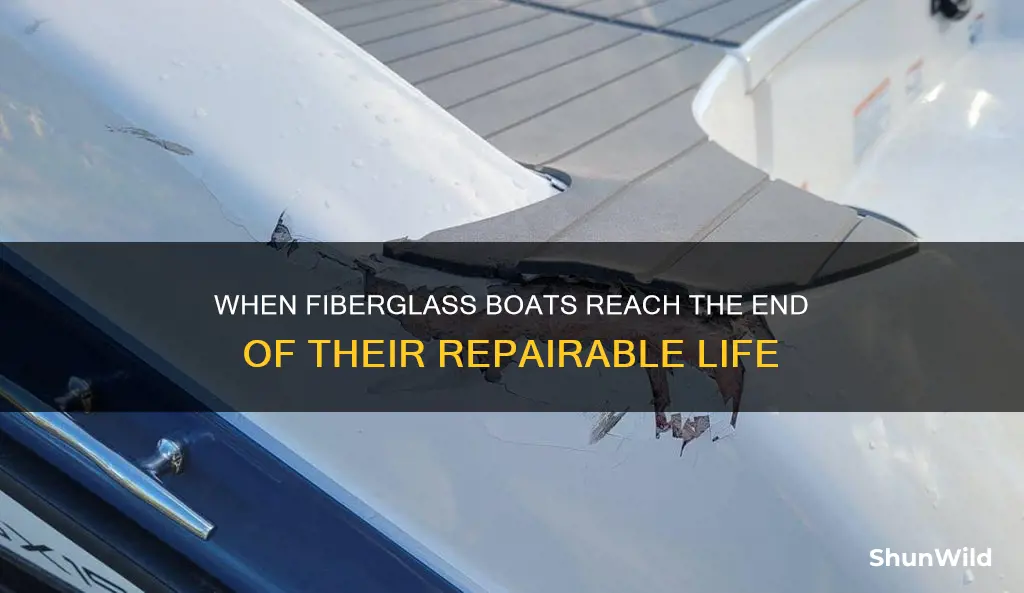

When it comes to fiberglass boats, determining if a vessel is beyond repair can be a complex and challenging decision. Over time, fiberglass boats can suffer from various issues, such as gelcoat fading, structural damage, or the deterioration of core materials. Understanding the extent of the damage and the cost-effectiveness of repairs is crucial for boat owners. This paragraph will explore the signs that indicate a fiberglass boat may be beyond repair, including significant structural weaknesses, extensive water damage, and the inability to restore its original condition through conventional means.

What You'll Learn

- Extensive Damage: When the hull is heavily damaged, with significant cracks or holes, it may be beyond repair

- Corrosion: Advanced corrosion, especially in the gelcoat, can render the boat unusable and unfixable

- Structural Weakness: Severe structural damage, like a collapsed frame, makes the boat unsafe and irreparable

- Water Intrusion: Persistent water leaks through the hull, leading to rot and irreversible damage

- Costly Repairs: If the cost of repairs exceeds the boat's value, it's often more practical to replace it

Extensive Damage: When the hull is heavily damaged, with significant cracks or holes, it may be beyond repair

When a fiberglass boat suffers extensive damage, it can be a challenging and costly endeavor to determine if it's worth repairing. One of the most critical areas to assess is the hull, as its structural integrity is fundamental to the boat's safety and performance. If the hull is heavily damaged, with significant cracks or holes, it may indeed be beyond repair. These openings can compromise the boat's structural integrity, leading to potential safety hazards and costly repairs.

Extensive hull damage often results from collisions, groundings, or severe weather conditions. In such cases, the boat's structure may have sustained multiple impacts or been subjected to extreme forces, leading to cracks and holes. These openings can allow water to penetrate the boat's interior, causing further damage to the core structure and potentially leading to flooding.

Assessing the extent of the damage is crucial. Small, isolated cracks may be repairable with specialized epoxy resins and careful reinforcement. However, when the damage is widespread and affects critical areas such as the hull's skin, stringers, or ribs, the repair process becomes significantly more complex. In these cases, the structural integrity of the boat may be compromised, making it unsafe for operation.

If the hull is heavily damaged, it's essential to consider the cost of repairs. Extensive damage often requires specialized equipment and materials, such as high-strength epoxy resins and carbon fiber reinforcements. The repair process can be time-consuming and may require professional expertise, making it a significant financial investment. Additionally, the boat's value and resale potential should be considered, as extensive damage can significantly reduce its market value.

In conclusion, when a fiberglass boat's hull is heavily damaged with significant cracks or holes, it may be beyond repair. The structural integrity of the boat is at risk, and the potential for further damage and safety hazards is high. Assessing the damage, considering the cost of repairs, and evaluating the boat's value are essential steps in making an informed decision about the boat's future.

Pondering Paddle Boat: One Word or Two?

