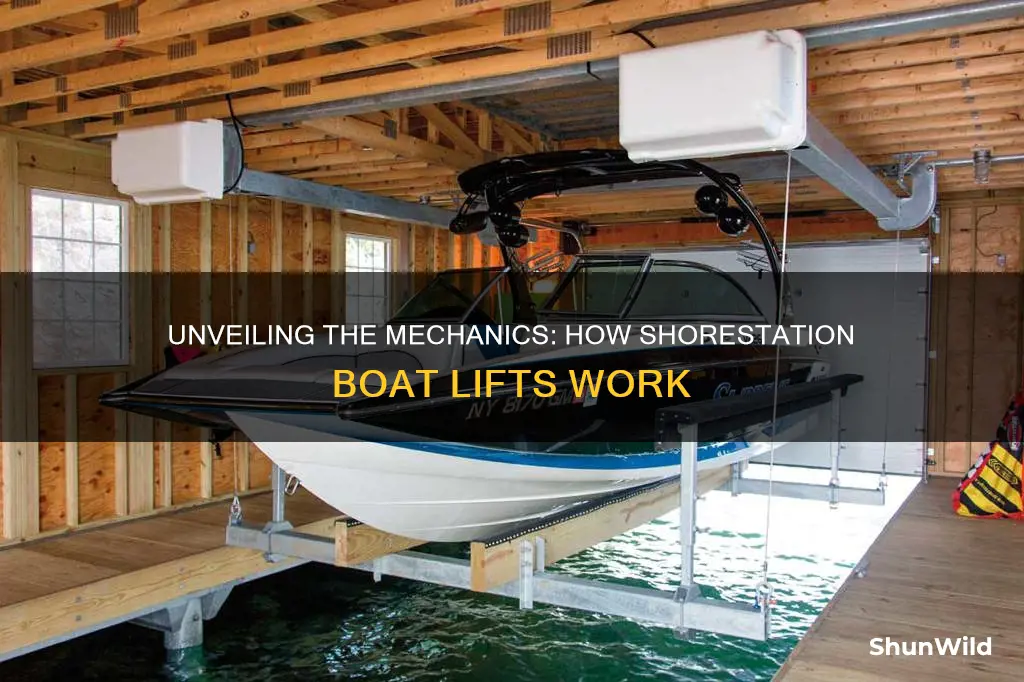

A shore station boat lift is a mechanical system designed to efficiently and safely raise and lower boats from a shore-based station to a water body. This innovative technology is crucial for managing water levels, ensuring safe boat access, and providing a seamless transition for vessels between land and water. The lift mechanism typically consists of a series of interconnected components, including a sturdy platform, powerful winches, and a control system. When activated, the lift smoothly elevates or descends the boat, allowing for easy transportation and reducing the risk of damage to both the vessel and the lift structure. Understanding the inner workings of this system is essential for operators and enthusiasts alike, as it ensures optimal performance and safety in various aquatic environments.

What You'll Learn

- Hydraulic Systems: Powerful pumps and cylinders lift boats by adjusting water pressure

- Mooring Mechanisms: Ramps and docks guide boats onto and off the lift

- Safety Features: Sensors and barriers prevent accidents and ensure secure operation

- Power Source: Electric or diesel engines provide the energy for the lift mechanism

- Design Considerations: Factors like boat size and water depth influence lift design

Hydraulic Systems: Powerful pumps and cylinders lift boats by adjusting water pressure

Hydraulic systems are a crucial component of shore-based boat lifts, providing the necessary power and precision to lift and lower boats with ease. These systems utilize the principles of fluid mechanics, specifically the control of water pressure, to achieve the lifting mechanism. At the heart of this process are powerful pumps and hydraulic cylinders, which work in tandem to adjust the water pressure and, consequently, the force required to lift or lower the boat.

The process begins with the pump, which is typically a high-pressure, variable-speed pump. This pump is designed to handle the demanding requirements of the lift system. When activated, it draws water from a reservoir or a connected water source and pressurizes it. The pressurized water is then directed into the hydraulic cylinders, which are strategically positioned on either side of the boat.

Hydraulic cylinders are essentially linear actuators that convert the pressurized water into a mechanical force. Each cylinder contains a piston that moves in response to the water pressure. The force generated by the piston is directly proportional to the pressure of the water and the piston's cross-sectional area. By adjusting the flow of water into and out of the cylinders, the lift system can control the speed and force of the piston's movement.

When the lift system is engaged, the pumps supply pressurized water to the cylinders, causing the pistons to extend and lift the boat. The force required to lift the boat is determined by the pressure of the water and the piston's size. By varying the water pressure, the system can precisely control the lifting speed and force, ensuring a smooth and controlled ascent or descent.

