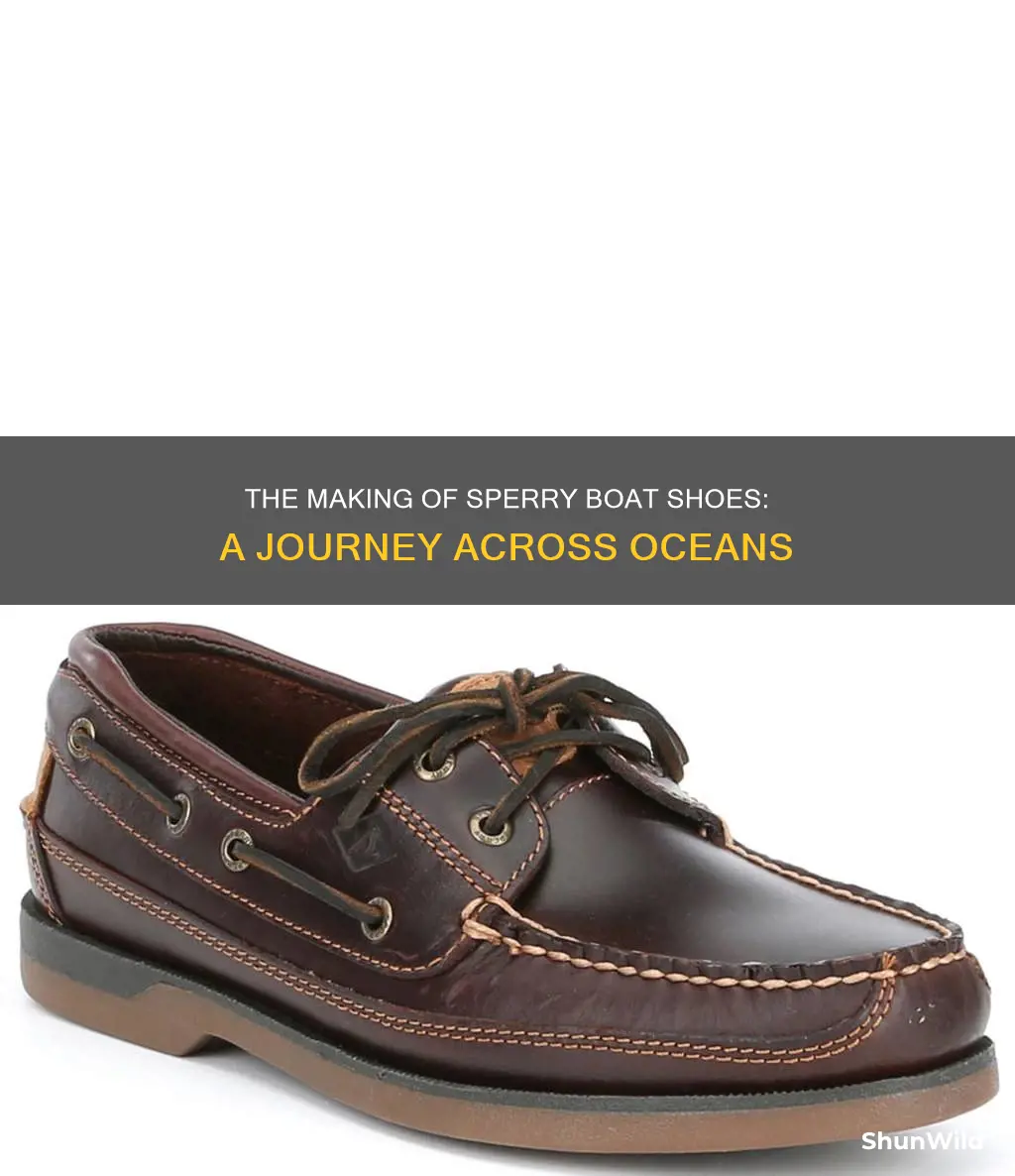

Sperry boat shoes are an iconic American brand of boat shoe, first designed in 1935 by Paul A. Sperry. The shoes are known for their soft leather, white stitching, and laces that weave around the shoe's opening. While Sperry did launch a Made in Maine product line in 2012, most of their iconic Top-Sider boat shoes are made in Vietnam, Indonesia, and China. This article will explore the history of Sperry boat shoes, their manufacturing process, and the extent to which their boat shoes are made in America.

| Characteristics | Values |

|---|---|

| Brand | Sperry or Sperry Top-Sider |

| Type of shoe | Boat shoe |

| Place of origin | United States |

| Current owner | Authentic Brands Group |

| Licensee for North America operations | Aldo Group |

| Places of manufacture | Vietnam, Indonesia, China |

| Place of manufacture for small product line | Maine, United States |

What You'll Learn

- Sperry boat shoes are designed in the USA but mostly made in Vietnam, Indonesia, and China

