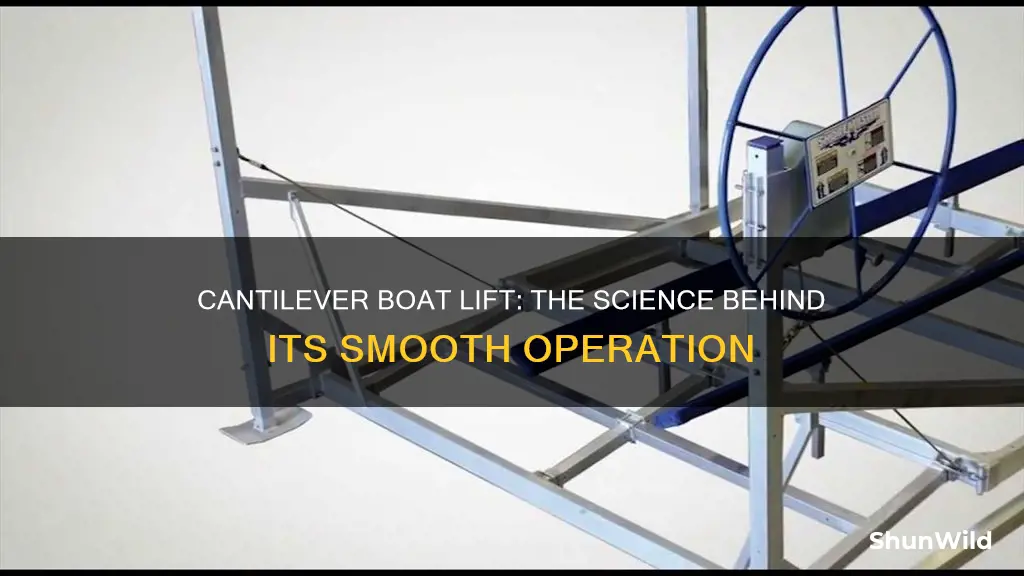

A cantilever boat lift is a unique and innovative system designed to efficiently raise and lower boats, particularly in narrow waterways or areas with limited space. This lift mechanism operates by extending a sturdy, rigid arm, or cantilever, from a fixed base, which can be adjusted to different heights. The boat is then securely attached to the cantilever, and by utilizing a controlled hydraulic or mechanical system, the lift can raise or lower the boat with precision. This design allows for a compact and space-efficient solution, making it ideal for marinas, canals, and other water bodies where traditional lift systems might not be feasible. Understanding the mechanics of a cantilever boat lift is essential for appreciating its efficiency and versatility in boat handling.

What You'll Learn

- Design and Structure: Cantilever lifts feature a single arm extending over water, supported by a sturdy base

- Hydraulic System: Hydraulic cylinders lift and lower the boat by extending and retracting the arm

- Balance Mechanism: Counterweights ensure stability by balancing the lift's weight and the boat's load

- Safety Features: Emergency stops and overload sensors prevent accidents and protect the lift and boat

- Material and Construction: High-strength materials and precision engineering ensure structural integrity and longevity

Design and Structure: Cantilever lifts feature a single arm extending over water, supported by a sturdy base

A cantilever boat lift is an innovative engineering solution designed to efficiently transport boats across bodies of water, such as rivers or canals. Its unique design and structure set it apart from traditional lifting methods, offering a range of advantages for both operators and boaters.

The key component of a cantilever lift is its single, long arm, which extends over the water's surface. This arm is carefully designed to be sturdy and robust, ensuring it can support the weight of the boats it will carry. The arm is typically made from high-strength materials, such as steel or reinforced concrete, to withstand the forces exerted by the boats and environmental factors. At the end of this arm, a platform or boat cradle is attached, providing a stable and secure resting place for the boats.

The structure's design is crucial to its functionality. The lift is anchored to a solid base, which can be either a fixed structure built into the riverbank or a floating platform. This base provides the necessary support and stability, allowing the cantilever arm to extend over the water without compromising its structural integrity. The base is designed to withstand the forces of the lift's operation, including the weight of the boats and any potential environmental stresses.

One of the advantages of this design is its simplicity. With fewer moving parts compared to other lifting mechanisms, cantilever lifts are generally easier to maintain and operate. The lift's operation often involves a simple mechanical system, such as a pulley or hydraulic system, which pulls or raises the boats. This simplicity contributes to the lift's reliability and makes it a cost-effective solution for boat transportation.

