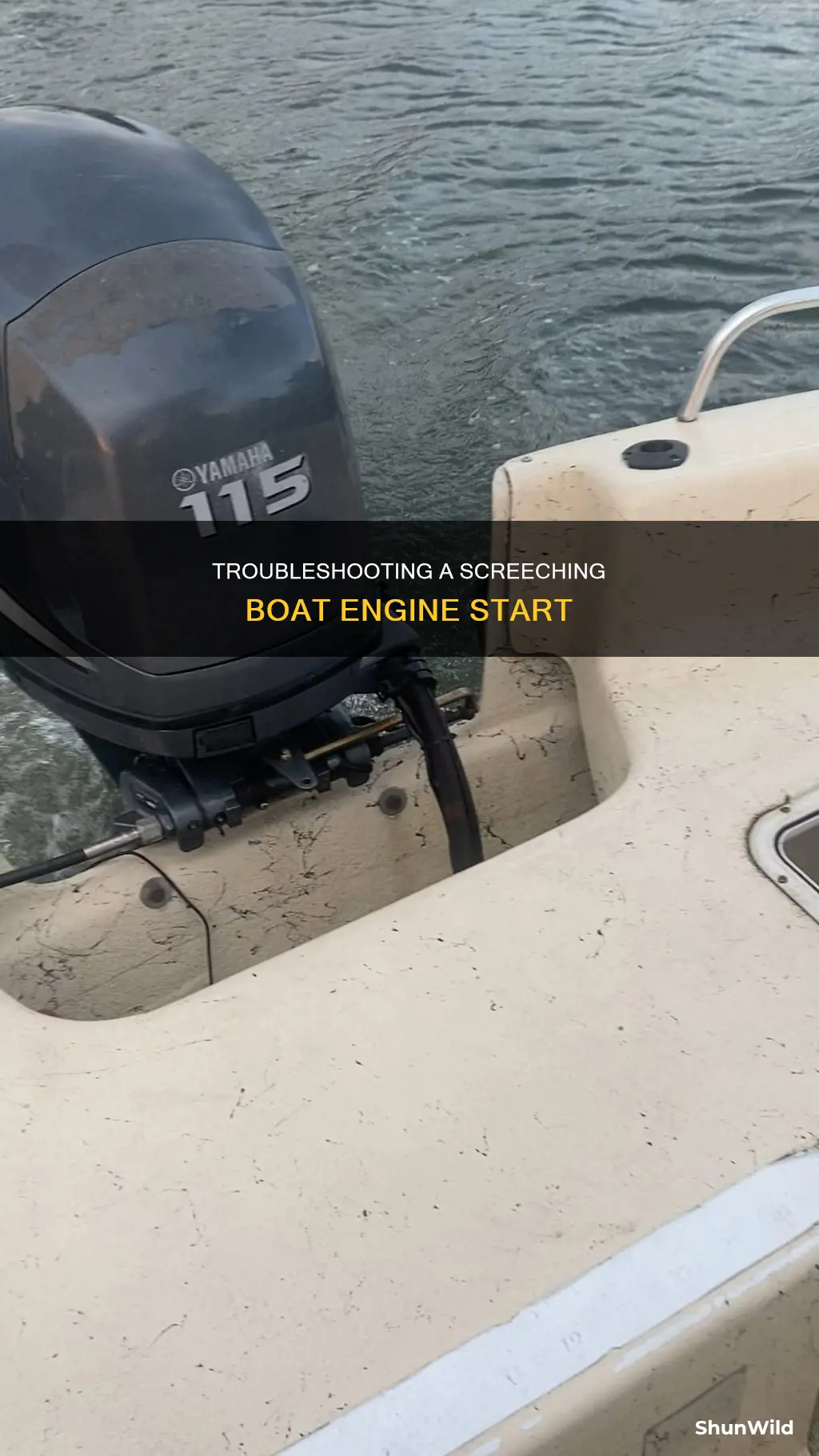

Boat engines can make a variety of noises, and it's important to be aware of these sounds as they can indicate a problem. A screeching sound when starting a boat engine could be caused by several issues. One possible cause is corrosion on the tilt pin or tilt tube, leading to friction and resulting in a loud screeching noise. This issue may require cleaning or replacement of the affected parts. Additionally, a worn cutlass bearing can cause a squealing noise, impacting the boat's performance and potentially leading to more serious repairs if left unattended. It is beneficial to be familiar with the various sounds a boat engine can make to identify potential problems early on.

