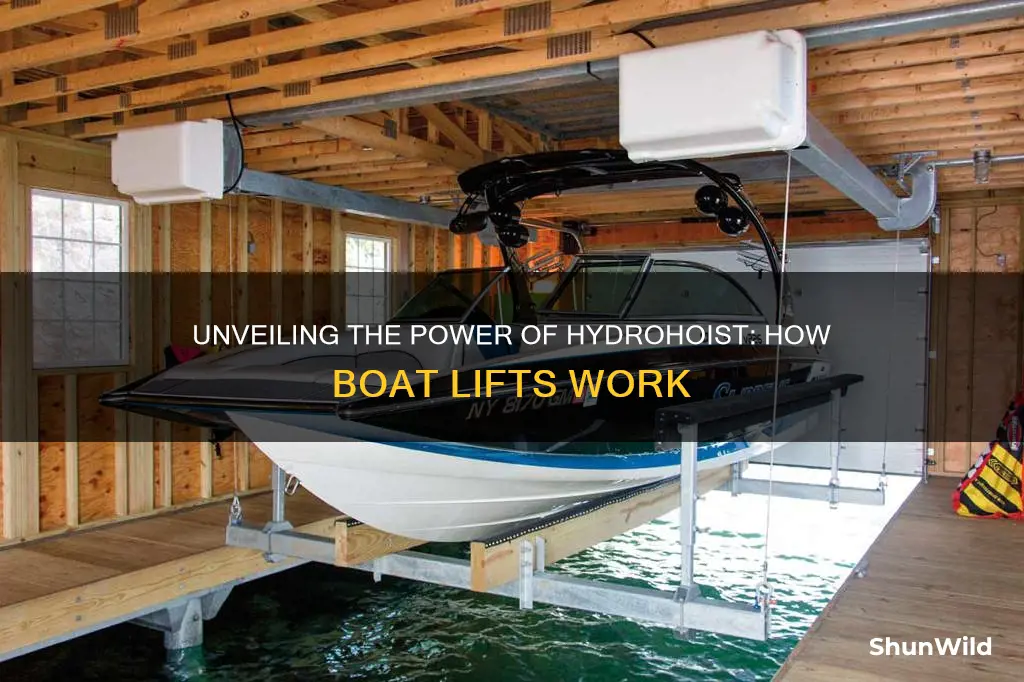

A hydrohoist boat lift is a clever mechanical system designed to effortlessly raise and lower boats, offering a convenient and efficient solution for watercraft storage and retrieval. This innovative lift mechanism operates by utilizing the principles of hydrostatic pressure and hydraulic systems. By applying pressure to a fluid, typically water, the lift can generate significant force, allowing it to lift heavy boats with ease. The process involves a series of pumps, valves, and cylinders that work in harmony to extend and retract the lift, providing a smooth and controlled movement. Understanding the inner workings of a hydrohoist boat lift is essential for appreciating its efficiency and reliability in managing boat storage and transportation.

What You'll Learn

Hydraulic System: Powering the lift with pressurized fluid

A hydrohoist boat lift is a fascinating engineering marvel, utilizing the power of hydraulics to effortlessly raise and lower boats between different water levels. At its core, the hydraulic system is the driving force behind this innovative technology. This system operates by employing pressurized fluid, typically an incompressible liquid, to transmit power and perform mechanical work.

The key component in this process is the pump, which takes in fluid and increases its pressure. This pump is often driven by an electric motor, ensuring efficient and reliable operation. The pressurized fluid is then directed through a series of pipes or hoses, forming a network of channels that carry the power throughout the lift mechanism. This network is carefully designed to ensure optimal fluid flow and pressure distribution.

When the lift is activated, the pressurized fluid is directed to specific areas, creating force that acts upon various components. For instance, in a typical hydrohoist lift, there are two main chambers: one at the top and one at the bottom of the lift mechanism. By controlling the flow of fluid into these chambers, the lift can be raised or lowered. This is achieved through a series of valves and check valves, which regulate the direction and amount of fluid flow.

The beauty of this system lies in its precision and control. By adjusting the pressure and flow rate of the fluid, operators can fine-tune the lift's movement, ensuring smooth and accurate boat positioning. This level of control is crucial for maintaining stability and safety during the lifting process, especially when dealing with different boat sizes and weights.

In summary, the hydraulic system in a hydrohoist boat lift is a sophisticated arrangement that harnesses the power of pressurized fluid to provide precise control over the lift's operation. This technology showcases the ingenuity of engineers in utilizing fluid dynamics to create efficient and reliable boat-lifting solutions.

