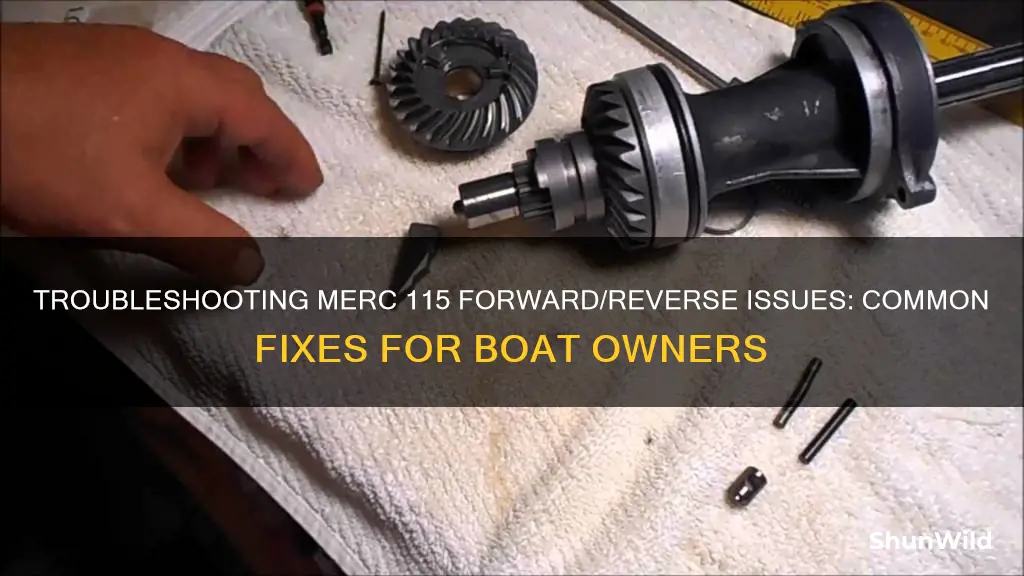

If you're experiencing issues with your Merc 115 boat not moving forward or in reverse, it can be frustrating. This problem could stem from various factors, including engine issues, propeller problems, or even electrical malfunctions. Understanding the potential causes and troubleshooting steps is essential to get your boat back on the water. Let's explore some common reasons why your Merc 115 might be acting up and how to address them.

What You'll Learn

- Engine Diagnostics: Check for error codes and sensor issues

- Throttle Control: Inspect the throttle lever and cables

- Propeller: Ensure proper installation and check for damage

- Transmission: Verify fluid levels and inspect the transmission system

- Electrical System: Test batteries, wiring, and the starter motor

Engine Diagnostics: Check for error codes and sensor issues

When dealing with a Mercruiser 115 engine that isn't responding to forward or reverse commands, a thorough engine diagnostics process is essential. This process involves checking for error codes and inspecting various sensors to identify the root cause of the issue. Here's a step-by-step guide to help you through this diagnostic process:

- Access the Engine Control Module (ECM): Start by locating the ECM, which is the brain of your engine. It is typically found near the engine block and is connected to various sensors and actuators. You can access it by removing any necessary panels or covers. Once you have access, you can connect a diagnostic scanner or a multimeter to the ECM. This device will allow you to read and clear any error codes stored in the ECM. Look for error codes related to the shift solenoids, transmission control, or engine speed and direction.

- Read Error Codes: Connect the diagnostic tool to the ECM and scan for error codes. These codes will provide valuable information about the specific issues within the engine's systems. Look for error codes related to the transmission, such as those indicating a problem with the shift solenoid, transmission control module, or the engine's ability to change gears. These codes will help narrow down the potential causes of the forward or reverse issue.

- Inspect Sensors: Mercruiser engines rely on several sensors to function properly. These include speed sensors, direction sensors, and temperature sensors. Start by checking the speed sensors, which monitor the engine's RPM (revolutions per minute). A faulty speed sensor can cause the engine to behave erratically or not respond to commands. Inspect the direction sensor, which provides information about the engine's direction of rotation. If this sensor is faulty, the engine may not be able to shift into forward or reverse gear. Also, check the temperature sensors to ensure the engine is operating within safe temperature limits.

- Test Shift Solenoids: Shift solenoids are responsible for engaging the forward and reverse gears. Use a multimeter to test these solenoids for continuity and proper voltage supply. If a solenoid is faulty, it may not be engaging the transmission correctly, leading to the issue you're experiencing.

- Verify Transmission Functionality: Ensure that the transmission itself is functioning correctly. Check for any signs of damage or wear, especially in the gears and shift mechanism. Sometimes, a simple transmission flush and rebuild can resolve issues related to gear slippage or improper shifting.

By following these engine diagnostics steps, you can systematically identify and address the reasons why your Mercruiser 115 engine isn't responding to forward or reverse commands. Remember, proper maintenance and regular diagnostics can save you from potential breakdowns on the water.

Boston Whaler 150 Montauk: Ideal Ocean Dive Boat?

