Understanding the mechanics of boat steering cables is crucial for any boater, especially when it comes to 13-foot vessels. These cables play a vital role in transmitting the operator's steering input from the helm to the rudder, allowing precise control of the boat's direction. The system involves a series of pulleys, sheaves, and cables that work in harmony to ensure smooth and responsive steering. This introduction aims to delve into the intricate workings of these cables, exploring their design, functionality, and the factors that can influence their performance in different boat sizes and conditions.

What You'll Learn

- Cable Structure: Inner and outer sheathing protect the steel wire core

- Hydraulic Power: Cylinders convert hydraulic pressure into mechanical movement

- Pulleys and Sheaves: These guide the cable and transfer force to the rudder

- Rudder Control: The cable's tension moves the rudder, allowing steering

- Safety Mechanisms: Devices like stops prevent over-steering and cable damage

Cable Structure: Inner and outer sheathing protect the steel wire core

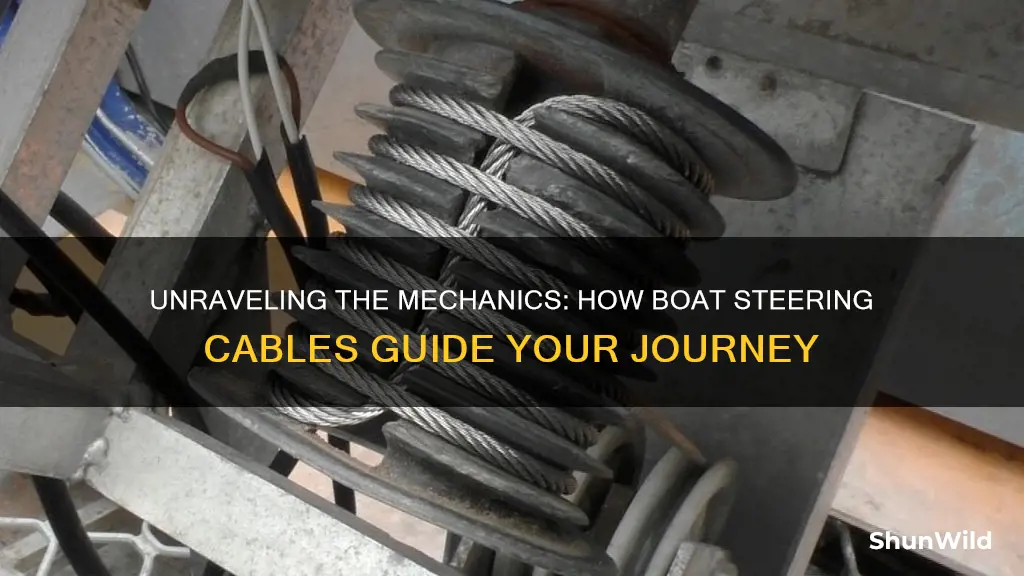

The structure of a boat steering cable is designed to ensure durability and reliability, especially in the harsh marine environment. At the heart of this design is the steel wire core, which is the primary component responsible for transmitting the force required to steer the vessel. However, this core alone would be susceptible to wear and damage, especially in the dynamic conditions of a boat's operation.

To protect the steel wire core, steering cables are constructed with an inner and outer sheathing system. The inner sheathing, typically made of a flexible, durable material such as synthetic rubber or a similar compound, is designed to encapsulate the wire core. This inner layer provides a protective barrier, shielding the core from the elements and preventing it from coming into direct contact with other components that could cause friction or damage.

The outer sheathing, often made of a more robust material like braided steel wire or a similar metal alloy, serves a different purpose. It provides additional protection against abrasion and corrosion, ensuring that the cable can withstand the rigors of regular use. This outer layer also helps to maintain the cable's shape and structure, preventing it from becoming distorted or damaged during operation.

Together, the inner and outer sheathing create a robust and flexible cable structure. The inner sheathing protects the core, while the outer sheathing safeguards the entire assembly from external threats. This design ensures that the steering cable can transmit the necessary force while remaining durable and reliable, even in the challenging conditions of a 13-foot boat.

In summary, the cable structure's inner and outer sheathing play a critical role in protecting the steel wire core, ensuring the steering cable's longevity and performance. This protective design is essential for maintaining the functionality and safety of the boat's steering system.