You may want to see also

Corrosion: Advanced corrosion, especially in the gelcoat, can render the boat unusable and unfixable

Corrosion is a significant concern for fiberglass boats, as it can lead to structural integrity issues and, in severe cases, render the vessel beyond repair. Advanced corrosion, particularly in the gelcoat, is a critical factor to consider when assessing the condition of a fiberglass boat. The gelcoat, a protective layer applied to the fiberglass hull, is designed to shield the underlying material from environmental damage. However, over time, it can deteriorate due to various factors, including exposure to sunlight, saltwater, and harsh weather conditions.

When corrosion reaches an advanced stage, it can cause extensive damage to the gelcoat, leading to a process known as "gelcoat failure." This failure occurs when the gelcoat becomes brittle, cracked, or flaked off, exposing the underlying fiberglass. The exposed fiberglass is then susceptible to further corrosion, creating a vicious cycle that can rapidly deteriorate the boat's structure. Advanced corrosion in the gelcoat often results in a noticeable change in the boat's appearance, with visible cracks, fading, or a chalky finish on the surface.

The consequences of advanced gelcoat corrosion are severe. As the gelcoat deteriorates, it loses its ability to provide a protective barrier, allowing water and moisture to penetrate the fiberglass. This intrusion can lead to further corrosion, weakening the boat's structure and compromising its safety. In extreme cases, the boat may become unseaworthy, with potential risks of capsizing or structural failure. Additionally, the aesthetic appeal of the boat is significantly impacted, as the gelcoat plays a crucial role in maintaining the boat's finish and appearance.

Addressing advanced corrosion in the gelcoat is essential to prevent further damage. If left untreated, the corrosion can spread to the underlying fiberglass, leading to a more complex and costly repair process. In such cases, the boat may require extensive work, including gelcoat repair, fiberglass reinforcement, and potentially even structural replacements. It is crucial for boat owners to regularly inspect their vessels for signs of corrosion, especially in areas prone to saltwater exposure, to catch the issue early and prevent it from becoming a major repair challenge.

In summary, advanced corrosion, particularly in the gelcoat, is a critical indicator that a fiberglass boat may be beyond repair. The deterioration of the gelcoat can lead to structural issues, safety concerns, and aesthetic damage. Boat owners should be vigilant in monitoring their vessels for corrosion and take prompt action to mitigate the problem, ensuring the longevity and safety of their fiberglass boats.

Clear-Coating Spray-Painted Boats: To Coat or Not?

You may want to see also

Structural Weakness: Severe structural damage, like a collapsed frame, makes the boat unsafe and irreparable

When a fiberglass boat suffers severe structural damage, it often reaches a point where repair is not only impractical but also potentially dangerous. One of the most critical signs of such damage is a collapsed frame. The frame of a boat is its backbone, providing structural integrity and support to the entire vessel. When this frame is compromised, the boat's overall structure becomes unstable and unsafe for navigation.

A collapsed frame can occur due to various factors, including manufacturing defects, poor maintenance, or extreme environmental conditions. Over time, the materials used in the frame, such as fiberglass, can weaken due to exposure to sunlight, water, and chemicals, leading to a loss of structural integrity. In some cases, the frame may also be affected by corrosion, especially if the boat has been exposed to saltwater for extended periods.

The consequences of a collapsed frame are severe. As the frame gives way, the boat's hull may distort or even break apart, leading to a loss of buoyancy and, ultimately, sinkage. This not only endangers the boat itself but also poses a significant risk to passengers and crew. In such cases, the boat becomes a hazard rather than a means of transportation, and the decision to write it off as beyond repair becomes necessary for safety reasons.

Identifying a collapsed frame requires a thorough inspection by a qualified marine engineer or boat mechanic. They will look for visible signs of distortion, cracks, or warping in the frame structure. Additionally, they may use diagnostic tools, such as ultrasound or infrared cameras, to detect internal damage that might not be immediately apparent. Once the extent of the damage is determined, the best course of action is to seek professional advice on whether the boat can be safely repaired or if it should be considered a total loss.

In summary, severe structural damage, particularly a collapsed frame, is a critical indicator that a fiberglass boat has reached the end of its useful life. It poses significant safety risks and often requires the boat to be written off as beyond repair. Recognizing and addressing this type of damage promptly is essential to ensure the safety of everyone involved in boating activities.

Sanctuary Cove Boat Show Dates Announced

You may want to see also

Water Intrusion: Persistent water leaks through the hull, leading to rot and irreversible damage

Water intrusion is a critical issue for fiberglass boats, as it can lead to severe and often irreversible damage. When water consistently leaks through the hull, it creates a hostile environment within the boat's structure, causing rot and deterioration that may render the vessel beyond repair. This problem is particularly insidious because it often goes unnoticed until it's too late, as the initial leaks might be small and intermittent, making it difficult to pinpoint the exact source.

The hull of a fiberglass boat is designed to be waterproof, but over time, various factors can compromise its integrity. These factors include age, wear and tear, poor initial construction, or damage from collisions, storms, or grounding. When the hull is compromised, water can seep into the boat's interior, leading to a cascade of problems. The first sign of water intrusion might be minor, such as a damp feeling in the cabin or a slight musty odor, but these early warnings should not be ignored.

