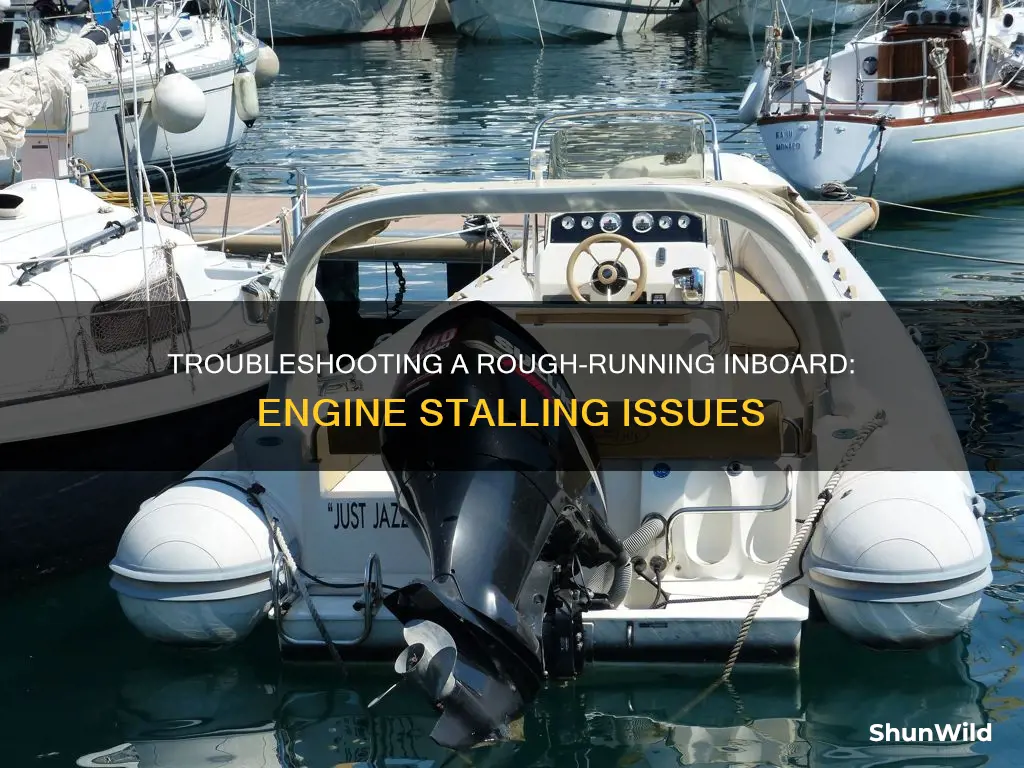

A boat engine can run rough and stall due to a variety of issues. Some of the most common causes include:

- Fuel issues: This could be related to stale fuel, a clogged fuel filter, or water in the fuel.

- Spark issues: A weak spark or issues with the spark plugs can cause the engine to run rough.

- Air issues: A clogged air filter or intake manifold leak can disrupt the air-fuel mixture, affecting engine performance.

- Engine maintenance: Lack of regular maintenance can lead to various issues, including carbon buildup, dirty or worn components, and low fluid levels.

- Electrical problems: A dead battery, faulty ignition switch, or corroded connections can cause the engine to stall.

- Overheating: Insufficient water flow in the cooling system can lead to engine overheating and potential failure.

| Characteristics | Values |

|---|---|

| Engine issues | Sputtering, losing power, not starting, overheating, sudden stop, not shifting into gear, stuck trim, lack of maintenance, broken drive belt |

| Engine issues causes | Clogged fuel filter, dirty carburetor, dirty or defective airflow sensor, fouled spark plugs, old gas, poor ignition, etc. |

| Engine issues fixes | Replace fuel filter, clean carburetor, replace airflow sensor, replace spark plugs, use fresh gas, fix ignition, etc. |

What You'll Learn

Faulty carburettor

A carburettor is an important component of a boat's gas engine, mixing the right amount of fuel and air for combustion. This mixture is then sucked into the engine by a vacuum. As the vacuum pulls the air down through the carburettor, the carburettor directs the fuel from the fuel bowl to mix with the incoming air, forming a combustion mixture that enables the engine to run.

