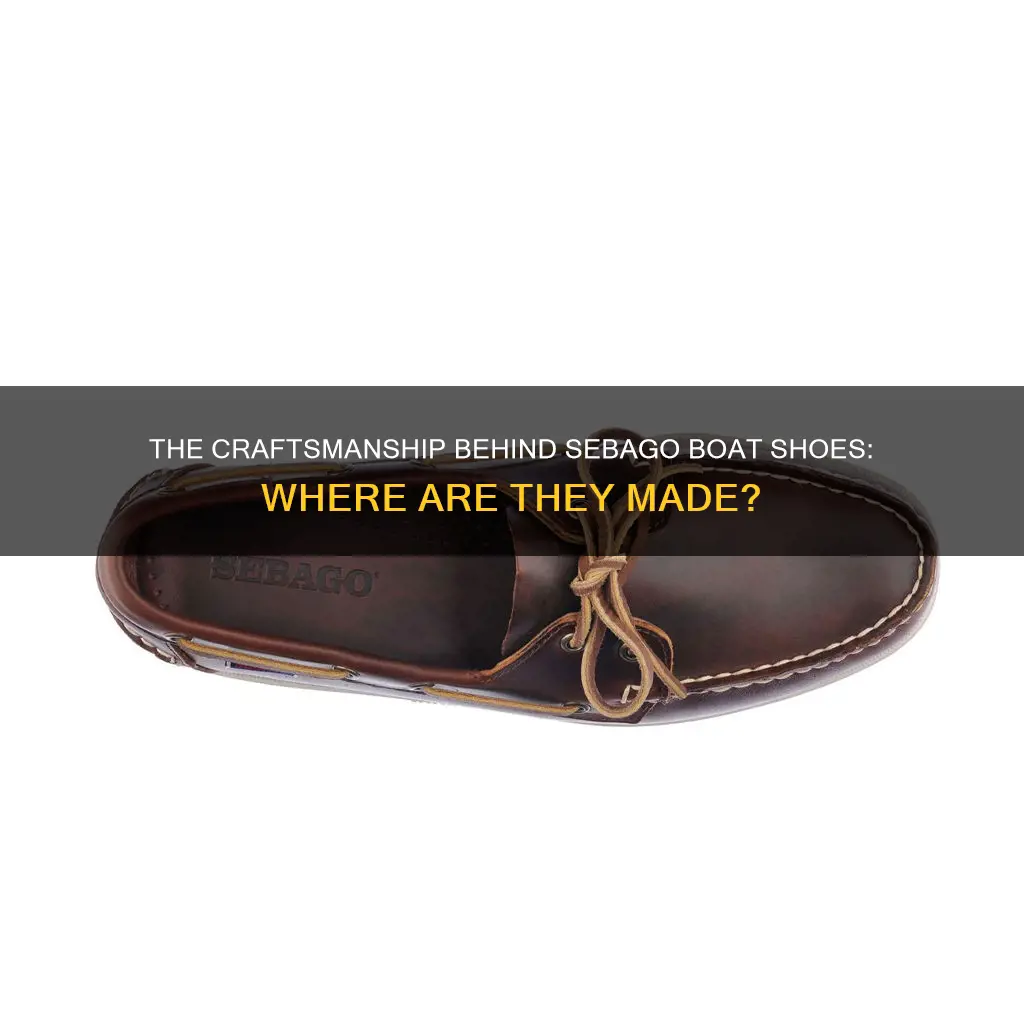

Sebago is a renowned brand known for its iconic boat shoes and classic designs. With a rich heritage rooted in New England's maritime culture, the brand has become a favourite among fashion-conscious individuals, boat enthusiasts, and those seeking high-quality footwear. The meticulous craftsmanship, attention to detail, and use of premium materials have made Sebago shoes a symbol of timeless elegance, comfort, and durability. In the following paragraphs, we will explore the fascinating world of Sebago boat shoes, from the careful selection of leather to the unique hand-sewn moccasin construction that sets them apart.