As the water continues to penetrate the hull, it can lead to more significant issues. The boat's interior, including the seats, floor, and walls, can become saturated, causing the materials to swell, weaken, and eventually rot. This is especially problematic in fiberglass boats because the material is highly sensitive to moisture. The core of the fiberglass can absorb water, leading to a loss of structural integrity, making the boat unsafe and potentially unrepairable.

The presence of water also encourages the growth of mold and mildew, which can further damage the boat's interior and pose health risks to anyone on board. Mold feeds on the organic materials found in the boat's interior, such as wood, foam, and fabric, and its presence can lead to a rapid deterioration of these components. Additionally, the electrical systems and wiring can be damaged by water intrusion, leading to potential safety hazards and further increasing the complexity and cost of repairs.

In cases of persistent water leaks, it is crucial to act promptly. Temporary solutions, such as using waterproof tape or sealing compounds, might provide short-term relief, but they do not address the root cause. A thorough inspection by a marine specialist is necessary to identify the source of the leaks and determine the extent of the damage. Depending on the severity, the boat may require extensive repairs, including replacing damaged sections of the hull, re-sealing the boat, and restoring the interior to its original condition.

Boat Owner Gift Ideas: What to Get Them

You may want to see also

Costly Repairs: If the cost of repairs exceeds the boat's value, it's often more practical to replace it

When it comes to fiberglass boats, there may come a point where the damage is so extensive that repair becomes an unfeasible and costly endeavor. One crucial factor to consider is the cost of repairs in relation to the boat's overall value. If the repairs required are substantial and would amount to a significant portion or even exceed the boat's worth, it might be more practical to consider replacing it.

For instance, imagine a scenario where a fiberglass boat has sustained severe damage to its hull, requiring extensive patching, gelcoat repairs, or even a complete re-glassing. The estimated cost of these repairs could be prohibitively expensive, especially if the boat is an older model or has accumulated mileage. In such cases, the financial burden of the repairs might surpass the boat's residual value, making it economically sensible to opt for a replacement.

Additionally, the age and condition of the boat play a vital role in this decision. Older fiberglass boats, particularly those that have been exposed to the elements for many years, may have a higher likelihood of developing structural issues or damage that is difficult to repair without extensive work. If the boat's age and condition make it a candidate for a major overhaul, the potential risks and costs associated with the repairs could outweigh the benefits of keeping the boat afloat.

Another aspect to consider is the availability of replacement parts and the expertise required for the repairs. For older or less common boat models, sourcing specific parts or finding skilled technicians who can perform the necessary repairs might be challenging and expensive. In these situations, the practical solution could be to acquire a new boat, ensuring a more reliable and cost-effective long-term investment.

In summary, when faced with the question of whether a fiberglass boat is beyond repair, the cost of repairs in relation to the boat's value is a critical determinant. If the repairs are extensive and expensive, and the boat's age and condition make it a candidate for a major overhaul, it may be more sensible to replace the boat rather than shoulder the financial burden of costly repairs. This decision ensures a more practical and sustainable approach to boat ownership.

Protecting Your Boat: Best Sealants for Wooden Surfaces

You may want to see also

Frequently asked questions

A fiberglass boat can be considered beyond repair if the damage is extensive and widespread, affecting the structural integrity of the vessel. This often includes significant gelcoat fading or damage, extensive osmosis (a process where water penetrates the gelcoat and fiberglass), delamination of the fiberglass layers, or severe structural damage to the hull or deck. In such cases, the repairs would require a significant amount of work and may not be cost-effective compared to replacing the boat.

Yes, small holes or cracks in the fiberglass can typically be repaired. This process often involves filling the void with a specialized epoxy resin and using a cloth or tape to reinforce the area. The repair should be carefully blended to match the surrounding surface to ensure a seamless finish. However, the extent of the damage and the location play a crucial role in determining the feasibility of the repair.

Osmosis is a significant issue for fiberglass boats, especially those made with traditional solid fiberglass construction. It occurs when water seeps through the gelcoat and into the fiberglass matrix, causing the fibers to swell and weaken over time. This can lead to structural issues, including delamination and reduced boat strength. Osmosis is often irreversible and can be a major factor in determining the long-term viability of a fiberglass boat.

Yes, there are several signs that may indicate a fiberglass boat is deteriorating:

- Discoloration or fading of the gelcoat, which can be a sign of UV damage or osmosis.

- Soft or spongy areas on the hull or deck when pressed, indicating potential osmosis or structural issues.

- Cracks or small holes in the fiberglass, especially around fittings and hardware.

- Delamination, which can be identified by lifting or peeling of the fiberglass layers.

- Corrosion or rusting of metal components, which may be a result of water intrusion.

The decision to repair an old fiberglass boat with multiple issues depends on various factors. If the boat has sentimental value, is a classic model, or has been well-maintained, it might be worth the investment to repair it. However, if the boat is old, has significant structural damage, or the cost of repairs exceeds the value of the vessel, it may be more practical to consider replacing it. It's essential to assess the boat's overall condition, the extent of the damage, and the potential cost of repairs before making a decision.