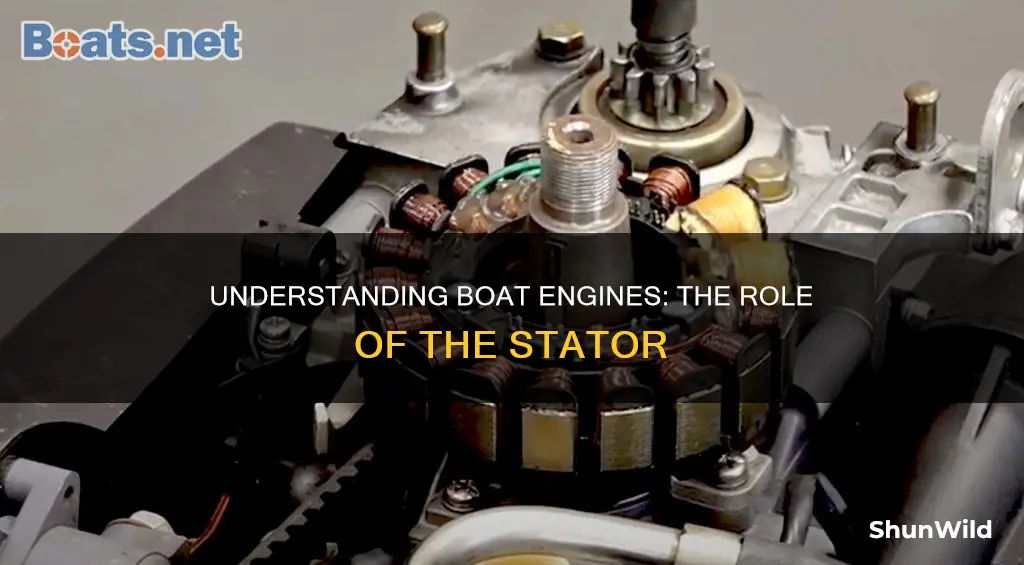

A stator is a crucial component of an electric motor, and its evolution has paved the way for advancements in efficiency, sustainability, and design optimization. In the context of a boat engine, a stator is a component attached under the flywheel of the engine. It generates electricity, which the engine uses to operate the ignition system and run the engine. The engine's flywheel has magnets attached to the inside that spin around the stator, which is made up of windings that produce alternating current electricity. This AC electricity powers the ignition components of the engine, creating the spark necessary for the engine to run. A stator also charges the boat's batteries and, if it fails, the batteries will not charge while the boat is in motion.

What You'll Learn

The stator's role in a boat engine

The stator is a crucial component of a boat engine, playing a pivotal role in its operation and overall performance. It is a stationary part of the engine, located under the flywheel, and its primary function is to generate electricity for the engine's ignition system.

The stator's design and operation are based on the principles of electromagnetism, specifically electromagnetic induction, discovered by Michael Faraday in the early 19th century. This discovery laid the foundation for the development of stators in electric machines.

In a boat engine, the stator consists of windings or coils that produce alternating current (AC) electricity. The engine's flywheel, which is located above the stator, contains magnets attached to its inside. When the engine runs, these magnets spin around the stator's windings, inducing an alternating electrical current in the coils. This AC electricity is then used by the engine to power the ignition components, creating the spark necessary for the engine to run.

The stator also plays a vital role in charging the boat's batteries. It supplies the charge current for the batteries through its charge coils, ensuring that the batteries remain charged while the boat is in operation. This charging function is particularly important for smaller boats with fewer cylinders, as a failed stator can prevent the engine from even starting.

Additionally, the stator's output can vary from 6 to 40 Amps, and it is important to note that the stator's rated output is only achieved at wide-open throttle. Therefore, with lower output stators, the charge output at idle or low rpm may be minimal, and a battery charger may be necessary to ensure the battery is fully charged before venturing out on the water.

