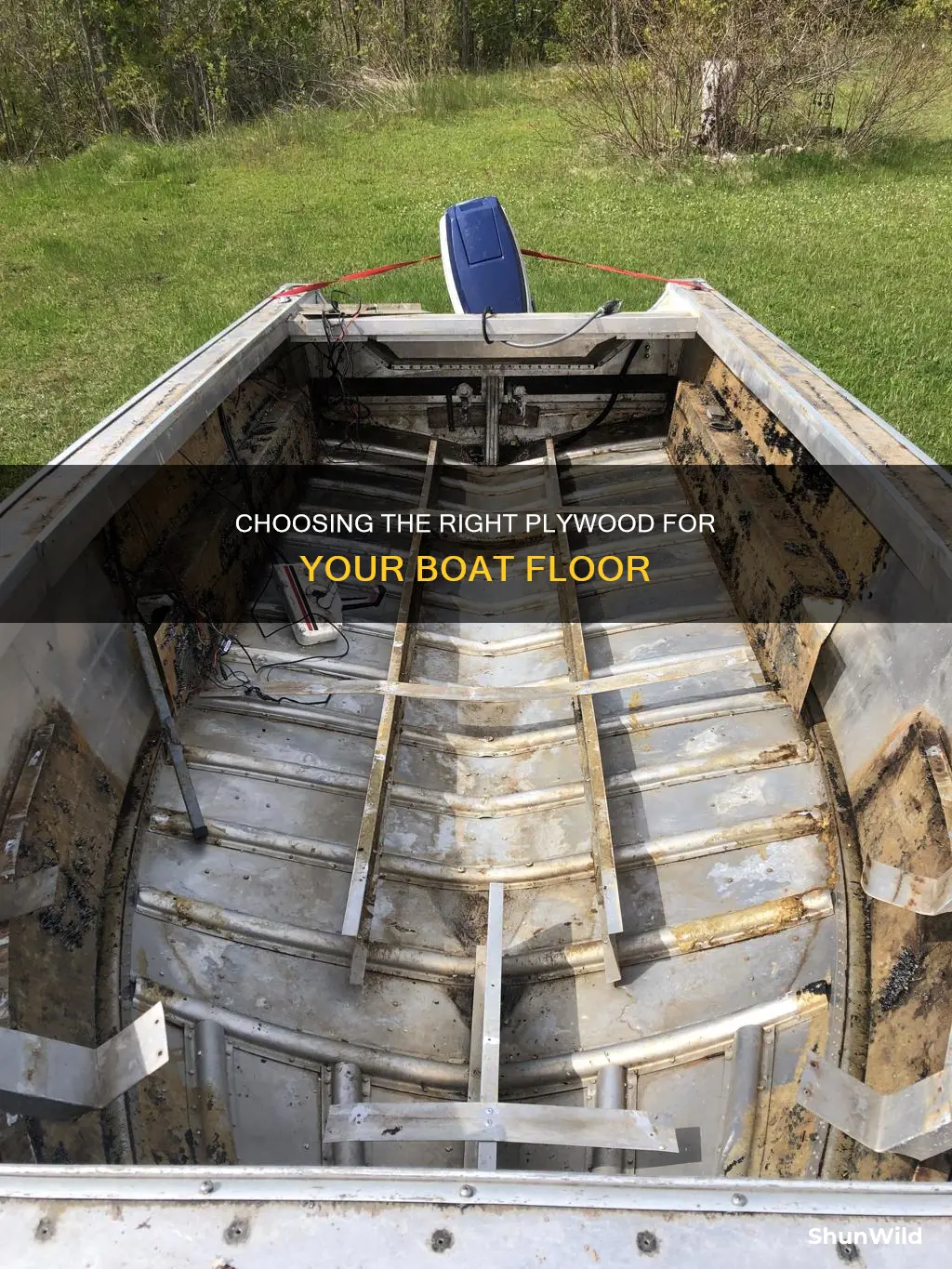

When it comes to choosing the best plywood for a boat floor, there are several options to consider. While marine-grade plywood is often recommended for its durability and moisture resistance, other types of plywood can also be used as more affordable alternatives.

