The ignition coil is an essential component of a boat engine's ignition system, which is responsible for producing an electrical spark to ignite the air-fuel mixture within the engine's cylinders. The ignition coil's primary function is to transform low-voltage electrical power from the battery into the high-voltage electricity required to create sparks in the spark plugs. This process of converting low voltage to high voltage is known as 'transformer action' and is crucial for efficient engine operation and power delivery.

| Characteristics | Values |

|---|---|

| Function | Transforms low-voltage electrical power from the battery into high-voltage electricity needed to create sparks in the spark plugs |

| Type of engine | Internal combustion engines |

| Spark plug wires | Heavily insulated to prevent extreme high-voltage current from arcing |

| Spark plug gap | Conditions must be precise for the electrical current to make the jump to the spark plug |

What You'll Learn

The ignition coil's role in a boat engine

The ignition coil is an essential component of a boat engine's ignition system. Its primary function is to convert low-voltage electrical power from the battery into the high-voltage electricity required to generate sparks in the spark plugs. This conversion process is crucial for the ignition system to initiate combustion in the engine.

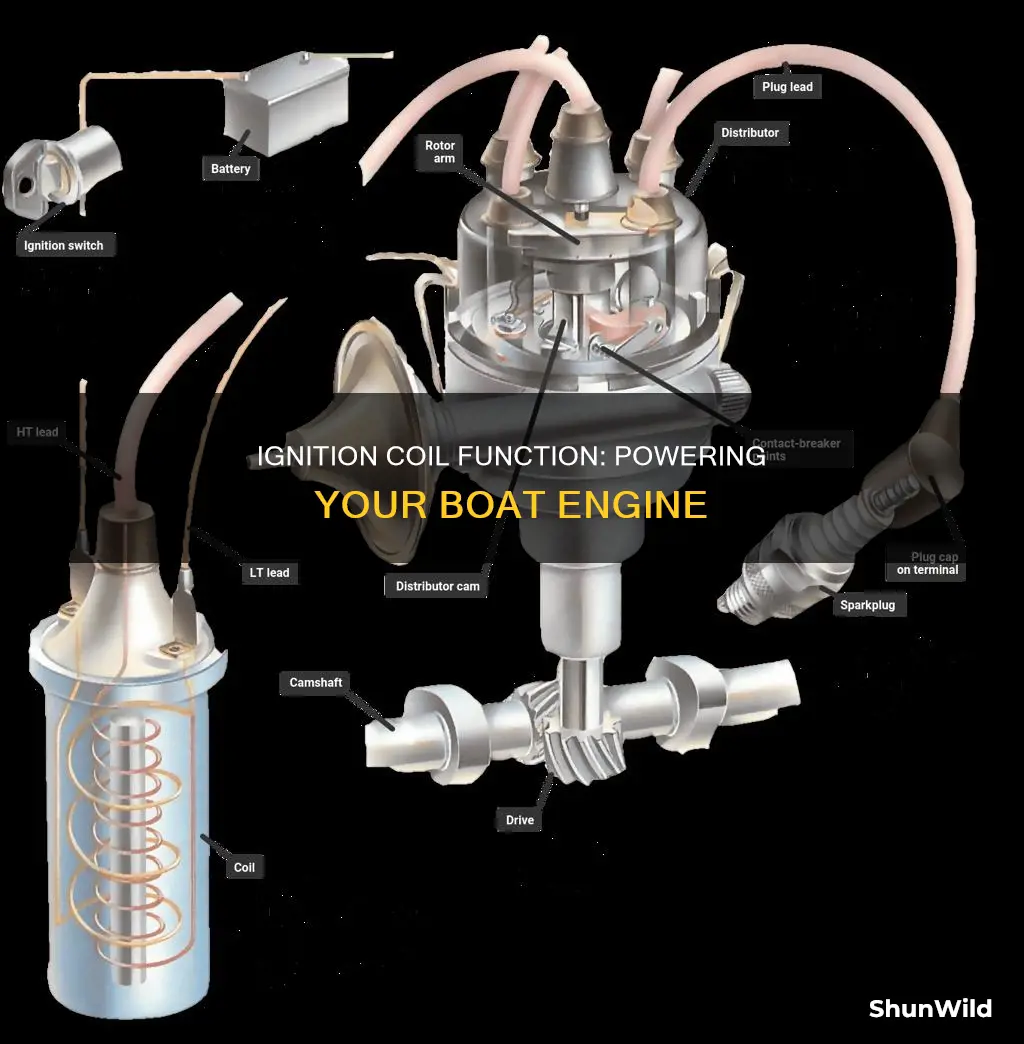

The ignition coil consists of two main parts: the primary winding and the secondary winding. The primary winding is made of thicker wire with relatively few turns, and it carries the low-voltage current from the battery. When the ignition switch is turned on, a low-voltage current flows through the primary winding, creating a magnetic field. This magnetic field collapses rapidly when the current is interrupted, inducing a high voltage in the secondary winding.

