The steering system on a boat, often referred to as the helm or tiller, is a crucial component for navigation and control. However, there are several reasons why it may not function properly. One common issue is mechanical failure, where the steering mechanism, such as the rudder or steering gear, may become jammed, worn out, or damaged, leading to a loss of steering authority. Another potential cause is the lack of hydraulic fluid or air pressure in the system, which can result in a unresponsive or sluggish steering response. Additionally, issues with the steering cables, pulleys, or steering wheel itself can contribute to steering problems. Understanding these potential causes is essential for boaters to address steering malfunctions and ensure safe navigation on the water.

What You'll Learn

- Hydraulic System: Leaks or pressure issues can cause steering failure

- Power Loss: Engine failure or low battery can render steering inoperable

- Mechanical Wear: Over time, steering components like pulleys and cables can wear out

- Control Cable: Damage or misalignment can lead to unresponsive steering

- Electrical Faults: Short circuits or faulty wiring may prevent steering from functioning

Hydraulic System: Leaks or pressure issues can cause steering failure

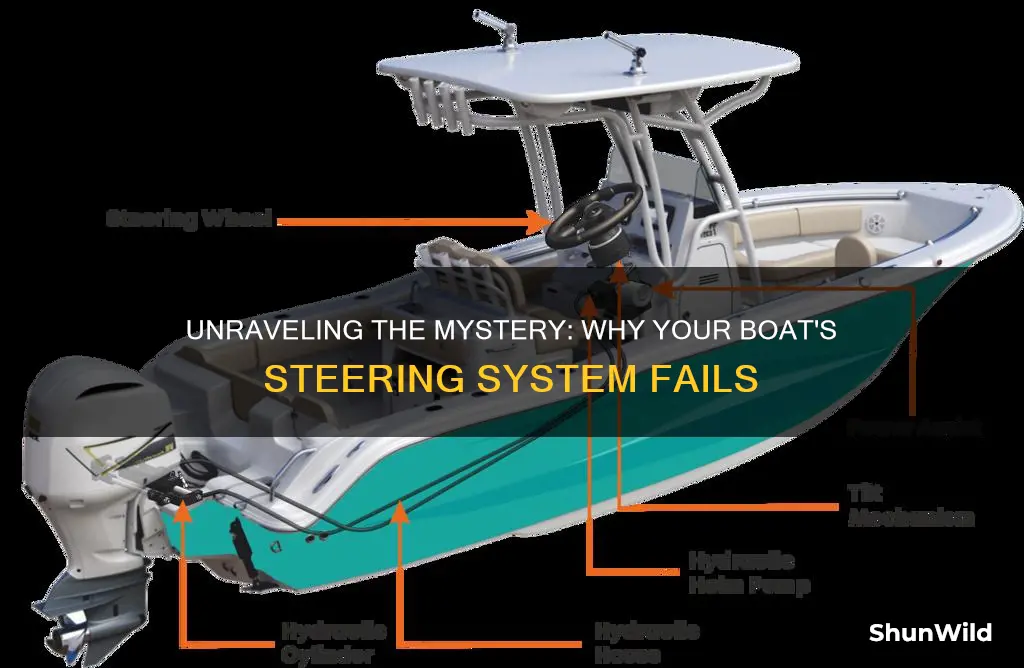

The hydraulic system is a critical component of a boat's steering mechanism, and its proper functioning is essential for safe navigation. This system relies on pressurized fluid to transmit force from the steering wheel to the helm, allowing the boat to turn. However, like any mechanical system, it is susceptible to issues that can lead to steering failure. One of the most common problems is hydraulic system leaks or pressure-related complications.

Leakage in the hydraulic system can occur at various points, including the hoses, fittings, and seals. Over time, these components may wear out or become damaged due to factors such as corrosion, abrasion, or improper maintenance. When a leak develops, it results in a loss of hydraulic fluid, which is necessary to maintain the system's pressure. As the fluid escapes, the pressure within the system drops, making it challenging for the steering wheel to transmit the necessary force to the helm. This can lead to a heavy or unresponsive steering feel, making it difficult for the captain to maneuver the vessel.

Pressure issues within the hydraulic system can also cause steering failure. The system operates on the principle of Pascal's law, which states that a change in pressure at any point in a confined fluid is transmitted undiminished to all points in the system. If the pressure in the hydraulic fluid is compromised, it can lead to reduced steering response and control. Low pressure might be caused by a leak, as mentioned earlier, or by air entering the system, a condition known as cavitation. Cavitation occurs when the pressure drops to the point where the fluid can no longer hold its dissolved gases, causing them to form bubbles that collapse violently, creating tiny, damaging explosions. These explosions can erode the internal components of the hydraulic system, leading to further leaks and pressure drops.

To address hydraulic system issues, it is crucial to inspect the system regularly for any signs of leaks or damage. Any detected leaks should be promptly repaired or replaced to prevent further fluid loss. Maintaining the correct fluid level and ensuring its cleanliness is vital to avoiding contamination that could lead to system failure. Additionally, checking the system's pressure regularly and addressing any deviations from the recommended range can help prevent steering problems.

