If your boat's throttle response is inconsistent, with the engine only reaching half its potential, it can be frustrating and concerning. This issue could stem from various factors, including mechanical problems, electrical malfunctions, or even user error. Understanding the root cause is crucial to finding an effective solution, whether it's a simple adjustment or a more complex repair.

What You'll Learn

- Engine Performance: Check for issues with the engine, such as faulty sensors or fuel delivery problems

- Throttle Control: Inspect the throttle body and cables for obstructions or damage

- Propeller Efficiency: Ensure the propeller is in good condition and properly balanced

- Throttle Cable: Examine the throttle cable for wear and proper tension

- Electrical System: Test the throttle control circuit for any wiring or component faults

Engine Performance: Check for issues with the engine, such as faulty sensors or fuel delivery problems

When you encounter a situation where your boat's throttle response is inconsistent, with it only going to half throttle, it's crucial to investigate potential engine performance issues. This problem could stem from various components within the engine system, and addressing it promptly is essential for safe and efficient boating. Here's a detailed guide on how to approach this issue:

Sensor Malfunctions: The engine control unit (ECU) relies on various sensors to receive real-time data about the engine's performance. One of the most critical sensors for throttle control is the throttle position sensor. If this sensor is faulty or malfunctioning, it may send inaccurate signals to the ECU, leading to improper throttle response. To check for sensor issues, you can start by inspecting the sensor's wiring for any signs of damage or corrosion. Ensure that all connections are secure and clean. If the sensor appears faulty, it might need replacement, as sensors can wear out over time due to the harsh marine environment.

Fuel Delivery Problems: Efficient fuel delivery is vital for optimal engine performance. If the fuel system is not functioning correctly, it can result in poor throttle response. Start by inspecting the fuel filter for any clogs or signs of contamination. A clogged fuel filter can restrict fuel flow, causing the engine to run poorly. If the filter is dirty, replace it with a new one. Additionally, check the fuel pump for any leaks or signs of wear. The fuel pump's role is to deliver fuel at the right pressure to the engine, and a failing pump can lead to inconsistent throttle control.

Throttle Body or Carburetor Issues: In older boats with carbureted engines, the throttle body or carburetor plays a significant role in controlling the air-fuel mixture. Over time, these components can accumulate deposits or suffer from mechanical wear. Inspect the throttle body for any signs of carbon buildup or damage. If necessary, clean or replace it. For carbureted engines, ensure that the float bowl is properly filled with fuel, and check for any clogs or issues with the carburetor jetting.

ECU and Wiring: The ECU is the brain of the engine, processing sensor data and sending commands to various actuators, including the throttle. If the ECU is receiving incorrect data due to sensor failures or wiring issues, it may result in half-throttle response. Inspect the wiring harness for any signs of damage, especially near the engine and throttle body. Ensure that all connections are secure and free from corrosion. In some cases, recalibrating the ECU might be necessary, but this should be done by a professional to avoid further complications.

By systematically checking these engine performance aspects, you can identify and resolve the underlying causes of your boat's half-throttle issue. Remember, proper maintenance and timely repairs are key to ensuring a smooth and reliable boating experience.

Maintaining Boat Battery Charge: Tips for Constant Power

You may want to see also

Throttle Control: Inspect the throttle body and cables for obstructions or damage

If your boat's throttle response is inconsistent, with it only operating at half power, it's crucial to inspect the throttle body and cables for any potential issues. This inspection is a fundamental step in diagnosing and resolving throttle control problems. Here's a detailed guide on how to approach this task:

Understanding the Throttle System: Begin by familiarizing yourself with your boat's throttle mechanism. Throttle control is typically achieved through a combination of a throttle body, cables, and a throttle pedal or lever. The throttle body is the central component, often located near the engine, and it regulates the air-fuel mixture entering the engine, thus controlling the engine's speed and power output.

Inspecting the Throttle Body: Start the inspection process by carefully examining the throttle body. Look for any visible signs of damage, such as cracks, warping, or corrosion. Over time, the throttle body can accumulate wear and tear, especially if it's made of metal. Check for any obstructions or debris that might be blocking the throttle body's passages. Even a small piece of dirt or a broken piece of plastic can restrict the airflow, leading to reduced throttle response. Use a soft brush or compressed air to gently clean the throttle body, ensuring no foreign objects remain.

