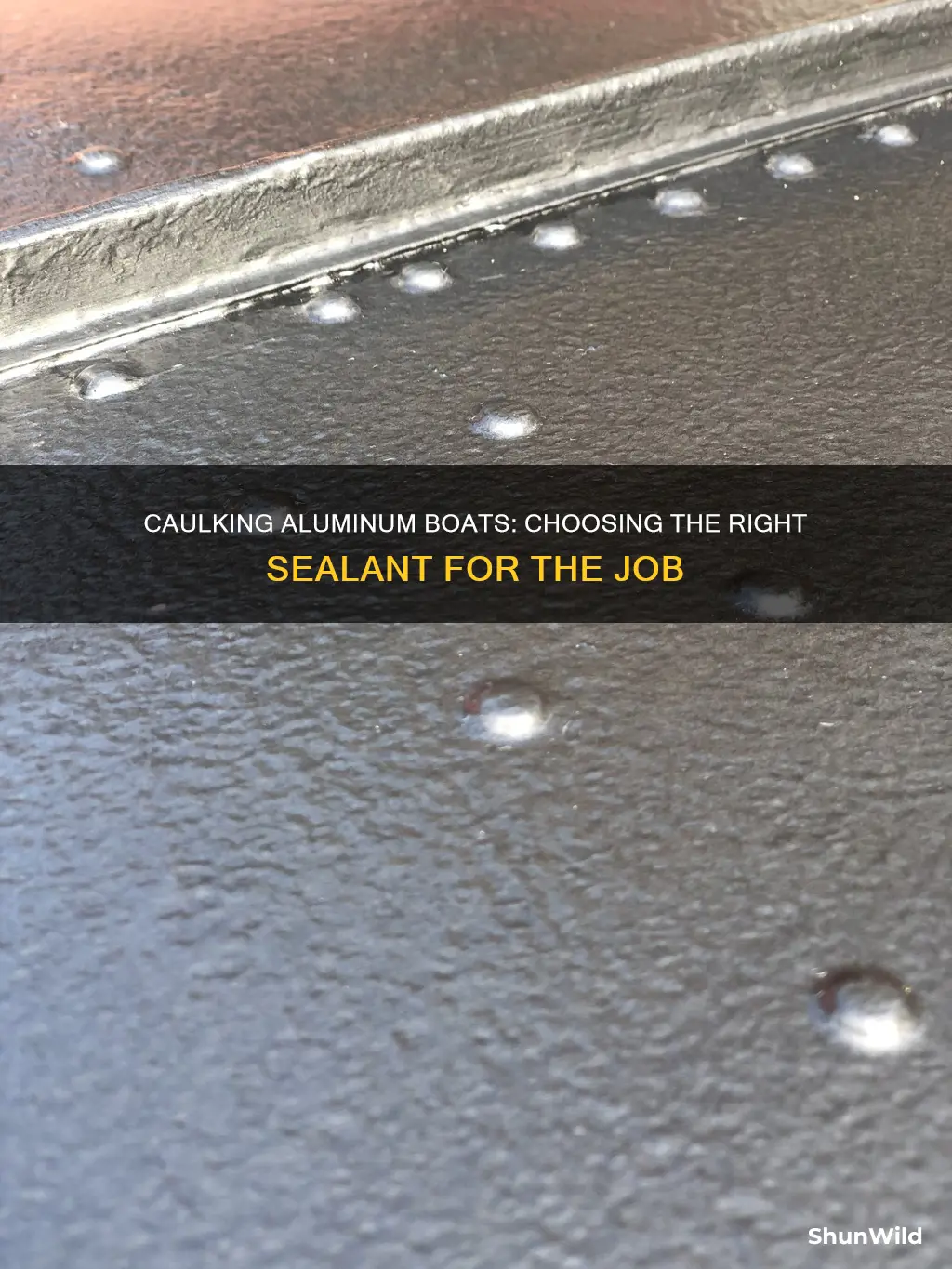

Choosing the right caulk for an aluminium boat is essential to prevent leaks and ensure a smooth ride. The sealant should be specifically designed to adhere to metal and withstand the flexing of the aluminium without cracking. One popular option is 3M's 5200 Marine Fast Cure, which is commonly used in the industry and has a good reputation. Another option is Amazing GOOP Marine, which has proven to be tougher, more elastic, and has better adhesion to aluminium than 5200. When applying the sealant, it is important to clean and prepare the surface thoroughly and follow the directions for a proper cure.

| Characteristics | Values |

|---|---|

| Purpose | To seal up leaky rivets and seams on an aluminium boat |

| Types | 5200 Marine Fast Cure, Amazing GOOP Marine, Life-Calk, Silicone Rubber Sealant, TotalBoat Aluminum Boat Leak Sealer |

| Application | Apply generously, as it is better to over-seal than under-seal |

| Cure time | Overnight |

| Waterproof | Yes |

| Temperature requirements | Can be applied when the air and substrate temperature is as low as 40°F |

| Ease of use | Some caulks are easier to apply than others; the ideal consistency should be a paste-like material that can be easily injected into a seam or spread on a piece of hardware |

| Flexibility | Some caulks become too brittle after curing and crack when there is any flexing of the aluminium |

| Adhesion | Some caulks have weak adhesion to aluminium |

| Price | GOOP is half the price of 5200 |

What You'll Learn

Sealing an aluminium boat

Identify Leaks:

Start by thoroughly inspecting your boat to identify any leaks. Pay close attention to seams and rivets, as these areas are prone to leaking if they become loose. Dry the boat and carefully observe for any signs of water ingress.

