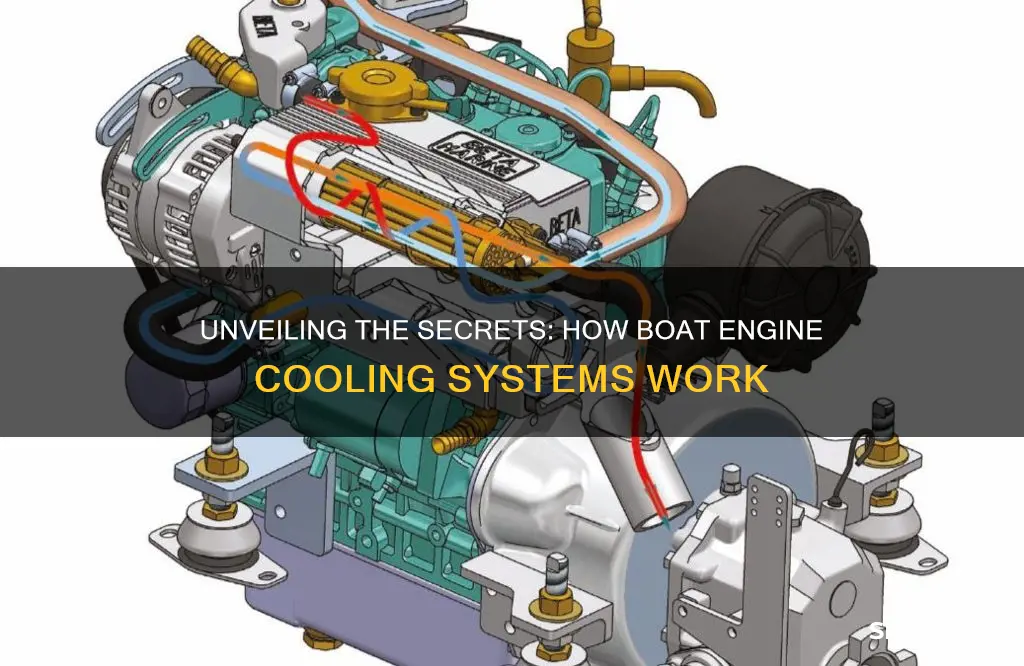

Cooling systems are essential for maintaining the optimal performance and longevity of boat engines, especially in the demanding marine environment. Understanding the cooling process is crucial for boat owners and operators to ensure their engines run efficiently and avoid overheating. This paragraph will explore the mechanisms behind cooling systems, detailing how they regulate engine temperature and prevent overheating, ultimately contributing to the overall reliability and safety of boating operations.

What You'll Learn

- Engine Cooling System: Overview of the components and their functions

- Thermostat: Regulates coolant flow, preventing overheating

- Radiator: Dissipates heat through air flow, keeping engine cool

- Coolant Circulation: The process of coolant circulation and its role

- Heat Exchange: How heat is transferred from engine to coolant

Engine Cooling System: Overview of the components and their functions

The engine cooling system is a critical component of any boat's powerplant, ensuring optimal performance and longevity by maintaining the engine's operating temperature within a safe range. This system is designed to prevent overheating, which can lead to engine damage and failure. The primary function of cooling is to dissipate the heat generated during the combustion process, allowing the engine to operate efficiently and reliably.

The cooling system typically consists of several key components, each playing a vital role in the overall process. Firstly, the radiator is a central component, often located near the front of the boat, where it can be cooled by the surrounding air. It is designed to absorb and transfer heat from the engine coolant to the air, facilitating efficient heat dissipation. The radiator's core is made up of numerous small passages or fins that increase the surface area, allowing for more effective heat exchange.

Another crucial element is the coolant, a liquid mixture of water and additives that circulates through the engine and radiator. Coolant absorbs heat from the engine block and cylinder head, carrying it to the radiator for cooling. It also acts as a lubricant, reducing friction between engine components and preventing corrosion. The coolant's temperature is carefully monitored, and if it exceeds a safe limit, a cooling fan may engage to provide additional air flow and lower the temperature.

The cooling fan, often driven by the engine's alternator or a dedicated electric motor, is responsible for drawing air through the radiator. This forced airflow enhances heat dissipation, especially during high-load conditions or when the engine is under stress. The fan's speed can be adjusted based on engine temperature, ensuring efficient cooling without unnecessary energy consumption.

Additionally, the cooling system includes a series of hoses and pipes that connect the engine, radiator, and other components. These hoses ensure a continuous flow of coolant throughout the system, facilitating the transfer of heat. The design and layout of these hoses are critical to maintaining optimal cooling performance and preventing leaks or blockages.

