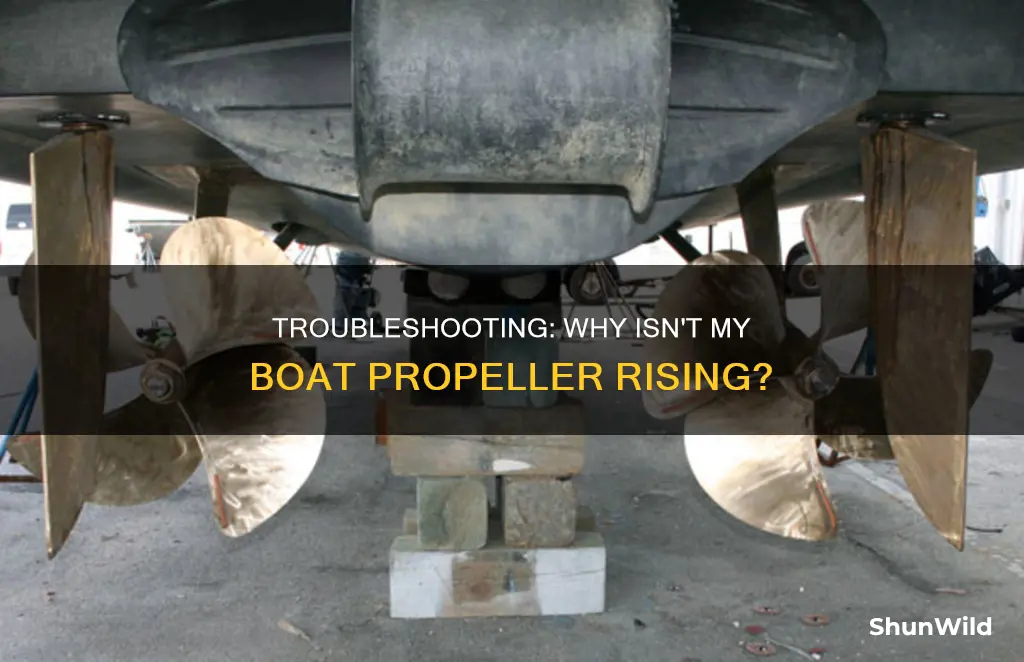

Many boat owners encounter frustration when their boat's propeller fails to engage, leaving them wondering why it isn't functioning properly. This issue can be particularly perplexing, especially for those new to boat maintenance. Understanding the potential causes of a non-functioning propeller is essential for effective troubleshooting. Common reasons for this problem include mechanical failures, such as a broken or damaged gear, or electrical issues, like a faulty motor or control system. Identifying the root cause is the first step toward resolving this issue and getting your boat back on the water.

What You'll Learn

- Propeller Damage: Inspect for bends, cracks, or missing blades

- Motor Issues: Check for electrical problems or mechanical failures

- Propeller Pitch: Ensure it matches the boat's speed and water conditions

- Propeller Hub: Verify proper alignment and secure attachment

- Water Flow: Assess if water is reaching the propeller efficiently

Propeller Damage: Inspect for bends, cracks, or missing blades

When your boat's propeller isn't performing as expected and failing to lift the vessel, it's crucial to inspect the propeller for any signs of damage. One of the most common issues that can cause this problem is physical damage to the propeller itself. Here's a step-by-step guide on how to inspect for bends, cracks, or missing blades:

- Visual Inspection: Start by carefully examining the propeller for any visible signs of damage. Look for bends or kinks in the blades. Even a slight bend can significantly impact the propeller's performance. Check for any cracks or fractures along the length of the propeller, especially at the hub where the blades attach. These cracks might be small and hard to spot, but they can lead to structural failure. Additionally, inspect the blades for any missing or broken pieces. A missing blade or a blade with a significant chunk missing will likely result in reduced lifting capacity.

- Blade Count and Condition: Ensure that the propeller has all its blades intact. Some boats might have a spare blade or two, but a complete absence of a blade is a clear sign of damage. Also, check the condition of the remaining blades. Look for any signs of wear, such as excessive corrosion, pitting, or gouging. These issues can reduce the propeller's efficiency and lifting power.

- Propeller Balance: A damaged propeller might not be balanced correctly, which can cause vibrations and further issues. Inspect the propeller to ensure that the blades are evenly spaced and aligned. If the propeller is not balanced, it may wobble or vibrate during operation, leading to reduced performance and potential damage to other components.

- Professional Assessment: If you notice any significant damage or are unsure about the propeller's condition, it's best to consult a marine mechanic or a propeller specialist. They can provide a thorough inspection and offer solutions, such as propeller repair or replacement, to ensure your boat's propeller functions optimally.

