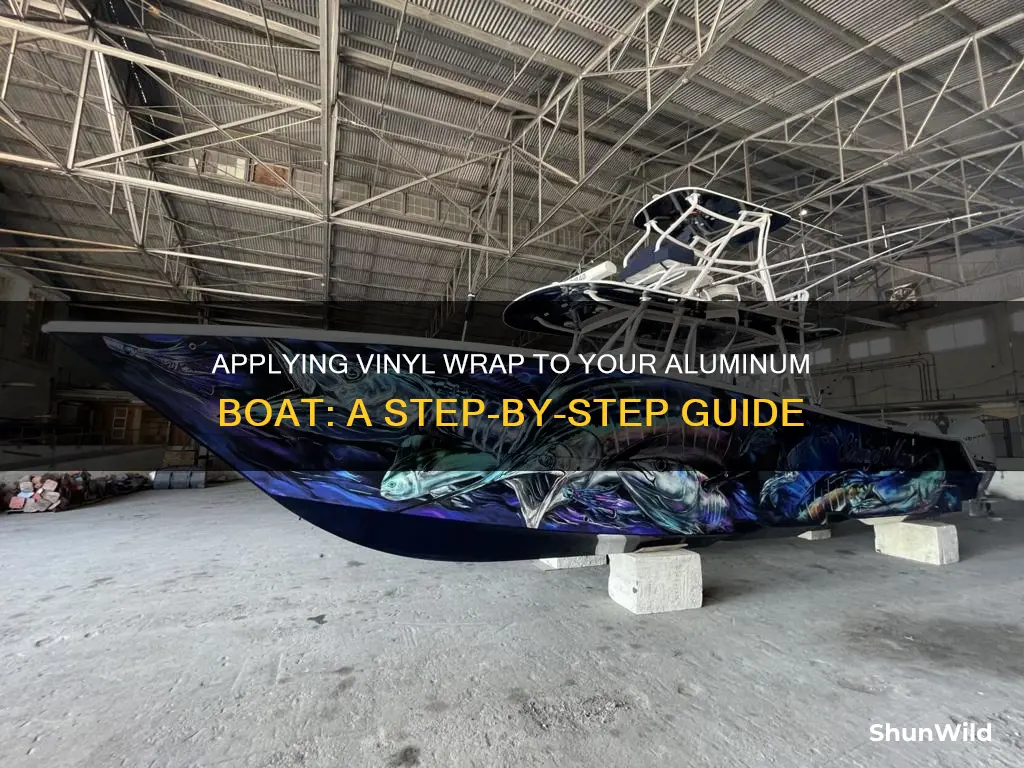

Applying a vinyl wrap to your boat is a great way to give it a new lease of life. It's a cost-effective way to change the colour of your boat without the commitment or expense of a permanent paint job. Vinyl wraps are also quicker to apply than paint, and they offer enhanced appeal and total customisation. You can add a personal touch to your boat or use it as an advertising opportunity for your business. They're also easy to repair and can be removed without damaging the existing paint.

| Characteristics | Values |

|---|---|

| Cost | Cheaper than a marine paint job or gel coat |

| Time Efficiency | Faster than painting |

| Durability | Less durable than paint but easy to patch |

| Design | Customisable design |

| Fade Resistance | More fade-resistant than paint |

| Installation | Requires professional installation |

| Protection | Protects against UV rays and material deterioration |

| Maintenance | Requires minimal maintenance |

What You'll Learn

Preparing the surface

Before applying a vinyl wrap to an aluminium boat, the surface must be meticulously prepared. The application surface should be in "like new" condition, and any existing styling lines, graphics, and name badges should be removed. Scratches, lumps, or bumps should be removed or filled. This can be done using a hairdryer to warm the vinyl and a paint scraper to gently peel it off. It is important to note that this process may need to be adapted for an aluminium boat, as one source suggests that cutting around rivets on an aluminium hull could be tedious.

Once the surface is smooth, it should be washed with soapy water to remove any salt or grime. After washing, the surface should be wiped with a panel to remove any remaining greasy residues. The surface must then be kept dust-free as dust and particles can cause small bumps under the vinyl.

