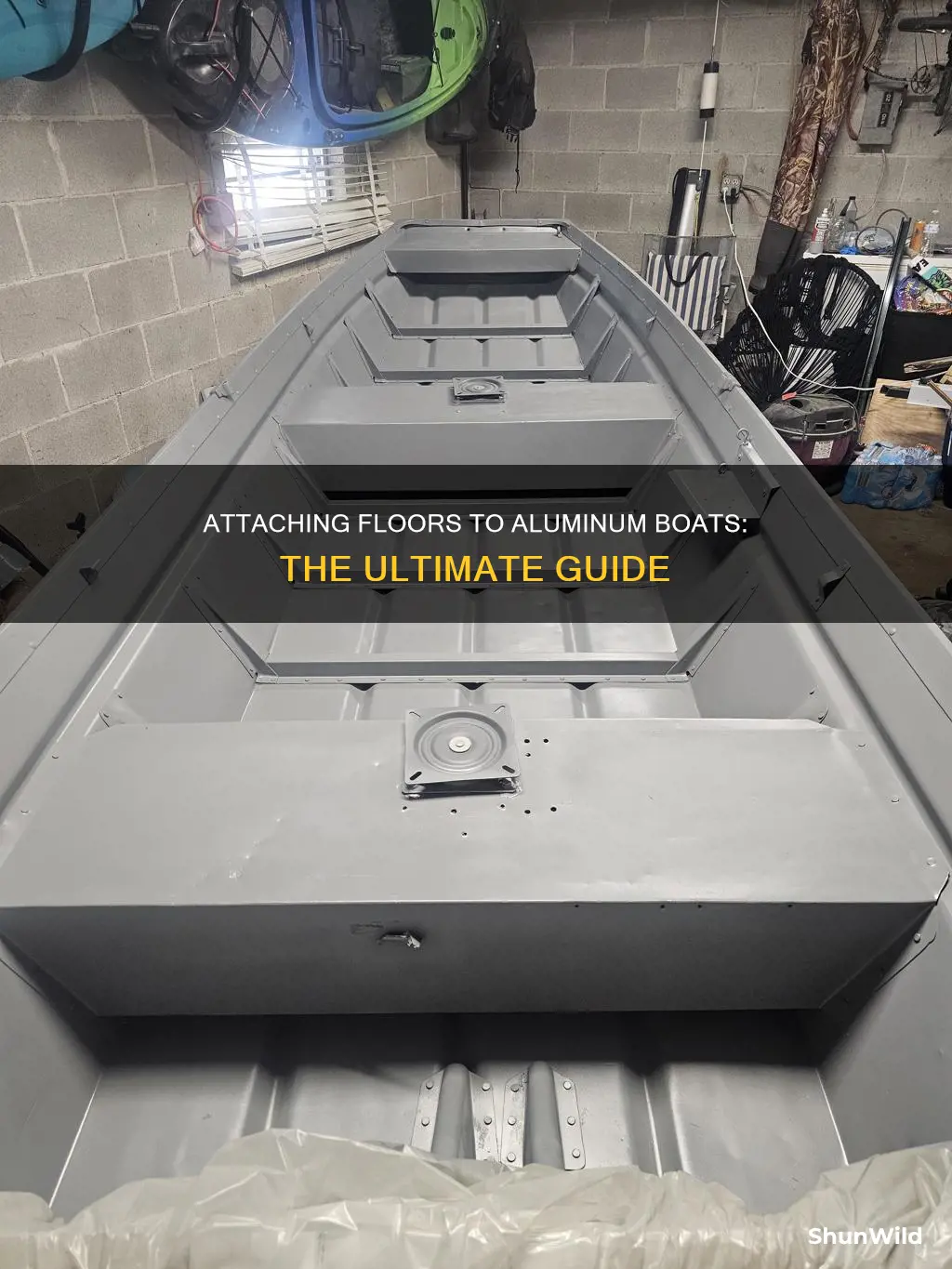

There are many ways to attach a floor to an aluminium boat. One of the most popular methods is to use rivets, specifically 3/16 aluminium wide flange rivets or 3/16 solid aluminium rivets. Some people also use stainless rivets or self-tapping sheet metal screws. One person used Velcro to attach their boat floor, which they found worked very well and allowed for easy access for maintenance. Another option is to use nutserts to attach the floor, although getting the floor lined up with the threads can be tricky. When it comes to the flooring material, marine-grade plywood is a popular choice, although some people also use aluminium sheet metal or Veranda HP PVC sheets.

| Characteristics | Values |

|---|---|

| Materials | Marine-grade plywood, aluminium, screws, rivets, weld, velcro, staples, glue, paint, oil, silicone, vinyl, carpet |

| Tools | Safety glasses, hearing protection, leather gloves, tape measure, saw, drill, air compressor, air hammer, staple gun, pop rivet gun, jig saw, circular saw, tapered punch set, screwdriver, hammer, chisel, punch |

| Techniques | Drilling, cutting, splicing, stapling, gluing, welding, sealing, riveting, dry-fitting, aligning, measuring, trimming, sanding, inspecting, filling, marking, punching, tightening |