In summary, the engine cooling system is a complex network of components working in harmony to regulate the engine's temperature. By effectively managing heat dissipation, this system ensures the boat's engine operates at its peak performance while minimizing the risk of overheating and potential damage. Understanding these components and their functions is essential for maintaining a healthy and reliable boat engine.

The Appeal of Boat Shoes for Fraternity Men

You may want to see also

Thermostat: Regulates coolant flow, preventing overheating

A boat engine's cooling system is a critical component that ensures optimal performance and longevity. One of the key elements in this system is the thermostat, a device that plays a vital role in maintaining the engine's operating temperature. The primary function of a thermostat is to regulate the flow of coolant, which is a liquid mixture of water and antifreeze, through the engine block. This regulation is essential to prevent overheating, a condition that can lead to engine damage and failure.

Overheating occurs when the engine's temperature rises beyond the optimal range, typically between 150°F and 190°F (65°C and 88°C). When this happens, the engine's performance is compromised, and the risk of permanent damage increases. The thermostat acts as a gatekeeper, controlling the coolant's journey through the engine. It is designed to open and close based on the engine's temperature, allowing coolant to flow when necessary and restricting it when the engine is cool.

When the engine is cold, the thermostat remains closed, preventing coolant from circulating. This initial restriction allows the engine to heat up gradually, reaching its optimal operating temperature. As the engine warms up, the thermostat's bimetallic strip, a key component, starts to expand. This expansion causes the thermostat to open, allowing coolant to flow into the engine block and absorb heat. The coolant then carries this heat away, maintaining the engine's temperature within the desired range.

The thermostat's ability to regulate coolant flow is crucial for several reasons. Firstly, it ensures that the engine doesn't overheat, which can lead to engine failure. Secondly, it helps to maintain the engine's efficiency by keeping it at the optimal temperature. When an engine overheats, its performance can deteriorate, leading to increased fuel consumption and reduced power output. By preventing overheating, the thermostat contributes to the engine's overall reliability and longevity.

In summary, the thermostat is a critical component in a boat engine's cooling system, acting as a regulator of coolant flow. Its primary function is to prevent overheating by controlling the coolant's journey through the engine. This regulation is essential for maintaining the engine's performance, efficiency, and overall health, ensuring that the boat engine operates reliably and safely. Understanding the thermostat's role provides valuable insight into the intricate workings of boat engine cooling systems.

Unveiling the Magic: How Boat Jack Plates Lift Your Craft

You may want to see also

Radiator: Dissipates heat through air flow, keeping engine cool

A boat engine's radiator is a critical component designed to manage and dissipate heat, ensuring optimal engine performance and longevity. This component is an essential part of the cooling system, which is vital for any engine, especially those used in marine environments. The primary function of a radiator is to maintain the engine's operating temperature within a safe range, preventing overheating, which can lead to engine damage.

The radiator's design is based on the principle of heat exchange. It is typically made of a series of thin, flat metal fins or tubes that are strategically arranged to maximize surface area. When the engine operates, the coolant, a mixture of water and antifreeze, circulates through the engine block, absorbing heat from the engine components. This heated coolant then flows into the radiator, where the heat transfer process begins.

As the coolant enters the radiator, it encounters a stream of air flowing through it. The radiator is positioned in front of the boat's propeller, allowing the airflow to be directed over its surface. The metal fins or tubes of the radiator provide a large surface area, which increases the rate of heat dissipation. The air flowing over these fins absorbs heat from the coolant, causing the coolant to cool down. This process is facilitated by the natural convection of air, where the heated air rises, creating a continuous flow of fresh, cool air over the radiator.

The design of the radiator also includes a series of baffles or cross-flow passages that further enhance the heat exchange process. These baffles force the air to flow in a zigzag pattern, increasing the contact time between the air and the coolant. This design ensures that the maximum amount of heat is transferred from the coolant to the air, resulting in efficient cooling.

In summary, the radiator plays a crucial role in the cooling system of a boat engine by dissipating heat through air flow. Its design, with metal fins and baffles, facilitates efficient heat exchange, ensuring that the engine operates at an optimal temperature. This process is essential for maintaining engine performance, preventing overheating, and ensuring the longevity of the boat's engine. Regular maintenance and monitoring of the radiator and cooling system are recommended to ensure its effectiveness and the overall health of the engine.

Luxurious 18-Reeler Boat Owners: Exploring Their Exclusive World

You may want to see also

Coolant Circulation: The process of coolant circulation and its role

Cooling systems in boat engines are designed to maintain optimal engine temperature, ensuring efficient performance and longevity. At the heart of this system is the coolant circulation process, which plays a critical role in dissipating heat generated during engine operation. This circulation process involves a series of components working in harmony to facilitate the transfer of heat from the engine to the surrounding air or water.

