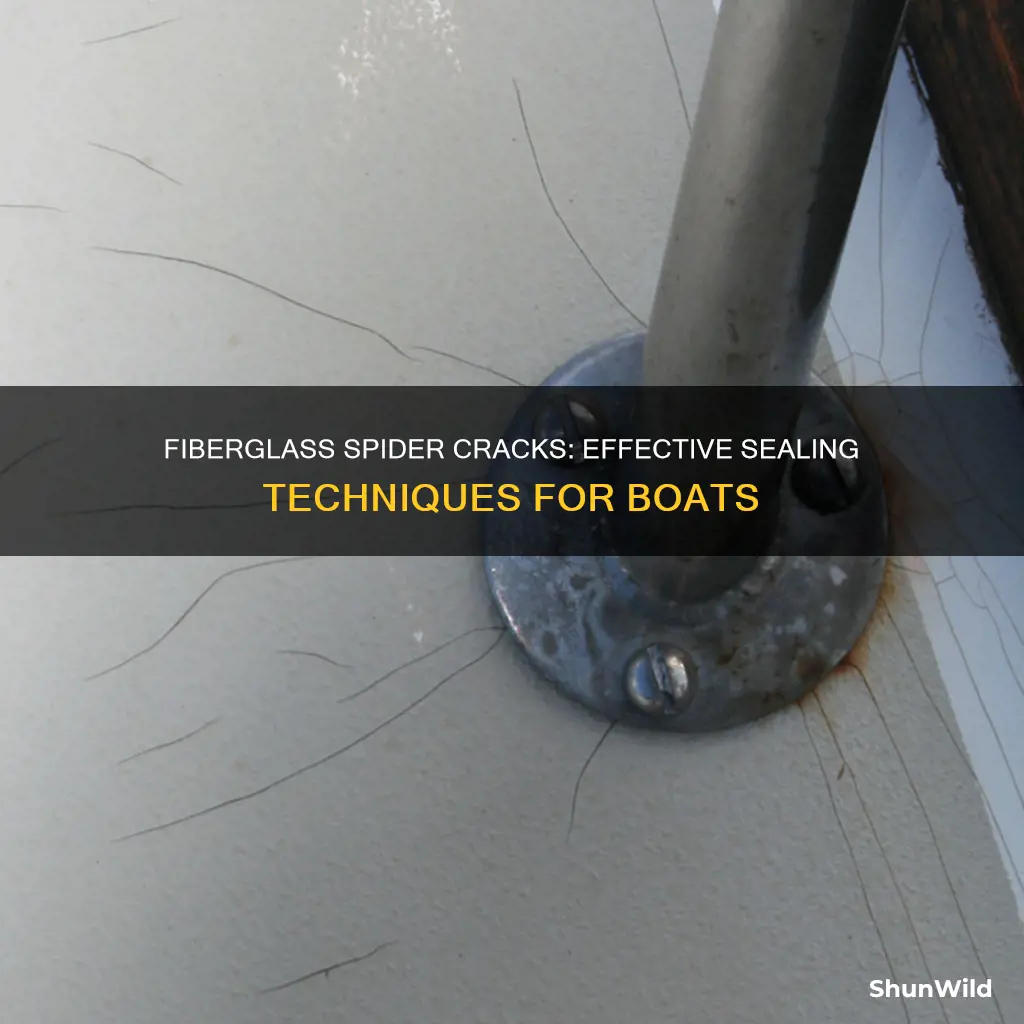

Sealing cracks in fiberglass boat structures can be a challenging task, especially when dealing with spider cracks, which are small, fine fissures that can appear on the surface of the boat. These cracks often occur due to the natural expansion and contraction of the material or from minor impacts. To effectively address this issue, boat owners and enthusiasts need to understand the specific techniques and materials required to ensure a durable and long-lasting repair. This introduction aims to provide an overview of the process, highlighting the importance of proper preparation, the choice of suitable sealants, and the application methods to achieve a seamless and robust repair for fiberglass spider cracks.

