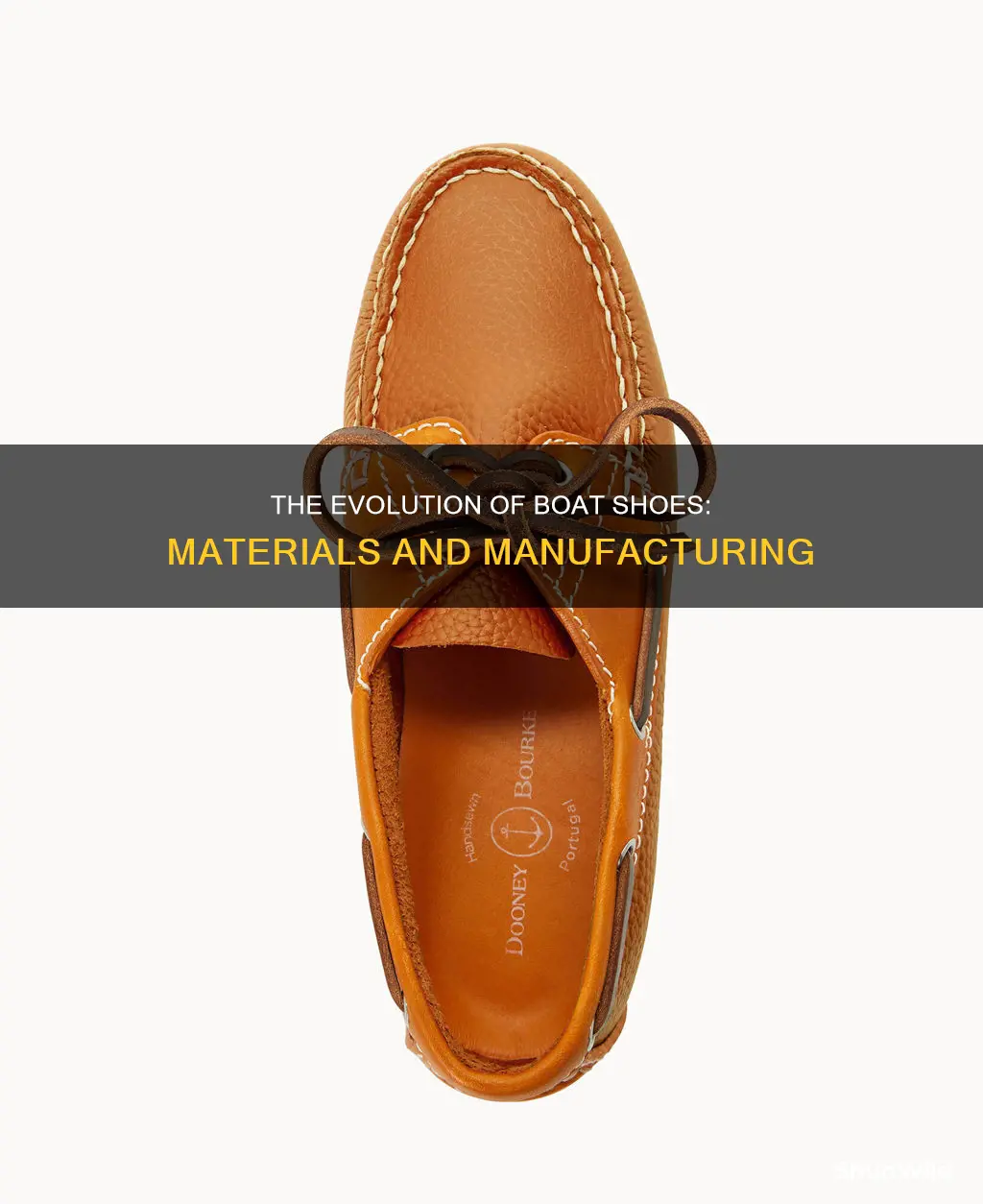

Boat shoes, also known as deck shoes or top-siders, are typically made of canvas or leather with non-marking rubber soles designed for use on a boat. The leather is usually treated with wax or oil to repel water and the soles are cut into a siping pattern to provide grip on wet surfaces. In this article, we will explore the materials used to make boat shoes, their history, and how they are designed for functionality and fashion.