Unveiling the Role of Boat Brokers: Navigating the Sale

You may want to see also

Counterbalance: Weighing the boat to ensure smooth movement

The concept of counterbalance is crucial to the operation of a hydrohoist boat lift, ensuring smooth and controlled movement of boats. This system relies on a precise balance of weights to counteract the force of the boat's weight, allowing for easy raising and lowering. The primary goal is to maintain equilibrium, preventing sudden movements and ensuring the boat glides effortlessly along the lift's path.

To achieve this balance, the hydrohoist lift incorporates a counterweight system. This system is strategically positioned to match the weight of the boat, creating a symmetrical distribution of mass. The counterweight is typically located above or below the boat, depending on the design of the lift. By mirroring the boat's weight, the counterbalance ensures that the lift's mechanism doesn't have to exert excessive force to move the boat.

The process begins with the boat being positioned on the lift, and the counterweight is adjusted accordingly. This adjustment is critical to achieving the desired balance. If the counterweight is too heavy or too light, it can lead to instability and potential damage to the lift mechanism. Therefore, precise calibration is essential. Once balanced, the lift's motor or hydraulic system can smoothly raise or lower the boat without any sudden jerks or vibrations.

This counterbalance mechanism is particularly important in high-capacity boat lifts, where the weight of the boats can be substantial. Without proper counterweighting, the lift might struggle to move the boats, leading to increased energy consumption and potential mechanical issues. The hydrohoist design ensures that the lift's power is utilized efficiently, providing a seamless and controlled movement experience.

In summary, the counterbalance system in a hydrohoist boat lift is a critical component that enables smooth and safe boat handling. By carefully weighing the boat and implementing a matching counterweight, the lift can operate with precision, ensuring a reliable and efficient process for boat owners and operators. This design feature showcases the ingenuity of hydrohoist technology, providing a solution that balances power and control.

Fixing Your Boat Lift: Crank Wheel Repair Guide

You may want to see also

Mooring Mechanism: Securing the boat in place

The mooring mechanism is a critical component of a hydrohoist boat lift, ensuring the boat is securely held in place during loading and unloading. This system employs a combination of mechanical and hydraulic elements to provide a stable and controlled environment for boat handling. Here's a detailed explanation of how the mooring mechanism operates:

Mooring Process:

When a boat is to be lifted or moved, the mooring mechanism engages to secure it firmly. This process typically involves a series of steps: First, the boat is positioned directly beneath the lift, ensuring it aligns with the mooring guides. These guides are usually adjustable and can be tailored to accommodate boats of various sizes and shapes. Once aligned, the mooring arms, which are an integral part of the mechanism, extend towards the boat. These arms are designed with a secure grip, often featuring a robust locking mechanism to hold the boat in place. The locking mechanism can be a simple pin-and-socket system or a more advanced hydraulic clamp, providing a firm and reliable hold.

Hydraulic Control:

The hydraulic aspect of the mooring mechanism is crucial for precise control. Hydraulic cylinders are used to extend and retract the mooring arms, allowing for smooth and controlled movement. Operators can adjust the pressure and speed of the hydraulic system, ensuring the boat is secured gently yet firmly. This hydraulic control is particularly useful when dealing with larger boats or when precise positioning is required. The system can be operated remotely, providing safety and convenience to operators.

Safety Features:

To ensure the safety of the boat and its contents, the mooring mechanism incorporates several safety measures. These include pressure sensors that monitor the force applied to the boat, preventing excessive pressure that could damage the vessel. Additionally, emergency release mechanisms are often included, allowing for quick and safe disengagement of the mooring arms in case of unexpected situations. These safety features are essential, especially when handling valuable or delicate cargo.

Customizability:

One of the advantages of hydrohoist boat lifts is their adaptability. The mooring mechanism can be customized to suit specific boat types and sizes. This customization ensures that the lift can accommodate a wide range of vessels, from small personal boats to large commercial ships. The adjustable guides and mooring arms provide flexibility, making the lift versatile and efficient.

In summary, the mooring mechanism of a hydrohoist boat lift is a sophisticated system that combines mechanical and hydraulic principles to secure boats effectively. Its design allows for controlled and safe boat handling, making it an essential component of any boat lifting operation.

The Intriguing Lengths of Paddle Boats Explored

You may want to see also

Control Panel: Operator interface for lift operation

The control panel is the central hub for operating a Hydrohoist boat lift, providing the operator with an intuitive interface to control the lift's functions. It is typically located on the ground, offering a clear view of the lift's position and status. This panel is designed with a user-friendly layout, ensuring efficient and safe operation.

