Putting a plywood floor in a boat is a great way to improve comfort and usability. It makes it easier to stand up and move around, and can be customised with trap doors for storing items. When it comes to the type of plywood, marine-grade is recommended to prevent rot, although this can be costly. An alternative is to use regular plywood and seal it with resin, epoxy or varnish. It's important to ensure that all surfaces, including the edges, are coated to protect the plywood from moisture. Some people also choose to add a layer of outdoor carpet or bedliner coating for a non-slip surface. The thickness of the plywood will depend on the supporting structure of the boat, but it's generally recommended to use at least half-inch plywood for strength and stiffness.

What You'll Learn

Choosing the right plywood for your boat floor

When it comes to choosing plywood for your boat floor, there are several factors to consider to ensure durability and safety. The type of plywood you select will depend on various factors, including the intended use, exposure to moisture, desired durability, and budget. Here are some guidelines to help you make the right choice:

Marine-Grade Plywood:

Marine-grade plywood is specifically designed for the marine environment and is manufactured to withstand rough water conditions. It is constructed with high-quality hardwood veneers, such as birch or mahogany, and bonded with waterproof adhesives. This type of plywood is ideal for boat floors as it provides uniform strength and complete waterproofing. It is also resistant to rotting, even with constant water exposure. However, marine-grade plywood is more expensive than regular plywood and may require purchasing from specialised marine supply stores.

Regular Plywood:

Regular plywood is made from a mix of wood species and standard adhesives that may not be waterproof. While it is more affordable, it is more susceptible to water damage and can warp or delaminate over time. If you opt for regular plywood, ensure it is exterior-grade and treat it with a waterproof coating to enhance its durability.

Pressure-Treated Plywood:

Pressure-treated plywood is reinforced with chemical formulations to enhance its durability and resistance to rotting, moulding, and termite damage. However, it may not be suitable for direct water exposure and is typically used in areas with minimal water contact. If you choose pressure-treated plywood, ensure proper ventilation during the treatment process to avoid high moisture content, which can affect the bonding of epoxy coatings.

Fire-Treated Plywood:

Fire-treated plywood undergoes a process of pressure and fire treatment, making it fire-resistant. This type of plywood can absorb moisture and is suitable for boat flooring that needs to bear gas fuels. However, it may still catch fire, so additional fire-prevention measures should be considered.

Exterior-Grade Plywood:

Exterior-grade plywood is a good alternative to marine-grade plywood for boat flooring. It is designed for superior external use and can withstand frequent exposure to extreme weather conditions and both fresh and saltwater environments. Waterproof sealants and phenol glue are often used to reinforce the planks and enhance their durability.

When choosing plywood for your boat floor, it is essential to consider the specific requirements of your boat, including weight capacity and exposure to the elements. Additionally, factor in your budget and the level of maintenance you are willing to undertake. Remember that proper sealing and regular maintenance are crucial to maximising the lifespan of your boat floor.

Boat Registration Records: Public or Private in Florida?

You may want to see also

Sealing and protecting your plywood floor

Sealing and protecting your plywood boat floor is a crucial step in ensuring the longevity of your boat. Here are some detailed instructions to help you through the process:

Step 1: Choose the Right Plywood

It is essential to select the right type of plywood for your boat floor. Marine-grade plywood is ideal, as it is designed to withstand direct contact with water. The layers of marine-grade plywood are held together with waterproof adhesive, making it a durable option for your boat.

Step 2: Prepare the Surface

Before applying any sealant, it is crucial to clean and prepare the surface of the plywood. Use a soft cloth or paper towel dipped in acetone to wipe down the wood, removing any grease or stains. Allow the acetone to dry completely before proceeding to the next step.

Step 3: Sand the Wood

Sand both sides of the plywood, including the edges, using 80-grit sandpaper. This step will create a smooth surface and help the sealant adhere better to the wood. Make sure to wipe away all the dust with a soft cloth after sanding.

Step 4: Apply the Sealant

For the sealant, a clear, penetrating epoxy is recommended. This type of epoxy penetrates deep into the wood, dries transparent, and requires less maintenance than other sealants. You can also use a marine-grade sealer, but it will require more coats and need to be reapplied every 3 to 4 years.

When applying the epoxy, start with the top and side edges, and then move to the front face of the plywood. Allow the epoxy to dry completely before flipping the wood over and applying it to the bottom edge and back.

Step 5: Add Additional Coats

To maximize the lifespan of your plywood floor, it is essential to apply multiple coats of sealant. A good rule of thumb is to apply as many coats as there are layers of plywood. For example, if your plywood has seven layers of wood, apply seven layers of sealant.

Be sure to gently scuff the wood with sandpaper between each coat to enhance adhesion, and always wipe away any dust before adding the next layer.

By following these steps, you can effectively seal and protect your plywood boat floor, ensuring its longevity and durability in the face of moisture and water exposure.