What You'll Learn

Use screws, rivets or weld to attach the floor

When it comes to attaching a floor to an aluminium boat, you have a few options: screws, rivets, or welding. Each method has its own advantages and considerations. Here is a detailed guide to help you decide which option is best for your project:

Screws:

Screws are a popular choice for attaching a floor to an aluminium boat. They offer the advantage of being easy to install and providing a secure hold. When using screws, it is recommended to use stainless steel screws with collars to prevent them from coming loose over time. It is also important to pre-drill holes and use a screwdriver to slowly screw them in, ensuring that the carpet or flooring material is not damaged. Consider using "oval" head screws with screw head cup washers to prevent water from sitting on top of the screws.

Rivets:

Rivets are another common method for attaching boat floors. They provide a strong and quick installation. When using rivets, opt for large-headed, large-diameter rivets made of stainless steel or aluminium to prevent corrosion. Using an air riveter can make the process faster and ensure a secure fit. If you ever need to replace the floor, simply drill the heads off with a sharp bit.

Welding:

Welding is a permanent solution for attaching a boat floor. It provides a strong and secure hold but may not be the best option if you anticipate needing to access the underside of the floor for maintenance. Welding is also a more involved process that may require additional equipment and expertise. Consider the ease of future maintenance and the initial investment in equipment when deciding whether to weld your boat floor.

Additional Considerations:

When attaching a floor to your aluminium boat, there are a few other factors to keep in mind. Firstly, ensure that your boat has adequate supports to eliminate flexing, especially if you're considering using Velcro or screws. Additionally, take into account the type of flooring material you'll be using. Plywood flooring, for example, can be coated with epoxy for added protection.

Boat Insurance in PA: What's the Law?

You may want to see also

Seal the plywood floor with oil-based paint

Sealing the plywood floor with oil-based paint is an important step in the process of attaching a floor to an aluminium boat. This step will help to extend the life of the plywood by providing protection from the elements.

To begin, you will need to gather your materials and tools. These include oil-based paint, a paintbrush or roller, sandpaper, a clean cloth, and a sanding sealer. It is also recommended to wear safety gear such as gloves, eye protection, and a respirator when working with these materials.

The first step in sealing the plywood is to sand the surface. Using 80-grit sandpaper, sand the plywood in a back-and-forth motion along the natural grain of the wood. Repeat this process with 120-grit sandpaper for a smoother finish. Wipe away any dust with a clean cloth.

Next, apply a sanding sealer to the plywood using a clean paintbrush. Ensure that you coat the surface evenly and levelly to avoid a rough finish. Allow the sealer to dry according to the manufacturer's instructions. If you are sealing both sides of the plywood, finish one side first and let it dry before moving on to the other side.

Once the sealer is dry, lightly sand the surface again using 120-grit sandpaper. This will help to remove any bumps and create a smooth finish. Wipe away any dust, then apply a final coat of the sanding sealer and allow it to dry.

Finally, you can apply the oil-based paint to the plywood. Use a paintbrush or roller to apply an even coat, following the directions on the paint can for drying times. You may need to apply multiple coats for the best results.

By following these steps and allowing adequate drying time between coats, you will effectively seal your plywood floor with oil-based paint, ensuring its longevity and performance in your aluminium boat.

Exploring the Boat Route: Stormwind to Orgrimmar

You may want to see also

Use aluminium or stainless steel rivets

When it comes to attaching a floor to an aluminium boat, the use of aluminium or stainless steel rivets is a common method. Here are some detailed instructions and considerations for this process:

Choosing the Right Rivets:

It is essential to select the appropriate rivet material to prevent galvanic corrosion. Using aluminium rivets to attach an aluminium floor is generally recommended to avoid corrosion issues. However, if you choose stainless steel rivets, it is crucial to apply a corrosion inhibitor like Tef Gel, Lanocote, Neverseze, or Locktite.

Preparing the Rivets and Surfaces:

Before riveting, ensure that the surfaces of the aluminium floor and the boat are clean and dry. Apply a corrosion inhibitor to the rivets as per the manufacturer's instructions. It is also recommended to use a marine-grade sealant or epoxy to seal the rivet holes and create a watertight seal.

Riveting Techniques:

When riveting, it is crucial to work in a systematic manner to ensure an even and secure attachment. Start by drilling holes in the aluminium floor and the boat frame, ensuring they are aligned and spaced appropriately. Insert the rivets into the holes and secure them with a rivet gun or hand riveter. Ensure the rivets are tight and flush with the surface.

Maintenance and Inspection:

Rivets should be inspected periodically for any signs of corrosion or loosening. It is essential to address any issues promptly to maintain the integrity of the floor attachment. If necessary, replace corroded or loose rivets with new ones, following the same procedure as the initial installation.

