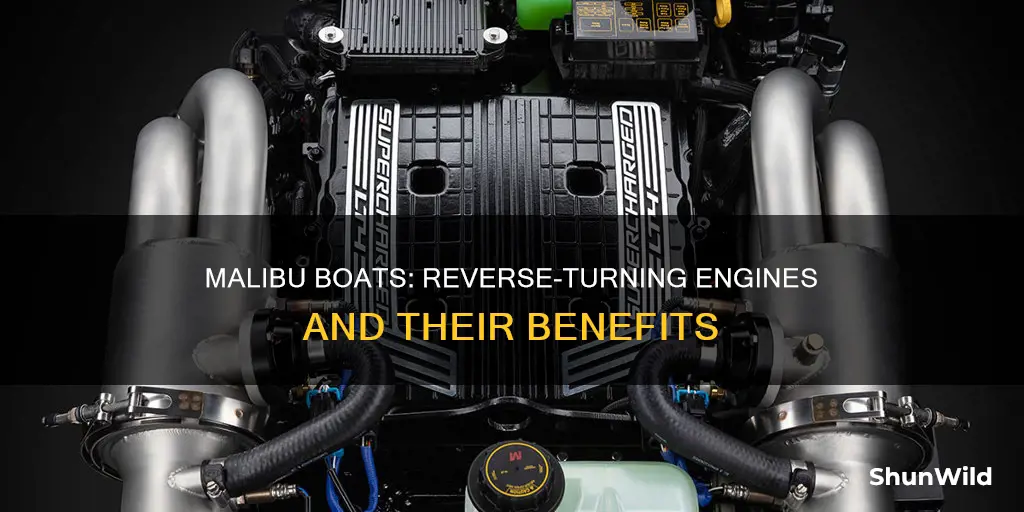

Malibu boats are equipped with Monsoon engines, which are designed to ensure reliability and simplify the complex engineering of the boat's engine. The Malibu Monsoon M5Di and M6Di engines are direct injection engines that have been designed to prevent engine issues from cutting into family time on the water. The Malibu Monsoon engines are built with smart tools that remove human error and ensure precision in the torque specs for each fastener. In addition, the Front-End Accessory Drive (FeAD) system eliminates the automotive water pump and relocates important components like the alternator, glycol circulation pump, and thermostat housing to a higher, more easily serviceable position in the engine. This innovation also substitutes glycol for raw water cooling, which cools the engine and its components more efficiently. Malibu's exclusive FeAD system also includes a strainer to prevent seaweed from getting caught in the oil coolers and causing the engine to overheat. With thousands of hours of testing, Malibu's Monsoon engines are designed to be the most reliable and hassle-free on the water today.

What You'll Learn

- Reverse rotation engines can be identified by looking at the crank pulley

- The pistons and rods of an engine must be rotated 180 degrees to change the direction of the engine

- The camshaft, distributor gear, and timing chain or gears may also need to be changed when converting an engine

- Prop walk is the term used to describe the turning motion of a boat when the propeller is in reverse

- The direction of the propeller's rotation determines the direction in which the boat will turn when reversing

Reverse rotation engines can be identified by looking at the crank pulley

It is important to note that the direction of propeller rotation should not be relied upon to determine engine rotation. All I/O engines are Left-Hand rotation engines. To identify a reverse rotation engine, one must examine the crank pulley, which is located at the front of the engine. By observing the direction of rotation of the belts and pulleys, one can determine the type of engine rotation.

When facing the front of the engine and observing the belts and pulleys, if they turn in a clockwise direction, it indicates a Left-Hand engine rotation. On the other hand, if the belts and pulleys turn in a counter-clockwise direction, it corresponds to a Right-Hand engine rotation. This perspective is crucial for identifying reverse rotation engines, as it provides a clear indication of the engine's rotation direction without the need to access the flywheel.

In summary, to identify a reverse rotation engine, one should observe the crank pulley from the front of the engine. By determining the direction of rotation of the belts and pulleys, one can establish the type of engine rotation. This method is reliable and accessible, providing a straightforward way to identify reverse rotation engines without relying on propeller rotation or other less accurate methods.

Boat Haulout Repair: What, Why, and How?

You may want to see also

The pistons and rods of an engine must be rotated 180 degrees to change the direction of the engine

The crankshaft is connected to the pistons and rods through a series of bearings and journals. The crankshaft main journals rotate in a set of supporting bearings, which cause the offset rod journals to rotate in a circular path around the main journal centers. The big ends of the connecting rods contain bearings that ride on the offset rod journals, while the small ends of the rods are attached to the pistons by wristpins.

When the crankshaft rotates, it imparts reciprocating motion to the pistons and rods, causing them to move up and down in the cylinders. The motion of the pistons is not symmetric, with the crankshaft rotation moving the pistons more than half the stroke value in the first 90 degrees after top dead center (TDC) and less than half the stroke value in the second 90 degrees. This asymmetry is important for the operation, performance, and longevity of the engine.

The velocity and acceleration of the pistons are also affected by the crankshaft rotation. The piston velocity is zero at TDC and bottom dead center (BDC) as the piston changes direction, and it reaches its maximum velocity at a point between TDC and BDC. The piston acceleration is highest at TDC and gradually decreases towards BDC, with a brief period of negative acceleration as the piston changes direction.