Buying a 22ft Polar Boat: Is It a Good Choice?

You may want to see also

Using epoxy to coat your plywood floor

Epoxy is a great option for sealing your plywood boat floor. It is important to note that the plywood will need to be coated with something to prevent it from rotting, and epoxy is a good choice for this. When applying epoxy, it is recommended to do two coats, as the first coat will soak into the wood and the second coat will provide a good seal. You will need to calculate the square footage of your floor to determine how much epoxy to purchase. For reference, one gallon of epoxy will cover about 12 square feet at 1/8 inch thickness.

Before applying the epoxy, make sure the plywood is clean and free of any debris or contaminants. You may also want to consider sealing the holes for mounting with epoxy as well. This will help protect your floor from water damage and ensure a long-lasting finish. After the epoxy has dried, you can add a topcoat or paint if desired.

While epoxy is a great option, it can be expensive. If you are looking for a more cost-effective solution, you can use a varnish mix or polyester resin to seal your plywood floor. However, keep in mind that these options may not provide the same level of protection as epoxy.

Additionally, some people choose to use fiberglass resin to seal their plywood floors. This option is less expensive than epoxy and provides similar benefits. However, it is important to note that you will need to add a topcoat to the resin to provide a durable finish.

Obtaining an Electric Boat Title: Navigating the Process in South Carolina

You may want to see also

Adding a carpet or vinyl layer to your plywood floor

Preparation:

Before you begin, ensure your plywood floor is well-prepared. Fill any voids or gaps in the plywood with a suitable sealant such as silicone. Sand the plywood surface with coarse sandpaper to create a rough texture, which will help the adhesive grip effectively. You may also want to apply a few coats of spar varnish or resin to the plywood and let it cure thoroughly. This will protect the wood and provide a better base for adhesion.

Choosing the Right Carpet or Vinyl:

Select a marine-grade carpet or vinyl that is specifically designed for boat floors. These materials are designed to withstand the unique challenges of a marine environment, including water resistance and durability.

Adhesives and Installation:

When it comes to adhesives, there are a few options. You can use an outdoor carpet adhesive or a marine vinyl flooring adhesive, both of which are readily available at hardware stores. Alternatively, some people recommend using contact cement or 3M rubber cement/weather strip adhesive.

Work in small sections at a time. Apply the adhesive to the plywood, following the manufacturer's instructions. Then, carefully lay the carpet or vinyl, using a roller to smooth it out and remove any air bubbles. For vinyl, you can also use a rolling pin. Make sure you work quickly, as some adhesives set up fast.

For added security, especially with carpets, you can use stainless steel staples along the bottom of the floor to hold the covering in place. Be generous with the staples, especially at the corners, to ensure a firm hold.

Sealing and Protection:

Some people recommend sealing the plywood with a coat of oil-based paint, spar varnish, or epoxy before installing the carpet or vinyl. This adds an extra layer of protection against moisture.

Tips and Tricks:

- Always work in a well-ventilated area when using adhesives, and consider wearing a mask to avoid inhaling fumes.

- If you're using vinyl, you can wrap the edges of the plywood to protect them from moisture.

- If you're working with new marine plywood, seal the cut edges with paint or varnish to protect them.

- If you're unsure about the type of adhesive to use, consult a professional or a marine supply store for advice.

By carefully following these steps, you can successfully add a carpet or vinyl layer to your plywood boat floor, creating a durable and attractive finish.