A faulty carburettor can cause a multitude of problems with your engine, such as rough idling, stalling, flooding, poor fuel economy, and hard starting. A dirty carburettor, for example, cannot properly regulate the air and fuel mixture that the engine needs to run, which can lead to stalling problems.

One of the most common carburettor problems is a result of heat accumulation in the carburettor, fuel pump, lines, and its vicinity. This creates a vapor lock, making it harder for a hot engine to start. This can be solved by rerouting the fuel lines away from sources of heat, or insulating them.

As carburettors age, the material around the throttle shaft, located in the base of the carburettor, wears out from constant movement. This causes an increase in the tolerance between the base and the t-shaft, allowing air to leak and making the engine run rough at idle speed. This issue can be fixed by inserting new brass bushings around the throttle shaft, restoring the tightness of the throttle shaft and eliminating leaks.

A carburettor may also experience hard cold-starting issues. This is caused by a choke failing to close, resulting in a rich fuel mixture while the engine is cold. This can be fixed by cleaning the choke linkage and mechanism, and adjusting or replacing the bi-metal spring inside the choke housing, which controls the opening and closing of the choke plate.

A faulty power valve in the carburettor can cause the engine to hesitate or misfire when under load. This is due to a vacuum-sensing mechanism within the power valve failing, or the valve becoming clogged. In this case, the power valve will need to be replaced.

Aman Gupta's Nautical Naming: The Story Behind 'Boat

You may want to see also

Poor fuel quality

To prevent fuel-related issues, it is recommended to use fuel additives specifically designed for marine engines. These additives help keep the fuel optimized, protect the fuel system, and remove harmful deposits. Additionally, it is advised to buy gas from trusted sources and avoid gasoline containing more than 10% ethanol, as higher concentrations can damage marine engines. Keeping the boat's fuel tank full can also prevent condensation from forming.

Another issue related to poor fuel quality is a clogged fuel line. This can be caused by a damaged or dirty fuel filter, leading to a lean fuel mixture and stalling under acceleration. A clogged fuel line can be detected by testing the fuel pressure at the engine, and the problem can be rectified by flushing the fuel line and replacing the filter.

Furthermore, spark plugs can become fouled due to carbon buildup from normal combustion. This results in sporadic fuel ignition and poor sparking, leading to rough engine performance and potential stalling. Replacing the spark plugs can resolve this issue.

The Night Boat to Albany: A Mysterious Journey

You may want to see also

Spark plug issues

Spark plugs are responsible for igniting the fuel in the cylinder. Over time, spark plugs will foul in response to carbon buildup from the normal combustion of oil in the cylinder. This is especially common in two-cycle engines that require the mixing of fuel and oil before filling up the gas tank.

Fouled spark plugs result in sporadic fuel ignition because of poor sparking. This becomes more evident under load when the cylinder is saturated with fuel. Spark plug fouling can be detected by removing the spark plugs and comparing them with a plug colour chart.

If you are experiencing engine issues, it is a good idea to check your spark plugs for fouling and make sure your plug wires are properly connected.

If your spark plugs are damaged, replacing them will fix the problem by restoring the proper combustion of fuel.

Sailing Boats: When Do They Earn the 'Yacht' Title?

You may want to see also

Clogged fuel line

A clogged fuel line can cause an inboard boat engine to run rough and stall. This is because a clogged fuel line inhibits the flow of fuel from the boat's gas tank to the engine, resulting in a lean mixture and stalling under acceleration. A clogged fuel line can be caused by a damaged or dirty fuel filter, which is designed to filter particles from the fuel before they can reach the small, easy-to-clog lines.

To detect a clogged fuel line, you can test the fuel pressure at the engine. If the fuel pressure is low, it is likely that the fuel line is clogged. In this case, the problem can be fixed by flushing the fuel line and replacing the fuel filter.

