, plan their journeys, and ensure they have sufficient fuel for safe and enjoyable trips. Additionally, being aware of the different types of fuel gauges allows boaters to choose the most suitable option for their boat's specific needs and preferences.

The Rise of Boat Shoes in the 1980s

You may want to see also

Fuel Level Measurement: How gauges detect and display fuel volume

Fuel gauges are essential components in any vehicle, including boats, as they provide a visual indication of the fuel level, ensuring that the operator is aware of the remaining fuel in the tank. The primary function of a fuel gauge is to measure and display the volume of fuel in the tank, allowing the operator to make informed decisions about refueling. This is particularly crucial for boats, as it enables safe navigation and prevents running out of fuel in remote areas.

The measurement of fuel volume is typically achieved through a combination of mechanical and electronic systems. In older boat models, a traditional mechanical fuel gauge is often used, which operates based on the principle of buoyancy. This type of gauge consists of a float that is attached to a needle or pointer. The float is designed to rise and fall within a calibrated tube filled with fuel. As the fuel level changes, the float's position alters, causing the needle to move accordingly, providing a visual representation of the fuel volume. This mechanical system is straightforward and reliable, offering a clear indication of the fuel level.

In modern boats, electronic fuel gauges have become increasingly popular due to their accuracy and advanced features. These gauges utilize a sensor or transducer that measures the electrical conductivity or pressure of the fuel. The sensor is typically placed in the fuel tank, where it comes into direct contact with the fuel. When the fuel level changes, the sensor detects this variation and sends an electrical signal to the gauge's display unit. This signal is then processed to calculate the fuel volume and display it on a digital or analog meter. Electronic gauges often provide additional features such as real-time fuel consumption monitoring, low-fuel alerts, and even wireless connectivity for data transfer.

The process of fuel level detection involves several key components. Firstly, the fuel sensor, which can be a float-type or a pressure/conductivity sensor, is crucial. Float-type sensors use a magnetic or mechanical linkage to transmit the fuel level information, while pressure sensors measure the fuel's specific gravity or density. Conductivity sensors, on the other hand, detect the electrical properties of the fuel. These sensors provide accurate measurements of the fuel's position within the tank. Secondly, the gauge's display unit, which can be analog or digital, plays a vital role in presenting the fuel volume data to the operator. Analog displays use a needle or pointer, while digital displays show the fuel level as a numerical value or a bar graph.

In summary, fuel level measurement in boat gauges is a critical aspect of vehicle management. Both mechanical and electronic systems are employed to detect and display fuel volume accurately. The traditional mechanical gauge uses buoyancy principles, while electronic gauges utilize sensors and electrical signals. These mechanisms ensure that boat operators can make informed decisions about refueling, contributing to safe and efficient boating experiences. Understanding the inner workings of fuel gauges empowers operators to maintain their vessels effectively and avoid unexpected fuel-related issues.

Sanding an Aluminum Jon Boat: The Ultimate Guide

You may want to see also

Float Mechanism: The role of floats in measuring fuel height

The float mechanism is a fundamental component of fuel gauges in boats, ensuring accurate fuel level readings. This system relies on a simple yet ingenious design: a float that rises and falls with the fuel level in the tank. When the boat's fuel tank is filled, the float is submerged, and as the fuel level decreases, the float moves upward. This movement is directly proportional to the fuel height, providing a visual indication of the remaining fuel.

At the heart of this mechanism is the float, typically made of lightweight materials like plastic or metal. It is designed to displace a specific volume of fuel, which is crucial for accurate measurement. The float is connected to a needle or pointer on the gauge's face, often through a slender tube or rod. As the float moves, it pulls the needle, causing it to rotate and indicate the fuel level. This design ensures that the gauge provides a real-time representation of the fuel height.

The float's position is influenced by the specific gravity of the fuel. Different fuels have varying densities, and this property affects how the float interacts with the fuel. For instance, if the fuel is less dense, the float will rise higher for the same volume, requiring adjustments to the gauge's calibration. This consideration is essential for accurate fuel level readings across different fuel types.

In operation, the float mechanism offers a reliable and cost-effective solution for fuel level monitoring. It eliminates the need for complex electronic sensors, making it a popular choice for boats and other vehicles. The simplicity of the design also contributes to its durability, ensuring long-lasting performance. However, it's important to note that regular maintenance and calibration are necessary to ensure the gauge's accuracy, especially after refuelling or when the fuel type changes.

Understanding the float mechanism is key to appreciating the functionality of boat fuel gauges. This basic principle allows for the continuous monitoring of fuel levels, providing boaters with essential information for safe navigation and efficient fuel management. By grasping the role of floats, boat owners can better maintain their vessels and ensure a reliable fuel supply during their aquatic adventures.

Positioning Subwoofers in Daycruiser Boats: Best Placement Options

You may want to see also

Send/Receive System: How electrical signals indicate fuel levels

The fuel gauge in a boat is an essential component for monitoring the vessel's fuel levels, ensuring safe and efficient operation. It operates through a send/receive system, which utilizes electrical signals to provide real-time updates on the fuel status. This system is designed to be both reliable and user-friendly, offering a clear indication of the remaining fuel in the tank.