Checking the Throttle Cables: The throttle cables are responsible for transmitting the driver's input from the throttle pedal to the throttle body. Inspect these cables for any signs of damage, wear, or kinks. Frayed or damaged cables can cause inconsistent or delayed throttle response. Ensure that the cables are securely attached to both the throttle pedal and the throttle body. If any cables are found to be damaged, they should be replaced to ensure smooth and responsive throttle operation.

Testing for Smooth Operation: After inspecting the throttle body and cables, it's essential to test the throttle's smooth operation. Rev the engine gently and observe how the throttle responds. If the throttle feels sluggish or unresponsive, it may indicate a problem with the throttle body or cables. Try adjusting the throttle pedal to its full range of motion and note if there are any sudden stops or lags in the engine's response.

Addressing Potential Issues: If the inspection reveals any obstructions or damage, prompt action is required. Clean or replace the throttle body as necessary to ensure optimal airflow. For cable issues, tighten any loose connections and replace damaged cables. Regular maintenance and inspections can prevent throttle control problems and ensure your boat's engine operates efficiently and reliably.

Boat Mechanics: Unlocking Eador's Aquatic Secrets

You may want to see also

Propeller Efficiency: Ensure the propeller is in good condition and properly balanced

When you notice that your boat is performing poorly, with reduced throttle response, it's essential to consider the propeller as a critical component. Propeller efficiency is a key factor that can significantly impact your boat's performance. The propeller's primary function is to convert the engine's rotational energy into forward propulsion, and any issues with its condition or balance can lead to reduced power and control.

One of the most common reasons for a boat's poor throttle response is a damaged or worn-out propeller. Over time, propellers can accumulate wear and tear, especially in areas where they come into contact with the water and other marine debris. This wear can cause the propeller blades to become bent, cracked, or damaged, leading to reduced efficiency. Inspect the propeller regularly for any signs of damage, such as bent or broken blades, and replace it if necessary. A well-maintained propeller will ensure optimal power transmission from the engine to the water, allowing for better throttle response.

Proper balancing of the propeller is another crucial aspect of propeller efficiency. An unbalanced propeller can cause vibrations and reduced performance. When the propeller is not balanced, it may wobble or vibrate as it rotates, leading to uneven power distribution and decreased throttle control. This issue is often overlooked but can be easily addressed by a professional. Balancing the propeller involves ensuring that the weight distribution is even across all blades, allowing for smooth rotation and optimal power transfer.

To ensure propeller efficiency, it's recommended to perform regular maintenance checks. This includes inspecting the propeller for any signs of damage, corrosion, or debris buildup. Keeping the propeller clean and free from obstructions is essential, as debris can interfere with its performance. Additionally, checking the propeller's pitch and diameter to ensure they match the engine's specifications is vital. Proper propeller selection and maintenance will significantly enhance your boat's overall performance and throttle response.

In summary, propeller efficiency plays a critical role in a boat's throttle response. By ensuring the propeller is in good condition and properly balanced, you can address potential issues that may be causing your boat to only go half throttle. Regular maintenance, including inspections and cleaning, will help maintain optimal propeller performance, allowing for a smoother and more responsive boating experience.