The interface consists of several key components. Firstly, there are control switches, usually in the form of buttons or levers, which allow the operator to initiate the lift's movement. These switches are strategically placed for easy access and are often color-coded to indicate different functions, such as up, down, and emergency stop. For instance, a simple press of the 'Up' button will start the lift's ascent, while the 'Down' button initiates descent. The emergency stop function is critical and is often highlighted with a distinct red button, ensuring it is easily identifiable in case of an urgent situation.

In addition to the control switches, the panel may also feature a display screen, providing real-time feedback and information. This display can show the current position of the lift, any error codes, and system status. For example, it might indicate whether the lift is in the fully raised or lowered position, or if there are any issues with the motor or sensors. This visual representation enhances the operator's awareness and allows for quick decision-making.

Another essential feature of the control panel is the safety interlock system. This mechanism ensures that the lift cannot be operated unless all safety protocols are met. For instance, it may require the operator to press and hold the 'Up' button for a few seconds before the lift begins to move, preventing accidental or unauthorized operation. This interlock system is crucial for maintaining safety, especially in public or high-traffic areas.

Furthermore, the control panel might include additional controls for advanced features, such as programmable settings and remote monitoring. These settings allow operators to customize the lift's behavior, such as adjusting the speed of ascent or descent, or setting specific positions for different boat sizes. Remote monitoring capabilities enable operators to oversee the lift's performance from a distance, receiving alerts and notifications via a connected device. This level of control and flexibility ensures that the Hydrohoist boat lift can be tailored to various operational needs.

Teak Boat Decks: When to Replace and Why

You may want to see also

Safety Features: Sensors and brakes to prevent accidents

The hydrohoist boat lift is a clever mechanical system designed to safely and efficiently raise and lower boats, ensuring a smooth and controlled movement. One of the key safety features of this lift is the integration of advanced sensors and braking mechanisms, which play a crucial role in preventing accidents and ensuring the well-being of both the boat and its occupants.

Sensors are strategically placed throughout the lift mechanism to monitor various parameters. These sensors include proximity sensors, which detect the presence of objects or obstacles in the path of the boat. By constantly scanning the surroundings, these sensors can identify potential hazards and trigger an immediate response. For instance, if a sensor detects an object too close to the boat's path, it can activate the braking system, bringing the lift to a safe and controlled stop. This real-time monitoring ensures that the lift avoids collisions and maintains a safe distance from any nearby objects.

In addition to proximity sensors, pressure sensors are also employed to monitor the weight and load on the lift. These sensors provide critical information about the boat's weight and ensure that the lift operates within safe load limits. If the pressure sensors detect an excessive load, they can trigger an alarm or automatically engage the braking system to prevent overloading and potential damage. This feature is particularly important for maintaining the structural integrity of the lift and the safety of the boat being lifted.

The braking system is a vital component of the hydrohoist boat lift's safety features. It consists of powerful hydraulic brakes that can be rapidly engaged to bring the lift to a stop. When the sensors detect a potential hazard or an excessive load, they send a signal to the braking system, which responds by applying pressure to the lift's wheels or tracks. This action slows down or stops the lift, preventing any accidental movement that could lead to accidents. The braking system is designed to be highly responsive, ensuring that the lift can quickly react to any unforeseen circumstances.

Furthermore, the lift's braking system incorporates a fail-safe mechanism. In the event of a power failure or system malfunction, the brakes automatically engage, providing an additional layer of safety. This fail-safe feature ensures that even in the absence of power, the lift can still come to a controlled stop, preventing any potential accidents. The combination of sensors and brakes creates a robust safety net, allowing the hydrohoist boat lift to operate with minimal risk and maximum efficiency.

Mastering Boat Driving for Wakeboarders: Tips and Tricks

You may want to see also

Frequently asked questions

A Hydrohoist boat lift is a mechanical system designed to raise and lower boats from a trailer or a dock. It operates by utilizing a hydraulic pump and cylinder assembly, which provides the necessary force to lift the boat. The lift is typically mounted on a trailer or a sturdy platform, and the boat is secured onto it. When the lift is activated, the hydraulic system extends or retracts, allowing the boat to be lifted or lowered with precision.

The main components include a hydraulic pump, a cylinder with a piston, a control valve, and a power source. The hydraulic pump creates pressurized fluid, which is then directed to the cylinder, causing the piston to extend or retract. The control valve regulates the flow of fluid, allowing for precise control of the lift's movement. The power source can be an electric motor or a manual hand pump, depending on the model.

Yes, they are designed with user-friendliness in mind. The lift can be operated manually or with an electric motor, making it accessible for both personal and commercial use. The control valve provides a smooth and controlled movement, ensuring that the boat is lifted or lowered safely and efficiently. Additionally, many models offer features like automatic leveling and load sensors, further enhancing ease of use and safety.