Prepare the Area:

Once you've identified the leak, it's time to prepare the area for sealing. Use a dedicated aluminium boat cleaner to ensure a thorough cleaning while protecting the metal surface. Allow sufficient time for the area to dry completely, providing you with a smooth and clean surface to work on.

Choose the Right Sealant:

When selecting a sealant, opt for one specifically designed to adhere to metal surfaces. Look for products labelled for use on metals or aluminium boats. For example, Life-Calk and Silicone Rubber Sealant are recommended for their ability to seal and protect metal surfaces.

Apply the Sealant:

Don't hold back when applying the sealant—it's better to be generous than to under-seal. You can always scrape off any excess later. Follow the directions on your chosen boat sealant for the proper curing process, which may involve leaving the boat undisturbed overnight.

Test the Seal:

After the sealant has cured, inspect the area and test if it is truly waterproof. You don't want to discover leaks when you're already out on the water!

Maintain and Care:

To extend the life of your aluminium boat, regular maintenance and care are essential. Use aluminium boat care products designed to protect and enhance the appearance of your boat.

Recommended Products:

Some recommended products for sealing aluminium boats include TotalBoat Aluminum Boat Leak Sealer, 3M Marine Adhesive Sealant 5200, and Pro Seal RTV Silicone Sealant. These products offer effective sealing solutions and are widely used by boaters.

Remember, always read the instructions and directions on your chosen sealant carefully, as application techniques and curing processes may vary. By following these steps and choosing the right products, you can ensure your aluminium boat remains sealed and protected for your aquatic adventures.

Wiring a Boat Starter Switch: A Step-by-Step Guide

You may want to see also

Choosing the right sealant

Type of Sealant

Select a sealant designed specifically for aluminium boats or, at the very least, one that adheres to metals. For instance, Life-Calk and Silicone Rubber Sealant are suitable for metal surfaces. Silicone-based sealants are also an option, but they may leave behind a residue that interferes with the adhesion of subsequent paint or varnish coatings.

Application and Ease of Use

Consider the viscosity and consistency of the sealant. An ideal sealant should have a paste-like consistency that can be easily injected into seams and spread onto hardware. Sealants that are too thin may not form an even bead, while those that are too thick can be challenging to work with and may require more manual manipulation to achieve a smooth finish.

Cure Time and Durability

Some sealants require an extended cure time, such as overnight curing, to ensure a proper seal. Consider the flexibility and toughness of the sealant after curing. You want a sealant that can withstand the stress of abrasion, jarring, and flexing without cracking or losing adhesion.

Adhesion and Compatibility

Ensure the sealant has strong adhesion to bare aluminium. Some sealants may exhibit weak adhesion or fail to adhere to the metal surface effectively. Additionally, consider the compatibility of the sealant with boat coatings. Many boat paints do not adhere well to certain sealants, so choosing a compatible sealant and coating system is crucial to prevent cracking and ensure a robust seal.

User Reviews

Reading user reviews can provide valuable insights into the performance and ease of use of a sealant. Consider the functionality, ease of application, leak resistance, consistency, and flexibility of the sealant based on the experiences of other boat owners.

Price and Value

Finally, consider the price and value of the sealant. Some sealants may offer better performance and durability at a more affordable price, making them a more economical choice.

By considering these factors, you can make an informed decision when choosing a sealant for your aluminium boat, ensuring a proper seal and protecting your boat from leaks.

Warp-Resistant Woodworking: Mastering Boat Hulls

You may want to see also

Preparing the area

Identify the Leak:

Firstly, identify the source of the leak. While seams and rivets are the primary suspects, give your entire boat a thorough inspection to ensure you don't miss any potential leak sources.

Clean the Area:

Once you've identified the leak, it's time to prepare the area. Use a dedicated aluminium boat cleaner to ensure a high-quality clean while protecting the metal. Allow the area to dry completely, so you have a smooth, clean surface to work with.

Mask Surrounding Areas:

Protect the surrounding areas from potential damage by using painter's tape, plastic sheets, or old rags. You don't want the caulk or any chemicals to splatter or stick to unwanted surfaces.

Apply Adhesives (Optional):

If you're using a chemical-based caulk, you may need to apply a special adhesive remover or solvent to the area. Follow the manufacturer's instructions carefully, and only apply it to the caulk itself, avoiding surrounding surfaces.

