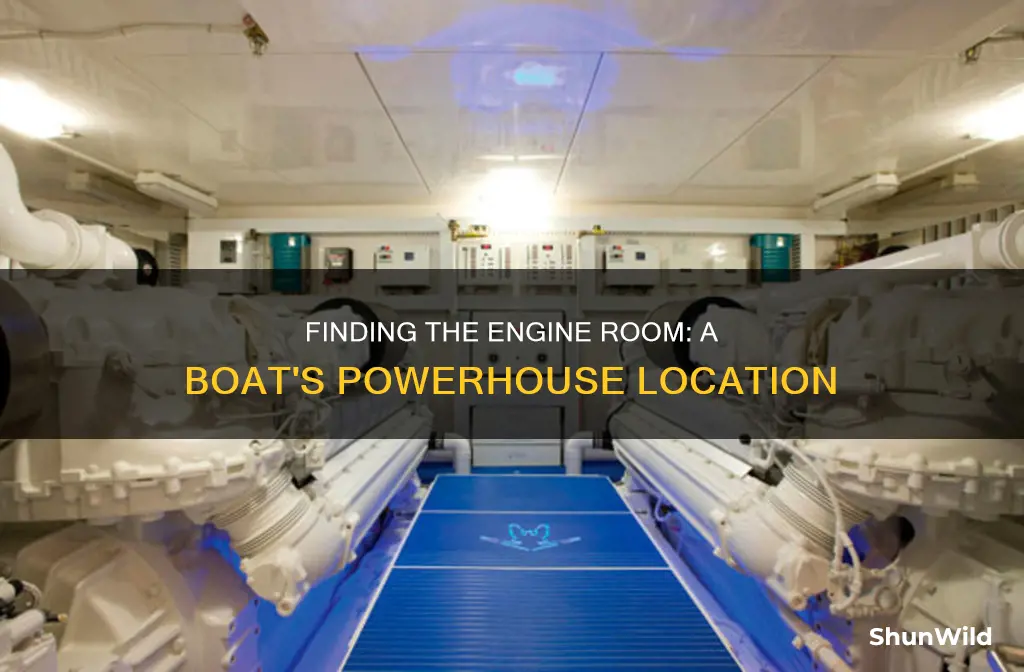

The engine room is a crucial part of any boat, housing the machinery that propels the vessel through the water. It is typically located near the bottom and at the rear of the ship, and can be identified by the loud noises and vibrations coming from within. The engine room is usually the largest compartment in the machinery space, and can cover several decks on larger ships. Inside, you'll find not just the engines, but also fuel tanks, generators, control rooms, and workshops.

The design of the engine room is important, as it is a potentially dangerous place, full of hot surfaces, spinning objects, and toxic chemicals. A well-designed engine room will minimise the need for people to enter, and ensure their safety when they do.

What You'll Learn

Engine room safety considerations

Engine rooms are typically located near the bottom, at the rear of a vessel, and comprise a few compartments. They are noisy, hot, usually dirty, and potentially dangerous places. The presence of flammable fuel, high-voltage electrical equipment, and internal combustion engines means that a serious fire hazard exists in the engine room, which is monitored continuously by the ship's engine department and various monitoring systems.

Procedures and Training

Given the complexity of modern vessels, engine room safety is paramount. Most fires on board ships start in the engine room, and a failure can significantly affect overall safety. Therefore, strict adherence to established procedures and recognised best practices is critical. Crew training and familiarity with engine room operations are essential for enhanced safety.

Fire Safety

One of the most important considerations for engine room safety is fire prevention. Onboard fires pose grave threats to crew safety and should be prioritised when creating safety protocols. Ensure that fire safety equipment, such as extinguishers, is accessible and regularly checked. Additionally, implement clear procedures for fuel handling and disposal to minimise fire risks.

Waste Management

Engine rooms create waste by-products, particularly oil-contaminated materials. Properly disposing of these contaminants is crucial to prevent fire hazards and potential environmental compliance issues. Have designated disposal containers for oil rags and other contaminated materials, and ensure waste is stored and discarded appropriately when docked.