In summary, the hydraulic system's role in boat steering is vital, and its proper functioning is dependent on maintaining adequate fluid and pressure levels. Leaks and pressure issues are common causes of steering failure, and addressing these problems promptly is essential to ensure safe and effective boat operation. Regular maintenance and inspections can help identify and rectify these issues before they lead to more significant steering problems.

Repacking Boat Drive Shaft: A Step-by-Step Guide

You may want to see also

Power Loss: Engine failure or low battery can render steering inoperable

Power loss is a common issue that can cause steering problems on boats. When the engine fails or the battery is low, the steering system may become inoperable, leaving the boat's captain with limited control. This can be a dangerous situation, especially in adverse weather conditions or when navigating through busy waters. Understanding the causes and potential solutions for power loss is essential for boaters to ensure their safety and the smooth operation of their vessel.

One primary cause of power loss is engine failure. Boat engines are complex mechanical systems, and like any machinery, they can malfunction or break down. Engine failure can occur due to various factors, including old age, improper maintenance, or the use of low-quality fuel. When the engine stops, the power source for the steering system is cut off, rendering the steering wheels or pedals non-responsive. In such cases, the captain must rely on alternative methods to steer the boat, such as using emergency tiller handles or, in extreme cases, manual steering with oars.

Another critical aspect of power loss is related to the boat's battery. Modern steering systems often rely on electric power to function, and a low or dead battery can lead to steering issues. The battery provides the necessary energy to operate the steering mechanism, and if it is not charged or has insufficient power, the steering may fail. This is particularly common in boats with advanced electronic steering systems, where the battery plays a vital role in powering the electric motor that assists in steering. To prevent this, boaters should regularly check the battery's charge and ensure it is adequately maintained.

In both scenarios of engine failure and low battery, it is crucial to have backup plans and emergency procedures in place. Boat owners should be prepared for such situations by carrying spare batteries or having access to emergency power sources. Additionally, understanding the basic mechanics of steering systems can empower captains to take temporary control in case of power loss. This may include knowing how to manually override the steering system or having a basic understanding of the engine's starting process to potentially restart the engine and restore power.

To minimize the risk of power loss and its impact on steering, regular maintenance and inspections are essential. Boat owners should schedule routine check-ups with qualified mechanics to ensure the engine and battery are in optimal condition. By addressing potential issues early on, boaters can avoid the inconvenience and safety hazards associated with steering problems caused by power loss. Being proactive and well-prepared can significantly contribute to a safe and enjoyable boating experience.

Docking Your Boat: Tips for a Smooth Arrival

You may want to see also

Mechanical Wear: Over time, steering components like pulleys and cables can wear out

Mechanical wear is a common issue that can affect the functionality of a boat's steering system. Over time, the constant friction and stress placed on steering components can lead to deterioration, causing the steering to become unresponsive or difficult to control. One of the primary components susceptible to wear is the pulley system. Pulleys, which are responsible for transferring the force from the engine or motor to the steering wheel, can experience significant wear due to the repetitive motion and the weight of the boat. As the pulleys wear down, the belt or rope connecting them may become frayed, causing slippage or reduced efficiency in power transmission. This can result in a loss of steering control, making it challenging for the boat to turn or maneuver accurately.

Cables are another critical component that can suffer from mechanical wear. Steering cables, often made of steel or synthetic materials, connect the steering wheel to the steering gear or rudder. With prolonged use, these cables can stretch, corrode, or develop cracks, leading to a loss of steering feel and responsiveness. When cables wear out, the steering effort required to turn the wheel may increase, making it harder for the boat operator to make precise maneuvers. Additionally, worn-out cables can cause the steering to feel loose or unresponsive, compromising the boat's overall handling and safety.

Regular maintenance and inspection are essential to prevent mechanical wear and ensure the longevity of the steering system. Boat owners should periodically check the condition of pulleys, cables, and other steering components. Look for signs of wear, such as frayed belts, rust or corrosion on cables, and any visible damage to the pulley housing or cable sheathing. Replacing worn-out parts with new, high-quality alternatives is crucial to maintaining steering performance. Upgrading to more durable materials, such as stainless steel cables or reinforced belts, can significantly reduce wear and improve the overall reliability of the steering system.

In some cases, the design and quality of the steering system itself can contribute to mechanical wear. Older boat models or those with less advanced steering mechanisms may have components that are more prone to wear and tear. Upgrading to a modern steering system with improved materials and design can enhance durability and reduce the likelihood of mechanical issues. It is also important to ensure that the steering system is properly lubricated to minimize friction and wear between moving parts.

To address mechanical wear, boat owners should consider implementing a regular maintenance schedule. This may include annual inspections, where a professional technician can assess the steering system's condition and perform necessary adjustments or replacements. By proactively maintaining the steering system, boat owners can prevent unexpected failures and ensure a smooth and responsive steering experience, even after many years of use.

Protect Your Boat Battery: Prevent Theft with These Tips

You may want to see also

Control Cable: Damage or misalignment can lead to unresponsive steering

The steering system of a boat is a critical component that ensures safe navigation, and it relies on a network of cables and pulleys to function effectively. One of the most common issues that can cause steering problems is related to the control cable, which is responsible for transmitting the driver's input to the steering mechanism. This cable plays a vital role in translating the force applied by the driver into the necessary movement of the boat's helm.