Marine-grade plywood, typically made from Douglas Fir or Western Larch, is constructed with 5 or more layers of veneer glued together with waterproof adhesive. This gives it superior strength and waterproofing compared to regular plywood. However, it is important to note that not all marine-grade plywood is created equal, and the quality can vary between grades A and B.

As a more budget-friendly option, exterior-grade plywood can also be used for boat flooring. While it may not offer the same level of waterproofing as marine-grade, it is still suitable for outdoor use and can be sealed with epoxy to improve its durability.

Other alternatives to marine-grade plywood include pressure-treated plywood, fire-treated plywood, and weather and boil-proof plywood. These options may be more readily available at local hardware stores and can provide varying levels of moisture and fire resistance. However, it is important to consider the specific needs of your boat and the environment it will be used in when making a decision.

What You'll Learn

Marine-grade plywood is best for boat flooring

Marine-grade plywood is the best option for a boat floor. This type of plywood is manufactured to be sturdy and to withstand rough water environments. It is made with thin sheets built perpendicularly to provide maximum strength and complete waterproofing. The glue used to make marine-grade plywood is both weatherproof and heatproof, and the sheets are made with no voids or holes.

Marine-grade plywood is made by gluing together five or more layers of veneer, giving it more strength and durability. It is also easier to cut than other types of wood, as it can be cut with a hand saw or any basic tool.

While exterior-grade plywood is a good alternative for boat flooring, it is not as strong or durable as marine-grade plywood. Exterior-grade plywood is typically made with three layers of veneer and is not void-free, so it will require more work to fill in any voids with wood filler.

Marine-grade plywood is also available in two grades: Grade A and Grade B. Grade A is the highest quality and is smooth and sanded, while Grade B may have minor splits and tight knots.

When choosing plywood for a boat floor, it is important to consider the weight capacity or load-bearing capacity of the plywood. Thicker plywood will be needed if the boat needs to carry a large number of people and supplies.

Understanding Bass Boat Controls: Function and Features

You may want to see also

Exterior-grade plywood is a good alternative

Exterior-grade plywood is made with waterproof sealants and phenol glue, which make it tough for external use and suitable for a longer lifespan. It is not void-free like marine-grade plywood, so you will need to pay particular attention to filling in any voids with wood filler. However, it is still more void-free than regular plywood, which is typically made with just 3 layers, whereas exterior-grade plywood usually has 5 layers.

Exterior-grade plywood is also not typically pre-sanded and smooth like marine-grade plywood, so it will require more work to get it ready for your boat flooring project. However, it is still a good alternative if you are looking for a more budget-friendly option than marine-grade plywood.

When choosing exterior-grade plywood for your boat floor, look for plywood that is made with waterproof adhesive and that is visually free of damages and imperfections. This type of plywood is used on exterior constructions such as roofing, so it should be able to handle outdoor elements.

The World's Most Expensive Boats and Their Owners

You may want to see also

RTD plywood is not suitable for boat flooring

RTD plywood is designed for high-humidity environments or temporary water contact, not continuous water submersion. The wood layers in RTD plywood may not have the necessary strength for a boat floor. Therefore, while RTD plywood is a great option for some wet applications, it is not the best choice for a boat floor.

Additionally, RTD plywood is not void-free, and it may require additional work to fill in any voids with wood filler before installation. It is also important to note that regular shop-standard plywood, made with non-waterproof adhesive, will quickly rot away on a boat.

For a boat floor, it is best to use marine-grade plywood or, as a more budget-friendly option, exterior-grade plywood. Marine-grade plywood is made with five or more veneered layers glued together with waterproof adhesive and offers superior waterproofing compared to even exterior plywood sheets. It is also smooth and void-free, requiring less preparation before installation.

The Right-Side Boat Driver: Why This Position?

You may want to see also

Pressure-treated plywood is not recommended for boats

The specific chemical compound causing this issue is known as Alkaline Copper Quaternary (ACQ), which is used in pressure-treated plywood to prevent wood rot and insect damage. However, when ACQ-treated plywood is used in direct contact with aluminium, it can lead to rapid corrosion and deterioration of the metal. This problem is not limited to aluminium and can also affect other metals used in boat construction.