The beauty of hydraulic systems lies in their ability to provide a smooth and controlled lifting mechanism. By adjusting the water pressure, the system can accommodate different boat weights and sizes, making it a versatile solution for various marine applications. Additionally, hydraulic systems offer excellent control and precision, allowing operators to fine-tune the lifting process for optimal performance. This level of control is essential for ensuring the safety and efficiency of boat lifts, especially in busy harbor areas or when handling delicate vessels.

Protect Your Boat: Covering with a T-Top

You may want to see also

Mooring Mechanisms: Ramps and docks guide boats onto and off the lift

Mooring mechanisms are a crucial component of a shore station boat lift, ensuring smooth and safe operations for vessels of various sizes. When it comes to guiding boats onto and off the lift, ramps and docks play a pivotal role in the process. These structures are designed to provide a stable and controlled environment for boats to access the lift, facilitating efficient loading and unloading.

Ramps are typically constructed with a gentle incline, allowing boats to glide smoothly onto the lift. The design of the ramp is critical to ensure that the boat's weight is evenly distributed, preventing any potential damage to the vessel or the lift mechanism. Ramps are often made of durable materials such as steel or reinforced concrete to withstand the forces exerted by boats during the mooring process. The angle and length of the ramp are carefully calculated to accommodate different boat sizes and ensure a safe approach.

Docks, on the other hand, provide a stable platform for boats to rest while being lifted or lowered. These docks are strategically positioned at the end of the ramps, offering a secure mooring point. The design of the dock includes features like handrails, fenders, and mooring lines to protect the boat from potential impacts and provide a safe environment for passengers and crew. Docks are often made of sturdy materials to support the weight of the boats and withstand the elements.

The process of mooring involves carefully aligning the boat with the ramp and dock, ensuring that the vessel's center of gravity is over the lift mechanism. This precise alignment is crucial for a smooth transition onto or off the lift. Once the boat is securely moored, the lift mechanism engages, either raising or lowering the boat to the desired level. Ramps and docks are designed to accommodate this movement, providing a seamless and controlled environment for the boat's journey.

In summary, ramps and docks are essential mooring mechanisms that facilitate the safe and efficient mooring of boats onto and off shore station boat lifts. Their design and construction are tailored to handle the unique challenges of boat lifting, ensuring a secure and stable environment for vessels of all sizes. Understanding these mechanisms is key to operating and maintaining a shore station boat lift effectively.

The Mystery Owner of the Irimari Boat

You may want to see also

Safety Features: Sensors and barriers prevent accidents and ensure secure operation

The safety features of a shore station boat lift are crucial to its operation, ensuring the secure and efficient transport of boats while minimizing the risk of accidents. One of the primary safety mechanisms is the use of sensors, which play a vital role in monitoring and controlling the lift's operations. These sensors are strategically placed throughout the system and are designed to detect various parameters to ensure safe and precise movement.

Sensors are employed to monitor the boat's position, speed, and weight, providing real-time data to the control system. For instance, weight sensors can detect the boat's load and ensure it adheres to the lift's capacity limits. If the weight exceeds the safe threshold, the sensors trigger an alarm, alerting the operators and preventing potential overloading. This feature is essential for maintaining stability and preventing structural damage to the lift.

In addition to weight monitoring, sensors are also used to track the boat's vertical and horizontal positioning. Proximity sensors, for example, can detect the boat's proximity to the lift's guide rails, ensuring it stays within the designated path. If the boat deviates from the correct course, the sensors activate safety protocols, such as slowing down the lift's movement or automatically stopping the process to prevent collisions. This real-time feedback system enhances safety by minimizing human error and allowing for quick responses to potential hazards.

Barriers and physical obstacles are another critical safety feature of shore station boat lifts. These physical barriers act as a visual and physical reminder to operators and boats, guiding them through the lift's operation. For instance, guide rails along the lift's path provide a clear direction for boats to follow, reducing the chances of accidental drift or collision. Additionally, barriers can be installed at key points to restrict access to certain areas, preventing unauthorized personnel from entering and reducing the risk of accidents.

The combination of sensors and barriers creates a comprehensive safety net for shore station boat lifts. Sensors provide continuous monitoring and feedback, allowing for immediate responses to potential issues, while barriers offer a physical and visual guide, ensuring boats and operators adhere to safe practices. This dual approach significantly reduces the likelihood of accidents, making the lift a reliable and secure method of boat transportation.

New Boat Registration Procedures in Arkansas: What Changed?

You may want to see also

Power Source: Electric or diesel engines provide the energy for the lift mechanism

The power source for a shore-station boat lift is a critical component, as it directly influences the efficiency and reliability of the lift mechanism. Typically, these lifts utilize either electric or diesel engines to generate the necessary force to raise and lower boats.