You may want to see also

Throttle Control: Inspect the throttle lever and cables

If you're experiencing issues with your Mercury 115 boat not moving forward or in reverse, one of the critical components to inspect is the throttle control system. This system is responsible for translating your input from the throttle lever into the engine's response, either moving the boat forward or engaging the reverse gear. Here's a detailed guide on how to inspect the throttle lever and cables:

Throttle Lever Inspection:

- Start by locating the throttle lever, typically found on the boat's dashboard or steering column. It's a lever that you operate to control the engine's speed and direction.

- Check for any visible damage or wear. Look for cracks, bends, or any signs of deterioration. Ensure that the lever moves freely without binding or sticking.

- Test the throttle's range of motion. It should move smoothly through its entire travel, allowing for full forward and reverse movement. If it feels stiff or unresponsive, this could indicate a problem.

- Pay attention to the throttle's position indicators. Some boats have indicators that show the throttle's position, and these should be functioning correctly.

Cable Inspection:

- The throttle lever is connected to the engine via a cable or a series of cables. Inspect these cables for any signs of damage, corrosion, or wear.

- Check for any kinks, twists, or breaks in the cables. Ensure they are securely attached to both the throttle lever and the engine's throttle body.

- Lubricate the cable(s) if necessary. Over time, cables can become dry and stiff, affecting their performance. Use a suitable lubricant to ensure smooth operation.

- If you suspect a cable issue, consider replacing it. Cables can wear out, especially in marine environments, and replacing them can often resolve throttle control problems.

Throttle Body and Motor:

- On some models, the throttle body and motor are located separately from the throttle lever. Inspect these components for any signs of damage or debris.

- Ensure that the throttle body is clean and free of any obstructions. Debris or dirt can interfere with the throttle's operation.

- Check the motor that operates the throttle. It should be lubricated and free of any mechanical issues.

Electrical Connections (if applicable):

- If your Mercury 115 has an electronic throttle control system, inspect the wiring harnesses and connectors. Ensure they are securely connected and free of corrosion.

- Check for any error codes or warning lights on the boat's dashboard, as these could indicate throttle control issues.

Remember, proper throttle control is essential for safe and efficient boat operation. If you're unsure about any of these inspections or suspect a more complex issue, it's best to consult a qualified marine mechanic for further diagnosis and repair.

Hydroplane Speed: Unlocking the Secrets of High-Performance Watercraft

You may want to see also

Propeller: Ensure proper installation and check for damage

When dealing with a Mercruiser 115 engine that isn't responding to forward or reverse commands, one of the critical components to inspect is the propeller. The propeller is responsible for translating the engine's power into forward or reverse propulsion, so ensuring it is properly installed and in good condition is essential.

First, you should check the propeller's installation. Mercruiser 115 engines typically use a propeller with a specific pitch and blade design to ensure optimal performance. If the propeller is not installed correctly, it may not be able to generate the necessary thrust. This could include issues like an improper angle, misaligned hub, or a propeller that is too large or too small for the engine. Always refer to the manufacturer's guidelines for proper propeller selection and installation. If you suspect an improper installation, consult a marine mechanic or a professional who can ensure the propeller is correctly fitted and balanced.

Next, inspect the propeller for any signs of damage or wear. Propellers can be susceptible to damage from rocks, debris, or even accidental impacts. Inspect the blades for any cracks, chips, or bends. Even minor damage can affect the propeller's ability to generate thrust efficiently. Look for any signs of corrosion or wear on the propeller's surface, as this can also impact its performance. If you notice any damage, it may be necessary to replace the propeller to ensure safe and efficient operation.

Additionally, check the propeller's pitch and blade design. Mercruiser 115 engines often require a specific pitch propeller to achieve the desired performance. The pitch refers to the number of blades and their angle, which determines the propeller's ability to move water and generate forward or reverse thrust. If the propeller has been modified or replaced with an incorrect design, it could be the reason for the engine's lack of response.

In summary, ensuring the propeller is properly installed and free from damage is crucial when troubleshooting a Mercruiser 115 engine that isn't functioning as expected. Always consult the manufacturer's guidelines and consider seeking professional assistance to ensure the propeller is correctly fitted and balanced. Regular maintenance and inspection of the propeller will help prevent issues and ensure your boat's engine operates smoothly.

Boarding a Boat: Launch Ramp Techniques for Beginners

You may want to see also

Transmission: Verify fluid levels and inspect the transmission system

If you're experiencing issues with your Mercury 115 boat not moving forward or in reverse, one of the first steps to take is to inspect the transmission system, specifically the fluid levels. Proper fluid maintenance is crucial for the smooth operation of your boat's transmission. Here's a detailed guide on how to verify fluid levels and inspect the transmission system:

Fluid Levels: Start by checking the engine oil and transmission fluid levels. These fluids are essential for lubricating and cooling the transmission components. Locate the oil dipstick, which is typically a small tube with a handle, and pull it out. Check the level of the oil and ensure it is within the 'full' and 'add' marks on the dipstick. If the level is low, add the appropriate type of engine oil until it reaches the 'full' mark. Similarly, inspect the transmission fluid. The fluid reservoir is usually located near the engine and has a cap for easy access. Check the color and quantity of the fluid. If it appears dark or has a burnt smell, it might indicate a problem and could require professional attention.

