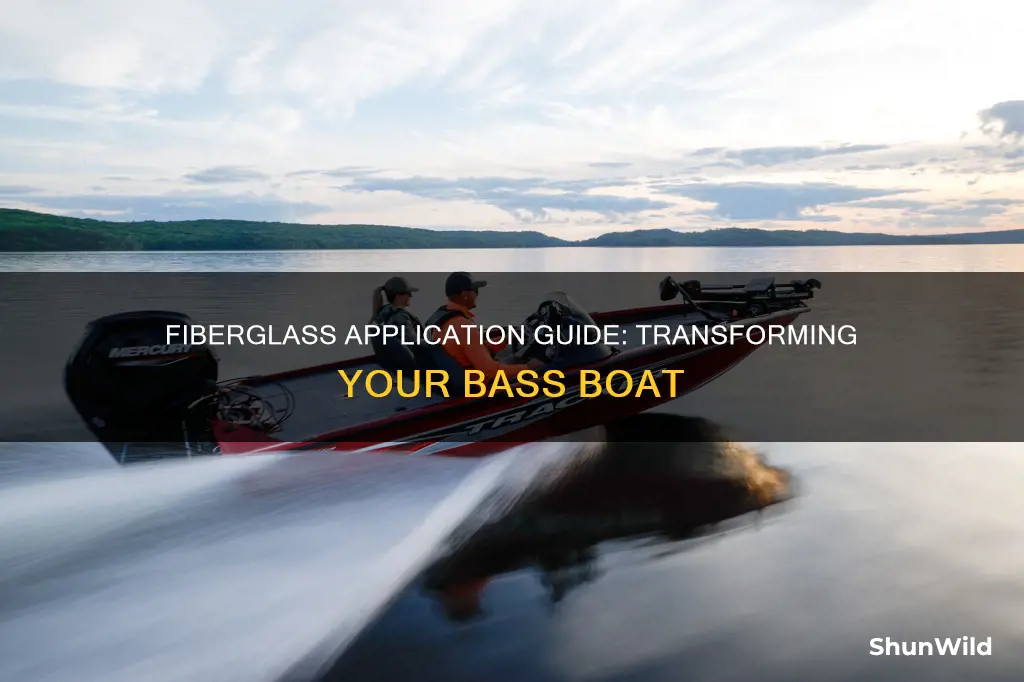

Applying fiberglass to a bass boat is a popular upgrade for anglers looking to enhance the boat's performance, durability, and aesthetics. This process involves carefully laying down layers of fiberglass cloth over a mold or a specific area of the boat, using a resin as a bonding agent. It's a detailed and precise task that requires skill and experience to ensure a smooth, seamless finish. The process typically begins with preparing the boat's surface, ensuring it's clean and free of debris, and then applying a primer to create a suitable base for the fiberglass. Once the primer is dry, the fiberglass cloth is carefully laid over the area, ensuring it's smooth and even, and then covered with multiple layers of resin to create a strong, durable bond. This method can significantly improve the boat's structural integrity and appearance, making it a valuable investment for any bass boat owner.

What You'll Learn

- Preparation: Clean and prepare the boat's surface, ensuring it's smooth and free of contaminants

- Material Selection: Choose the right fiberglass type and resin for your boat and desired finish

- Layup Technique: Apply layers of fiberglass cloth and resin, following a specific pattern for strength

- Reinforcement: Add glass tape or mats for structural integrity, especially in high-stress areas

- Finishing Touches: Sand, fair, and paint to achieve a smooth, professional-looking finish

Preparation: Clean and prepare the boat's surface, ensuring it's smooth and free of contaminants

Before you begin the process of applying fiberglass to your bass boat, proper preparation is crucial to ensure a successful and long-lasting repair. The key to a strong bond between the fiberglass and the boat's surface is a clean and smooth preparation. Here's a step-by-step guide to achieving this:

Start by thoroughly cleaning the entire surface of the boat where the fiberglass will be applied. Use a mild detergent or a specialized boat cleaner to remove any dirt, grime, or old paint. Rinse the boat thoroughly with water to ensure no residue remains. Pay close attention to areas around the existing fiberglass, as these spots may require extra care to ensure a seamless finish. For stubborn stains or old glue residue, consider using a scraper or a razor blade to carefully remove the contaminants without damaging the underlying material.