Choose the Right Caulk:

Select a caulk that is specifically designed to adhere to metal. Look for a label that indicates it adheres to metals. For example, Life-Calk will seal to metals, and Silicone Rubber Sealant has an acid-free formula that won't corrode metal.

Apply the Caulk:

Don't be afraid to be generous with the caulk. It's better to over-seal than under-seal, as you can always scrape off the excess later. Under-sealing may require you to start over or remove the old caulk. Always read the label to understand the specific product's characteristics.

Cure and Test:

Follow the directions of your chosen boat sealant to ensure proper curing. This often involves keeping the boat stable and undisturbed overnight. After curing, inspect the seal and test it to ensure it's waterproof.

Maintenance:

To sustain your boating adventures, remember to perform regular maintenance on your aluminium boat. This includes sealing any leaks and protecting your boat from further damage.

By following these steps, you'll be able to effectively prepare the area for caulking your aluminium boat, ensuring a successful and long-lasting seal.

The Luxury Yacht Temptation: Who Owns It?

You may want to see also

Applying the sealant

When you have chosen the right sealant for your aluminium boat, it's time to apply it. Here is a step-by-step guide:

Prepare the area

Use an aluminium boat cleaner to ensure you get a high-quality clean while protecting the metal. Give the area enough time to dry out so that you can work with a smooth, clean surface without any interference from lingering water.

Choose the right sealant

When working directly with aluminium, opt for a sealant designed to adhere to metal. The label should specify that it adheres to metals. For instance, Life-Calk will seal to metals, and the acid-free formula of Silicone Rubber Sealant won't corrode metal.

Apply the sealant generously

Don't be afraid to be generous with the sealant. It's better to over-seal than under-seal, as you can always go back and scrape off the excess. If you under-seal, you may have to start all over or remove the old sealant, although some products will adhere to themselves. Always read the label to understand which product you're working with.

Follow the curing instructions

Follow the directions of your boat sealant to ensure a proper cure. This often requires keeping the boat in a stable place to cure overnight.

Inspect the seal

After curing, inspect the seal and test to see if it's waterproof.

Remove excess sealant

Once the sealant has cured, you can go back and remove any excess sealant.

Tips:

- If you are sealing hatches or ports, or adding mast or deck hardware, you can use butyl tape or a bedding compound like Dolphinite.

- If you are fastening hardware to a mast, use an anti-seize compound in addition to a bedding.

- To prevent sealant from hardening, push the sealant back into the tube with a piece of plastic (like Saran Wrap) over your finger, then replace the tube's cap. Alternatively, caulk savers are small plastic screws that fit into the cap to prevent hardening.

- Storing opened sealant in the refrigerator can also extend its life.

Boat Trailers and Breakaway Kits: What's the Law?

You may want to see also

Curing the sealant

Firstly, it is important to choose the right sealant. Opt for a sealant specifically designed to adhere to metal, such as Life-Calk or Silicone Rubber Sealant. The latter is a good choice as its acid-free formula won't corrode metal.

Once you have selected the appropriate sealant, it's time to apply it generously to the prepared aluminium surface. Don't be afraid to be liberal with the sealant, as it's better to have excess that can be scraped off later than to under-seal and risk leaks.

After application, follow the directions on your chosen sealant to ensure proper curing. This typically involves keeping the boat in a stable place overnight. For example, both 5200 Marine Fast Cure and Amazing GOOP Marine advertise a cure time of 24-48 hours.

Once the sealant has cured, it's time to inspect the seal and test its waterproofness. This is a crucial step to ensure the integrity of your boat and prevent future leaks.

Additionally, consider over-coating your rivets, seams, and seals with a high-quality boat coating like Wetlander to create a robust, complete leak-stopping system. This extra step will provide added protection and ensure the long-term success of stopping leaks.

Finally, remember that proper surface preparation is key to achieving a reliably caulked seam. Make sure to scrape, sand, dust, and wash the surface before applying the sealant.

Sewing Boat Seats: A Step-by-Step Guide to Success

You may want to see also

Frequently asked questions

Marine GOOP is recommended by Scott Hogan, who has years of experience in the marine and freshwater boat coatings industry. It is both tough and elastic, has strong adhesion to aluminium, and is more economical than other sealants.

Other recommended sealants include 5200 by 3M, Amazing GOOP Marine, Life-Calk, and Silicone Rubber Sealant.

It is important to choose a sealant that is specifically designed to adhere to metal. Other desirable traits include viscosity (a paste-like consistency that can be injected into seams) and ease of application.

First, identify the source of the leak, then use an aluminium boat cleaner to thoroughly clean the area. Allow enough time for the area to dry before applying the sealant.

Apply the sealant generously, as it is better to over-seal than under-seal. Follow the directions on your chosen boat sealant for a proper cure, then inspect the seal and test if it is waterproof.