In summary, the design and structure of a cantilever boat lift are carefully considered to ensure stability, strength, and efficiency. The single-arm cantilever design, supported by a sturdy base, allows for the safe and effective transportation of boats across water bodies, making it a popular choice for various applications, from recreational boating to industrial cargo transport.

Choosing Wood for Boat Engine Deck Lids

You may want to see also

Hydraulic System: Hydraulic cylinders lift and lower the boat by extending and retracting the arm

A cantilever boat lift utilizes a hydraulic system to achieve the lifting and lowering of boats with precision and control. This system is designed to extend and retract the lift arm, allowing for the smooth and efficient movement of boats. Here's a detailed explanation of how the hydraulic system operates:

The hydraulic system in a cantilever boat lift typically consists of a powerful hydraulic cylinder, which is the heart of the mechanism. This cylinder is connected to the lift arm, often made of sturdy materials to withstand the forces involved. When the hydraulic cylinder is activated, it extends or retracts, depending on the desired action. The lift arm is firmly attached to the cylinder, ensuring a direct and controlled movement.

To lift a boat, the hydraulic cylinder extends, pushing the lift arm downward. This extension is achieved by applying pressure to the hydraulic fluid inside the cylinder, forcing it to move the piston and extend the arm. The force generated by the hydraulic system is carefully calibrated to handle the weight of the boat, ensuring a safe and stable lifting process. As the lift arm descends, it securely grips the boat, providing a stable base for transportation.

Lowering the boat is accomplished by retracting the hydraulic cylinder. When the control system receives the command to lower, it releases pressure, allowing the hydraulic fluid to flow back into the reservoir. This action causes the piston to retract, pulling the lift arm upward. The boat is gently released as the lift arm rises, ensuring a smooth descent. The hydraulic system's precision ensures that the boat is lowered to the desired level without any abrupt movements.

The hydraulic cylinders used in this application are designed to handle heavy loads and provide smooth, controlled movements. They are typically filled with incompressible hydraulic fluid, which transmits force effectively. The system's design allows for quick response times, enabling the lift to accommodate boats of various sizes and weights. Additionally, the hydraulic system's reliability and durability make it a preferred choice for boat lifts, ensuring safe and efficient operation over extended periods.

Best TV Aerials for Boats: Enhancing Your Signal

You may want to see also

Balance Mechanism: Counterweights ensure stability by balancing the lift's weight and the boat's load

The balance mechanism in a cantilever boat lift is a critical component that ensures the system's stability and safety. This mechanism relies on counterweights, which play a crucial role in maintaining equilibrium. Counterweights are strategically placed to counteract the weight of the lift and the boat it carries. By doing so, they provide a stable and secure lifting process.

When a boat is lifted, the lift's structure, often a cantilever arm, extends over the water. The boat's weight is supported by this arm, which is designed to bear the load. However, to ensure stability, counterweights are positioned on the opposite side of the lift. These counterweights are typically heavy structures, often made of steel or concrete, and their placement is carefully calculated. The primary function of these counterweights is to balance the lift's weight and the boat's load, preventing the lift from toppling over.

The design of the counterweights is such that they match the weight of the lift and the boat. This balance is essential to maintain the lift's center of gravity at a stable position. As the lift moves, the counterweights adjust accordingly, providing a continuous stabilizing force. This dynamic adjustment is crucial, especially when the lift is in motion, as it ensures that the lift remains upright and secure.

In the event of an uneven load or sudden movements, the counterweights' role becomes even more critical. They act as a buffer, absorbing the extra weight and preventing the lift from becoming unstable. This is particularly important in dynamic environments, such as busy waterways, where the lift may experience varying loads and movements.

By utilizing counterweights, the cantilever boat lift system achieves a remarkable level of stability. This mechanism is a testament to the engineering ingenuity required to design safe and efficient lifting solutions for boats. It highlights the importance of considering weight distribution and balance in the construction of such systems.

Replacing Pop Rivets: A Boat Owner's Guide

You may want to see also

Safety Features: Emergency stops and overload sensors prevent accidents and protect the lift and boat

The safety mechanisms in a cantilever boat lift are crucial to its operation, ensuring the well-being of both the vessel and its passengers. One of the primary safety features is the emergency stop system, which is designed to halt the lift's operation in case of an unforeseen issue. This mechanism is typically triggered by a switch or sensor located at the top of the lift, which is easily accessible to the operator. When activated, the emergency stop immediately cuts power to the lift's motor, bringing the boat to a safe, stationary position. This feature is essential in preventing accidents, especially in emergency situations where the lift might malfunction or encounter unexpected resistance.

