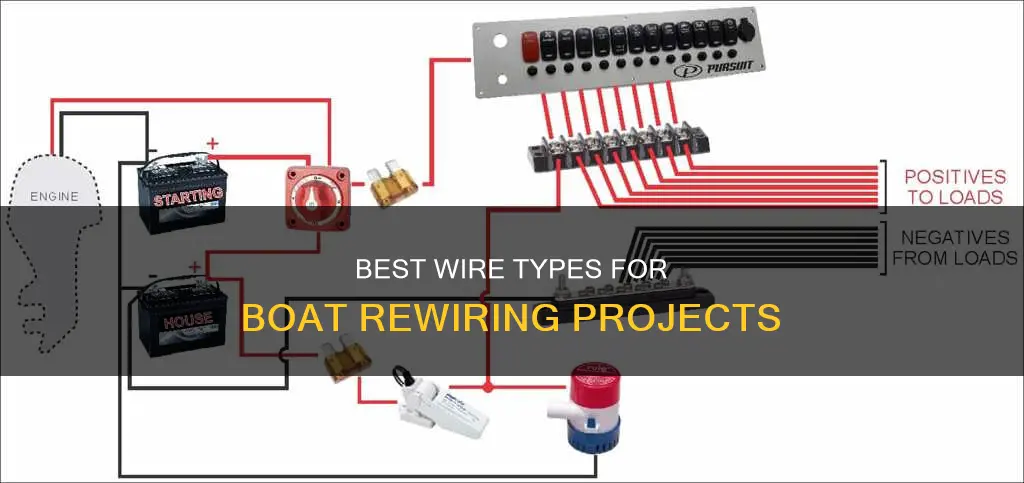

Rewiring a boat can be a challenging task, but it is important to ensure the safety of the vessel and its occupants. The most common cause of electrical failure on boats is poor connections, so it is crucial to use the correct type and size of wire to prevent issues such as voltage drop and overheating, which can lead to fires. When rewiring a boat, it is recommended to use tinned, multi-stranded copper wire, which offers flexibility and corrosion resistance. The wire size will depend on factors such as the length of the circuit, the current draw, and the acceptable level of voltage drop. It is generally advised to use a larger wire size to avoid overheating and ensure adequate power delivery. Circuit protection devices, such as fuses or circuit breakers, are also essential to prevent overloading the wires.

| Characteristics | Values |

|---|---|

| Wire type | Multi-stranded, with tinned copper conductors |

| Wire flexibility | Flexible strands to compensate for movement or vibration typical of a vessel at sea |

| Wire protection | Tinning to protect the copper wire from oxidisation |

| Wire size | Specified by cross-sectional area (CSA) |

| Wire insulation | Fuel-resistant, fire-retardant |

| Wire connections | Clean, firmly attached, with adjacent cable secured |

| Wire terminations | Use a good quality bus bar and crimped cable terminals |

| Wire resistance | Increases or decreases according to cable length and CSA |

| Circuit protection | Circuit Protection Device (CPD), e.g. a 60A thermal breaker |

| Wire gauge | Depends on the amp draw of the load |

What You'll Learn

- Wire type: Tinned copper wires are best for boats as they are more flexible and less susceptible to corrosion

- Wire size: Undersized wires can overheat and cause fires

- Connections: Poor connections are the most common cause of electrical failure on boats

- Circuit protection: Devices like fuses or circuit breakers protect wiring from shorts and overloads

- Planning: Calculate the maximum current and add a safety margin to determine wire size

Wire type: Tinned copper wires are best for boats as they are more flexible and less susceptible to corrosion

When rewiring a boat, it is important to use the correct type of wire to avoid electrical failure and potential fires. Tinned copper wires are best suited for boats as they are more flexible and less susceptible to corrosion.

Tinned copper wires are multi-stranded, providing the flexibility needed to compensate for the movement and vibration of a vessel at sea. The tinning also protects the copper wire from oxidisation, which can lead to increased resistance and faulty connections. This makes tinned copper wires ideal for the marine environment, where salt water can corrode contacts very quickly.

When choosing tinned copper wires, it is important to ensure they meet the MilSpec or ABYC Standard. These standards ensure that the insulation is UV stable, fuel and solvent resistant, and rated for use in high-temperature engine rooms. The insulation should also be fire-retardant to prevent fires caused by overheated wiring.

In addition to choosing the right type of wire, it is crucial to consider the wire size or grade. Undersized wiring can overheat and become a fire hazard. It is generally recommended to use a higher grade of wiring to be on the safe side. When in doubt, it is best to consult a professional marine electrician or refer to resources like the ABYC Electrical Certification Study Guide or Pat Manley's book, "Essential Boat Electrics."

By selecting tinned copper wires that meet the required standards and choosing the appropriate wire size, boat owners can ensure a safe and reliable electrical system for their vessels.

Finding Land-Based Roles in the Boating Industry

You may want to see also

Wire size: Undersized wires can overheat and cause fires

Undersized wires can overheat and cause fires, so it is important to choose the correct wire size when rewiring a boat. The wire size, or gauge, is specified by the cross-sectional area (CSA) of the wire, which dictates how much current can safely flow through it. The smaller the CSA, the greater the wire's resistance and the larger the voltage drop over its length.

When choosing a wire for a boat, it is important to consider the ambient heat the wire will be exposed to, as this will increase the wire's resistance. Wires running through engine compartments, for example, will have a reduced current-carrying capacity and must be of a larger capacity and covered with fuel-resistant, fire-retardant insulation.