The secondary winding is composed of much finer wire with a significantly higher number of turns. It is responsible for generating the high-voltage output. The high voltage produced in the secondary winding is then sent to the spark plugs to create sparks. This process is known as electromagnetic induction, and it ensures that the spark plugs receive a high-voltage pulse, which ignites the air-fuel mixture in the engine's cylinders.

The ignition coil's ability to generate high-voltage sparks is vital for the engine's efficient operation and power delivery. A well-maintained ignition coil ensures that the spark plugs consistently produce strong and timely sparks, leading to efficient combustion and optimal engine performance. However, if the ignition coil malfunctions, it can cause issues such as engine misfires, difficult starting, decreased fuel efficiency, and even damage to the catalytic converter.

In modern boat engines, the ignition coil connects directly to the spark plug, eliminating the need for spark plug wires. Additionally, some newer engines feature an all-in-one control box that incorporates sensors for various parameters, such as engine RPM, water temperature, and manifold pressure, enabling more precise and efficient ignition timing systems.

WWII Normandy: What Was the Boat Named?

You may want to see also

How does an ignition coil work?

An ignition coil is a vital component of a vehicle's ignition system, including boats. It is responsible for converting the low voltage from the battery into the high voltage needed to produce sparks at the spark plugs. The ignition coil acts as a transformer, using electromagnetic induction to generate the high voltage required for efficient combustion in the engine.

The ignition system is a crucial part of a vehicle's engine, initiating combustion. It comprises several components, including the ignition coil, spark plugs, distributor (in older systems), and control module. The ignition coil plays a pivotal role in the ignition system by generating the high voltage required to produce sparks at the spark plugs.

The ignition coil consists of two primary components: the primary winding and the secondary winding. The primary winding is made of thick wire with relatively few turns, while the secondary winding is composed of much finer wire with a significantly higher number of turns. The primary winding is connected to the vehicle's electrical system, while the secondary winding generates the high-voltage output.

The ignition process begins when the engine's control unit sends a signal to the ignition coil to start spark formation. This signal causes an interruption in the flow of current through the primary winding, creating a magnetic field around the coil. The magnetic field collapses rapidly when the current is interrupted, inducing a high voltage in the coil's secondary winding through electromagnetic induction. The high voltage output from the secondary winding is sent to the distributor or directly to the spark plugs to create sparks.

The transformation of low voltage to high voltage through induction in the ignition coil is a crucial step in the ignition process. It ensures that the spark plugs receive a high-voltage pulse, which ionizes the air-fuel mixture in the engine cylinders, creating a spark that ignites the mixture and initiates combustion. The ignition coil's ability to generate high-voltage sparks is vital for efficient engine operation and power delivery.

Understanding Boat Propulsion Systems and Their Meanings

You may want to see also

The importance of a well-functioning ignition coil

A well-functioning ignition coil is of paramount importance in a boat engine. Its primary function is to convert the low-voltage electrical power from the battery into the high-voltage electricity required to create sparks in the spark plugs. This ignition of sparks is essential to initiate the combustion process that powers the engine.

The ignition coil's role becomes even more critical when we consider its impact on spark plug performance. The coil ensures that the spark plugs consistently generate strong and timely sparks, leading to efficient combustion and optimal engine power. A malfunctioning ignition coil can result in engine misfires due to insufficient or weak sparks. This, in turn, leads to faulty combustion, reduced engine power, and increased exhaust emissions.

Additionally, a well-functioning ignition coil contributes to easier engine starting, especially in cold weather or after the boat has been stationary for an extended period. It also plays a role in maintaining fuel efficiency by ensuring adequate ignition, allowing the engine to burn fuel efficiently. Furthermore, a properly functioning ignition coil helps prevent catalytic converter damage by ensuring complete fuel combustion, protecting this crucial emission control component.

The ignition coil's ability to generate high-voltage sparks is, therefore, vital for the overall performance and efficiency of the boat engine. Its role in transforming low voltage to high voltage through electromagnetic induction is a critical step in the ignition process, ensuring that the spark plugs receive the required high-voltage pulse.