What You'll Learn

Corroded tilt pin

A corroded tilt pin is one of the most common causes of a screeching sound when starting a boat engine. This is due to the corrosion causing friction between the tilt pin and the tilt tube, which results in a loud noise.

To fix this issue, the pin must be removed, cleaned, and the corrosion build-up adequately addressed. This process can be complex and may require the assistance of a professional mechanic. It is important to follow the necessary safety precautions and refer to the owner's manual or a repair guide for detailed instructions on how to perform this task.

- Tilt the engine upwards and remove the tilt arm.

- Remove the E-clip and take out the pin.

- Clean the pin thoroughly, removing all corrosion and any other debris.

- Inspect the tilt tube and bushing for any signs of damage or excessive wear. Replace the bushing if necessary.

- Grease the components well and reassemble them, following the reverse of the disassembly process.

- Refill the fluid in the tilt tube until it runs out.

- Test the engine and listen for any remaining noise or unusual behaviour.

It is important to note that attempting to repair a corroded tilt pin without addressing the underlying corrosion issue can lead to further problems. Therefore, it is crucial to take the time to clean and maintain these components properly to ensure the long-term functionality of the boat engine.

Additionally, regular maintenance and inspections of the boat engine can help identify potential issues before they escalate. Staying vigilant and addressing problems early on can prevent more serious and costly repairs in the future.

Explore Boat Insurance Options with Markel

You may want to see also

Corrosion on the tilt tube

To prevent corrosion and keep your boat engine in good condition, it is important to regularly clean the engine tilt tube and lubricate the components. Here are the steps you can follow:

- Disconnect the steering cable: Use a wrench to loosen the bolts holding the steering cable to the steering helm and the engine.

- Pull out the cable: Get a rope and tie it to the end of the helm. Pull the cable back through the boat gently by pulling on the rope from the engine end. Be careful not to damage the control box.

- Clean the tilt tube: Remove the steering cable and telescoping ram from the tilt tube. Use a wire brush to clean the inside of the tilt tube thoroughly, removing all corrosion.

- Lubricate the components: Apply a water-resistant grease to the tilt tube and use marine grease to lubricate the sliding parts of the telescoping ram.

- Reassemble the parts: Put everything back together, making sure all fasteners are tight and intact.

It is important to note that you should not refill the tilt tube with grease as this can cause problems. Instead, use a small amount of marine grease on the sliding parts of the telescoping ram. Additionally, if you use your boat in seawater, corrosion may occur more frequently due to the presence of salt, so cleaning and maintenance may be required more often.

Tri-Hull Boat Identification: Which One Is Mine?

You may want to see also

Worn cutlass bearing

A worn cutlass bearing is a potential cause of a screeching sound when starting a boat engine. The cutlass bearing is a crucial component in a boat's propulsion system, connecting the engine to the propeller and enabling smooth rotation. When this bearing wears out, it can result in a range of issues, including unwanted noise.

The sound produced by a worn cutlass bearing can vary, with some boat owners describing it as a squeak, a squeal, or even a grinding noise. This sound is often more noticeable at lower RPMs, and it may come and go, depending on the engine speed and gear selection. In some cases, the sound may be constant and get louder as the bearing continues to deteriorate.

To diagnose a worn cutlass bearing, it is essential to pay attention to the boat's performance and behaviour. One common indicator is increased vibration, particularly at higher speeds. Additionally, the presence of more water than usual in the bilge or stuffing box could suggest that the shaft is wobbling due to a faulty cutlass bearing.

If a worn cutlass bearing is suspected, it is recommended to consult a marine engineer or mechanic. They can provide expert advice and perform a thorough inspection, which may involve diving underwater to examine the propeller and shaft. In some cases, the boat may need to be hauled out of the water for a detailed assessment.