Best Cleaning Supplies for Sparkling Boat Hulls

You may want to see also

Hydraulic Power: Cylinders convert hydraulic pressure into mechanical movement

Hydraulic power systems are a fascinating and powerful method of converting force and pressure into mechanical movement, and they play a crucial role in various applications, including boat steering. In the context of a 13-foot boat, understanding the mechanics of hydraulic power can be essential to ensuring smooth and precise steering.

At the heart of this system are hydraulic cylinders, which are devices designed to convert hydraulic pressure into linear mechanical motion. These cylinders operate based on Pascal's principle, which states that a change in pressure applied to an enclosed fluid will be transmitted undiminished to all portions of the fluid and to the walls of its container. In the case of a boat's steering system, this principle is utilized to provide controlled movement.

When a boat's steering wheel is turned, it triggers a series of events. The steering wheel is connected to a hydraulic pump, which is typically driven by the boat's engine. This pump creates hydraulic pressure by forcing a fluid, often an incompressible liquid like hydraulic oil, through a small opening or orifice. The pressure generated is directly proportional to the force applied by the pump.

The high-pressure hydraulic fluid then travels through a series of pipes or hoses to the hydraulic cylinder. This cylinder is designed with a piston inside, which moves in response to the pressure. The piston's movement is guided by a rod that extends from the cylinder, often connected to the boat's steering gear or rudder. As the hydraulic pressure acts on the piston, it creates a force that moves the rod, ultimately turning the boat's rudder and changing its direction.

The beauty of hydraulic power lies in its ability to amplify force. Since the pressure is transmitted undiminished throughout the system, even a relatively small force applied to the steering wheel can result in a much larger force being exerted on the rudder, allowing for precise control of the boat's direction. This makes hydraulic steering systems ideal for boats, ensuring that the captain can navigate the vessel effectively, even in challenging conditions.

When the Boat Race Starts This Year

You may want to see also

Pulleys and Sheaves: These guide the cable and transfer force to the rudder

Pulleys and sheaves are essential components in the steering system of boats, particularly those with smaller vessels like the 13-foot model you mentioned. These mechanical devices play a crucial role in guiding the steering cable and transferring the necessary force to the rudder, allowing for precise control of the boat's direction.

In the context of boat steering, pulleys and sheaves are typically part of a block and tackle system. This system consists of multiple pulleys arranged in a specific configuration to create a mechanical advantage. The primary function of this arrangement is to reduce the force required to operate the rudder, especially when the boat is moving at high speeds or in rough waters. By using pulleys, the steering cable's load is distributed across several points, making it easier to maneuver the boat.

Each pulley in the system has a specific role. The sheave, a wheel with a groove around its circumference, is designed to guide the cable and ensure it runs smoothly. It is usually made of durable materials like bronze or steel to withstand the corrosive effects of seawater. The sheave's groove provides a path for the cable to follow, preventing it from tangling or becoming misaligned, which could lead to steering issues.

When the boat's helm (steering wheel or tiller) is turned, the steering cable is pulled or pushed, depending on the steering mechanism. This movement is then transferred through the block and tackle system, which includes the pulleys and sheaves. The pulleys guide the cable, ensuring it remains taut and directed towards the rudder. As the cable moves, it winds around the sheave, allowing for the transfer of force to the rudder, thus changing the boat's direction.

The design and arrangement of pulleys and sheaves can vary depending on the boat's size, type, and intended use. For smaller boats like the 13-foot model, a simpler system might be employed, but larger vessels often feature more complex block and tackle arrangements to handle increased steering loads. Understanding the mechanics of these components is vital for boat owners and operators to ensure proper maintenance and troubleshooting of the steering system.

Fixing a Boat Starter: A Step-by-Step Guide

You may want to see also

Rudder Control: The cable's tension moves the rudder, allowing steering

The steering system of a boat, especially one with a length of 13 feet, relies on a simple yet crucial mechanism: the tension in the steering cables. This system is designed to enable precise control over the boat's direction, allowing the operator to navigate through various waters with ease. At the heart of this mechanism is the rudder, a critical component that plays a pivotal role in steering.

When you turn the steering wheel or lever, it initiates a series of movements that ultimately lead to the adjustment of the rudder's position. The steering cable, typically a sturdy and flexible rope or wire, connects the steering wheel to the rudder. As you apply force to the wheel, the cable transmits this force, creating tension. This tension is then transferred to the rudder, which is usually located near the rear of the boat.