Finding Old Boat Oars: Best Places to Look

You may want to see also

How does a stator work?

A stator is a crucial component of an electric motor, generating a rotating magnetic field that interacts with the rotor to create rotational motion. This process is fundamental to the operation of various electric devices, from industrial machinery to household appliances. By alternating the current direction, the stator induces continuous rotation in the rotor, converting electrical power into mechanical power.

In the context of boat engines, a stator is typically located under the flywheel, which has several magnets attached to it. The stator itself consists of a specific number of coils or windings. As the flywheel rotates, the magnets pass over these coils, generating an alternating electrical current. This alternating current is then rectified and regulated to become a stable direct current, providing the energy required to operate the ignition system, charge the batteries, and power auxiliary systems.

The output of boat stators can vary from 6 to 40 Amps, and they are commonly installed in outboard motors. It's important to note that the stator's ability to generate power is dependent on the engine's speed, with lower output stators having minimal charge output at idle or low RPM.

The stator's design and materials have been refined over time to improve efficiency and performance. Advancements such as laminated cores and better insulating materials have contributed to the development of highly efficient stators, enabling the widespread use of electric motors.

Additionally, the emergence of Printed Circuit Board (PCB) Stator Technology offers several advantages, including higher efficiency, lightweight construction, and reduced raw material usage, making it a more sustainable option for electric motor stator technology.

Exploring Cococay: A Quick Boat Ride from Nassau

You may want to see also

Stator faults and failures

A stator is a crucial component of a boat engine, generating the electricity needed for the engine to run. However, stator faults and failures are not uncommon, and they can cause significant issues for boat owners. Here are some detailed insights into stator faults and failures:

Signs and Symptoms of a Faulty Stator:

Stator faults can exhibit various hard-to-trace symptoms, making diagnosis challenging. It's important to consider the type of engine in question. Smaller outboard engines with one or two cylinders may refuse to start if the stator has failed. In contrast, larger engines with more cylinders may continue to run but with reduced performance due to a loss of spark in some cylinders.

Common Causes of Stator Failure:

The leading causes of stator failure include ageing, overheating, deformation, and wear during use. Corrosion and dirt are significant factors, as they can lead to short circuits and winding damage. Overheating can be caused by various factors, such as clogged thermostats, impaired cooling systems, or excessive charging of depleted batteries.

Testing and Diagnosing a Faulty Stator:

To confirm a stator fault, specific tests are required. The most common test is to ground the stator using a digital multimeter. By disconnecting the stator plug and checking for continuity between the wires and the engine ground, you can identify short circuits. Additionally, checking the resistance and voltage readings can provide further insights. However, it's important to refer to the specific service manual for your engine, as different manufacturers may have unique testing requirements.

Impact of Stator Failure:

When a stator fails, it directly affects the engine's performance. The stator is responsible for generating the electricity needed to operate the ignition system and charge the boat's batteries. As a result, a faulty stator can cause the engine to run poorly, or in some cases, not start at all. This highlights the importance of prompt repair or replacement of faulty stators to ensure a reliable boating experience.

Preventative Measures:

To reduce the risk of stator failure, it's essential to maintain a clean engine, prevent overheating, and ensure proper charging practices. Regular inspections and maintenance can help identify potential issues before they lead to stator failure. Additionally, balancing the battery bank with the charging system and using separate consumption and start batteries can reduce the strain on the stator.

Fixing Boat Engines: A Step-by-Step Guide

You may want to see also

Testing a boat engine stator

A stator is a component on a boat engine that is attached under the flywheel. The flywheel rotates around the stator, generating an alternating electrical current in the coils. This energy is needed to run the ignition system and power various auxiliary systems.

Firstly, it is important to note that different manufacturers will have different tests, readings, and styles of stators. However, there are some general tests that can be performed on most stators to determine whether they have failed or not.