What You'll Learn

Leather selection

The Art of Leather Selection

The process of leather selection involves a discerning eye for detail, considering various factors that contribute to the overall excellence of the final product. Texture, strength, and suppleness are among the key attributes assessed by the artisans. By choosing hides that exhibit the perfect balance of these characteristics, Sebago ensures that their shoes possess both durability and a luxurious feel.

The artisans' expertise lies in their ability to identify and select only the highest quality materials. This meticulous process ensures that each pair of Sebago shoes embodies the brand's commitment to craftsmanship and attention to detail. The leather chosen for Sebago shoes undergoes a rigorous inspection process, guaranteeing that it meets the brand's exacting standards.

The natural beauty of the leather is further enhanced through expert buffing, polishing, and treatment techniques. This finishing process not only brings out the unique character of each shoe but also provides essential protection against the elements. As a result, Sebago shoes are renowned for their ability to withstand the test of time, offering customers a true investment in style and comfort.

The leather selection process at Sebago is a testament to the brand's unwavering dedication to quality. By choosing only the finest materials, the company lays the groundwork for the exceptional craftsmanship that goes into every pair of their iconic boat shoes. This careful selection ensures that Sebago shoes are not just footwear but masterpieces designed to provide the ultimate in style, comfort, and durability.

Exploring New Orleans and Cancun: A Boat Journey

You may want to see also

Hand-sewn moccasin construction

Sebago boat shoes are renowned for their meticulous craftsmanship, blending classic designs with premium materials and careful manufacturing processes. One of the defining features of Sebago shoes is their hand-sewn moccasin construction, a traditional technique that sets them apart.

The hand-sewn moccasin construction involves stitching the upper part of the shoe directly to the sole by hand. This method requires a high level of skill and precision from the craftsmen who meticulously sew each pair of shoes. The result is a flexible and comfortable fit that moulds to the wearer's foot.

To achieve the perfect shape, Sebago employs a lasting process. Once the upper and the sole are stitched together, the shoe is placed on a last, a foot-shaped mould, which helps to maintain its structure during manufacturing. This crucial step ensures consistency and a comfortable fit, guaranteeing that each shoe conforms to the wearer's foot.

The hand-sewn moccasin construction is a testament to Sebago's commitment to quality and attention to detail. This traditional technique ensures that each pair of shoes is unique, with a flexible and comfortable fit that is perfect for boat enthusiasts and anyone seeking high-quality footwear.

The process begins with the careful selection of premium leather, with artisans choosing the finest hides based on texture, strength and suppleness. The hand-sewn construction then transforms this leather into a durable and elegant shoe, showcasing the brand's dedication to blending style, comfort and longevity in every pair.

Sailing a Boat: Is It Really That Difficult?

You may want to see also

Lasting process

The lasting process is a crucial step in the manufacturing of Sebago shoes, ensuring consistency and a comfortable fit for the wearer. This process begins once the upper and sole of the shoe have been stitched together. The shoe is then placed on a last, a foot-shaped mould, which helps to shape the shoe and maintain its structure.

The last plays a critical role in the lasting process, as it ensures that the shoe retains its intended shape throughout the manufacturing journey. This phase is essential in guaranteeing a consistent and well-fitting shoe. By using the last, Sebago is able to achieve the perfect shape for its shoes, ensuring they meet the brand's high standards for both form and function.

The lasting process is a meticulous and precise operation, requiring skilled craftsmanship. The process involves stretching and shaping the material over the last, ensuring a snug fit. This step is crucial, as it determines the overall comfort and feel of the shoe. Any errors or imperfections during this stage can impact the final product, highlighting the importance of expertise and attention to detail.

The lasting process is not just about shaping the shoe, but also reinforcing its structure. By pulling and securing the material around the last, the shoe's stability is enhanced, creating a durable and long-lasting product. This step showcases Sebago's commitment to quality and craftsmanship, as it ensures the shoe can withstand the test of time and provide customers with a reliable and comfortable experience.