The rudder's primary function is to provide lateral resistance to the boat's motion, allowing it to change direction. When the cable is pulled or pushed, it exerts a force on the rudder, causing it to rotate around a pivot point, often referred to as the rudder post. This rotation is what enables the boat to turn. The angle and direction of the rudder's movement are carefully designed to ensure optimal steering performance, allowing the boat to respond efficiently to the operator's inputs.

The tension in the cable is a critical factor in this process. As the cable tightens or loosens, it directly affects the rudder's position and, consequently, the boat's direction. A well-maintained steering cable should provide a smooth and responsive connection, ensuring that the operator can make quick and accurate steering adjustments. Regular inspection and adjustment of the cable's tension are essential to guarantee safe and efficient steering, especially in smaller boats where the steering system's reliability is vital for maneuverability.

In summary, the tension in the steering cable is the key element that translates the operator's steering input into the physical movement of the rudder. This simple yet effective mechanism ensures that even a small boat can be steered with precision, making it an essential component of any vessel's navigation system. Understanding this basic principle is fundamental to appreciating the complexity and ingenuity of boat steering systems.

Mariah Boat Company: A Rise and Fall Story

You may want to see also

Safety Mechanisms: Devices like stops prevent over-steering and cable damage

Boat steering cables are an essential component of a vessel's navigation system, allowing for precise control of the vessel's direction. These cables are designed to transmit the force from the steering wheel or tiller to the rudder, enabling the boat to turn and maneuver effectively. However, without proper safety mechanisms, over-steering can become a significant risk, potentially causing damage to the cable and compromising the boat's stability.

One crucial safety feature is the implementation of stops or limiters on the steering cable. These devices are strategically placed along the cable's length and serve as a physical barrier to prevent excessive movement. When the steering wheel is turned beyond a certain angle, the stops engage, limiting the cable's travel and ensuring it doesn't exceed its operational range. This mechanism is vital in avoiding cable damage, as it prevents the cable from being pulled or twisted beyond its capacity, which could lead to frays, kinks, or even breaks.

Over-steering can occur due to various factors, such as sudden maneuvers, operator error, or mechanical issues. When a boat is over-steered, the rudder may be forced to move beyond its intended range, causing unnecessary strain on the steering cable. This excessive movement can lead to the cable's internal components wearing out or becoming misaligned, resulting in reduced performance and potential failure. By installing stops, boat owners and operators can significantly reduce the likelihood of such damage, ensuring the steering system remains reliable and efficient.

Additionally, these safety stops can provide a visual and tactile indication of the boat's steering limits. Many designs incorporate audible or visual cues, such as a beeping sound or a flashing light, when the stops are activated. This feature not only alerts the operator to potential over-steering but also serves as a reminder to maintain controlled steering inputs. The tactile feedback of the stops engaging can further enhance the operator's awareness, allowing for quicker reactions to prevent cable damage.

In summary, safety mechanisms like stops are integral to the proper functioning and longevity of boat steering cables. They act as a protective barrier, preventing over-steering and the subsequent damage to the cable. By incorporating these devices, boat owners can ensure a safer and more controlled steering experience, reducing the risk of mechanical failures and promoting overall vessel safety. It is essential to regularly inspect and maintain these safety features to guarantee their effectiveness when needed.

Launching a Boat in Kingdom: Two Crowns

You may want to see also

Frequently asked questions

The steering cable system in a 13-foot boat typically consists of a series of pulleys, cables, and a tiller or wheel. When you turn the steering wheel or push the tiller, it activates a mechanical linkage that pulls or pushes on the steering cable. This cable is usually made of steel or synthetic materials and is designed to transmit the force from the steering mechanism to the rudder or propeller, allowing the boat to change direction.

The pulley system is an essential component of the steering mechanism. It helps to amplify the force applied to the steering wheel or tiller, making it easier for the operator to maneuver the boat. Pulleys are often used to reduce the effort required, especially in larger boats, by increasing the mechanical advantage.

A tiller is a traditional steering mechanism used in smaller boats, typically consisting of a rod or shaft that extends from the helm (the operator's position). When you push or pull the tiller, it moves the rudder, which then steers the boat. On the other hand, a steering wheel is a circular control that is connected to the steering cable system. Turning the wheel activates the mechanical linkage, which then operates the steering cable to direct the boat's movement.

Regular maintenance is crucial for the safe operation of your boat's steering system. It is recommended to inspect the steering cable and its components at least once a year or more frequently if you use the boat regularly. Look for any signs of wear, corrosion, or damage to the cable, pulleys, and connections. Proper lubrication and adjustment of the steering mechanism can also ensure smooth operation and prevent premature failure.