The next step is to apply a very thin Kevlar cutting filament along the top and bottom edges of the topsides to mark where the vinyl will start and finish. It is important to note that vinyl wraps are not designed for use below the waterline, so you will need to decide whether the vinyl will butt up to the antifouling paint or stop a few inches short, leaving a strip of exposed gel-coat or a painted line.

Best Destinations for Your Boat Vacation

You may want to see also

Applying the vinyl

The first step in applying the vinyl wrap is to prepare the surface of the boat. This involves removing any existing styling lines, graphics, name badges, and scratches. A hairdryer can be used to warm up and lift off the old vinyl, and a paint scraper can be used to gently peel it off. The surface should then be washed with soapy water to remove any salt or grime and ensure it is clean and ready for the vinyl application.

Next, a very thin Kevlar cutting filament is applied along the top and bottom edges of the boat to delineate where the vinyl will start and finish. The vinyl wrap comes in 1.5m wide strips that are unravelled along the length of the hull and hung loosely from the rubbing strip. The backing strip is then peeled off, exposing the adhesive surface, which is pressed onto the boat using a flexible plastic squeegee.

Strategic use of a heat gun is crucial to 'relax' the vinyl so that it stretches smoothly over the contours of the boat. Star-shaped cuts are made around details such as skin fittings, and overlapping vinyl is carefully cut away with a scalpel to create a perfect join. Once all the intricate areas are covered, a final pass with the heat gun is made to eliminate any memory effect and set the vinyl in position.

The process is repeated on the other side of the boat, with a 2-inch overlap at the bow where the two sides meet. The join is barely visible, especially with darker colours. The entire process can be completed in a day or two, depending on the complexity of the design.

It is important to note that applying vinyl without leaving bubbles, ridges, and cutouts can be tricky. Therefore, it is recommended to seek professional help or refer to detailed guides for a smooth and proper application.

Sailing Near Crystal Lake: Best Boat Spots

You may want to see also

Using a heat gun

A heat gun is an essential tool when applying a vinyl wrap to an aluminium boat. It is used to provide heat to the vinyl wrap, making it more flexible and easier to work with during the installation process. Here is a detailed guide on how to use a heat gun when wrapping an aluminium boat with vinyl:

Before beginning the vinyl application, ensure that the boat's surface is thoroughly cleaned and free of any contaminants, especially dust, as this can compromise the strength of the vinyl's adhesive. Use cleaning supplies recommended by the boat manufacturer to achieve a "like new" surface.

When applying the vinyl wrap, start by laying the long strips of vinyl onto the surface, taking care when going around compound curves, hull windows, specialised features, and spray rails. Use a heat gun to apply heat to the vinyl, making it more pliable and easier to stretch and manoeuvre around tight corners and curves. The heat will help you achieve a smooth, tight fit without creases or air bubbles.

Once the vinyl is in the desired position, use a flexible plastic squeegee to press the vinyl onto the surface firmly. This step helps remove any remaining air bubbles and activates the adhesive. Pay particular attention to areas around details and fittings, using a scalpel to cut the vinyl for a perfect join.

After the vinyl is adhered, go over the entire surface with the heat gun once more. This final step ensures that the vinyl fully conforms to the shape of the boat and removes any memory effect, setting the vinyl in position for a long-lasting finish.

Toms Boat Shoes: Are They Worthy?

You may want to see also

Cutting the vinyl

Planning the Cut:

Before making any cuts, it is important to plan the layout of the vinyl wrap. Measure the boat's surfaces, including the hull, superstructure, and interior areas like doors and cabinets. Determine the placement of the vinyl strips to achieve a smooth and uniform finish.

Preparing the Vinyl:

The vinyl wrap comes in large rolls, typically with a width of 60 inches. Unroll the vinyl and cut it into strips that are slightly longer than the height of the boat's surfaces. This will allow for some overlap and ensure full coverage.

Cutting Technique:

When cutting the vinyl, use a sharp blade or scalpel. Carefully cut the vinyl in a straight line, ensuring that the edges are smooth and free of any jagged tears. It is important to work on a clean, flat surface to achieve accurate cuts.