| Characteristics | Values |

|---|---|

| Materials Needed | Fiberglass repair kit, epoxy resin, hardener, fiberglass cloth, tape, primer, sandpaper, cleaning supplies, masking tape, gloves, safety goggles |

| Preparation | Clean the cracked area thoroughly, removing any dirt or old filler. Ensure the surface is dry and free of debris. |

| Filling the Crack | Use a fiberglass repair kit or a suitable epoxy-based filler to fill the crack. Follow the manufacturer's instructions for mixing and application. |

| Sanding and Smoothing | After the filler has cured, sand the area to create a smooth surface. Use fine-grit sandpaper to avoid scratching the surrounding fiberglass. |

| Priming (Optional) | Apply a fiberglass primer to the repaired area to ensure better adhesion and a seamless finish. |

| Reinforcement | For larger cracks, consider reinforcing the repair with a layer of fiberglass cloth. Wet the cloth slightly, apply resin, and then lay it over the filled crack. |

| Curing and Drying | Allow the repair to cure according to the product instructions. Keep the boat out of water during the curing process. |

| Sanding and Fairing | Once cured, sand the entire surface to ensure a smooth transition between the repair and the original fiberglass. |

| Painting or Topcoating | Apply a suitable marine paint or topcoat to protect the repair and match the boat's finish. |

| Safety Precautions | Wear protective gear, including gloves and safety goggles, when working with epoxy resins and fiberglass. Ensure proper ventilation in the workspace. |

| Professional Help | For extensive damage or if you're unsure about the process, consider consulting a professional marine fiberglass repair specialist. |

What You'll Learn

- Preparation: Clean and roughen the surface for optimal adhesion

- Material Selection: Choose a suitable epoxy or fiberglass repair compound

- Application Technique: Follow a step-by-step process for best results

- Reinforcement: Use fiberglass cloth for added strength and durability

- Finishing: Sand and paint to match the boat's original appearance

Preparation: Clean and roughen the surface for optimal adhesion

Before you begin the process of sealing spider cracks in your fiberglass boat, it's crucial to ensure that the surface is properly prepared for optimal adhesion. This initial step is often overlooked but is essential for a successful repair. Here's a detailed guide on how to clean and roughen the fiberglass surface:

Cleaning the Surface: Start by thoroughly cleaning the area around the spider cracks. Use a mild detergent or a specialized marine cleaner to remove any dirt, grime, or old sealant. You can use a soft brush or a sponge to scrub the surface gently, ensuring you don't scratch the fiberglass. Rinse the area with clean water to remove any residue and allow the surface to dry completely. This step is vital as any remaining contaminants can interfere with the bonding process.

Surface Preparation Techniques: Fiberglass, being a smooth material, requires a slightly different approach for adhesion. Here are a couple of methods to roughen the surface:

- Sandblasting: This technique involves propelling small abrasive particles onto the surface using compressed air. Sandblasting creates a textured finish, providing an excellent base for the sealant. It's a professional method that ensures a consistent and effective surface for bonding. You can rent a sandblaster or hire a professional to achieve the best results.

- Fine Sandpaper: For smaller areas or touch-ups, using fine-grit sandpaper (600-1200 grit) is an effective way to roughen the surface. Gently sand the area, following the direction of the fiberglass weave. This method is more suitable for smaller repairs and should be done carefully to avoid scratching the surrounding areas. After sanding, wipe away any dust with a damp cloth.

The goal of this preparation process is to create a rough, textured surface that the sealant can grip and adhere to. This ensures that the repair is strong and long-lasting. Remember, a well-prepared surface is the foundation for a successful fiberglass repair.

Boat Insurance in Manitoba: What You Need to Know

You may want to see also

Material Selection: Choose a suitable epoxy or fiberglass repair compound

When it comes to repairing spider cracks in a fiberglass boat, selecting the right material is crucial for a successful and long-lasting fix. Spider cracks, often appearing as fine, web-like fissures, can be a result of various factors such as age, UV damage, or impact. The primary goal is to find a material that can effectively fill and strengthen these cracks, ensuring the structural integrity of the boat.

Epoxy resins are a popular choice for this task due to their versatility and strength. Epoxy systems typically consist of a resin and a hardener, which, when mixed, undergo a chemical reaction, forming a hard, durable bond. This reaction creates a strong, flexible material that can effectively bridge the gap in the fiberglass. Look for an epoxy specifically designed for marine applications, as these are formulated to withstand the harsh conditions of the water, including UV exposure and saltwater corrosion.

Fiberglass repair compounds, also known as fiberglass resins, are another option. These compounds are usually pre-mixed and ready to use, making them more convenient for on-site repairs. They are specifically formulated to be compatible with fiberglass, ensuring a strong bond. When choosing a repair compound, consider its viscosity; a more viscous compound will provide better structural support and fill larger gaps, while a less viscous one is suitable for finer cracks.