Skipper's Role: Commanding a Sail Boat's Course

You may want to see also

Throttle Cable: Examine the throttle cable for wear and proper tension

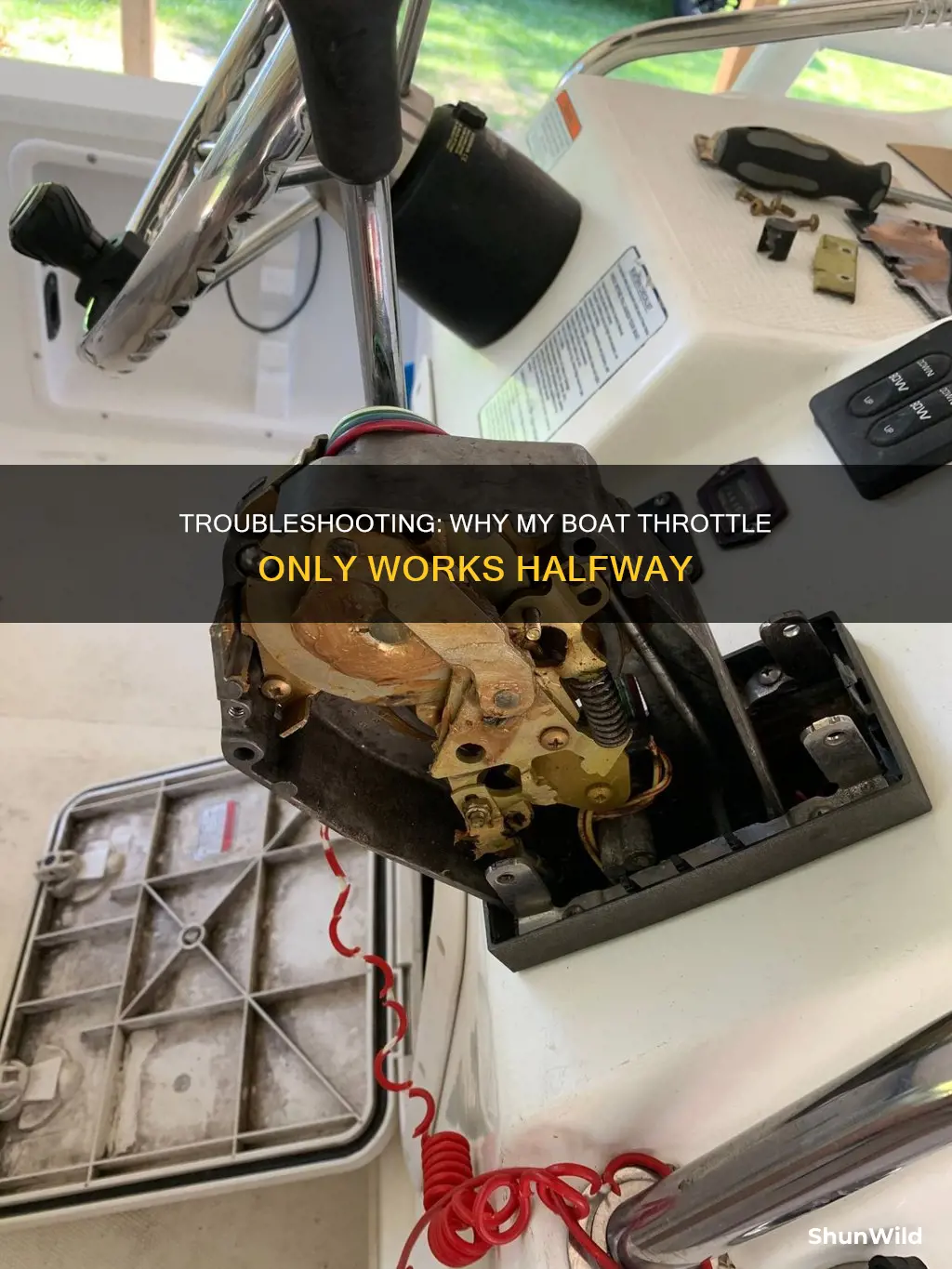

When you notice that your boat's throttle response is inconsistent, with it only going half throttle, it's essential to inspect the throttle cable as a potential cause. Throttle cables are responsible for transmitting the operator's input from the throttle control to the engine, and any issues with these cables can lead to reduced performance. Here's a step-by-step guide to examining the throttle cable:

- Visual Inspection: Start by visually examining the throttle cable. Look for any signs of wear, such as frayed or damaged insulation, cuts, or exposed wires. Over time, cables can deteriorate due to sun exposure, moisture, or physical damage. Check for any bends or kinks in the cable, as these can affect its functionality. Ensure that the cable is securely attached to both the throttle control and the engine's throttle body.

- Tension Check: Proper tension is crucial for the throttle cable's performance. If the cable is too loose, it may not transmit the throttle input effectively, resulting in inconsistent power delivery. To check the tension, you can try operating the throttle control while observing the cable's movement. It should move smoothly and consistently without any slack. If you notice excessive play or the cable feels loose, it might need adjustment or replacement.

- Cable Adjustment: Adjusting the throttle cable can help restore proper functionality. Locate the cable adjustment mechanism, which is typically found near the engine or the throttle control. Loosen the adjustment screw or bolt to allow movement and then tighten it to secure the desired tension. Ensure that the cable is neither too tight nor too loose, as this can cause binding or reduced throttle response.