Once the cleaning process is complete, inspect the surface for any imperfections, such as small holes, scratches, or imperfections. These areas need to be addressed before applying the fiberglass. Use a fine-grit sandpaper (e.g., 400-grit) to gently smooth out the surface. This step is essential to create a uniform texture and ensure the fiberglass adheres properly. After sanding, wipe away the dust and any remaining debris with a clean cloth.

It's important to work quickly after cleaning to avoid contaminants from the air settling on the surface. If you notice any dust or particles, gently blow them away with an air gun or a small fan. Ensure the area is well-ventilated to prevent any potential health risks associated with the chemicals used during the preparation process.

By following these preparation steps, you'll create a clean, smooth, and contaminant-free surface, providing an ideal foundation for the fiberglass application, resulting in a strong and durable repair.

Boat Registration HIN: Where Is It Located?

You may want to see also

Material Selection: Choose the right fiberglass type and resin for your boat and desired finish

When it comes to applying fiberglass to your bass boat, material selection is a critical step that can significantly impact the final outcome. The right choice of fiberglass type and resin will ensure a durable, smooth finish that enhances the boat's aesthetics and performance. Here's a detailed guide to help you make the right choices:

Fiberglass Types:

- Woven Fiberglass: This is a traditional and popular choice for boat repairs and custom work. It consists of fine glass fibers woven into a mat or cloth, providing excellent structural strength and flexibility. Woven fiberglass is known for its ability to conform to complex shapes and is often used for hull repairs, deck reinforcements, and creating custom panels.

- Glass Cloth: Glass cloth is a more advanced form of woven fiberglass, offering a smoother surface and more precise control over the application process. It is typically used for creating custom shapes, decorative elements, or when a seamless finish is desired. Glass cloth can be cut to size, allowing for intricate designs and repairs.

- Mat or Pre-impregnated Fiberglass: Mat is a continuous layer of fiberglass cloth that can be cut and shaped as needed. It is often used for larger areas or when a quick and efficient application is required. Pre-impregnated fiberglass, also known as "pre-preg," is a convenient option where the resin is already mixed with the fiberglass, making it ready for immediate use.

Resin Selection:

- Epoxy Resin: Epoxy resins are commonly used in boat building due to their excellent bonding properties and durability. They provide a strong, rigid structure and are often used in combination with woven fiberglass. Epoxy resins can be further categorized into two-part and one-part systems, each with its own advantages. Two-part epoxy resins offer better control over the curing process but require mixing, while one-part resins are easier to use but may have slightly lower strength.

- Polyester Resin: Polyester resins are known for their ease of use and fast curing time, making them a popular choice for beginners. They provide a smooth finish and are less prone to shrinkage compared to epoxy resins. However, polyester resins may not offer the same level of strength and durability as epoxy, making them less suitable for structural repairs.

- Vinylester Resin: Vinylester resins offer a balance between strength and ease of use. They are more resistant to chemicals and UV light compared to polyester resins, making them ideal for outdoor applications. Vinylester resins are often used in combination with woven fiberglass for boat hulls and structures.

When selecting the resin, consider the desired finish, the environmental conditions the boat will be exposed to, and the level of structural integrity required. For a professional-looking finish, it is recommended to use a resin that complements the chosen fiberglass type. Additionally, always follow the manufacturer's instructions for mixing and application to ensure optimal results.

Remember, the right material selection will set the foundation for a successful fiberglass application, ensuring your bass boat receives the necessary protection, strength, and style.

Boat Seat Redo: Worth the Cost?