In addition to epoxy and repair compounds, you might also consider using specialized fiberglass repair kits. These kits often include a variety of tools and materials, such as fiberglass cloth, tape, and a suitable epoxy or compound, all designed to work together for a seamless repair. These kits can be particularly useful for beginners or those with limited experience in boat repairs, as they provide a comprehensive solution.

When selecting your repair material, it's essential to consider the specific conditions of the crack. For deeper or more extensive damage, a stronger epoxy system might be required. For smaller, finer cracks, a repair compound or kit may be sufficient. Always follow the manufacturer's instructions for mixing and application to ensure the best results and a long-lasting repair.

The Benefits of Owning a Deeded Boat Dock

You may want to see also

Application Technique: Follow a step-by-step process for best results

Sealing fiberglass spider cracks on a boat requires a careful and meticulous approach to ensure a durable and long-lasting repair. Here is a step-by-step guide to help you achieve professional results:

- Preparation: Begin by thoroughly cleaning the cracked area. Remove any loose debris, dirt, or old sealant using a wire brush or a scraper. Ensure the surface is smooth and free from contaminants. Rinse the area with water and allow it to dry completely before proceeding.

- Repair Material Selection: Choose an appropriate epoxy-based repair compound or resin suitable for fiberglass. Consider the specific requirements of the crack and the boat's material. Some epoxy systems are designed for structural repairs and offer excellent strength, while others are more suitable for cosmetic touch-ups. Select a product that provides the necessary adhesion and flexibility for your application.

- Filling the Crack: Carefully fill the crack with the chosen repair material. Use a small spatula or a putty knife to spread the epoxy evenly, ensuring it fills the entire gap. Press the material into the crack, removing any air bubbles. You can use a piece of glass fiber cloth (woven or unidirectional) to reinforce the repair, especially if the crack is large or deep. Ensure the cloth is properly saturated with the epoxy and gently press it into the filled crack.

- Curing and Sanding: Allow the epoxy to cure according to the manufacturer's instructions. This process may take several hours or even overnight, depending on the product. Once cured, inspect the repair. If the surface is rough or uneven, gently sand it with fine-grit sandpaper (600-1200 grit) to create a smooth finish. Take care not to remove too much material, as this can weaken the repair.

- Final Touches: After sanding, wipe away any dust and debris. Apply a thin layer of the epoxy resin over the entire repair area to create a seamless finish. This step is optional but can enhance the appearance and provide additional protection. Allow this final layer to cure before testing the repair's strength and durability.

Remember, practice and patience are key when dealing with fiberglass repairs. Take your time, follow the manufacturer's guidelines, and seek guidance from experienced professionals if needed. With careful application and the right materials, you can effectively seal those spider cracks and restore your boat's structural integrity.

Boys in the Boat: Movie Adaptation Confirmed?

You may want to see also

Reinforcement: Use fiberglass cloth for added strength and durability

Sealing fiberglass spider cracks on a boat requires a careful and detailed approach to ensure a strong and durable repair. One effective method to reinforce the cracked area and prevent further damage is by using fiberglass cloth. This technique provides added strength and protection to the boat's structure.

Fiberglass cloth, also known as woven fiberglass, is a versatile material commonly used in boat repairs. It is made of fine glass fibers woven into a mat or cloth, which offers excellent structural integrity. When applied to the cracked area, the fiberglass cloth acts as a reinforcing layer, providing the necessary strength to withstand the stresses of the boat's environment. This is particularly important for spider cracks, as they often occur in areas with high stress concentrations, such as along the hull's seams or near attachments.

To begin the reinforcement process, carefully clean the cracked area to remove any dirt, debris, or old filler material. Ensure the surface is smooth and free from contaminants. Then, apply a suitable fiberglass repair resin to the crack, following the manufacturer's instructions. The resin acts as a bonding agent, creating a strong connection between the existing fiberglass and the new reinforcement. Once the resin is applied, carefully lay the fiberglass cloth over the crack, ensuring it covers the entire damaged area. Use a rolling pin or a similar tool to smooth out any wrinkles or air bubbles, creating a tight and secure bond.

After the fiberglass cloth is applied, allow the resin to cure according to the manufacturer's guidelines. This process typically involves a period of drying and hardening. Once cured, the fiberglass cloth becomes an integral part of the boat's structure, providing additional strength and protection against further cracking. This method is especially useful for larger spider cracks, as it helps to distribute the stress evenly and prevents the crack from spreading.