- The shoes are hand-stitched by artisans

- The leather is inspected and sometimes discarded if not up to standard

- The rubber outsole is pre-glued and attached to the midsole through a heat-activation process

- Sperry is the official footwear sponsor of the US Sailing Team Sperry

Sperry boat shoes are designed in the USA but mostly made in Vietnam, Indonesia, and China

Sperry boat shoes are an iconic American brand, designed in 1935 by Paul A. Sperry, an avid sailor. The shoes were the first of their kind, introduced to the boating and footwear markets. The design was inspired by a fall Sperry took on the deck of his boat, which drove him to develop a non-slip shoe for boating. The recognisable soft leather, white stitching, and laces that weave around the shoe opening are crafted by artisans who stitch the footwear by hand.

Despite being synonymous with American culture, most Sperry boat shoes are not made in the USA. Instead, they are made in Vietnam, Indonesia, and China. This is a result of the brand's change in leadership over the years, with pressure from parent companies to move manufacturing overseas for cheaper labour and materials.

In 2012, Sperry did attempt to bring back American manufacturing with a "Made in Maine" product line. However, this was a small portion of their overall production and has since been discontinued. Sperry's commitment to quality and heritage remains, but the international manufacturing locations for their popular shoes and other products have shifted.

The "Made in Maine" collection was handcrafted by artisans in Maine, using U.S.-sourced leather and the finest materials. The shoes were hand-stitched, featuring a 360° lacing system with rust-proof eyelets, a premium leather footbed, and a shock-absorbing EVA heel cup. While Sperry's boat shoes are no longer made in Maine, the brand continues to celebrate its heritage as an American icon.

Restoring Your Bass Boat: Reviving the Shine and Glory

You may want to see also

The shoes are hand-stitched by artisans

Sperry boat shoes are hand-stitched by artisans, with each shoe requiring the special skills of the craftspeople who stitch together the iconic footwear by hand. The process begins with the selection and cutting of soft leather, which is then inspected to ensure it meets the brand's high standards. Holes are punched into the leather, eyelets are added, and rawhide leather laces are intertwined. Rawhide is a type of leather known for its pliability, allowing it to be bent in different directions, making it ideal for lacing around the shoe.

Once the leather pieces are cut and prepared, the upper sections of the shoe are stitched together using a sewing machine. The leather is then soaked in water to enhance its pliability. The pieces are then pulled over a last, or shoe form, and secured with shoe tacks. At this stage, the top and bottom pieces of the shoe are hand-stitched together by artisans using an awl to punch holes and two needles to fasten the threads.

After being hand-sewn, the shoe is left to dry for about three hours, remaining on the last for an additional 24 hours to ensure it dries completely and takes on the shape of a shoe. The subsequent steps involve the attachment of the midsole and outsole, which are glued and heat-activated to ensure a secure bond. The edges of the sole are then trimmed and smoothed to create a neat finish. Finally, the last is removed, and a leather sock liner is glued into the bottom of the shoe.

The hand-stitched construction of Sperry boat shoes is a testament to the artisans' dedication to their craft, ensuring that each pair is meticulously assembled and reflects the brand's commitment to quality. This process has been a hallmark of the brand for over seventy-five years, contributing to the iconic status of Sperry boat shoes in American culture.

The Bass Drops: A Boat Party Like No Other

You may want to see also

The leather is inspected and sometimes discarded if not up to standard

Sperry boat shoes are known for their soft leather, white stitching, and laces that weave around the shoe's opening. The process of making each shoe requires the special skills of artisans who stitch together the footwear by hand.

The process begins with the selection and cutting of leather on a machine into different pieces that will later form the main parts of the shoe. This is a crucial step, as each piece of leather is inspected, and those that do not meet the brand's standards are discarded. This ensures that only the highest quality leather is used for the iconic Sperry boat shoes. The leather is sourced from the United States and is chosen for its durability and flexibility.

During the inspection process, artisans carefully examine each piece of leather for any imperfections or flaws that may impact the overall quality of the shoe. They look for scratches, discolouration, or inconsistencies in the texture and thickness of the leather. Only the pieces that meet the strict quality standards of Sperry are approved for the next steps in the shoe-making process. This meticulous inspection process guarantees that the final product embodies the brand's commitment to craftsmanship and attention to detail.

After the inspection, the leather pieces are punched with holes, and eyelets are added. The distinctive rawhide leather laces, known for their pliability, are then intertwined. Rawhide leather is an ideal choice for Sperry boat shoes as it can be bent in different directions, making it easy to lace around the shoe. This type of leather also contributes to the overall comfort and flexibility of the shoe.