The HMS Beagle: Darwin's Vessel of Discovery and Adventure

You may want to see also

How to test an ignition coil

An ignition coil is a vital component of any vehicle's ignition system, and is responsible for providing electricity to the spark plugs. Testing an ignition coil can be done in several ways, and can be done with the coil still in the vehicle or after removing it.

Testing the Coil in the Vehicle

One way to test an ignition coil is to use a diagnostic machine, such as an ODB2 scanner, which can be plugged into the port underneath the dashboard. If your coils aren't working, a code P0352 will usually show up.

If you don't have access to a diagnostic tool, you can test the coil by checking for misfires. Keep the engine running and unplug the coils one at a time. If the engine starts misfiring more when you unplug a particular coil, then that coil is working. If unplugging a coil makes no difference, then that coil is likely faulty.

Testing a Removed Coil

If you remove the ignition coil, you can test it with a multimeter or ohmmeter. This will give you a definitive, quantifiable measurement of the coil's effectiveness. To do this test, you will need to know the resistance specifications for your particular ignition coil, which can usually be found in the service manual. Most automotive coils will have a primary winding resistance of about 0.7-1.7 ohms, and a secondary winding resistance of 7,500-10,500 ohms. Place the leads of the ohmmeter on the poles of the coil and compare the reading to the specifications for your vehicle. If the reading falls outside the normal range, you will need to replace the coil.

Spark Test

Another test that can be performed is a spark test or active analysis. This involves testing the coil's output while the vehicle is running, so it is important to review any spark test procedures in a repair manual or online tutorial before attempting this. This test can be performed with a number of different tools, such as an inline ignition tester or an ignition spark tester.

Hydroplane Boat Races: Seafair's New Starting Line

You may want to see also

Different types of ignition coils

Ignition coils are used in spark-ignition engines to convert the battery voltage to the higher voltage required to operate the spark plug(s). The spark plugs then use this high-voltage electricity to ignite the air-fuel mixture.

The Kettering System

The Kettering ignition system, introduced around 1910/1911, was the first coil-based ignition system. It used a single ignition coil to produce a high voltage, which was passed to a rotor arm that directed the voltage to a series of electrical contacts in the distributor assembly. This type of system became the standard for mass-produced petrol cars until the 1970s and 1980s when electronically controlled ignition systems started to replace mechanical ones.

The Distributor Automotive Ignition System

A distributor-based automotive ignition system connects to the camshaft with gears. In a fully mechanical distributor, the gears spin the main distributor shaft. Inside, a set of "ignition points" rubs against a multi-sided cam on the distributor shaft, opening and closing the points to act as a mechanical switch that interrupts the current flow. This starts and stops the flow of power to the ignition coil. Once the coil generates the firing voltage, it travels to the top of the distributor cap, where a rotating disc distributes the power to each of the spark plug wires.

The Distributor-Less Automotive Ignition System (DIS)

The distributor-less system determines spark timing based on two shaft position sensors and a computer: the Crankshaft Position Sensor (CKP) and the Camshaft Position Sensor (CMP). Instead of a single coil powering all the cylinders, the DIS uses multiple ignition coils, or "coil packs," with each coil generating a spark for just two cylinders. This allows each coil to be "on" longer and develop a stronger magnetic field, resulting in a stronger and hotter spark.

The Coil-on-Plug (COP) System

The coil-on-plug (COP) system incorporates all the electronic controls found in a DIS but with each COP coil servicing only one cylinder. This allows for even more time to develop the maximum magnetic field, resulting in even higher voltages and hotter, stronger sparks. Another advantage of the COP system is the elimination of spark plug cables since the firing voltage is delivered directly to the plug.

Boat Title Confusion: Who Has the Real Deal?

You may want to see also

Frequently asked questions

An ignition coil transforms the low-voltage electrical power from the battery into the high-voltage electricity needed to create sparks in the spark plugs.

The ignition coil uses electromagnetic induction to generate the high voltage required for efficient combustion in the engine. The primary winding creates a magnetic field when the current flows through it. This magnetic field collapses rapidly when the current is interrupted, inducing a high voltage in the coil's secondary winding.

If the ignition coil starts to malfunction, it can result in engine misfires, reduced power, and increased exhaust emissions. It can also cause difficulties in starting the engine, especially during cold weather or after the vehicle has been parked for an extended period.