By utilizing fiberglass cloth for reinforcement, you create a robust and long-lasting repair. This technique is widely used in boat restoration and maintenance, ensuring the vessel's structural integrity and longevity. It is a practical and effective solution for addressing spider cracks, offering both strength and durability to the boat's fiberglass structure.

Semi Truck Engines: Powerful Enough for Boats?

You may want to see also

Finishing: Sand and paint to match the boat's original appearance

When it comes to restoring the appearance of a fiberglass boat with spider cracks, the finishing process is crucial to achieving a seamless and professional result. Here's a detailed guide on how to sand and paint the boat to match its original appearance:

Step 1: Sanding for a Smooth Surface

Start by carefully sanding the cracked areas to create a smooth surface. Use fine-grit sandpaper, preferably 400 or 600 grit, to gently remove any loose debris and rough edges. Work in small sections, ensuring you follow the natural curves and contours of the boat's surface. Take your time and use gentle, circular motions to avoid further damaging the fiberglass. After sanding, wipe away any dust or debris with a tack cloth to prepare the surface for the next step.

Step 2: Filling and Sanding Again

To ensure a seamless finish, use a fiberglass filler or putty to fill the sanded areas. Choose a product specifically designed for marine applications, ensuring it is compatible with fiberglass. Apply the filler sparingly, only where necessary, and allow it to dry completely according to the manufacturer's instructions. Once dry, sand the filled areas again, using a slightly finer grit (e.g., 600 or 800 grit) to create a smooth transition between the filled and original surfaces. This step is crucial for achieving a professional-looking finish.

Step 3: Priming and Painting

Before applying paint, it's essential to prime the surface to ensure better adhesion. Use a marine-grade primer suitable for fiberglass. Apply the primer evenly across the entire area, following the manufacturer's instructions for drying time. Once the primer is dry, sand it lightly with fine-grit sandpaper to create a smooth, even surface for the paint. Now, you can apply the paint to match the boat's original color. Use a high-quality marine paint designed for fiberglass to ensure durability and resistance to the marine environment. Apply multiple thin coats, allowing sufficient drying time between each coat, to achieve the desired color and finish.

Step 4: Final Touches

After the final coat of paint is dry, inspect the boat's surface for any imperfections. If necessary, touch up any small areas with additional coats of paint and sand as needed. Pay close attention to the edges and ensure they are smooth and consistent. Consider using a gelcoat or clear coat to protect the paint and add a glossy finish, especially if the original boat had a high-gloss appearance.

By following these steps, you can effectively sand and paint the fiberglass boat to restore its original appearance, making the spider cracks virtually invisible. Remember, patience and attention to detail are key to achieving a professional-grade finish.

St. Maries Idaho's Jet Boat Races: Dates and Details

You may want to see also

Frequently asked questions

Spider cracks in fiberglass can be a common issue, especially in older boats. To repair these cracks, you'll need to follow a step-by-step process. First, clean the area around the crack to remove any dirt or debris. Then, use a fiberglass repair kit specifically designed for marine applications. These kits typically include a filler compound and a hardening agent. Fill the crack generously, ensuring the material is level with the surrounding surface. Allow it to cure according to the manufacturer's instructions. Once cured, sand the repair area smooth and apply a marine-grade fiberglass cloth to reinforce the area. Finally, use a marine-grade epoxy or a specialized fiberglass repair sealant to provide a durable seal.

While home-repair epoxies can be used for general repairs, they may not be the best choice for sealing spider cracks in a marine environment. Marine-grade epoxies are specifically formulated to withstand the harsh conditions of saltwater and UV exposure. These specialized epoxies offer better resistance to corrosion and degradation, ensuring a longer-lasting repair. Additionally, marine-grade products often come with additional benefits like improved adhesion to fiberglass and enhanced flexibility, which can be crucial for repairing flexible areas like spider cracks.

It's generally not recommended to attempt sealing spider cracks without using specialized products designed for marine fiberglass repairs. DIY methods might include using common household materials, which can lead to inadequate results and potential damage to the boat's structure. For example, trying to fill cracks with regular wood filler or putty may not provide the necessary strength or flexibility required for a durable repair. It's best to invest in a proper fiberglass repair kit or seek professional assistance to ensure a successful and long-lasting seal.