There are several reasons why a bass boat may be difficult to steer. The first is the presence of corrosion around the steering cable. When rust and corrosion settle on the cable, it can restrict its normal movement, causing stiffness in the steering. Grease entering the support tubes can also cause issues. In some cases, the grease from the support tubes' grease fittings will be sucked into the tubes, resulting in a hydraulic lock. Another potential cause is the design of the boat's hull, along with factors such as weight distribution and trim, which can cause hydrodynamic forces to act differently in each direction, affecting the boat's steering responsiveness. Additionally, problems with the propeller, steering system, rudder, or outboard motor can make steering difficult.

What You'll Learn

Grease and lubrication

The engine of your bass boat has several grease fittings and well-greased nipples that need to be lubricated regularly. These are located under the power head of the motor, where the motor pivots on the shaft. It is recommended to grease this area about once every 12 months. If it has been longer than a year since the last greasing, or if there is little to no grease remaining, you should add more.

In addition to the power head, the tilt tube, which is a metal tube that routes the inner metal cable sleeve, should also be cleaned and lubricated. For freshwater use, this should be done once a year, and for saltwater use, it is recommended to do this twice a year. White marine grease is the recommended lubricant for the tilt tube.

If your bass boat has trim tabs, these can also be adjusted to improve steering control. Trim tabs act as horizontal stabilizers and can be lowered to keep the stern from wagging.

By maintaining proper lubrication and greasing the necessary components, you can ensure that your bass boat's steering system functions smoothly and efficiently.

Indianapolis Boat Show: Friend or Foe?

You may want to see also

Corrosion on the steering cable

If your bass boat is hard to steer, it could be due to corrosion on the steering cable. This is a common issue, especially in saltwater boats, as salt speeds up the corrosion process and leaves behind abrasive grains of salt.

To address this problem, start by inspecting the steering cable for any signs of corrosion or damage. If the corrosion is mild, you may be able to clean the cable by scrubbing it with a high-quality motor cleaning product. However, if the corrosion has eaten through the cable, replacement is the best option.

When choosing a replacement steering cable, it is important to select one that is compatible with your bass boat's make and model, as well as the type of steering system it uses. Outboard steering cables come in different lengths and styles, and factors such as cable diameter, fitting type, and turns per inch should be considered. Additionally, the cable should be made of a suitable material, such as stainless steel, steel-core vinyl, or stainless-steel-core vinyl, to ensure it can withstand the marine environment.

Replacing a steering cable can be a challenging task, especially if you are unfamiliar with the process. It typically involves disconnecting the old cable, running the new cable, securing the connection, and ensuring proper tension and lubrication. Consulting a professional or a guidebook is recommended to ensure the job is done correctly.

To prevent future issues with corrosion, it is important to maintain and lubricate your steering cable regularly. This can be done by applying grease to the motor and steering components, as well as using specialized lubricants designed for boat steering cables.

Handling a 24-Foot Boat: A Challenge or a Breeze?