Transmission Inspection: After verifying the fluid levels, it's time to inspect the transmission system. Start by ensuring that the boat is in a secure location and the engine is off. Engage the parking brake for added safety. Locate the transmission, which is typically a large, cylindrical component attached to the engine. Inspect the transmission for any visible damage, leaks, or corrosion. Look for signs of fluid seepage around the transmission pan and check if the pan is clean and dry. If you notice any leaks, it could indicate a damaged gasket or seal, which may require replacement. Additionally, inspect the transmission lines and hoses for any cracks, punctures, or signs of deterioration.

Fluid Type and Quality: It's important to use the correct type of transmission fluid recommended by Mercury for your specific engine model. Using the wrong fluid can lead to transmission issues. Check the owner's manual or consult the manufacturer's guidelines to determine the appropriate fluid type. If the fluid appears discolored or has an unusual smell, it might be contaminated and should be drained and replaced. Regularly changing the transmission fluid as per the recommended service intervals can prevent buildup and ensure optimal performance.

Testing and Troubleshooting: After inspecting the transmission system, start the engine and engage the transmission. Test the forward and reverse gears by slowly moving the throttle and observing the boat's response. If the boat responds as expected, the issue might be related to other factors, such as the propeller or throttle control. However, if the boat still doesn't move, further troubleshooting might be required, and it's advisable to consult a marine mechanic or refer to the Mercury troubleshooting guide for specific steps.

Remember, proper maintenance and regular inspections can help prevent transmission issues. By verifying fluid levels and inspecting the transmission system, you can identify potential problems early on and ensure your Mercury 115 boat runs smoothly on the water.

Costa Bass Boat: Who Took Home the Prize?

You may want to see also

Electrical System: Test batteries, wiring, and the starter motor

When dealing with an issue where your Mercury 115 boat won't move forward or reverse, it's essential to start with a thorough examination of the electrical system. This system is crucial for controlling the engine's operation, including forward and reverse movement. Here's a step-by-step guide to testing the electrical components:

Battery Testing:

Begin by checking the boat's batteries. Over time, batteries can lose their charge or develop internal issues. Start by ensuring the batteries are securely connected and free from any corrosion. Use a voltmeter to test the battery voltage. A fully charged battery should read around 12.6 volts. If the voltage is significantly lower, it might indicate a weak or failing battery. In such cases, consider replacing the battery or charging it if it's just low on power.

Wiring Inspection:

The wiring harness is responsible for connecting various components, including the batteries, engine control module, and the shift mechanism. Inspect the wiring for any signs of damage, corrosion, or loose connections. Look for frayed or exposed wires, as these can cause electrical shorts or interruptions. Ensure that all connections are tight and secure, especially those leading to the starter motor and the shift solenoid (if applicable).

Starter Motor Diagnostics:

The starter motor is essential for engaging the engine during the starting process and for shifting gears in automatic transmissions. To test it, you can use a multimeter or a starter motor tester. Here's how:

- Ensure the engine is off and disconnected from the battery.

- Locate the starter motor and inspect it for any visible damage or corrosion.

- Test the continuity of the starter motor circuit using the multimeter. It should show a low resistance path when the key is turned to the 'on' position.

- If the starter motor doesn't engage when you turn the key, it might be faulty and require replacement.

Engine Control Module (ECM) and Sensors:

The ECM is the brain of the engine, receiving input from various sensors and controlling the engine's operation. It's crucial for proper gear shifting and engine performance. Check the ECM for any error codes that might indicate a problem with the electrical system or engine sensors. Common sensors to test include the speed sensor, throttle position sensor, and crankshaft position sensor. These sensors provide critical data to the ECM for smooth operation.

Remember, when troubleshooting, it's essential to follow a systematic approach, testing each component to identify the root cause of the issue. If you're unsure about any step, consulting a marine mechanic or referring to the Mercury boat service manual is recommended.

Who is Responsible for the Boat that Crashed?

You may want to see also

Frequently asked questions

This issue could be due to a few potential causes. Firstly, check the engine's throttle control. Ensure it is functioning properly and not stuck in a particular position. If the throttle is responsive, the problem might be with the shift mechanism. Inspect the shift cables and ensure they are properly connected and not damaged. Another common cause is a faulty propeller or prop shaft. If the propeller is damaged or the shaft is misaligned, the engine won't be able to transmit power effectively.

Start by checking the engine's power supply. Ensure that the battery is fully charged and has sufficient power to operate the engine. If the battery is fine, the issue might be with the shift solenoid or the shift motor. These components are responsible for engaging the forward and reverse gears. Inspect the solenoid and motor for any signs of damage or wear. Sometimes, a simple cleaning or adjustment of these parts can resolve the problem.

Stalling when shifting into reverse can be caused by a few factors. One possibility is a clogged or damaged fuel filter, which can restrict fuel flow to the engine. Another potential cause is an issue with the engine's timing. Check the timing belt or chain to ensure it is properly tensioned and aligned. If the timing is off, it can cause the engine to stall during gear changes. Additionally, inspect the reverse gear mechanism for any obstructions or damage that might prevent the engine from shifting into reverse.