Control cables are typically made of strong, flexible materials to withstand the marine environment and the forces exerted during operation. However, over time, these cables can suffer from various forms of damage or misalignment, leading to steering issues. One of the primary causes of control cable problems is corrosion. Exposure to saltwater and the marine atmosphere can cause the cable's protective coating to deteriorate, resulting in rust and degradation of the cable's inner components. Corroded control cables may become stiff, lose flexibility, or even snap, rendering the steering unresponsive.

Another common issue is damage or wear caused by mechanical stress. The control cable is subjected to constant tension and movement, especially in larger boats with more complex steering systems. This can lead to the cable's sheathing becoming frayed or torn, exposing the inner wires. If the wires are damaged or cut, the cable will no longer transmit the necessary signals, causing the steering to become unresponsive. Misalignment of the control cable is another potential problem. Over time, the cable may shift or move due to vibrations, improper installation, or regular use, leading to a disconnect between the steering wheel and the actual steering mechanism. This misalignment can result in erratic steering or a complete loss of steering control.

Regular maintenance and inspections are crucial to preventing control cable issues. Boat owners should check the condition of the control cables periodically, looking for signs of corrosion, damage, or wear. Keeping the cables lubricated and ensuring they are securely attached to the steering mechanism can also help prevent misalignment. In the event of any steering problems, it is essential to address them promptly. A qualified marine mechanic can inspect the control cables, repair or replace damaged sections, and realign the system if necessary. By taking proactive measures and staying vigilant, boat owners can ensure that their steering systems remain reliable and responsive, enhancing overall safety and navigation capabilities.

Boat Collisions: What Really Happened and Why?

You may want to see also

Electrical Faults: Short circuits or faulty wiring may prevent steering from functioning

Electrical faults are a common reason why the steering on a boat may fail to respond. These issues often arise from short circuits or faulty wiring, which can be caused by various factors. One potential cause is the presence of damaged insulation on wires, which can lead to a short circuit when the bare wires come into contact with each other or other conductive materials. This can result in a loss of power to the steering system, rendering it inoperable. Additionally, corrosion or moisture intrusion within the wiring harness can create a similar problem, as the corrosion may act as a conductor, completing an unintended electrical path and disrupting the steering mechanism.

Another possible scenario is a faulty wiring connection, where the wires connecting the steering wheel to the engine or hydraulic system are not securely attached. Loose connections can lead to intermittent power supply, causing the steering to malfunction or become unresponsive. This issue might be more prevalent in older boats where wiring technology and connection methods may not be as advanced as in newer models.

To diagnose and address these electrical faults, a thorough inspection of the wiring system is necessary. This includes checking for any visible signs of damage, corrosion, or moisture intrusion. Ensuring that all connections are tight and secure is crucial. If any issues are found, repairs or replacements of the affected wiring or components should be carried out by a qualified marine electrician to ensure the steering system functions correctly and safely.

Regular maintenance and inspections can help prevent such electrical problems. Keeping the wiring clean and dry, especially in areas prone to moisture, is essential. Additionally, using high-quality marine-grade wiring and connectors can improve the reliability of the steering system. By addressing electrical faults promptly, boat owners can ensure their steering remains responsive and under their control, enhancing overall safety and navigation capabilities.

The Ultimate Guide to Repainting Your Boat's Hull

You may want to see also

Frequently asked questions

A common issue with boat steering is the presence of air in the hydraulic system or the steering cylinder. Over time, air bubbles can form, causing the steering to feel loose or unresponsive. This can be resolved by bleeding the system, which involves releasing the air bubbles by opening and closing the steering valve or using a specialized tool to purge the air.

If the steering feels heavy and requires excessive effort, it might be due to worn-out steering gear or a damaged steering shaft. In such cases, it is advisable to consult a marine mechanic or a professional to inspect and repair the steering system. They may need to replace worn parts, such as the steering gear or the steering column, to restore the smooth operation of the steering.

High-speed steering issues often arise due to the design of the steering system. Some boats have a 'speed-sensitive' steering system that reduces the steering effort at higher speeds for better control. However, this can sometimes lead to a loss of steering feel or responsiveness. Adjusting the steering sensitivity or seeking professional advice to calibrate the system might be necessary to address this problem.

Yes, salt water can be corrosive to the components of a boat's steering system, especially the steering gear, cables, and hydraulic lines. Regular maintenance and cleaning are essential to prevent corrosion. It is recommended to use marine-grade lubricants and regularly inspect the steering system for any signs of damage or wear caused by salt water exposure.

Vibrations or shakes in the steering wheel can be caused by several factors, including improper alignment of the steering system, worn-out steering components, or issues with the engine mount. Misalignment can lead to uneven pressure on the steering system, causing vibrations. Engine mounts that are worn out or damaged can also transmit vibrations to the steering wheel. Addressing these issues through professional repairs or replacements is crucial for a smooth and safe steering experience.