Maintenance and Housekeeping

Regular checks and maintenance can help identify wear and tear, leaks, or other issues before they become significant problems. Keep a detailed log of any repairs, replacements, or anomalies. Ensure that the engine room is well-maintained and clean, as oil and fuel leaks can indicate poor maintenance and potential safety hazards.

Personal Protective Equipment (PPE)

Given the potential hazards in the engine room, such as hot surfaces, chemicals, and moving parts, anyone entering should wear appropriate PPE. This includes gloves, eye protection, and non-slip footwear.

Clear Communication

Effective communication between the engine room and the bridge, as well as with other crew members, is essential, especially in emergencies. Ensure that communication workflows and channels are established and that all personnel are familiar with them.

Safe Working Environment

Engine rooms can present various physical hazards, such as blocked escape routes, slippery or loose deck plates, and working-at-height risks. Implement safety measures such as handrails, clear walkways, and proper lighting to minimise these risks and ensure a safe working environment for crew members.

Repairing Boat Canvas Snaps: A Step-by-Step Guide

You may want to see also

Engine room design and layout

Engine rooms are typically located near the bottom, at the rear or aft end of the vessel, though they can also be situated mid-ship or forward and even high. The design and layout of an engine room will depend on the type of boat and its specific requirements. However, there are some key considerations that apply to most engine room designs.

Firstly, accessibility is crucial. The engine room should be easy to enter, with well-placed handholds and non-skid steps to ensure safety. The layout should also provide adequate space to move around, including headroom, with key components placed close to the entrance for easy access. A well-designed engine room will have a logical arrangement, with proper labelling and everything accessible and clearly visible. This is essential for maintenance and can help save time and money when problems arise.

The engine room should also be well-ventilated to ensure the removal of heat and damp, salt-laden air, which can affect engine performance and migrate to other areas of the boat. In addition, the presence of flammable fuel and high-voltage electrical equipment means fire safety is a paramount consideration. A well-designed engine room will have a fire-suppression system installed, with the discharge outlets mounted close to the overhead to ensure maximum agent dispersion.

Finally, the layout of the engine room should facilitate the efficient operation and maintenance of the various systems and equipment housed within. This includes the propulsion engines, electrical generators, thruster systems, and auxiliary engines. The design should also accommodate the necessary cooling systems, such as liquid-to-liquid heat exchangers, and ensure the proper intake of air for internal combustion or turbine engines.

Flat-Bottom Boats for Chop: Which Design Handles Waves Best?

You may want to see also

Engine room maintenance

Engine rooms are typically located near the bottom, at the rear of the vessel, and comprise a few compartments. They are noisy, hot, dirty, and potentially dangerous places. Therefore, engine room maintenance is of utmost importance.

- Regularly inspect the engine room: Check for any signs of corrosion, damage, loose parts, unusual sounds or smells, and leaks. A well-maintained engine room will have everything accessible, logically arranged, and properly labelled.

- Keep the engine room clean: Use appropriate cleaning products and rags to wipe down the engine and surrounding surfaces. Pay attention to the ceiling and corners of the room. Use oil-absorbent pads to catch any drips or leaks, and ensure the bilge area is free of oily residue.

- Protect the surfaces: When performing repairs or maintenance, use cardboard, plastic, or tape to protect painted surfaces from tools and grease.

- Simplify maintenance tasks: Create a process to minimise mess and simplify tasks such as oil changes. Use containers to catch drips and spills, and keep spare parts on hand to reduce downtime.

- Manage waste properly: Dispose of oil-contaminated materials, sewage, and liquid waste in accordance with regulations. Use designated disposal containers and tanks, and ensure proper separation and filtration of waste streams.

- Prioritise fire safety: Implement fire safety measures such as having a fire extinguisher readily available and ensuring proper disposal of oily rags and other flammable materials. Diagnose and repair any fuel leaks promptly.

- Ensure good ventilation: Engine rooms require adequate ventilation to provide fresh air for engine operation and to maintain a comfortable working environment.

- Maintain safety equipment: Test and maintain safety equipment such as the ship's thruster system and emergency lighting.

- Follow safety procedures: Wear appropriate personal protective equipment (PPE) when working in the engine room, including anti-slip safety shoes, helmets, gloves, and protective eyewear.