Remember, proper maintenance and regular inspections can prevent many issues related to propeller performance. By identifying and addressing damage early on, you can avoid potential problems and ensure a smooth and efficient boating experience.

Exploring the Falls: Voyage Boat Tour Schedule

You may want to see also

Motor Issues: Check for electrical problems or mechanical failures

If your boat's propeller isn't engaging or moving as expected, it's essential to identify the root cause, especially if it's related to motor issues. Electrical and mechanical problems can often be the culprits behind this issue. Here's a step-by-step guide to help you troubleshoot and resolve motor-related problems:

Electrical System Inspection: Start by examining the electrical connections and components. Ensure that all wiring, including the motor's power cables and control lines, is intact and securely connected. Over time, wiring can become damaged or frayed, leading to poor conductivity. Check for any signs of corrosion or loose connections, especially at the motor mount and the battery terminals. If you find any issues, carefully clean or replace the affected parts. Additionally, test the battery to ensure it has sufficient power; a weak battery can result in inadequate motor performance.

Motor Control Panel: The control panel is the interface between the operator and the motor. It's crucial to inspect this area for any visible damage or malfunction. Check for error codes or warning indicators that might provide clues about the problem. Sometimes, a simple reset of the control panel can resolve minor glitches. If the issue persists, you may need to consult the motor's manual or contact the manufacturer for specific troubleshooting steps related to your motor model.

Mechanical Failures: Mechanical issues can also cause the propeller to fail to engage. Start by checking the motor's cooling system. Ensure that the water intake is clear of debris and that the cooling fans are functioning correctly. Overheating can lead to motor failure and reduced performance. Inspect the motor's internal components, such as the stator, rotor, and bearings, for any signs of wear or damage. If you notice excessive friction or unusual noises, it could indicate worn-out parts that require replacement.

Propeller and Pitch Adjustment: Sometimes, the issue might not be with the motor but with the propeller itself. Check the propeller's pitch and ensure it matches the motor's specifications. Incorrect pitch can result in poor performance. If you have access to a propeller puller, you can inspect the propeller for damage or debris. In some cases, adjusting the propeller's position or re-pitching it might be necessary to optimize performance.

Remember, when dealing with motor issues, it's crucial to prioritize safety. If you're unsure about any step or suspect a more complex problem, consult a qualified marine mechanic or the motor's manufacturer for professional assistance.

Winterizing Your Boat: The Essential Steps to Take

You may want to see also

Propeller Pitch: Ensure it matches the boat's speed and water conditions

When it comes to boat propulsion, the propeller pitch is a critical factor that can significantly impact performance. Propeller pitch refers to the angle of the blades relative to the shaft, and it plays a crucial role in determining how efficiently the propeller moves through the water. If your boat's propeller isn't performing as expected, it's essential to consider the pitch and how it relates to your boat's speed and the water conditions.

The pitch of a propeller is designed to match the boat's speed and the water's characteristics. For instance, a boat with a higher speed and a more powerful engine might require a propeller with a finer pitch, allowing for better acceleration and higher top speeds. On the other hand, a slower boat or one designed for leisurely cruising may benefit from a coarser pitch, which provides more torque and better low-speed performance. Understanding the relationship between propeller pitch and boat speed is key to optimizing your vessel's performance.

Water conditions also play a vital role in propeller pitch selection. In calm, still waters, a propeller with a finer pitch might be more efficient, as it can cut through the water more smoothly. However, in rough waters or when navigating through waves, a coarser pitch can provide better grip and control, ensuring the propeller doesn't become overwhelmed by the water's resistance. The pitch should be chosen to match the typical water conditions your boat encounters, ensuring optimal performance in various environments.

To ensure the right propeller pitch, it's essential to consider the boat's intended use and the typical operating conditions. For example, a fishing boat might require a different pitch than a luxury yacht. Additionally, factors like water temperature, salinity, and the presence of debris or aquatic plants can influence pitch selection. Consulting with marine experts or referring to the boat manufacturer's guidelines can provide valuable insights to help you make an informed decision.

Regular maintenance and inspection of the propeller are also crucial. Over time, propellers can accumulate wear and tear, debris, or even become damaged. This can alter the pitch and affect performance. Regular cleaning and checking for any signs of damage or wear will ensure that the propeller continues to function optimally, providing the best possible propulsion for your boat. By paying attention to propeller pitch and keeping it in line with your boat's capabilities and water conditions, you can address the issue of your boat's propeller not performing as expected.