You may want to see also

Layup Technique: Apply layers of fiberglass cloth and resin, following a specific pattern for strength

When applying fiberglass to your bass boat, the layup technique is crucial for ensuring strength and durability. Here's a detailed guide on how to achieve this:

Start by preparing your workspace and materials. Ensure you have a clean, dry surface to work on, free from any debris or contaminants. Gather your fiberglass cloth, resin, hardener, and any necessary tools like brushes, rollers, or spray equipment. It's essential to follow the manufacturer's instructions for mixing and preparing the resin and hardener to ensure proper curing.

Begin the layup process by applying a base coat of resin to the surface of the boat. Use a brush or roller to create an even layer, ensuring full coverage. Allow this base coat to cure partially, following the resin manufacturer's guidelines for handling time. This initial layer provides a key for the fiberglass cloth to adhere to the boat's surface.

Now, it's time to apply the fiberglass cloth. Cut the cloth to fit the contours of your boat, ensuring it overlaps slightly at the edges. Carefully place the cloth onto the partially cured resin, smoothing out any wrinkles or bubbles. Use a roller or your hands (gloves recommended) to press the cloth firmly against the surface, removing any air bubbles. Repeat this process, applying multiple layers of cloth and resin, following a specific pattern for strength.

The pattern you choose will depend on the structural integrity required for your boat. Typically, a crisscross or 'stitch' pattern is used, where each layer of cloth is applied at a right angle to the previous one. This creates a strong, load-bearing structure. Ensure that each layer is applied with the cloth running in the opposite direction to the previous layer to avoid delamination. Take your time with this process, as precision is key to a strong layup.

After completing the desired number of layers, allow the layup to cure fully according to the resin's instructions. Once cured, inspect the work for any imperfections and make any necessary repairs. This meticulous approach to layup technique will result in a robust and long-lasting fiberglass finish for your bass boat. Remember, practice and patience are essential when mastering the art of fiberglass application.

Sailing the Catalina: Tips and Tricks for Beginners

You may want to see also

Reinforcement: Add glass tape or mats for structural integrity, especially in high-stress areas

When reinforcing a bass boat with fiberglass, adding glass tape or mats is a crucial step to ensure the structural integrity of the vessel, particularly in areas prone to high stress. These materials provide additional strength and support to the existing structure, making it more robust and durable. Here's a detailed guide on how to effectively use glass tape and mats for reinforcement:

Understanding Stress Points: Before you begin, identify the high-stress areas on your bass boat. These are typically areas where the boat experiences the most force, such as the hull bottom, sides near the waterline, and the transom. These regions are more susceptible to damage and require extra reinforcement to withstand the rigors of boating.

Preparing the Surface: Ensure the surface of the boat is clean and free of any debris or old fiberglass. Use a wire brush or sandpaper to remove any old material and create a rough surface. This preparation step is essential for the glass tape or mats to adhere properly and provide optimal reinforcement.

Applying Glass Tape: Glass tape, also known as fiberglass tape, is a versatile reinforcement material. Start by cutting the tape to the appropriate length and width, ensuring it covers the identified stress areas. Begin at a corner or edge and carefully lay the tape, overlapping it slightly with the previous layer. Use a small amount of epoxy resin to bond the tape to the boat's surface, following the manufacturer's instructions for application. Smooth out any wrinkles or bubbles using a putty knife or a heat gun. This process creates a strong, flexible layer that can withstand the forces acting on the boat.

Using Glass Mats: Glass mats, also referred to as cloth or weave, offer a more comprehensive reinforcement solution. Cut the mats to fit the specific areas you want to reinforce. Start by laying a layer of mats, ensuring they are properly saturated with epoxy resin. Use a rolling pin or a heavy object to firmly press the mats onto the boat's surface, removing any air bubbles. This method provides a more uniform and continuous reinforcement, especially in larger areas.