You may want to see also

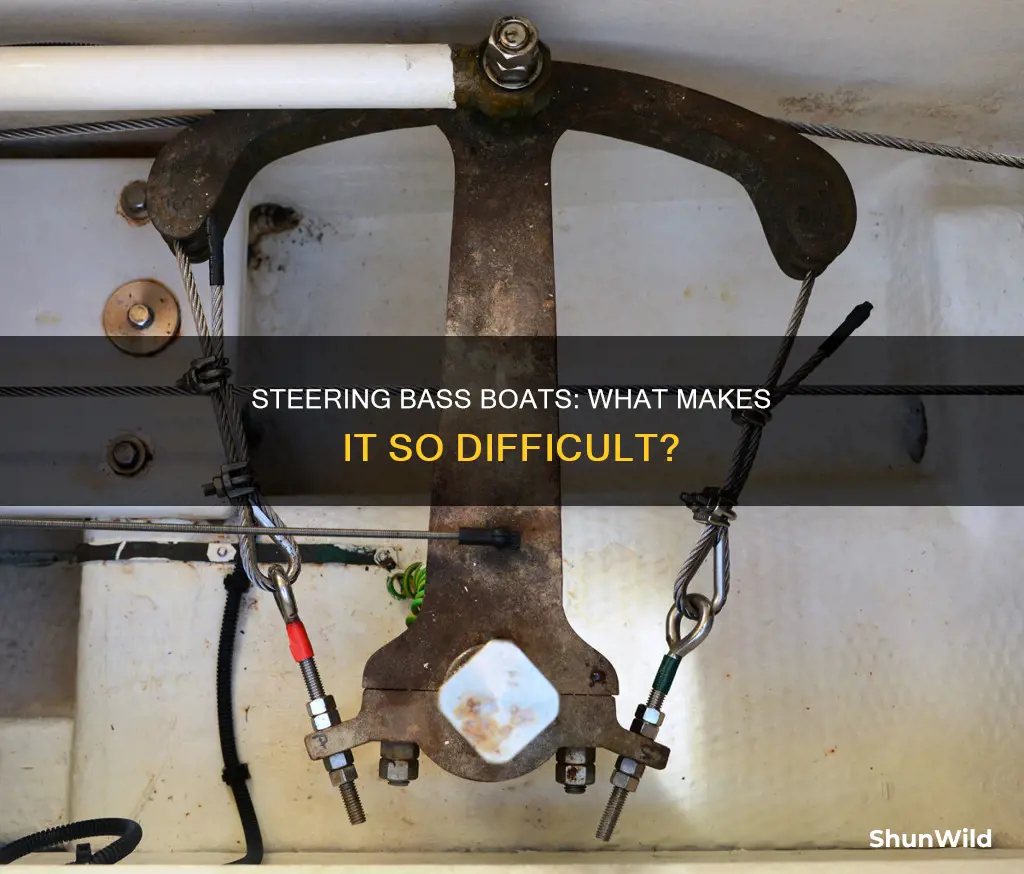

Grease in the support tubes

If your bass boat is hard to steer, it could be due to grease entering the support tubes. The support tubes, located on the engine, have grease fittings. Grease from these fittings can sometimes get sucked into the support tubes, resulting in a phenomenon known as a hydraulic lock. When this happens, the grease is pumped up through the cable jacket, causing the boat's steering to become stiff and hard to turn.

To prevent this issue, it is important to ensure that the grease fittings are properly maintained and that there is no excess grease that can be sucked into the support tubes. It is recommended to grease the motor pivot area about once every 12 months. If it has been longer than 12 months since the last greasing, or if there is little to no visible grease remaining, it is important to add more grease to this area.

Unfortunately, if grease has already entered the support tubes and caused a hydraulic lock, the only way to fix the problem is to replace the entire steering cable. This issue, if left unaddressed, could lead to further damage to the boat's motor and its components. Therefore, it is important to regularly inspect and maintain the grease fittings and support tubes to ensure smooth and unrestricted movement of the steering system.

By following these guidelines and performing regular maintenance, you can help ensure that your bass boat's steering system functions properly and reduce the likelihood of encountering steering difficulties due to grease-related issues.

Boat Repair Guide: BDO Essentials You Need to Know

You may want to see also

Propeller alignment

- Engine and propeller shaft alignment: Nearly all marine engines are designed to be adjustable relative to the propeller shaft. This adjustment is typically done using jacking nuts or adjustable motor mounts. However, it's important to note that this fine-tuning has a limited range, usually no more than an inch or two. The naval architect and boat builder play crucial roles in ensuring near-perfect alignment before the motor mounts are adjusted.

- Shaft alignment: This aspect involves the support and position of the propeller shaft relative to its bearings, the shaft log, and the engine. Shaft misalignment can lead to excessive shaft drag, increased fuel consumption, and accelerated bearing and shaft wear. Shaft alignment requires specialised knowledge and techniques, so it's important to ensure that the boatyards crew is experienced in this area.

- Alignment techniques: Traditional methods for aligning the propeller shaft to the engine involve using small-diameter strings or wires as reference points for positioning bearings and struts. More modern tools, such as lasers and optical sights, provide greater accuracy in positioning bearings along the sight line.

- Final adjustments: After initial alignment, the strut or bearing is typically dry-fitted to determine any necessary adjustments to height and orientation. Wedges are used for fine-tuning, and epoxy is used to set the position. For bearings within a shaft log and strut, the bearing is waxed and set in epoxy, with wedges used for positioning until the epoxy cures.

- Alignment tolerance: Achieving precise alignment is crucial. Using a dial indicator, the tolerance between the two coupling halves should be less than a thousandth of an inch. This precision helps prevent premature bearing wear and noise issues.

- Centering the propeller shaft: For wet propeller shafts with flexible gland sealing, it's important to centre the shaft in the shaft tunnel before aligning the engine. This step helps prevent serious damage caused by the spinning shaft contacting the tunnel sides.

By following these instructions and working with experienced professionals, you can ensure proper propeller alignment, which will improve the steering performance of your bass boat.

Boat Covers: When to Replace and Why

You may want to see also

Steering system issues

If your bass boat is hard to steer, there could be an issue with its steering system. This could be due to several reasons and can usually be fixed yourself if you have average mechanical skills.

Firstly, check if there is adequate grease on the motor. Lubrication is necessary to keep the components moving and functioning properly. Without it, the steering wheel may become difficult to turn. Grease the area under the power head of the motor where it pivots on the shaft. This area should be greased about once every 12 months.

Secondly, inspect the steering system for any loose or worn components, such as cables, connections, or the steering wheel itself. Lubricate any moving parts as needed. If the cables are worn, they may need to be changed. Additionally, check the cable routing to ensure it is not bound or bent too sharply. If the cable is routed correctly and is not impinged, you may need to replace it.

Thirdly, if you have a mechanical steering system, you can diagnose problems by isolating each component. Start by disconnecting the steering arm from the cable's motor/rudder end and turning the steering wheel. If the cable moves freely, the issue is with the motor, stern drive unit, or rudder. If the cable doesn't move, the problem is likely at the helm.

Finally, if you have a hydraulic steering system, problems can arise from leaks, low fluid levels, and/or air in the line. Inspect the hoses, helm, steering cylinder, and other components for any signs of hydraulic fluid leakage. Leaks can lead to low fluid levels, which can affect steering performance. Check and add hydraulic fluid if needed, and bleed air from the system to ensure the fluid is incompressible.

Flipping a Boat: The Safe Way to Turn Over a Hull

You may want to see also