It is also important to consider the length of the wire. Longer wires will have a greater voltage drop, which can impact the performance of electrical equipment. Therefore, it is crucial to choose a wire size that can accommodate the length of the circuit and the current draw of the electrical equipment.

In addition to wire size, it is important to use high-quality, marine-grade wire to prevent corrosion and ensure safety. Tinned copper wire, for example, is a popular choice for marine applications as it offers better corrosion resistance.

When in doubt, it is always best to err on the side of caution and choose a larger wire size. This will ensure that the wire can handle the electrical load and prevent overheating and potential fires.

The Mystery of Annabel Lee Boat's End

You may want to see also

Connections: Poor connections are the most common cause of electrical failure on boats

The salty marine environment means electrical connections on boats are susceptible to corrosion, which can cause resistance and reduced power. Connections should be clean and firmly attached, with the adjacent cable properly secured. Corrosion on connections can be checked for by removing any tape over a connection.

When replacing wiring, it is important to use a good quality bus bar and crimped cable terminals. Before wiring, invest in good quality wire cutters, strippers, and a crimper. A ratchet-type, double-action, parallel jaw crimper is recommended. A wire stripper with marked dies for each cable size will ensure a cleanly stripped cable.

To avoid issues with connections, it is best to minimise the number of connections in the electrical system.

Hot Foot Bass Boat Driving: Master the Controls

You may want to see also

Circuit protection: Devices like fuses or circuit breakers protect wiring from shorts and overloads

Circuit protection devices such as fuses and circuit breakers are essential for safeguarding a boat's wiring from shorts and overloads. These devices play a critical role in preventing fires and ensuring the safety of both the vessel and its occupants.

Fuses, for instance, contain a metal strip that melts when there is too much current, causing the element to break and protect the rest of the circuit. Fuses are typically made of see-through plastic and come in various colours, shapes, and sizes, with each colour indicating a different amperage rating. It is imperative not to replace the recommended fuse with one of a higher amperage rating, as this can damage sensitive components and wiring in the circuit.

Circuit breakers, on the other hand, create an open in the circuit when an overload occurs, and many modern circuit breakers can be reset and reused. Self-resetting breakers utilise a heating element that bends and creates an open until it cools and completes the circuit again. This feature is particularly useful in preventing fires, as it allows the circuit to continue functioning without requiring manual intervention.

When rewiring a boat, it is crucial to select the appropriate circuit protection devices for the specific wiring and equipment. High-load fuses, such as ANL, T-class, and MRBF types, are ideal for heavy current draws and battery protection. In contrast, fast-action, low-current fuses are more suitable for safeguarding delicate electronics.

Additionally, it is essential to consider the location of these circuit protection devices. They should be installed as close as possible to the device supplying the power. For instance, a cable running from the main positive battery bus bar to a distribution panel should have a circuit breaker positioned near the bus bar.

By employing these circuit protection strategies, boat owners can help ensure the safety and reliability of their vessel's electrical systems.

Haystack Boat Races: Dates and Details for the Upcoming Event

You may want to see also

Planning: Calculate the maximum current and add a safety margin to determine wire size

Planning is a crucial step in rewiring a boat to ensure the correct wire size. To determine the wire size, you need to calculate the maximum current and add a safety margin. Here's a step-by-step guide:

- Identify all the devices that will be powered by the wire.

- Calculate the maximum current that could flow when all these devices are turned on simultaneously. This can be done by dividing the power of each device in watts by the circuit voltage. For example, if you have a device with a power of 100 watts and a circuit voltage of 12 volts, the current would be 100/12 = 8.33 amps.

- Add a safety margin to the maximum current calculated in step 2. A good practice is to add around 30% to the calculated value. In the previous example, the maximum current with the safety margin would be 8.33 x 1.3 = 10.83 amps.

- Refer to a wire size chart or calculator to determine the appropriate wire size for the calculated current. You can use online wire size calculators or charts specifically designed for boats, which take into account factors such as cable length and voltage drop.

- Select a wire with a higher ampacity than the value calculated in step 3 to ensure it can safely handle the current.

- Consider the ambient temperature and any heat-generating components near the wire. Higher temperatures can affect the wire's ampacity, so you may need to choose a larger wire size to compensate.

- Consult a marine electrical specialist or a professional electrician if you're unsure about the calculations or wire selection.

It's important to choose the right wire size to prevent overheating and fire hazards. Undersized wires can pose a serious risk, so it's always better to err on the side of caution and choose a larger wire size if you're uncertain.

Restoring a Bass Boat: Tips for Reviving Faded Glory

You may want to see also

Frequently asked questions

Tinned, multi-stranded copper wire is best for rewiring a boat. The tinning protects the copper wire from oxidisation, which can lead to faulty connections. The flexibility of the strands also compensates for any movement or vibration typical of a vessel at sea.

The wire gauge you use will depend on the length of the circuit and the acceptable level of voltage drop. For DC circuits, the American Boat & Yacht Council (ABYC) recommends a maximum voltage drop of 10% for most circuits and 3% for critical circuits. You can use the ABYC wire sizing charts or the ABYC Wire Sizer app to determine the correct wire gauge for your boat.

In addition to standard power tools, you will need specialist electrical tools including a multimeter, wire cutters, long-nosed pliers, wire strippers, a crimping tool, a soldering iron, a cable threader, and cable ties.

It is important to thoroughly inspect and plan the rewiring of your boat. Label each wire and check what it is connected to. Test connections using a multimeter and look for signs of overheated wiring or exposed and corroded connections. Calculate how much cabling you will need and choose the correct size or grade of wiring to avoid overheating and fire risks.