Advantages of Rivets:

Rivets are favoured over screws for boat floors because they are less likely to back out due to the twisting and pounding of waves. They provide a strong and durable connection, ensuring the floor stays securely in place. Additionally, rivets can be easily drilled out for maintenance or repairs, making them a convenient choice for boat construction and maintenance.

Understanding the Power of Two-Stroke Boat Engines

You may want to see also

Consider the weight of the floor

When installing a floor in an aluminium boat, it's important to consider the weight of the floor. The weight of the floor will impact the boat's performance and capacity. A heavier floor will reduce the boat's speed and fuel efficiency, while a lighter floor will improve performance. Additionally, a heavier floor may require additional support structures to be installed, adding to the overall weight of the boat. Therefore, it is crucial to select an appropriate flooring material that balances weight and durability.

Plywood is a popular choice for boat flooring due to its strength and relatively light weight. Marine-grade plywood is recommended to ensure resistance to water damage. However, some boat owners prefer aluminium floors for their durability and ease of installation. Aluminium floors can be welded or riveted in place, creating a strong and long-lasting connection.

When choosing the type of flooring, it's essential to consider the intended use of the boat. If the boat will be used for fishing or carrying heavy equipment, a stronger and more durable floor may be necessary. In contrast, if the boat is primarily for recreational use, a lighter-weight floor may be sufficient. Additionally, the frequency of use and the expected load should be considered when selecting the flooring material.

It's also worth noting that the weight of the floor can affect the boat's handling and stability. A heavier floor can lower the boat's centre of gravity, making it more stable in rough waters. On the other hand, a lighter floor can make the boat feel more responsive and easier to manoeuvre. Therefore, it's crucial to strike a balance between weight and durability when selecting a flooring option.

Overall, carefully considering the weight of the floor is a critical aspect of installing a floor in an aluminium boat. By choosing an appropriate flooring material and taking into account the intended use and performance requirements, you can ensure a safe and enjoyable boating experience.

The Mystery of Todd's Fate on the Patricia Lee

You may want to see also

Ensure the floor is safe and doesn't affect the centre of gravity

Ensuring the safety of your boat and maintaining its centre of gravity are crucial considerations when attaching a floor to an aluminium boat. Here are some detailed instructions to help you achieve this:

- Use the Right Materials: Opt for marine-grade plywood of the same thickness as the original floor. This ensures the new floor doesn't affect the alignment between the boat seat and hull rivet holes. Additionally, select an appropriate coating or carpeting for the floor.

- Mind the Thickness: While thicker plywood may seem sturdier, it also adds significant weight to your boat. Consider using lighter alternatives like aluminium sheets or even cardboard as a template for your floor plan.

- Be Mindful of the Centre of Gravity: Raising the floor too high will alter the boat's centre of gravity, making it more unstable and prone to tipping. Keep the floor as low as possible to maintain the boat's original centre of gravity.

- Consider Weight Distribution: Distribute weight evenly and avoid placing heavy items too high. This will help lower the centre of gravity and improve stability.

- Use the Right Fasteners: Choose fasteners that are compatible with the aluminium hull to prevent galvanic corrosion. Stainless steel rivets or screws are often recommended, but some people also suggest using Velcro for easier maintenance access.

- Seal Properly: Seal the plywood floor with oil-based paint or epoxy to protect it from water damage and extend its lifespan.

- Test for Stability: Once you've installed the new floor, test the boat's stability in different conditions. Make adjustments as necessary to ensure the boat remains upright and stable during operation.

The Boston Whaler 13 Sport: A Classic, Versatile Boat

You may want to see also

Frequently asked questions

You can use screws, rivets, or weld the floor in place. Some people prefer screws because they are easier to remove than rivets, but rivets are less likely to come loose. If you use rivets, make sure they are large-head aluminum or stainless steel rivets, not the pop rivets used by some boat manufacturers, as these can come loose over time. If you are confident in your welding skills, welding can be a permanent solution.

Yes, sealing the plywood floor of your aluminum boat is important to extend its life. Use a good-quality oil-based paint and apply two coats to all surfaces, allowing each coat to dry for 24 hours.

It is recommended to use marine-grade plywood for the floor of your aluminum boat. Marine plywood is made from better materials, has no internal voids, and uses waterproof glue. Regular plywood may have internal voids and non-waterproof glue, which can shorten its life. Do not use treated lumber, as the chemicals can react with the aluminum and cause corrosion.

To remove the old floor from your aluminum boat, start by removing the seats and any other storage compartments that are attached to the hull using solid aluminum rivets. Drill out the rivets, taking care to center the bit as much as possible to avoid damaging the surrounding material. Once the rivets are removed, lift out the seats and compartments. Next, remove the old floor, which is likely held in place by aluminum pop rivets or screws. Again, drill out the rivets or remove the screws, and lift out the old floor.

First, seal the plywood floor and allow it to dry. Then, if necessary, splice the plywood sections together using an aluminum strap and large flange rivets. Install the floor covering, gluing it to the plywood and stapling it in place. Finally, place the new floor into the boat and drill holes for the pop rivets to secure it to the supports. Apply marine silicone to the rivets before installing them.