To avoid galvanic corrosion, it is recommended to use kiln-dried, chromated copper arsenate (CCA) pressure-treated plywood. This type of treatment does not have the same corrosive effect on aluminium and is suitable for use in boat construction. However, even with CCA-treated plywood, it is essential to ensure proper drying and insulation between the wood and aluminium surfaces.

Additionally, pressure-treated plywood is not designed to be waterproof. Continuous exposure to water will cause the preservative chemicals to leach out of the wood, rendering it ineffective against rot and insect damage. The softwoods typically used in pressure-treated plywood are more susceptible to water absorption, which further emphasises the importance of using marine-grade plywood for boat flooring.

Marine-grade plywood, on the other hand, is specifically designed for the harsh marine environment. It is constructed with multiple layers of high-quality, void-free hardwood, bound together with waterproof adhesive. This construction gives marine plywood superior strength, durability, and resistance to delamination, warping, and buckling compared to pressure-treated plywood.

Transforming a Row Boat to Bass Boat: Easy Steps

You may want to see also

Fire-treated plywood is a good option for boat flooring

When it comes to choosing the best plywood for a boat floor, there are several factors to consider. While marine-grade plywood is widely regarded as the ideal choice, other types of plywood can also be suitable for boat flooring. One such option is fire-treated plywood, which offers several advantages that make it a good choice for boat flooring.

Fire-treated plywood is a type of pressure-treated plywood that undergoes a special treatment process to enhance its fire-resistant properties. This treatment not only makes the plywood more resistant to fire but also helps it withstand extreme environments and prolonged weight loads. By injecting a preservative into the plywood under pressure, the treatment strengthens the boards' planks and improves their durability.

One of the key benefits of fire-treated plywood for boat flooring is its ability to resist rotting, moulding, and termite damage. This makes it a suitable option for boats that are exposed to water and high-moisture environments. While it can absorb moisture, fire-treated plywood is designed to withstand the impact of extreme conditions, making it a durable choice for boat flooring.

Another advantage of fire-treated plywood is its fire-retardant properties. This feature is especially important for boat flooring that comes into contact with gas fuels. By preventing combustion, fire-treated plywood enhances the safety of motorized boats.

In terms of construction, fire-treated plywood is typically made from softwoods, such as Douglas Fir or Southern Yellow Pine. These woods are known for their strength and stiffness, making them suitable for boat flooring applications. Additionally, fire-treated plywood often has a clear finish that can be stained or painted to match the desired aesthetic of the boat.

When compared to other types of plywood, fire-treated plywood offers a cost-effective solution for boat flooring. While it may not be as inexpensive as regular plywood, it provides a good balance between price and performance. By investing in fire-treated plywood, boat owners can benefit from its durability, fire resistance, and ability to withstand harsh marine environments.

In conclusion, fire-treated plywood is a viable option for boat flooring due to its enhanced fire-resistant properties, durability, and ability to withstand extreme conditions. While marine-grade plywood is often considered the gold standard, fire-treated plywood offers a practical alternative that can meet the specific needs of boat owners. By considering the unique features and benefits of fire-treated plywood, boat builders and owners can make an informed decision about the best flooring option for their vessels.

Boat Title Requirements in Washington State: What You Need to Know

You may want to see also

Frequently asked questions

Marine-grade plywood is the best option for a boat floor as it is durable and water-resistant. It is made with 5 or more layers of veneer and glued together with waterproof adhesive.

Exterior-grade plywood, pressure-treated plywood, and fire-treated plywood are alternatives to marine-grade plywood for a boat floor. However, these options may require more preparation and are not as durable.

Marine-grade plywood is lightweight, strong, and durable. It is also easy to cut and prepare, making it a convenient option for boat flooring.

Marine-grade plywood is usually graded as A or B. Grade A is the highest quality and is smooth and sanded, while Grade B may have minor splits and tight knots. Marine-grade plywood will also have a seal of approval.

Marine-grade plywood can last up to 25 years for a boat floor, depending on the grade and proper installation.