Polyethylene Boat Bunks: A Comprehensive Guide

You may want to see also

Propeller Hub: Verify proper alignment and secure attachment

When dealing with issues related to your boat's propeller not functioning as expected, it's crucial to start by verifying the alignment and ensuring a secure attachment. This process is fundamental to addressing any problems effectively. Here's a step-by-step guide to help you through this verification process:

- Inspect the Propeller Hub: Begin by carefully examining the propeller hub, which is the central component connecting the propeller to the boat's engine. Check for any visible signs of damage, corrosion, or wear. Ensure that the hub is free from any debris or obstructions that might interfere with its operation. Look for any signs of misalignment or uneven wear on the hub's surface, as these could indicate previous issues or improper installation.

- Check Alignment: Proper alignment is critical to the propeller's performance. Carefully inspect the propeller's position relative to the hub. It should be centered and aligned with the hub's axis. Misalignment can cause the propeller to vibrate, leading to reduced efficiency and potential damage over time. If you notice any deviation from the correct alignment, carefully adjust the propeller until it is perfectly centered.

- Secure Attachment: Ensure that the propeller is securely attached to the hub. This is essential to prevent any accidental detachment during operation. Tighten the propeller nut or locknut according to the manufacturer's specifications. Use the appropriate tools, such as a torque wrench, to achieve the recommended tightening force. Over-tightening can damage the propeller or hub, so be cautious and precise. Regularly check the tightness of the attachment to ensure it remains secure over time.

- Test and Monitor: After making any adjustments, test the propeller's operation. Start the engine and observe the propeller's performance. Pay attention to any unusual noises, vibrations, or changes in engine behavior. If the issue persists, further investigation may be required, but starting with these alignment and attachment checks can often reveal the root cause of the problem.

Remember, proper maintenance and regular inspections are key to keeping your boat's propeller in optimal condition. By following these steps, you can ensure that your propeller hub is correctly aligned and securely attached, contributing to the overall performance and longevity of your boat's propulsion system.

Refurbishing Boat Seats: A Step-by-Step Guide to Success

You may want to see also

Water Flow: Assess if water is reaching the propeller efficiently

When dealing with a boat propeller that isn't performing as expected, it's crucial to understand the role of water flow and its impact on the propeller's functionality. The propeller's primary function is to convert the boat's engine power into forward motion by efficiently moving water. If water flow is not reaching the propeller effectively, it can lead to reduced performance and the issues you're experiencing.

To assess water flow, start by examining the boat's hull and the surrounding water conditions. Ensure that the hull is clean and free of any debris or barnacles that might obstruct water flow. Inspect the intake pipes and ensure they are not blocked or damaged, as this can restrict the water supply to the propeller. Look for any signs of cavitation, which occurs when the pressure of the water drops below its vapor pressure, causing bubbles to form and collapse near the propeller, leading to reduced efficiency. Cavitation can be identified by the formation of a 'roaring' sound or a 'whistling' noise from the propeller.

The propeller's design and placement play a significant role in water flow efficiency. Check if the propeller is aligned correctly and if it is the right size and pitch for the boat's intended use. A propeller that is too small or with incorrect pitch will struggle to move water effectively, resulting in poor performance. Consider the boat's speed and load; excessive speed or heavy loads can create a turbulent flow, reducing the propeller's efficiency.

In some cases, the issue might be related to the boat's engine. Ensure that the engine is properly tuned and maintained. Insufficient engine power or improper fuel-to-air mixture can lead to reduced propeller performance. Check the engine's water intake and cooling systems to ensure they are functioning optimally, as overheating can cause performance issues.

If the problem persists, it might be beneficial to consult a marine mechanic or an expert in propeller systems. They can provide specialized advice and perform detailed inspections to identify any hidden issues affecting water flow and propeller performance. Understanding and addressing water flow efficiency is a critical step in resolving the problem of a boat propeller that isn't functioning as expected.

A Boat Ride to the Grand Palace: A Guide

You may want to see also

Frequently asked questions

Boat propellers are designed to move the vessel forward or backward, not necessarily upwards. If you're experiencing an issue with the propeller's functionality, it's essential to check for any obstructions, such as debris or barnacles, that might be blocking its movement. Additionally, ensure that the propeller is properly attached to the shaft and that the engine is functioning correctly.

Yes, the power of your engine plays a significant role in the propeller's performance. If your engine lacks the necessary power, it might struggle to turn the propeller efficiently, resulting in limited movement. Consider checking the engine's horsepower and ensuring it meets the recommended specifications for your boat. Upgrading to a more powerful engine could be an option if it's within your budget.

Regular maintenance is crucial to keep your boat propeller in optimal condition. Over time, propellers can accumulate wear and tear, leading to reduced performance. Inspect the propeller for any signs of damage, cracks, or bent blades. If you notice any issues, it's best to consult a marine mechanic for repairs or replacements. Proper maintenance, including regular cleaning and lubrication, can prevent such problems and ensure smooth operation.