The upper pieces of the shoe are then stitched together by a sewing machine. To make the leather more pliable, these pieces are soaked in water before being pulled over a last, which is the shoe form, and secured with shoe tacks. The artisans then hand-stitch the top and bottom pieces together, using an awl to punch holes and two needles to fasten the threads. This hand-stitching technique adds a human touch to the manufacturing process, ensuring that each shoe is uniquely crafted with precision and care.

Boat Show Prices: Bargain or Gimmick?

You may want to see also

The rubber outsole is pre-glued and attached to the midsole through a heat-activation process

Sperry boat shoes are an iconic American shoe brand, designed in 1935 by Paul A. Sperry. Sperrys, or Top-Siders, were the first boat shoes introduced to the boating and footwear markets. The process of making these shoes involves a series of intricate steps, with each step contributing to the overall quality and durability of the final product. One of the most crucial steps in the construction of Sperry boat shoes is the attachment of the rubber outsole to the midsole. This process involves the activation of pre-glued surfaces through the application of heat.

The rubber outsole is an essential component of the Sperry boat shoe, providing traction and grip on slippery boat decks. The outsole is made of natural rubber and features a pattern of grooves, known as siping, which enhance traction and prevent slipping. This design was inspired by the inventor's observation of his dog's ability to run down an icy hill without slipping. By mimicking the traction-enhancing grooves on his dog's paws, Sperry revolutionised boating footwear, ensuring sailors' safety and comfort.

Before the attachment process, the rubber outsole is pre-glued, which means that a layer of adhesive is applied to the surface of the rubber that will come into contact with the midsole. This pre-gluing step ensures that the outsole is ready for attachment and helps create a strong bond between the two layers. The midsole, made of leather, provides a sturdy base for the outsole and adds to the overall comfort and support of the shoe.

The heat-activation process is a critical step in securing the rubber outsole to the leather midsole. During this process, heat is applied to the pre-glued surfaces, activating the adhesive and creating a strong and durable bond. The specific temperature and duration of heat application are carefully controlled to ensure optimal adhesion without damaging the materials. This process requires precision and expertise to avoid overheating, which could compromise the integrity of the shoe.

Once the heat-activation process is complete, the rubber outsole and leather midsole are firmly attached, creating a unified base for the shoe. This attachment process ensures that the shoe can withstand the rigours of boating and provides the necessary stability and traction for sailors and boating enthusiasts. The heat-activation process is a testament to the craftsmanship and attention to detail that goes into the construction of each Sperry boat shoe, making them a trusted choice for those seeking both style and functionality.

Boat Impeller Failure: Understanding the Devastating Consequences

You may want to see also

Sperry is the official footwear sponsor of the US Sailing Team Sperry

Over the years, Sperry has continued to innovate and improve its boat shoes, partnering with the Commonwealth Shoe and Leather Co. to develop a water-resistant leather shoe that became the iconic Sperry "boat shoe". In recognition of its expertise in sailing footwear, Sperry has been chosen as the official footwear sponsor for several prestigious sailing events, including the America's Cup World Series and the America's Cup sailing tournament. Sperry has also been the official footwear partner of the 35th America's Cup and the official footwear supplier for Oracle Team USA and SoftBank Team Japan.

The brand's commitment to performance and innovation has made it the footwear of choice for champion sailors such as Dennis Conner, who wore Sperry shoes during his victorious America's Cup race. Sperry's sponsorship of the US Sailing Team Sperry further reinforces the brand's connection to the sport and its dedication to providing sailors with the best possible footwear. The US Sailing Team Sperry benefits from Sperry's expertise in creating non-slip, durable, and comfortable shoes, ensuring that the team has the necessary support and traction while sailing.

While most Sperry shoes are now made internationally, with popular styles produced in Vietnam, Indonesia, and China, the brand has occasionally released limited "Made in Maine" product lines. These shoes are handcrafted by artisans in Maine using US-sourced leather and the finest materials, showcasing Sperry's commitment to quality and craftsmanship. Despite the international production of most Sperry shoes, the brand remains an iconic American shoe company, with its roots firmly in the sailing world.

Mastering Boat Sailing with Fluctuating Currents: Miles Traveled

You may want to see also

Frequently asked questions

Most Sperry boat shoes are made in Vietnam, Indonesia, and China.

Sperry has a "Made in Maine" product line, which is handcrafted by artisans in Maine using U.S.-sourced leather and the finest materials. However, it seems that this product line has been discontinued.

Sperry is currently owned by Authentic Brands Group, with the North America operations licensed to Aldo Group.

Paul A. Sperry, an avid sailor, designed the first-ever boat shoe in 1935. He was inspired to create a non-slip shoe for boating after slipping off the deck of his boat and falling overboard.