Building a Paddle Boat: A Fun Primary School Project

You may want to see also

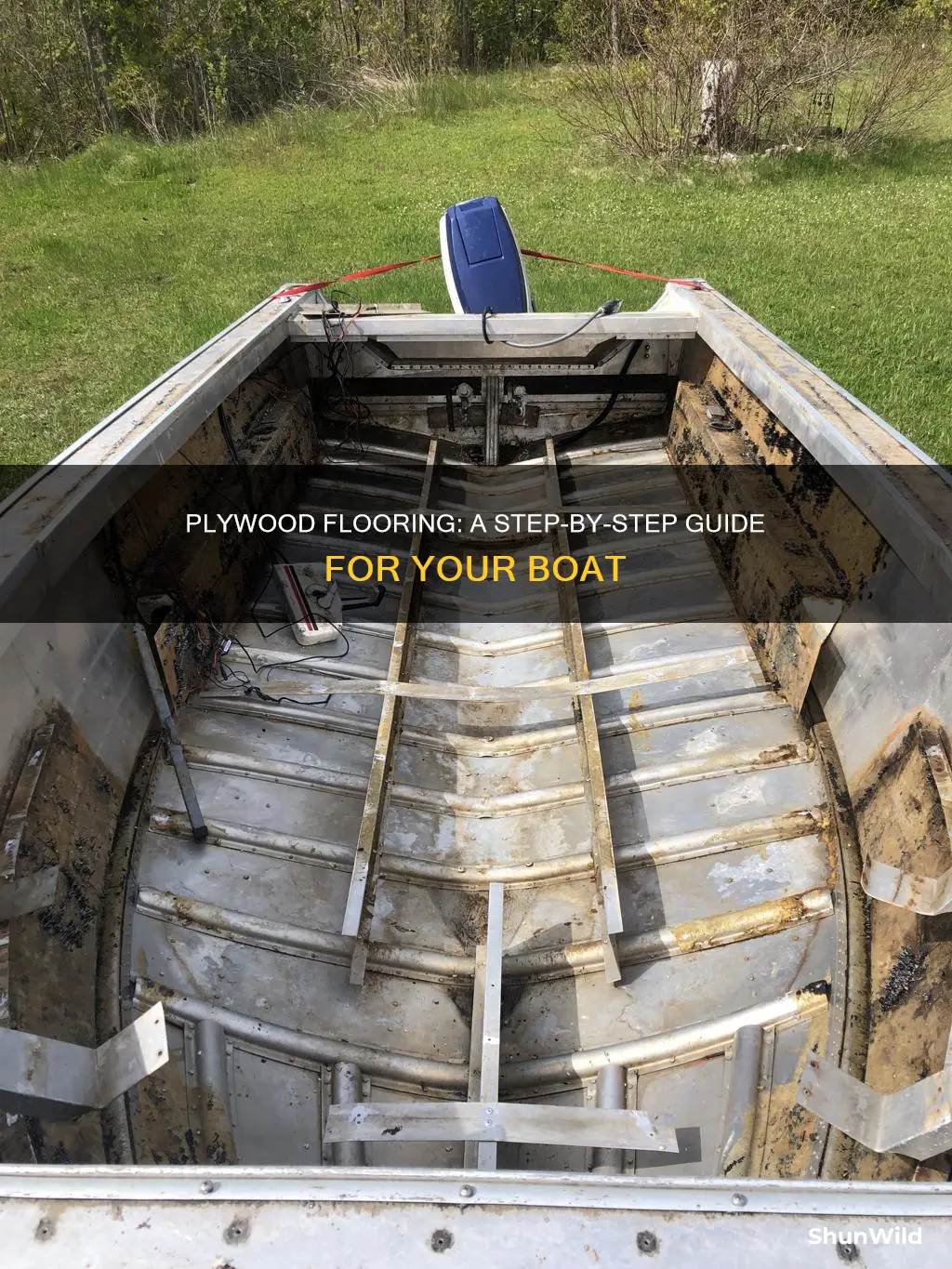

Installing your plywood floor

Before you begin, make sure you have all the right materials. You will need plywood, of course, but which type? Some people recommend using regular plywood, such as CDX, and sealing it well with varnish or epoxy. Others insist that only marine-grade plywood will do. If you're on a budget, CDX should be fine, but if you want your new floor to last, it might be worth investing in marine-grade.

You will also need to decide how to seal your plywood. Some options include varnish, epoxy, resin, and even bed liner or truck bed liner. You could also use a combination of these, such as sealing your plywood with varnish and then covering it with bed liner.

Now it's time to cut your plywood to size. If you're creating a floor with multiple removable sections, be sure to plan out your cuts carefully. Cut slowly and measure twice to ensure that your plywood fits together snugly.

Once your plywood is cut, it's time to seal it. If you're using varnish, you can thin it with mineral spirits and apply it liberally with a brush, roller, or spray. Allow it to dry for at least 48 hours before applying additional coats. If you're using epoxy, you'll want to apply a coat to the underside of your plywood first, followed by two or more coats to the top and edges. Sand the plywood between coats for better adhesion.

After your plywood is sealed, you can install it in your boat. Screw it into place, taking care not to screw it in too tightly, as plywood expands and contracts with the weather. If you're creating a removable floor, you may want to use snaps or another type of removable fastener.

Finally, it's time to finish your floor. You could cover it with outdoor carpet or vinyl, or apply a final coat of bed liner. Whichever you choose, make sure your floor is clean and dry before installing it. Enjoy your new boat floor!

Repairing Boat Carpet Snaps: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Marine-grade plywood is the best option for a boat floor as it is designed for strength and durability in water. However, if you are on a budget, exterior-grade plywood such as CDX plywood can also be used, as long as it is sealed properly.

Yes, it is important to treat the plywood before installation to protect it from water damage and rot. You can use a penetrating epoxy sealer, oil-based paint, or a varnish mixture. Make sure to apply multiple coats and seal all edges and surfaces.

Instead of carpet, consider using a bed liner coating, vinyl, or outdoor paint. Carpet can tangle tackle and hold unpleasant smells. A bed liner coating provides a non-skid surface that is easy to clean. Vinyl or outdoor paint are also good options that can be hosed off and cleaned easily.