It is important to address a worn cutlass bearing promptly to prevent further damage and ensure the safe and efficient operation of the boat. Regular maintenance and timely replacement of the cutlass bearing can help maintain the boat's performance and avoid unexpected breakdowns.

Restoring Ranger Boat Seats: A Step-by-Step Guide

You may want to see also

Engine's water pump issue

A screeching sound when starting a boat engine could be due to a number of issues with the engine's water pump.

Water pumps are usually attached to several other moving parts, so a noise coming from the water pump will resonate throughout the engine, making it harder to identify. However, a water pump noise could be the first sign of failure. If left too long, a failed water pump could overheat and destroy your engine.

The most common cause of water pump failure is worn-out bearings. This can cause a squealing, howling, or grinding noise coming from the front of the engine. The bearings allow the shaft to transfer rotating force to the impeller, so worn bearings will cause a rough rotation of the pump shaft.

A rattling noise could be caused by a bent or broken impeller shaft, or worn-out bearings. If the impeller shaft is broken, it is likely that the water pump problem has been ignored for a long time. Mixing coolants or using the wrong coolant can also cause this issue.

A clicking or squeaking noise is usually caused by worn bearings. These sounds can sometimes be heard when the engine is idling, or more clearly after shutting off the engine and loosening the tensioner.

A whining or groaning noise usually means that either a drive belt is loose or the water pump pulley is bad. Pulleys can fail due to rust, which can cause cracking between their bolt holes. This allows the pulley to flex slightly when spinning, causing the noise.

To diagnose a water pump noise, start the engine and touch the water pump housing with the tip of a screwdriver or a length of rubber hose, with the other end against your ear. If the bearings are worn out, you will hear the noise coming from the water pump.

Planning a Boat Engine Rebuild: How Much Time is Needed?

You may want to see also

Faulty engine alarms

Boat engine alarms are designed to alert you to potential issues with your vessel, so it is important to be aware of the different types of alarms and what they indicate. Here are some things to keep in mind regarding faulty engine alarms:

Types of Alarms

Bilge high water alarms, engine temperature monitors, and cooling water monitors are some of the alarms available for boat engines. These alarms are designed to detect issues such as high water levels, low oil pressure, and overheating. Modern marine propulsion systems, including diesels, inboard gasoline engines, and outboard motors, are equipped with various sensors to prevent catastrophes.

Testing and Maintenance

It is recommended to test your boat's alarms regularly, as they can degrade over time even if they are never activated. Test the alarms a few times each season and review your owner's manual to familiarise yourself with the procedures. Additionally, consider investing in a high-quality bilge pump and regularly checking for leaks and corrosion to prevent false alarms.

Troubleshooting

If you encounter a faulty engine alarm, there are several steps you can take to identify and resolve the issue. First, refer to your boat's manual for troubleshooting guidance. If the problem persists, consider consulting a certified technician or seeking advice from experienced boaters or mechanics. They can help you identify specific issues, such as a faulty O2 sensor, spark plugs, or corrosion, and provide guidance on necessary repairs or replacements.

Choosing an Alarm System

When selecting a bilge alarm system, consider factors such as the type and size of your boat, water level sensitivity, and power source. Choose a system that accurately detects water levels and has both audible and visual indicators. Additionally, ensure the alarm system is designed for your specific type of vessel and usage.

In conclusion, faulty engine alarms can be a cause for concern, but with regular testing, maintenance, and a basic understanding of your boat's alarm systems, you can confidently identify and address potential issues. Remember to pay attention to unusual noises and always prioritise safety when operating your vessel.

The Evolution of Crew Boat Names: Unraveling the Mystery

You may want to see also

Frequently asked questions

A screeching sound could be caused by a corroded tilt pin or tilt tube.

You can try to grease the tilt tube at the lubricating fittings on the front of the motor brackets. If that doesn't work, you may need to remove and clean the tilt pin, replacing the bushing.

A worn cutlass bearing can cause a squealing noise, which can affect the boat's performance. Additionally, changes in the exhaust sound can indicate a problem with the engine's water pump.