Star-Shaped Cuts:

For areas with details or fittings, create star-shaped cuts around these elements. These cuts will allow the vinyl to fit snugly around protrusions and create a seamless finish. Overlapping vinyl can then be carefully trimmed with a scalpel for a precise join.

Heat Application:

Strategic use of a heat gun is crucial to achieving a smooth finish. Apply heat to 'relax' the vinyl, allowing it to stretch and conform to the boat's contours. This is especially important when wrapping around curved surfaces or tight corners.

Final Trimming:

Once the vinyl is applied and heat-treated, use a sharp blade to trim away any excess material. Carefully cut along the edges of the boat's surfaces, ensuring a precise and straight cut. Remove any backing strips or protective layers before proceeding.

Overlapping Seams:

For larger boats that require multiple vinyl strips, create overlapping seams. Position the seams strategically to minimise their visibility. Typically, a 2-inch overlap is sufficient to ensure a strong bond and a seamless appearance.

Quality Assurance:

Throughout the cutting process, regularly check your work for accuracy and precision. Ensure that the cuts are straight and smooth, and all excess material is removed. A keen eye for detail is essential to achieving a high-quality finish.

Remember, taking your time during the cutting process will pay off in the final result. A well-cut vinyl wrap will not only look seamless but also provide better protection for your boat's surfaces.

Repairing a Boat Transom: A Comprehensive Guide to Fixing Yours

You may want to see also

Aftercare and maintenance

Once your aluminium boat has been vinyl-wrapped, it's important to take good care of it to ensure the wrap lasts a long time and continues to look its best. Here are some detailed aftercare and maintenance tips:

Cleaning

Dirt and grime buildup can reduce the lifespan of your vinyl wrap and affect its overall quality, so regular cleaning is essential. Compared to boat paint, cleaning vinyl boat wraps is generally easier. When cleaning, always be gentle and use only water, a marine-safe soap, and a soft cloth or sponge. Avoid using solvents or abrasives, as they can damage the vinyl. For tough dirt or contaminants, an ultra-soft brush can help with additional scrubbing power. After cleaning, dry the boat with a microfiber towel to prevent water spots.

It is recommended to wait at least a week after the vinyl wrap has been applied before washing your boat for the first time. This allows the vinyl enough time to properly adhere to the hull. If you use your boat regularly, stick to a regular wash schedule to maintain its appearance.

Polishing

If you wish to polish or wax your vinyl wrap to add shine, only use gentle, high-quality formulas that are suitable for vinyl and marine-safe. Avoid using abrasive waxes. Do not polish textured wraps or matte finishes, as this can damage them.

Transportation

When transporting or hauling your boat in or out of the water, add a protective layer between the lifts and wraps to prevent damage to the graphics.

Sunlight Exposure

Prolonged exposure to direct sunlight can harm your boat wrap, so keep it away from sunlight when not in use. Even though vinyl wraps are made with UV-resistant material, it's best to store your boat away from the sun or use a UV-protective cover during the off-season.

Repairs

Vinyl wraps are easy to maintain and repair. In the case of scratches or dents, you can simply cut around the affected area and apply a patch. While it may not be perfect, it will be a quicker, easier, and cheaper solution than a professional gel-coat repair.

Longevity

The longevity of a boat wrap depends on various factors, including material quality, installation practices, climate, and the type of vinyl and adhesive used. Most permanent adhesives and vinyl should last for around seven years, sometimes longer, depending on the colour and the surface it is applied to. For example, solid colours tend to have better fading resistance than metallic colours, and vertical surfaces last longer than horizontal ones.

Replacing Boat Earphones: Using Your Warranty for New Ones

You may want to see also

Frequently asked questions

Vinyl wrapping your boat is a cheaper and quicker alternative to painting it. It offers enhanced appeal and total customisation, allowing you to add your company logo or a personal touch to your boat. It also provides an extra layer of protection to the underlying paint, safeguarding it from scratches and UV damage.

The downtime for a hull wrap is typically one-third but can be as little as a quarter of the time required to prep and paint. For smaller boats, it can be as fast as one day.

There is no need to buff or polish a vinyl wrap. You can simply wash it with mild soap and water using a soft cloth. Do not use a pressure washer or abrasive brush as this may cause small tears.