At the heart of this system is a sender unit, typically located within the fuel tank. This unit is responsible for measuring the fuel level and converting it into an electrical signal. It does so by utilizing a float or a similar mechanism that moves in response to the fuel level. As the fuel level rises or falls, the float's position changes, and this movement is translated into an electrical signal. This signal is then transmitted to the receiver unit.

The receiver unit is usually mounted in a convenient location within the boat's dashboard or console. It is designed to interpret the electrical signal received from the sender unit and provide a visual or audible indication of the fuel level. This receiver can display the fuel level as a percentage, a specific value, or a simple green-to-red indicator, making it easy for the boat operator to quickly assess the fuel situation.

The electrical signal transmission ensures that the fuel gauge provides accurate and immediate feedback. When the fuel level is low, the sender unit sends a weak signal, and the receiver interprets this as a low-fuel condition, triggering a visual or audible warning. Conversely, when the fuel tank is nearly full, the sender unit sends a stronger signal, indicating a higher fuel level. This system allows for efficient management of fuel resources, preventing unexpected runouts during boating trips.

In summary, the send/receive system in boat fuel gauges is a sophisticated yet straightforward mechanism. It employs electrical signals to bridge the gap between the fuel tank and the operator's dashboard, providing a clear and immediate representation of the fuel level. This system is a vital safety feature, ensuring that boat owners can make informed decisions about their fuel usage and plan their journeys accordingly.

Boat Wake: How Far Does It Really Travel?

You may want to see also

Calibration: Adjusting gauge accuracy for precise fuel readings

Calibration is a critical process to ensure the accuracy and reliability of your boat's fuel gauge. Over time, fuel gauges can drift and provide inaccurate readings, which can lead to poor fuel management and potentially dangerous situations on the water. By calibrating your gauge, you can restore its precision and ensure that you have an accurate representation of your fuel levels. Here's a step-by-step guide on how to calibrate your boat's fuel gauge for precise fuel readings:

Step 1: Understanding the Process

Before you begin, it's essential to understand the basic principle of fuel gauge calibration. Fuel gauges typically work by measuring the electrical resistance or pressure in the fuel tank. This measurement is then converted into a fuel level reading. Calibration involves adjusting the gauge's settings to match the actual fuel levels in the tank.

Step 2: Gathering the Tools

You'll need a few tools to calibrate your fuel gauge. Firstly, a fuel gauge tester or a multimeter with an ohmmeter function is essential. This tool will help you measure the electrical resistance or pressure in the fuel tank. Additionally, you might need a small screwdriver or a similar tool for adjusting the gauge's settings.

Step 3: Draining the Tank

For accurate calibration, it's crucial to drain the fuel tank partially. This step ensures that you're measuring the actual fuel level and not the residual fuel at the bottom of the tank. Carefully drain the tank until you reach a point where the gauge reads zero. Take note of the fuel level at this point.

Step 4: Measuring and Adjusting

Using the fuel gauge tester, measure the electrical resistance or pressure at the fuel level you noted in Step 3. Compare this measurement with the gauge's reading. If there's a discrepancy, you'll need to adjust the gauge's settings. Turn the gauge's adjustment screw (usually located on the back or side) to calibrate it. The goal is to make the gauge read the correct fuel level at the drained tank position.

Step 5: Re-filling and Testing

Once you've adjusted the gauge, re-fill the tank with fuel and allow it to settle. Then, check the gauge's reading against the actual fuel level. If the gauge is still inaccurate, repeat the adjustment process until you achieve precise readings.

Step 6: Regular Maintenance

Calibration should be done periodically, especially if you frequently use your boat or notice any discrepancies in fuel readings. Regular maintenance ensures that your fuel gauge remains accurate and reliable, providing you with the confidence to manage your fuel effectively during boating trips.

Remember, proper calibration is essential for safe boating and efficient fuel management. By following these steps, you can ensure that your boat's fuel gauge provides accurate and reliable fuel readings, allowing you to make informed decisions about your vessel's fuel consumption.

Exploring Docking Options for Boaters at New Ports

You may want to see also

Frequently asked questions

Boat fuel gauges typically use a sending unit that is connected to the fuel tank. This sending unit has a float that rises and falls as the fuel level changes. The float is connected to a wire or rod, which moves a needle or pointer on the gauge, indicating the fuel level.

The float is a critical component that directly interacts with the fuel. It is designed to float on the surface of the fuel, and its position relative to the tank's capacity determines the fuel level. As the fuel level rises or falls, the float moves accordingly, providing an accurate reading to the gauge.

Yes, fuel gauges can be calibrated to ensure accuracy. If the gauge is not reading correctly, it may be due to a calibration issue. This process involves adjusting the gauge's settings to match the actual fuel capacity and the gauge's scale. Proper calibration ensures that the fuel gauge provides an accurate representation of the fuel remaining.

Several factors can lead to inaccurate fuel gauge readings. These include air bubbles in the fuel line, sending unit malfunctions, or issues with the gauge's wiring. Air bubbles can cause the float to float higher than the actual fuel level, while sending unit problems may result in incorrect signals being sent to the gauge. Wiring issues can also disrupt the gauge's functionality.

It is recommended to check the fuel gauge's accuracy regularly, especially before long trips or when there are significant changes in fuel consumption. You can do this by adding a known quantity of fuel and observing the gauge's reading. If the gauge doesn't match the actual fuel added, it may require calibration or further investigation to identify the issue.