- Consult professionals: Engage professionals with the expertise and equipment to perform regular engine room cleaning and maintenance if you are unable to do so yourself.

Rendering Aid: A Boater's Responsibility and Legal Requirement

You may want to see also

Engine room temperature control

Engine rooms are typically located near the bottom, at the rear of a vessel, and comprise a few compartments. This design maximises cargo capacity and situates the prime mover close to the propeller.

Engine rooms are noisy, hot, and potentially dangerous. They contain flammable fuel, high-voltage electrical equipment, and internal combustion engines, which present a serious fire hazard. Therefore, engine rooms require adequate ventilation and temperature control.

- Install engine room fans to increase air movement and create directional airflow focused on equipment and hot spots.

- Assess air paths to ensure they are free and clear, allowing air to circulate efficiently.

- Optimise the positioning of intake and outlet air vents to ensure proper air turnover and prevent recirculation of hot air. Intake vents should supply fresh cool air low into the engine room, while hot air should be exhausted high and as far from the intake as possible.

- Get a qualified assessment from a specialist who can help reduce operating costs, improve efficiency, and extend the life of equipment.

- Use liquid-to-liquid heat exchangers connected to fresh seawater or recirculate through tanks of seawater in the engine room to cool the engines.

- Ensure proper ventilation and airflow in the engine room, especially if individuals are normally present in these spaces. Screens placed over hull openings can reduce airflow by approximately 50%, so the opening area may need to be increased.

- Install automatic intake and exhaust fans to ensure engines receive sufficient air and to maintain a cool temperature in the engine room.

- Utilise demisters to remove salt-laden damp air before it reaches the engines, extending their life.

Boat Recovery: Best Places for Boat Repairs

You may want to see also

Engine room lighting

Engine rooms are typically found near the bottom, at the rear of a vessel, though they can also be located mid-ship or forward and high, depending on the type of vessel. As the heart of the boat, the engine room is a crucial space that requires good lighting to ensure safety during maintenance, inspections, and repairs.

Lighting in engine rooms should provide clear visibility in these complex environments. High-quality LED lights are a popular choice for engine rooms as they are energy-efficient, long-lasting, bright, and resistant to vibrations and shocks. LED lights also offer a range of colour options, including cool white and soft blue, as well as dual-colour lights. The brightness of LED lights is adjustable, allowing users to customise the lighting according to their specific needs.

When choosing lighting for an engine room, it is important to consider factors such as mechanical strength, impact resistance, and ingress protection (IP) rating for particle and water ingress resistance. The limited space and height restrictions in engine rooms also call for compact, low-profile lighting designs to prevent head injuries. Additionally, the high ambient temperature and hot spots near exhaust pipes in engine rooms should be considered when selecting appropriate lighting solutions.

Some engine rooms may have windows or peepholes to allow for a visual inspection of the interior before entering, which can be crucial in the event of a fire or flooding. It is also important to have emergency lighting in the engine room as a backup in case the main electrical system fails. Overall, engine room lighting plays a vital role in ensuring the safety, efficiency, and functionality of marine vessels.

The Best Cuddy Cabin Boats: Top Picks Reviewed

You may want to see also

Frequently asked questions

The engine room on a boat is typically located near the bottom, at the rear or aft end of the vessel. On newer boats, the engine room is found on the aft of the ship and on the lower decks, closer to mid-ship.

The engine room is often referred to as the "Holy Place" as it houses the machinery that propels the boat forward. It is also where crucial maintenance tasks are performed to sustain life aboard during long-distance voyages.

Safety and accessibility are paramount when designing an engine room. It should be well-lit, with bright, 110-volt lighting, and have ample headroom and shoulder-width space to move around. The placement of essential equipment, such as switch panels, fuel valves, and battery switches, should be easily accessible from the engine room entrance.

The engine room can be a dangerous place due to hot surfaces, spinning objects, and toxic chemicals. It is crucial to have proper protective gear, such as earmuffs and gloves, easily accessible near the engine room entrance. Engine rooms also pose a fire risk, so having a well-designed cooling and exhaust system, as well as a fire suppression system, is essential.