| Characteristics | Values |

|---|---|

| Materials | Canvas or leather |

| Sole | Non-marking rubber |

| Sole pattern | Siping |

| Leather treatment | Wax or oil |

| Upper | Open |

| Lacing system | 360-degree |

| Laces | Leather |

| Toe box | Moccasin-style |

| Heel | Pinched and stitched |

What You'll Learn

Boat shoes are made of canvas or leather

Boat shoes are typically made of canvas or leather. They are designed with sailing functionality in mind, and every part of the shoe is designed to be used on a boat. The soles are made of rubber to provide extra traction on wet boat decks. The original black rubber sole was replaced with white rubber soles to avoid leaving black marks on the boat deck. The soles are also designed with a unique pattern to improve grip on slippery surfaces.

Boat shoes usually have a moc-toe (like a moccasin) construction. The toe box of a boat shoe has moccasin-style stitching, where the tongue of the shoe is joined with the upper via stitching around the front of the shoe. This makes the toe box more comfortable when wearing the shoes barefoot. The leather used for the upper part of the shoe is often treated with wax or oil to repel water and keep feet dry. The top of the shoe is open so that if water does get into the shoe, it can easily escape.

The lacing system of boat shoes is also unique. They traditionally feature long laces that feed through eyelets near the ankle and heel of the shoe, locking the foot into the shoe and ensuring a firm grip in rough waters. The laces themselves are typically made of leather for durability and waterproofing. The heel of a boat shoe is pinched and stitched in a horizontal line, mimicking the moccasin toe. This creates shape for the heel cup without using multiple pieces of leather.

Boat shoes are comfortable and flexible, and many traditional boat shoes are unlined to maintain suppleness and provide a light feel when worn. They are also designed to be worn without socks, as socks would trap moisture against the feet, defeating the purpose of the open-top design. However, boat shoes can also be worn with socks, especially in an urban setting. No-show or ankle socks are recommended to maintain the style and comfort of the shoe.

In addition to their functionality, boat shoes have become a popular fashion choice, offering versatility and style. They can be worn with various outfits, from casual to business casual attire, and are perfect for summertime wear. Boat shoes are a great way to add a touch of class to any outfit and are widely popular among people of all ages and genders.

Gibbs' Boat Removal: A Basement Escape Challenge

You may want to see also

Leather is treated with wax or oil to repel water

Leather is a popular material for boat shoes. The uppers of traditional boat shoes are made from leather, which is usually treated with wax or oil to repel water. This treatment keeps the wearer's feet dry and protects the leather from water damage. The leather is also supple, allowing it to shape to the wearer's foot over time, providing a comfortable fit.

The leather uppers of boat shoes are often left unlined, which helps the shoes remain flexible and supple, as well as providing a lightweight feel. The leather is typically soft, such as nubuck, and may contain natural oils that make it soft and pliable. Over time, the leather may dry out, so it is important to clean and condition it regularly. This will ensure that the shoes remain comfortable and do not lose their shape.

The leather laces of boat shoes are also chosen for their durability and waterproofing properties. The lacing system of boat shoes is designed to keep the shoe securely on the wearer's foot, with the laces wrapping around the heel to ensure the heel does not slip out of the shoe.

In addition to the use of leather, boat shoes typically feature rubber soles with a "siping" pattern cut into them. This pattern provides grip on wet surfaces, such as boat decks. The soles are usually white or dark non-marking rubber, to avoid leaving marks on boat decks.

Repairing a Boat's Thread: Fixing a Messed-Up Tangle

You may want to see also

Leather laces are used for durability and waterproofing

Boat shoes are typically made of canvas or leather with non-marking rubber soles designed for use on a boat. The leather construction, along with the application of oil, is designed to repel water, and the stitching is highly durable.

Boat shoes are traditionally crafted with soft leather, such as nubuck, and are designed to shape to your foot over time. The leather is usually treated with a wax or oil that repels water and keeps feet drier than other materials. The leather contains natural oils that make it soft and pliable, and it is important to clean and condition the leather to ensure that it doesn't dry out.

Boat shoes are known for their unique lacing system, which wraps around the heel of the shoe to ensure that the wearer's heel doesn't slip out when moving about. The laces themselves are typically made of leather for durability and waterproofing. Leather laces are strips of leather, often in white to fit the shoe's coastal identity. They are more durable than waxed cotton laces, which are more common in formal footwear styles.