Curing and Sanding: After applying the glass tape or mats, allow sufficient time for the epoxy to cure according to the product's guidelines. Once cured, inspect the area and sand it gently to create a smooth surface. This step ensures that the final finish will be even and professional-looking.

By reinforcing high-stress areas with glass tape or mats, you significantly enhance the structural integrity of your bass boat. This process is a critical part of the fiberglass repair and customization process, ensuring your boat remains strong and durable for many adventures on the water. Remember to follow safety precautions and consider seeking guidance from experienced professionals when working with epoxy resins and fiberglass materials.

The Basics of Revving Boat Engines While in Neutral

You may want to see also

Finishing Touches: Sand, fair, and paint to achieve a smooth, professional-looking finish

Before you begin the painting process, it's crucial to ensure that the fiberglass surface is smooth and free of any imperfections. Start by sanding the entire surface of the boat with fine-grit sandpaper (e.g., 400-grit or higher). This initial sanding will help remove any minor scratches, imperfections, or manufacturer's seams, creating a seamless and smooth base for your paint. Pay close attention to all edges, corners, and areas where the fiberglass meets other materials, such as the hull, transom, or any additional components.

Once the initial sanding is complete, switch to a finer-grit sandpaper (e.g., 600-grit) to achieve an even smoother finish. This step is essential for creating a professional-looking surface that will ensure optimal paint adhesion. After sanding, wipe away any dust or debris using a tack cloth or a damp cloth to remove any remaining particles. This step is vital to ensure a clean and dust-free surface for the final paint application.

Next, consider using a fiberglass filler or putty to address any remaining imperfections or low spots. Carefully apply the filler along the seams and areas where the fiberglass may have been damaged or altered. Allow the filler to dry completely according to the manufacturer's instructions, and then sand it again with a fine-grit paper to ensure it blends seamlessly with the surrounding surface. This step is crucial for achieving a smooth and continuous finish, especially when transitioning between different surfaces or components of the boat.

After the sanding and filler work, it's time to prepare the surface for painting. Clean the entire boat thoroughly to remove any dust, debris, or residue. You can use a mild detergent mixed with water and a soft brush or sponge to ensure a clean and smooth surface for the paint. Rinse the boat thoroughly and allow it to dry completely before proceeding with the painting process.

Finally, when you're ready to paint, choose a high-quality marine paint suitable for fiberglass surfaces. Apply the paint in thin, even coats, allowing each coat to dry completely before adding the next. This process ensures a smooth and professional finish. Remember to follow the manufacturer's instructions for the best results. Properly sanding, filling, and preparing the fiberglass surface will result in a durable and aesthetically pleasing finish for your bass boat.

The Art of Formatting Boat Names in APA Style

You may want to see also

Frequently asked questions

For bass boats, a suitable fiberglass choice is E-glass (also known as fiberglass type I or S-glass). E-glass is a common and cost-effective option, offering a good balance of strength and flexibility. It is often used in boat construction due to its ability to withstand the elements and provide structural integrity.

Proper surface preparation is crucial for a successful fiberglass application. Start by thoroughly cleaning the boat's surface to remove any dirt, grease, or old paint. Use a wire brush or sandpaper to create a rough surface, ensuring the fibers have something to adhere to. Repair any holes or damage with a suitable fiberglass repair kit, and ensure the area is dry before proceeding.

You will need several tools and materials for the job, including a fiberglass cloth (also known as a weave or mat), a resin (usually epoxy or polyester), a catalyst to mix with the resin, a spray gun or brush for application, and a heat gun or hairdryer for curing. Additionally, safety gear like gloves, goggles, and a respirator is essential to protect yourself during the process.

While it is possible to apply fiberglass to a bass boat yourself, it is a complex process that requires skill, experience, and the right equipment. If you are new to fiberglass work, it is highly recommended to seek guidance from an experienced professional or take a fiberglass boat-building course. They can provide valuable insights and ensure the job is done correctly and safely.