By rotating the crankshaft 180 degrees, the direction of piston motion, velocity, and acceleration are reversed. This allows the engine to operate in the opposite direction, with the pistons, rods, and crankshaft moving in the opposite direction of their original rotation. This process can be applied to various types of engines, including those found in Malibu boats, to change their direction of operation.

Universal Orlando's Boat Stunt Show: What Happened?

You may want to see also

The camshaft, distributor gear, and timing chain or gears may also need to be changed when converting an engine

When converting an engine, it is critical to ensure that the camshaft and distributor gear are properly matched. The wrong combination can lead to premature gear wear, camshaft wear, and ultimately, engine failure. The distributor gear should be slightly softer than the camshaft to ensure accurate ignition timing and prolong engine life. Composite, melonized or hardened steel, and bronze are the three most common types of distributor gear materials. Composite gears are the most durable and lightweight, and they work with any camshaft gear material. However, they are also the most expensive. Melonized or hardened steel gears are often used by OEMs for their long life and are typically the default option for replacement distributors. Bronze gears, on the other hand, are self-sacrificing and intended for racing applications only, requiring replacement about once a year.

The type of camshaft you have will determine the right distributor gear material. For cast iron hydraulic or solid flat tappet cams, cast iron or composite distributor gears are suitable. Meanwhile, austempered ductile iron hydraulic or solid roller cams require melonized or hardened steel, or composite distributor gears. It is worth noting that a steel gear is not compatible with a cast iron flat tappet cam.

In addition to the camshaft and distributor gear, the timing chain or gears may also need to be changed when converting an engine. Timing chains and gears are crucial components that ensure the camshaft and crankshaft are properly synchronised. Most pushrod engines use a timing chain, while some older four and six-cylinder engines use a gear set. Overhead cam (OHC) engines, on the other hand, typically require a much longer chain or a rubber belt due to the distance between the camshaft and the crankshaft.

Timing belts and chains are subjected to significant stress and heat, which can cause them to wear out over time. While timing chains are more durable and have a longer service life, they are also noisier and more expensive to replace. Therefore, timing belts are commonly used on many OHC engines. It is recommended to replace timing belts and chains before they fail, with older engines typically requiring replacement every 60,000 miles, and newer engines every 100,000 miles or more.

Maximizing Boat Hull Space: Creative Ways to Expand

You may want to see also

Prop walk is the term used to describe the turning motion of a boat when the propeller is in reverse

Prop walk, or propeller walk, is a phenomenon observed in boats with a single propeller that causes the boat to turn when put in reverse. The direction of the turn depends on the direction of rotation of the propeller, with a clockwise rotation leading to a left turn and an anti-clockwise rotation leading to a right turn. This effect is more pronounced when the boat is stationary.

The cause of prop walk is debated, with several theories proposed. One theory suggests that the lower part of the propeller rotation has more "bite", creating greater drag due to increased pressure or the greater density of water. Another theory suggests that asymmetric thrust or the p-factor, similar to that experienced by aircraft, creates a torque due to the difference in blade velocities caused by the propeller being mounted at an angle to the water flow. The shape and design of the hull can also play a role, as the hull creates a wake or disturbance in the water that interacts with the propeller, affecting its performance.

Prop walk is caused by a combination of factors, including the design of the propeller, the direction of rotation, and the interaction between the propeller and the surrounding water. The asymmetrical design of most propellers, with the lower part having a larger surface area, creates more drag and a torque or turning force on the boat. The angle of the propeller in relation to the water flow also contributes to the turning motion, with an asymmetric thrust causing the boat to turn.

Prop walk can be a problem for inexperienced boaters or in tight docking situations, as it can cause the boat to move sideways rather than straight back. However, it can also be used to advantage by experienced boaters to help maneuver the boat in reverse. While prop walk cannot be completely eliminated, it can be reduced by adjusting the position and angle of the propeller, using counter-rotating propellers, or employing bow thrusters.

Iowa Boating Requirements: What You Need to Know

You may want to see also

The direction of the propeller's rotation determines the direction in which the boat will turn when reversing

The direction of a boat's turn when reversing is determined by the rotation of its propeller, a phenomenon known as "prop walk". When viewed from the back, if the propeller rotates clockwise, the boat will turn left, and if it rotates anti-clockwise, the boat will turn right. This occurs due to the increased 'bite' of the lower part of the propeller rotation.

There are several theories as to why this happens. One theory suggests that the greater pressure on the lower part of the propeller creates more drag, causing the boat to turn. Another theory posits that the greater density of water at the lower part of the propeller generates more drag, resulting in the boat turning. A third theory, known as the "p-factor", suggests that the propeller's angle to the water flow creates asymmetric thrust, similar to that experienced by aircraft, which causes the boat to turn.

Additionally, the interaction between the hull and propeller wake may also play a role in the direction of the turn. The shape and design of the hull can create a wake or disturbance in the water, which interacts with the propeller and affects its performance. This can cause the boat to turn in a specific direction, depending on the hull and propeller design.

It is important to note that prop walk is influenced by a combination of factors, including propeller design, rotation direction, and the interaction between the propeller and the water. While it can be a challenge for inexperienced boaters, prop walk can also be utilised by skilled boaters to assist in reversing manoeuvres.

The Actor Playing Joe in Boys in the Boat

You may want to see also