The lasting process is an intricate and detailed operation, requiring precision and skill. It is a testament to Sebago's dedication to creating high-quality footwear that not only looks elegant but also provides an exceptional wearing experience. By utilising the lasting process, Sebago ensures that its shoes are not just stylish but also offer a superior fit and feel for customers seeking both fashion and function.

The Evolution of Crew Boat Names: Unraveling the Mystery

You may want to see also

Finishing touches

The final stage of crafting Sebago shoes involves meticulously finishing each shoe, paying attention to every seam, edge, and stitch. The leather is expertly buffed, polished, and treated to enhance its natural beauty and provide protection against the elements. This process brings out the unique character of each shoe, making it a distinctive masterpiece.

Sebago's commitment to excellence is evident in its stringent quality control measures. Each pair of shoes undergoes meticulous inspections to ensure they meet the brand's high standards. From the selection of materials to the final product, Sebago upholds its reputation for quality at every step.

The finishing touches are a testament to Sebago's attention to detail, ensuring that customers receive nothing less than perfection. Each pair of shoes tells a story of craftsmanship, passion, and dedication to style and comfort. The result is a true investment in footwear that combines timeless elegance with durability.

The process of creating Sebago shoes is a meticulous endeavour, from the initial selection of premium leather to the hand-sewn moccasin construction and, finally, the precise finishing touches. This dedication to craftsmanship has solidified Sebago's reputation for producing exceptional footwear that stands the test of time.

Creative Boat Naming: 10 Cool and Unique Names for Your Vessel

You may want to see also

Quality control

Sebago is renowned for its meticulous quality control measures, ensuring that every pair of shoes bearing its name meets the brand's exacting standards. The quality control process at Sebago involves multiple stringent steps, with each pair of shoes undergoing meticulous inspections.

The first step in quality control begins with the selection of materials. Sebago is meticulous in its choice of leather, opting only for premium hides that meet specific criteria in terms of texture, strength, and suppleness. This initial quality check ensures a solid foundation for the subsequent manufacturing process.

Once the materials are sourced, the focus shifts to the construction of the shoes. Sebago's unique hand-sewn moccasin construction technique is a key element in this phase. Skilled craftsmen play a pivotal role here, meticulously hand-stitching each pair of shoes. Their expertise and attention to detail are crucial in ensuring the precision and consistency of the stitching.

The lasting process further reinforces the quality of Sebago shoes. After the upper and the sole are stitched together, the shoe is placed on a last—a foot-shaped mold. This step is essential for shaping the shoe and maintaining its structure. The last helps to ensure that the shoe retains its intended form throughout the manufacturing process, guaranteeing a comfortable fit for the wearer.

However, Sebago's commitment to quality doesn't end with construction. The finishing process is equally important, with each shoe receiving the utmost attention to detail. The leather is expertly buffed, polished, and treated to enhance its natural beauty and resilience. This phase brings out the unique character of each shoe, transforming it into a distinctive masterpiece.

The final stage of quality control involves rigorous inspections. Each pair of shoes is meticulously examined to ensure they meet Sebago's high standards. This comprehensive assessment covers every aspect, from the overall construction to the tiniest details, such as the seams, edges, and individual stitches. Only when a pair of shoes passes this final scrutiny is it deemed ready for the customer, ensuring that only perfection leaves the Sebago workshop.

Bottom Painting a Boat: Timing and Maintenance Tips

You may want to see also

Frequently asked questions

The exact location of where Sebago boat shoes are made is unclear, but the company is based in New England and has been producing footwear for over seven decades.

Sebago boat shoes are distinguished by their hand-sewn moccasin construction, where the upper part of the shoe is stitched directly to the sole by skilled craftsmen, resulting in a flexible and comfortable fit.

Sebago boat shoes are made from carefully selected premium leather. Artisans consider factors such as texture, strength, and suppleness to ensure the highest quality and longevity.