MCA-treated wood is a preservative used in the pressure treatment of residential application wood products. It can be used above ground, in ground contact or in freshwater contact. MCA-treated wood is less corrosive to metals than CCA-treated wood, which contains chromate copper arsenate (CCA). CCA-treated wood is corrosive to aluminum, and can cause pitting and holes in aluminum boats. MCA-treated wood, on the other hand, can come into contact with aluminum without causing corrosion or discoloration.

| Characteristics | Values |

|---|---|

| Corrosiveness | Less corrosive than other copper-based preservatives |

| Use cases | Residential and commercial applications, decks, and freshwater docks |

| Toxicity | Less toxic than previous copper-based preservatives |

| Colour | Lighter than previous copper-based preservatives |

| Paintability | Paintable |

| Metal fasteners | Can be used with ceramic-coated, stainless steel, or other approved fasteners |

| Aluminium contact | Can come into contact with aluminium without corrosion |

What You'll Learn

- MCA-treated wood is less corrosive to aluminum than other types of treated wood

- MCA-treated wood is safe to use in aluminum boats if a barrier is placed between the wood and the aluminum

- MCA-treated wood is lighter in color than other types of treated wood

- MCA-treated wood is less prone to off-gassing than other types of treated wood

- MCA-treated wood is more expensive than CCA-treated wood

MCA-treated wood is less corrosive to aluminum than other types of treated wood

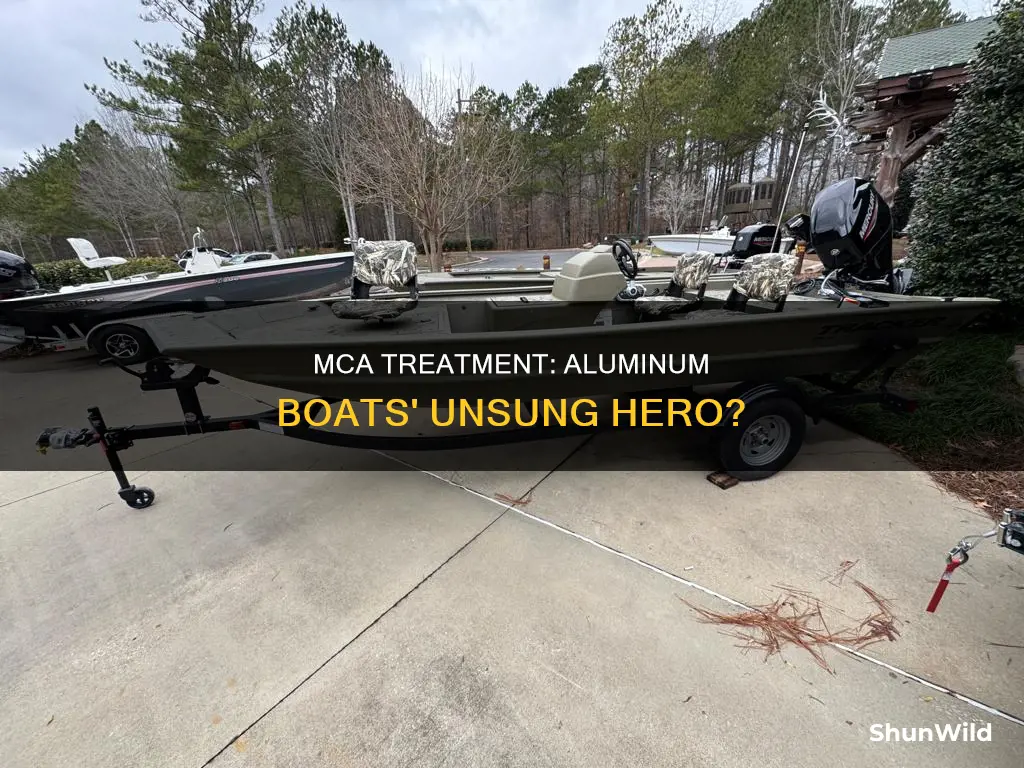

MCA, or Micronized Copper Azole, is a preservative used in the pressure treatment of wood products for residential applications. It is designed to protect wood from decay caused by insects and moisture. While all pressure-treated wood contains copper, which can corrode aluminum, the way that the copper is delivered in MCA-treated wood makes it a better option for use with aluminum.

In MCA-treated wood, the copper is ground into microscopic particles and suspended in water before being injected into the wood. This means that the copper is less likely to leach out and react with the aluminum, causing corrosion. Other types of pressure-treated wood, such as CCA (chromate copper arsenate) and ACQ, have higher levels of copper that are more likely to corrode aluminum.

However, it is important to note that MCA-treated wood is still not recommended for direct contact with aluminum. Even with the reduced corrosion risk, the copper in the wood can still react with the aluminum over time and cause damage. It is always best to use a barrier, such as plastic or rubber, between MCA-treated wood and aluminum to prevent any potential corrosion.

Additionally, MCA-treated wood is more expensive than other types of pressure-treated wood due to its higher copper content. The increased cost may be a factor in deciding whether to use MCA-treated wood or another type of wood for your project.

The Open Boat: Naturalism and Man Against Nature

You may want to see also

MCA-treated wood is safe to use in aluminum boats if a barrier is placed between the wood and the aluminum

MCA, or Micronized Copper Azole, is a preservative used in the pressure treatment of wood products. It is designed to eliminate the corrosive qualities of previous treatments while still protecting the wood from rot, decay, and termite infestation. While MCA-treated wood is less corrosive than wood treated with other chemicals, it can still cause issues when in direct contact with aluminum.