It is important to note that a clogged fuel line is just one of several potential causes of a boat engine stalling. Other potential causes include a spark plug fouled by fuel, carbon, dirt, or oil; a dirty flame arrestor/air box; worn piston rings, cylinders, and leaking valves; a defective airflow sensor; a dirty or worn carburetor or linkage; and a defective idle air control valve.

To prevent a clogged fuel line from causing your boat engine to stall, it is important to regularly flush the fuel line and replace the fuel filter. It is also a good idea to carry a spare fuel filter onboard in case the one you are using becomes clogged or damaged. Additionally, keeping your boat engine well-maintained can help to prevent issues such as a clogged fuel line from occurring.

Jorah's Boat: An Unexpected Journey and Its End

You may want to see also

Airflow sensor problems

A boat engine, like any internal combustion engine, needs air, fuel, and a spark to run properly. A dirty or damaged airflow sensor can cause a reduction in engine performance or even cause the engine to stall.

A mass airflow sensor (MAS) determines the mass of air entering a vehicle's fuel injection engine. This data is passed to the Engine Control Unit (ECU), which uses it to balance and deliver the correct amount of fuel to the engine. When the MAS is faulty, it can cause a variety of problems, including very poor engine performance.

A contaminated or failed MAS cannot measure the amount of airflow correctly, which causes the engine computer to miscalculate the amount of fuel to inject. This results in various driveability problems, including a no-start, stalling, lack of power, and poor acceleration. A faulty MAS might also cause the "Check Engine" or "Service Engine Soon" light to come on.

Some common symptoms of a faulty MAS include:

- The engine is very hard to start or turn over.

- The engine stalls shortly after starting.

- The engine hesitates or drags while under load or idle.

- Hesitation and jerking during acceleration.

- Excessively rich or lean idling.

If you suspect a faulty MAS, a qualified mechanic can run a complete computer diagnostic to determine the issue. In most cases, a faulty MAS has a specific code that will generate during computer diagnostics and can be easily determined with computer testing equipment.

Cleaning and Replacing the Airflow Sensor

You can clean your MAS every six months or every time you change your oil. To clean it, first, remove the sensor by opening the vehicle's air box and using a flathead screwdriver to take it out. Be careful not to touch the wires, as they are delicate and small. Breaking one will require a replacement.

Once the sensor is removed, you can place it in a plastic bag filled with rubbing alcohol, ensuring that the alcohol washes off all the dirt and grime. Alternatively, you can buy a special MAS cleaner from an auto parts store and spray it onto the sensor. After cleaning, let the sensor dry for at least 20 minutes before reinstalling it.

If cleaning does not resolve the issue, you may need to replace the MAS. This is a fairly simple job, and the part typically costs between $89 to $380.

Removing Interior Boat Siding: A Step-by-Step Guide

You may want to see also

Frequently asked questions

There could be a number of reasons for this. A dirty flame arrestor/air box can cause your boat engine to stall. A dirty carburetor can also cause stalling problems as it cannot properly regulate the air and fuel mixture. A defective airflow sensor, a defective idle air control valve, and a clogged fuel line can also be the reason for your engine to stall.

A clogged fuel filter is a common culprit for your engine running rough. An obstructed fuel injector or carburetor jet could also be the reason. A dirty air filter could also be the reason for your engine running rough.

A fouled spark plug could be the reason for your engine to be stalling and running rough. A spark plug fouled by fuel, carbon, dirt, or oil on the electrodes may not produce a spark strong enough to ignite the air/fuel mixture.

Some common problems with boat engines include sputtering and losing power, the engine not starting, the engine overheating, the boat motor stopping suddenly, vibration from the engine prop, the engine not shifting into gear, and the trim being stuck on the engine.

Regularly check engine parts that incur wear and tear and follow the recommendations in your owner's manual. You should also follow the "Rule of Thirds" for fuel usage.