To begin testing, you will need to disconnect the battery cables from the battery, as an electrical flow is not required for this test. Next, try wiggling the stator plate to check if it is loose. If it is, tighten it with a wrench, as a loose plate can cause the gap between the points to change settings and prevent your engine from firing.

Now, refer to your motor operator's manual to determine the range of resistance for your stator. Set your multimeter to the "Ohms" setting. Then, place one of the multimeter probes against one of the connections of the stator wires (usually blue) and the other probe against the remaining connection. Read the number of ohms on the multimeter and compare it to the range in the operator's manual. If the resistance is within the specified range, your stator is functioning correctly. If the resistance is significantly higher (infinite resistance), the stator needs to be replaced.

Another test is to ground out the stator. For this test, you will need a digital multimeter. Disconnect the plug that goes to the stator and set the meter to read ohms or resistance. Connect the negative meter lead to any engine ground on the block. Then, take the positive meter lead and check for a short to ground in each wire coming out of the stator. If there is continuity between the wire going to the windings in the stator, the stator is shorted to the ground and requires replacement.

Additionally, on certain stators, you can check the resistance between the wires. Some stators will have a specific amount of resistance between the wires, while others will have straight continuity. Therefore, it is crucial to refer to the service manual for your specific engine to ensure accurate testing.

Remember to always exercise caution when working with electricity and follow safety guidelines.

Repairing Rotten Wood on Your Boat: A Step-by-Step Guide

You may want to see also

Stator maintenance and replacement

A stator is a crucial component of a boat engine, but it requires proper maintenance and occasional replacement to ensure the engine's performance and longevity. Here are some detailed instructions on stator maintenance and replacement for boat engines:

Understanding the Stator

The stator is a stationary part of the boat engine, usually located under the flywheel. It consists of coils that produce electricity as the flywheel's magnets spin around them. This electricity powers the ignition system and charges the boat's batteries.

Maintenance Tips

To maintain the stator and prevent premature failure, it is essential to keep the engine clean and free from dirt and corrosion. Regularly inspect the stator for any signs of damage, such as melted or burnt windings, and test it using a digital multimeter to ensure it is functioning correctly.

Signs of a Failing Stator

A failing stator can exhibit various symptoms, including difficulty starting the engine, reduced engine performance, and a discharge instead of charging the battery. If you notice any of these issues, it is crucial to test the stator and, if necessary, replace it.

Replacement Procedure

When replacing the stator, start by consulting the service manual for your specific engine. This will provide detailed instructions and specifications for the replacement process. In general, you will need to:

- Disconnect the plug that goes to the stator.

- Perform resistance and voltage tests on the stator's wires using a digital multimeter.

- If the tests indicate a failure, remove the flywheel and inspect the stator for any visible damage.

- Purchase a replacement stator that is compatible with your engine.

- Install the new stator, ensuring proper connections and positioning.

- Reattach the flywheel and secure it in place.

- Test the new stator to ensure it is functioning correctly.

Seeking Professional Help

If you are unsure about performing the replacement yourself, it is advisable to seek assistance from a qualified marine mechanic or a dealer specializing in boat engine repairs. They will have the knowledge and tools to diagnose and replace the stator correctly.

By following these maintenance and replacement guidelines, you can ensure the optimal performance of your boat engine and minimize the chances of unexpected breakdowns on the water.

Understanding Abstracts of Title for Boat Ownership

You may want to see also

Frequently asked questions

A stator is a component on a boat engine that is attached under the flywheel of the engine. It generates electricity for the engine to operate the ignition system and run the engine.

The engine's flywheel has magnets attached to the inside of it, that spin around the stator. The stator is made up of windings that produce alternating current electricity. As the magnets on the flywheel spin around the windings when the engine is running, alternating current electricity is generated.

If your boat engine's stator fails, you won't be able to charge your boat's batteries while the boat is running. Additionally, smaller outboard engines with one or two cylinders will not even start, while larger engines with four, six, or eight cylinders will run poorly.