Overload sensors are another critical component of the safety system. These sensors are strategically placed within the lift structure and are responsible for monitoring the weight and balance of the boat. If the lift detects that the boat exceeds its weight capacity, it triggers an alarm and activates the emergency stop. This prevents the lift from attempting to lift a boat that is too heavy, which could lead to structural damage or failure. The overload sensors ensure that the lift operates within safe limits, providing peace of mind to both the operator and the boat's occupants.

In addition to these features, the lift's design incorporates a fail-safe mechanism that engages when the boat is fully loaded. This mechanism ensures that the lift cannot be operated until the boat is securely in place and balanced. By requiring a specific sequence of actions, such as locking the boat into position before starting the lift, this design element further enhances safety. It minimizes the risk of accidents caused by improper loading or positioning of the boat.

The combination of emergency stops and overload sensors creates a robust safety net for the cantilever boat lift. These features are designed to respond swiftly to any potential hazards, ensuring that the lift and the boat are protected from damage and that the passengers remain safe. Regular maintenance and testing of these safety mechanisms are essential to guarantee their reliability and effectiveness over time.

Boat Insurance: Does It Travel With You to Another Province?

You may want to see also

Material and Construction: High-strength materials and precision engineering ensure structural integrity and longevity

The design and construction of a cantilever boat lift require a meticulous approach to ensure its stability and longevity. High-strength materials are essential to withstand the forces acting on the lift, particularly the weight of the boats and the dynamic loads during operation. Materials such as advanced composites, high-tensile steel alloys, and aluminum alloys are commonly utilized due to their exceptional strength-to-weight ratios. These materials provide the necessary structural integrity while keeping the overall weight of the lift manageable.

Precision engineering plays a critical role in the construction process. Every component, from the main support structure to the individual boat cradles, must be meticulously designed and manufactured to exact specifications. Computer-aided design (CAD) software is employed to create detailed models, allowing engineers to simulate various load conditions and optimize the structure. This precision ensures that the lift can handle the anticipated loads without compromising safety.

The main support structure, often a series of interconnected beams, is a key element in the design. It must be robust enough to support the entire weight of the lift and the boats it carries. Advanced welding techniques and precision joining methods are employed to create a sturdy and rigid framework. The use of high-strength bolts and fasteners further enhances the structural integrity, ensuring that the lift remains stable even under the most demanding conditions.

In addition to the main structure, the boat cradles or supports are another critical aspect. These cradles need to securely hold the boats in place while allowing for smooth movement during the lifting process. Precision engineering ensures that the cradles are perfectly aligned and balanced, providing a stable platform for the boats. The materials used for the cradles are carefully selected to offer both strength and corrosion resistance, as they will be in direct contact with the water and boat surfaces.

Furthermore, the integration of precision engineering extends to the mechanical and electrical systems. The lift's operation involves precise control mechanisms, such as hydraulic or mechanical actuators, which require meticulous design and assembly. These systems must be reliable and capable of withstanding the environmental conditions they will encounter. Regular maintenance and the use of high-quality materials further contribute to the overall longevity and performance of the cantilever boat lift.

Properly Disconnecting Your Boat Battery: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A cantilever boat lift is a mechanical system designed to raise and lower boats or small watercraft vertically, typically for storage or maintenance purposes. It operates on a simple yet innovative principle.

The lift mechanism is based on a cantilever arm, which is a rigid structure that extends horizontally from a vertical support. This arm is connected to a motor or actuator, which provides the necessary force to move the boats. When the motor is activated, it pulls or pushes the arm, causing the boat to move up or down along the arm's length.

The main components include the cantilever arm, a motor or actuator, a guide system, and a safety mechanism. The arm provides the structural support and movement, while the motor drives the action. The guide system ensures smooth and controlled movement, and the safety mechanism prevents accidents by limiting the lift's travel range.

Cantilever boat lifts offer several benefits. They provide a compact and space-efficient solution, as the lift can be installed near the water's edge without occupying a large area. The lift's design allows for easy access to boats, making it convenient for storage and retrieval. Additionally, the mechanical lift ensures a consistent and controlled movement, reducing the risk of damage to the boats.

Safety is a critical aspect of cantilever boat lifts. The system should be designed with overload protection to prevent damage to the lift or boats. Emergency stop mechanisms and regular maintenance are essential to ensure safe operation. It is also important to follow proper operating procedures and guidelines to minimize risks associated with boat handling and lift mechanisms.