Electric engines are a popular choice for shore-station boat lifts due to their reliability and low maintenance requirements. These engines are often powered by a shore-based electrical supply, which is then transmitted to the lift via cables or wires. The electric motor converts electrical energy into mechanical energy, driving the lift's hydraulic or mechanical systems. This method is efficient and environmentally friendly, making it a preferred option for many boat lifts, especially in areas with strict environmental regulations.

On the other hand, diesel engines are also commonly used, particularly in larger or more remote locations where access to electricity might be limited. Diesel engines provide a robust and reliable power source, capable of handling the demanding tasks required for boat lifts. These engines are typically fueled by diesel fuel, which is stored in tanks and supplied to the engine via a fuel system. The diesel motor then drives the lift mechanism, often through a series of gears or a hydraulic pump, to lift or lower the boats. While diesel engines offer high power output and durability, they may require more frequent maintenance and can be less environmentally friendly compared to electric alternatives.

The choice between electric and diesel power sources depends on various factors, including the specific requirements of the boat lift, the availability of power infrastructure, and environmental considerations. Electric lifts are often favored for their ease of installation and lower operating costs, while diesel lifts provide a more independent solution, ideal for remote locations.

In both cases, the power source is connected to the lift mechanism through a series of components, ensuring efficient energy transfer. This setup allows for precise control of the lift's movement, ensuring smooth and safe operations for boats of various sizes and weights.

Wiring a Boat Engine: A Comprehensive Guide

You may want to see also

Design Considerations: Factors like boat size and water depth influence lift design

When designing a shore station boat lift, several critical factors come into play, primarily related to the boat's size and the water depth. These considerations are essential to ensure the lift's efficiency, safety, and structural integrity. Firstly, the boat's size is a significant determinant of the lift's design. Larger boats require more substantial and robust lifting mechanisms to handle their weight and size. The lift's capacity should be able to accommodate the boat's dimensions, including its length, width, and height, to ensure a secure and stable lift. For instance, a lift designed for a small fishing boat will have different specifications compared to one intended for a larger yacht or ferry.

Water depth is another critical factor that influences the lift's design. The lift must be capable of reaching the boat's waterline, ensuring that the boat is lifted out of the water without any part touching the bottom. This requires precise calculations to determine the minimum water depth required for the lift to function effectively. In shallow waters, the lift might need to be designed with a higher lifting capacity or incorporate additional features like adjustable supports to accommodate varying water levels.

The design of the lift's mechanism also plays a vital role. Different boat sizes and water depths may require various lifting systems. For example, a vertical lift system, where the boat is lifted vertically, might be more suitable for shallow waters and smaller boats, as it provides a more straightforward and efficient lifting process. In contrast, a horizontal lift system, which involves pulling the boat horizontally towards the shore, could be more appropriate for deeper waters and larger vessels.

Additionally, the materials used in the lift's construction are essential. The choice of materials should consider the lift's load-bearing capacity, corrosion resistance, and durability, especially in marine environments. Advanced materials like high-strength alloys and composite materials can enhance the lift's performance and longevity, ensuring it can withstand the challenges of lifting boats in various conditions.

In summary, designing a shore station boat lift requires careful consideration of boat size and water depth. These factors directly impact the lift's capacity, mechanism design, and overall structural requirements. By understanding these influences, engineers can create efficient and reliable boat lifts that cater to specific needs, ensuring safe and effective boat transportation.

Best Aluminum Gauge for a Jon Boat: Strength and Durability

You may want to see also

Frequently asked questions

A Shorestation Boat Lift is a type of boat hoisting system designed for residential or commercial use on lakes, rivers, or other bodies of water. It is an automated solution to raise and lower boats from a shore-based platform, providing easy access to the water for boating enthusiasts.

The lift mechanism typically utilizes a combination of hydraulic or electric systems. It involves a sturdy frame with a boat cradle or platform attached. The boat is positioned on the platform, and the lift mechanism then extends or retracts the platform, raising or lowering the boat into the water or onto a designated storage area.

These lifts offer several benefits. They provide a convenient and safe way to launch and retrieve boats, eliminating the need for manual dragging or launching. They can handle various boat sizes and weights, making them versatile. Additionally, they are often customizable, allowing users to choose the lift height and other features to suit their specific needs.

Yes, regular maintenance is essential to ensure the longevity and safe operation of the Shorestation Boat Lift. This includes checking hydraulic fluid levels (if applicable), inspecting cables or chains for wear and tear, lubricating moving parts, and testing safety mechanisms. It is recommended to follow the manufacturer's guidelines for maintenance schedules and best practices.