To safely use MCA-treated wood in an aluminum boat, a barrier must be placed between the two materials. This barrier can be something as simple as a thin sheet of plastic or rubber. It is important to ensure that the barrier will not wear off over time, as this will leave the aluminum vulnerable to corrosion.

In addition to creating a barrier, it is also recommended to coat or cover any bolts or fasteners used to secure the wood. These can also be corroded by the copper in the MCA-treated wood if they are in direct contact.

By taking these precautions, you can safely use MCA-treated wood in your aluminum boat without worrying about corrosion or damage to your vessel.

Engaging a Boat's Starter Battery: Easy Steps to Follow

You may want to see also

MCA-treated wood is lighter in color than other types of treated wood

MCA-treated wood is lighter in colour than other types of treated wood. This is because the copper in the chemical used to treat the wood is dissolved in an organic solvent, which gives the wood a green cast. In contrast, the copper in MCA-treated wood is ground into microscopic particles, eliminating the need for solvents to dissolve the copper into the water-based treatment solution. This results in a lighter colour that is more appealing to homeowners who want to achieve a natural wood look with light-coloured paints or stains.

The use of MCA-treated wood is becoming more common due to its advantages over wood treated with other chemicals. One of the most important advantages is that MCA-treated wood is less corrosive to fasteners and hardware, including aluminium. This is because the copper in MCA-treated wood is present in microscopic particles suspended in water, which are then injected into the wood. This process ensures that the preservative holds up to exterior environmental factors much better than other types of treated wood.

MCA-treated wood is also suitable for any residential or commercial application where the wood will be exposed to outdoor elements, such as decks and freshwater docks. It can also be used for fences, posts, pilings, playground structures, and boardwalks.

However, it is important to note that MCA-treated wood should not be used in direct contact with aluminium products that do not provide proper water drainage or are exposed to standing water or water immersion. While MCA-treated wood is approved for direct contact with aluminium, it is still corrosive and can cause pitting and corrosion over time. Therefore, it is recommended to use non-treated wood for aluminium boats and coat it with a water sealant to prevent water damage.

Exploring Tampa to the Keys: Boat Trip Distance

You may want to see also

MCA-treated wood is less prone to off-gassing than other types of treated wood

The use of MCA-treated wood is advantageous over wood treated with copper azole (CA). One of the most important advantages is that the copper in MCA-treated wood is less corrosive to fasteners and hardware than the copper in wood treated with CA. Additionally, MCA-treated wood can safely come into contact with aluminum without causing corrosion or discolouration.

MCA-treated wood also has the benefit of retaining more of its natural colour. The lighter colour is more aesthetically pleasing and can be painted with light-coloured paints or stains.

MCA-treated wood is created through a different chemical process to CA-treated wood. In MCA-treated wood, the copper is present in microscopic particles suspended in water and injected into the wood. This slow process helps to provide continuous protection against decay caused by fungi and mould.

Overall, MCA-treated wood is a good choice for any residential or commercial application where the wood will be exposed to outdoor elements, such as decks and freshwater docks. It is also suitable for use in aluminium boats without causing corrosion, making it a versatile and safe option for a variety of projects.

Boat Engine Expense: Why the High Cost of Marine Power?

You may want to see also

MCA-treated wood is more expensive than CCA-treated wood

MCA-treated wood is a newer type of treated wood that has gained popularity in recent years for its natural appearance and high resistance to decay, rot, and insect damage. It is often used for above-ground applications such as decks and fencing. On the other hand, CCA-treated wood is considered by many construction professionals to be the best wood treatment option for its durability and resistance to the elements. It is commonly used for outdoor projects and specific residential, commercial, and water applications.

The retention level of a preservative in the wood is expressed in pounds per cubic foot (lb. per cu. ft.) of wood fiber. The higher the retention level, the more preservative retained in the wood after pressure treatment, and the higher the cost. To offset the higher cost of MCA-treated wood, manufacturers produce pressure-treated lumber with different retention levels. CCA-treated wood has a lower retention level and, therefore, a lower cost.

In summary, the higher copper content of MCA-treated wood makes it more expensive than CCA-treated wood. MCA-treated wood is also more expensive due to its higher retention levels, which require more copper to be effective. CCA-treated wood, while less expensive, is limited in its applications due to toxicity concerns.

Fresh Off the Boat: Is It Streaming on HBO Max?

You may want to see also

Frequently asked questions

No, it is not recommended. While MCA-treated wood is less corrosive than other types of pressure-treated wood, it can still cause pitting, indentations, and corrosion in aluminium over time.

MCA-treated wood contains copper, which can leach out and corrode the aluminium when it gets wet. This can lead to leaks and may require costly repairs or replacements.

Yes, regular exterior plywood that has been sealed with a non-copper-based sealant is a good alternative. Aluminium sheets are another option, as they are lightweight and won't rot like wood.

Early signs of corrosion include pitting, indentations, and discolouration of the aluminium. It is important to address these issues promptly to prevent further damage.

It is not advisable. Even with a barrier, the copper can still leach out and corrode the aluminium over time. It is best to avoid using MCA-treated wood in direct or indirect contact with aluminium.