- Testing: After making any adjustments, test the throttle cable thoroughly. Rev the engine and observe the throttle's response. It should now respond more consistently, going all the way to full throttle. If the issue persists, further investigation may be required, but starting with the throttle cable examination is a practical first step.

Remember, regular maintenance and inspection of the throttle cable can prevent unexpected issues and ensure your boat's engine operates smoothly. If you're unsure about any adjustments or suspect other components might be at fault, consulting a professional marine mechanic is always a good idea.

Aluminum Tiller Boat: Design and Appearance Explained

You may want to see also

Electrical System: Test the throttle control circuit for any wiring or component faults

If your boat's throttle is unresponsive or only operates at half power, it could be an issue with the electrical system, specifically the throttle control circuit. This circuit is responsible for transmitting the throttle command from the control lever or pedal to the engine's throttle body. Here's a step-by-step guide to troubleshooting and testing the throttle control circuit:

- Visual Inspection: Begin by inspecting the throttle control circuit for any visible signs of damage or loose connections. Check for any frayed or exposed wires, especially those connected to the throttle body, control cables, and the throttle control module (if applicable). Look for any signs of corrosion or moisture intrusion, as these can affect the circuit's performance.

- Wiring Diagram and Manual: Refer to your boat's wiring diagram and user manual to understand the layout of the throttle control circuit. Identify the specific wires and components involved, including the throttle position sensor, control module, and any relays or solenoids. This information will help you locate the relevant connections and test points.

- Throttle Control Module (TCM): If your boat has a throttle control module, it acts as a central processor for throttle control. Test the TCM by disconnecting it from the power source and checking for any error codes or fault indicators. You can use a multimeter to measure the resistance across the TCM's input and output terminals to ensure proper functionality.

- Throttle Position Sensor: The throttle position sensor provides feedback to the TCM about the throttle's position. Test this sensor by disconnecting it and using a multimeter to measure the resistance across its terminals when the throttle is at different positions (full open, half, and closed). The sensor should show varying resistance values corresponding to the throttle's position. If the sensor is faulty, it may provide incorrect feedback, leading to throttle issues.

- Control Cables and Relays: Inspect the control cables and relays (if present) for any signs of damage or wear. Ensure that the cables are securely connected to the throttle body and the TCM. Test the relays by applying power to their input terminals and checking for the expected output at the relay's load terminals. A faulty relay can disrupt the circuit's functionality.

- Engine Control Unit (ECU): In some cases, the throttle control circuit may be integrated with the Engine Control Unit (ECU). Test the ECU's throttle control functions by connecting a scan tool and checking for any error codes related to the throttle. Ensure that the ECU is receiving accurate throttle position data from the sensor.

- Professional Assistance: If the issue persists or you're unsure about any step, it's recommended to consult a professional marine technician or your boat's manufacturer for further guidance. They can provide specialized testing equipment and expertise to identify and resolve complex electrical system issues.

Replacing a Boat Fuel Tank Sending Unit: A Step-by-Step Guide

You may want to see also

Frequently asked questions

This issue could be due to a few potential causes. Firstly, check the throttle control cable for any signs of damage or wear, as this can affect the smooth operation of the throttle. Another possibility is a faulty throttle body or carburetor (if your boat uses one), which may need to be cleaned or replaced. It's also important to ensure that the fuel system is functioning correctly, as poor fuel supply can lead to inconsistent power delivery.

Start by inspecting the throttle pedal and its linkage for any obstructions or damage. Sometimes, debris or dirt can interfere with the smooth movement of the throttle. Also, check the throttle body for any clogs or deposits, especially if your boat has a high-performance engine. If the issue persists, it might be worth consulting a marine mechanic to diagnose and fix any potential electrical or mechanical problems.

There are a few common reasons for this problem. One possibility is a restricted exhaust system, which can cause back pressure and limit the engine's ability to rev. Inspect the exhaust for any blockages or damage. Another potential cause is a faulty throttle position sensor, which sends signals to the engine control unit (ECU). The ECU then adjusts the fuel and spark timing accordingly. If the sensor is faulty, it might send incorrect signals, resulting in reduced throttle response.