Replacing Wheel Bearings on a Boat Trailer: Step-by-Step Guide

You may want to see also

Boat shoes have a moccasin-style toe

Boat shoes are typically made of canvas or leather and are designed with sailing functionality in mind. They are worn without socks, as socks would trap moisture against the feet and defeat the purpose of the open-top design. The toe box of a boat shoe has a moccasin-style construction, with puckered stitching resembling that of an apron. This moccasin-style stitching, where the tongue of the shoe is joined with the upper via stitching around the front of the shoe, makes the toe box more comfortable when wearing the shoes barefoot by reducing rubbing and chafing against the toes.

The moccasin-style toe is one of the most distinct parts of a boat shoe's makeup. The puckered stitching gives the shoe a more rugged look, resembling the stitching on another preppy fashion staple, the penny loafer. The toe box of a boat shoe is designed to be close-fitting, ensuring a comfortable fit even without socks.

The moccasin-style construction of boat shoes, where the leather sits underneath the sole and is built around the foot, provides a supple and flexible feel. This construction, combined with the soft leather or canvas material, allows the shoe to shape to the foot over time for a customised fit. The unlined leather uppers of traditional boat shoes also contribute to their comfort and flexibility, providing a light and supple feel when worn.

Boat shoes are designed with sailing in mind, and the moccasin-style toe plays a functional role in this regard. The stitching on the toe box helps to create a firm grip, essential for maintaining footing on the slippery decks of boats. The moccasin-style construction also allows for a more precise and comfortable fit, reducing the risk of slipping on wet surfaces.

In summary, the moccasin-style toe of boat shoes is a defining characteristic that combines functionality and style. It provides comfort, flexibility, and a secure fit, all while contributing to the distinctive rugged look of this classic footwear.

Fresh Off the Boat: Foxtel Schedule and Viewing Options

You may want to see also

Rubber soles are designed with a siping pattern to provide grip

Boat shoes are typically made of canvas or leather and have rubber soles. The rubber soles are designed with a siping pattern to provide grip on wet surfaces, such as boat decks. This feature is essential for sailors and boaters to prevent slipping. The siping pattern was inspired by the grooves on a dog's paws, which provide traction on ice. The rubber soles of boat shoes are also non-marking, meaning they won't leave scuff marks on surfaces.

The siping pattern on boat shoe soles is created by cutting slits or grooves into the rubber. This process, known as siping, was invented and patented in 1923 by John F. Sipe. Paul A. Sperry, the inventor of modern boat shoes, utilised this technique to create the first non-slip deck shoe. Sperry's dog, Prince, inspired him as he noticed his dog's ability to run easily over ice without slipping. By imitating the grooved patterns on his dog's paws, Sperry was able to create a shoe with excellent grip on wet and slippery surfaces.

The siped rubber soles of boat shoes provide several benefits. Firstly, they offer superior traction and grip compared to other types of footwear. This feature is especially useful for sailors and boaters who need to maintain a firm foothold on slippery boat decks. Secondly, the siping pattern helps to channel water away from the shoe, providing additional stability and preventing slipping. This is crucial for activities where a firm grip is necessary, such as sailing or walking on wet surfaces.

The siped soles of boat shoes have become a signature feature, setting them apart from other types of footwear. The unique pattern not only provides functional benefits but also adds to the aesthetic appeal of the shoes. Boat shoes have become a classic and versatile piece of footwear, suitable for both maritime activities and everyday wear. The siped rubber soles contribute to their popularity by providing traction and stability, ensuring a comfortable and secure fit for the wearer.

In summary, rubber soles designed with a siping pattern are an essential feature of boat shoes. They provide grip and traction on wet and slippery surfaces, making them ideal for sailors and boaters. The inspiration for this design comes from nature, specifically the grooves on a dog's paws, which provide stability on ice. By incorporating siping into the rubber soles, boat shoes offer superior performance and safety for individuals engaged in maritime activities or simply seeking comfortable and stylish footwear.

Grady-White Boat Handling: Tips and Tricks

You may want to see also

Frequently asked questions

Boat shoes are typically made of canvas or leather with non-marking rubber soles. The leather is usually treated with wax or oil to repel water.

The soles of boat shoes are made of rubber, which is cut with a "siping" pattern to provide grip on wet surfaces like boat decks.

The uppers of boat shoes are usually made of leather, specifically soft leather like nubuck, which is treated with wax or oil to make it water-resistant.