The process begins with the coolant, typically a liquid mixture of water and ethylene glycol, being drawn from the engine's reservoir. This coolant is then pumped through a series of passages within the engine block and head, absorbing heat from these components. As it circulates, the coolant passes through a series of fins or heat exchangers, which transfer the absorbed heat to the surrounding air or water. This is where the primary cooling effect takes place, as the heat is dissipated, preventing the engine from overheating.

The coolant circulation system is designed to maintain a consistent and efficient flow. It operates under pressure, ensuring that the coolant moves through the engine and back to the reservoir without any dead spots or areas of stagnation. This consistent flow is crucial for effective heat dissipation, as it allows for a continuous exchange of heat between the engine components and the coolant. The system's design also includes a thermostat, which regulates the coolant flow based on engine temperature, ensuring that the engine is cooled optimally without wastage.

In addition to the primary cooling function, the coolant circulation process also serves to lubricate the engine components and prevent corrosion. The coolant's additives create a protective layer on metal surfaces, reducing friction and wear. Furthermore, the coolant's pH level is carefully controlled to inhibit corrosion, ensuring that the engine's internal components remain in optimal condition over extended periods of operation.

The efficiency of the coolant circulation system is vital for the overall performance and longevity of the boat engine. Proper maintenance, including regular coolant checks and replacements, is essential to ensure that the system functions optimally. This includes monitoring coolant levels, checking for leaks, and maintaining the engine's temperature within the specified range. By understanding and maintaining the coolant circulation process, boat owners can ensure their engines operate efficiently and reliably, even in demanding marine environments.

Luxury Yacht Ghost 2: Owner and Features Explored

You may want to see also

Heat Exchange: How heat is transferred from engine to coolant

The cooling system in a boat engine is a critical component that ensures optimal performance and longevity. It operates on the principle of heat exchange, where the engine's internal components generate heat, and this heat is transferred to a coolant, which then dissipates the heat to the surrounding environment. This process is essential to maintain the engine's operating temperature within a safe range, preventing overheating and potential damage.

At the heart of this system is the engine block, which houses the cylinders and other critical components. As the engine operates, these components generate a significant amount of heat due to the combustion process and friction between moving parts. The heat is then transferred to the engine block, causing it to become hot. This is where the coolant comes into play.

Coolant, typically a mixture of water and a special additive, is circulated through the engine block via a closed loop system. The coolant absorbs the heat from the engine block as it flows through, raising its temperature. This heated coolant then exits the engine block and enters a radiator, which is often located near the front of the boat. Inside the radiator, the coolant is exposed to the air, allowing for efficient heat dissipation.

The radiator is designed with a series of fins and tubes that increase the surface area, facilitating better heat transfer. As the coolant flows through the radiator, it loses heat to the surrounding air, which is then carried away by the airflow created by the boat's movement. This process effectively cools the coolant, reducing its temperature significantly. The cooled coolant is then recirculated back into the engine, completing the cycle.

This continuous cycle of heat exchange is vital for maintaining the engine's performance and longevity. It prevents the engine from overheating, which could lead to reduced power, increased fuel consumption, and potential engine damage. Additionally, the cooling system helps to lubricate the engine components, reducing friction and wear, and ensuring smooth operation. Proper maintenance of the cooling system, including regular coolant checks and radiator cleaning, is essential to guarantee the engine's reliability and efficiency on the water.

Choosing the Right Solar Panel Size for Boat Batteries

You may want to see also

Frequently asked questions

The cooling system in a boat engine is designed to maintain optimal engine temperature by dissipating excess heat. It typically involves a combination of components such as a radiator, a coolant, a water pump, and a cooling fan. When the engine operates, the water pump circulates coolant through the engine block, absorbing heat from the engine components. The hot coolant then flows through the radiator, where it is cooled by the surrounding air. The cooled coolant is recirculated back into the engine, ensuring efficient heat management.

A cooling fan plays a crucial role in the cooling process by providing additional airflow over the engine's radiator. When the engine is running, the cooling fan spins, drawing air through the radiator and enhancing heat dissipation. This is especially important during high-speed cruising or when the boat is stationary, as it helps prevent the engine from overheating. The fan's speed can often be adjusted to match the engine's cooling needs, ensuring optimal performance and longevity.

Yes, there are a few ways to check if your boat engine's cooling system is functioning correctly. Firstly, you can monitor the engine temperature gauge while driving. If the temperature remains stable and within the optimal range, the cooling system is likely working as intended. Additionally, you can inspect the coolant level regularly. It should be a light blue or green color, indicating proper coolant mixture. If the coolant appears discolored or there is a significant drop in level, it may suggest a leak or other cooling system issues that require attention.