Wiring two batteries on a John boat is a complex process that requires careful consideration and planning. It is important to understand the electrical system of the boat, including the types of batteries, wiring options, and safety measures. The first step is to determine the battery setup, which can be single or dual. A dual battery setup is commonly used for fishing boats, with one battery acting as the starter battery and the other powering tools and electronics. When choosing batteries, factors such as cold cranking amps (CCA) and conductor gauge compatibility should be considered to ensure the batteries meet the engine's requirements and avoid safety hazards.

Additionally, an overcurrent protection device, such as a circuit breaker, is necessary to protect the electrical system. The circuit breaker should be sized according to the trolling motor used. Proper tools, such as lithium batteries, cables, cable cutters, and a wrench, are also essential for the wiring process.

There are two main wiring options: series and parallel. Series wiring is suitable for high-powered applications and uses 2 to 4 similar batteries, while parallel wiring increases total battery capacity and longevity and is commonly used in most other situations. It is important to follow the correct wiring procedure for the chosen option, ensuring proper connections and voltage compatibility.

Safety should be a priority when working with batteries. It is recommended to wear safety gear, handle batteries carefully, and refer to guidelines from organizations like the American Boat and Yacht Council (ABYC) for circuit protection, wire sizes, and related standards.

What You'll Learn

- Dual battery setup: one battery to start the engine, the other to power tools

- Cold cranking amps: the current a battery can provide in freezing temperatures

- Conductor gauge: must be compatible with battery size to avoid safety hazards

- Circuit breaker sizing: use an overcurrent protection device to safeguard the boat's energy system

- Wiring options: series wiring for large boats; parallel wiring for most other situations

Dual battery setup: one battery to start the engine, the other to power tools

A dual battery setup is ideal for a fishing boat as it allows for separate power sources, providing the most efficient level of energy needed for starting the boat and operating tools.

Plan Your Layout:

Decide where to place your batteries and how they will connect to the boat's electrical system. The American Boat and Yacht Council (ABYC) standards dictate that the battery switch should be as close to the batteries as possible and readily accessible.

Gather Materials:

You will need two batteries (lithium batteries are a good option), cables, a dual battery switch, and installation tools. The cables should be marine-grade, and you may need cable lugs, heat-shrink tubing, and terminal caps for the positive terminals.

Follow Safety Precautions:

Always disconnect the power and wear protective gear before starting work on your boat's electrical system.

Mount Batteries:

Securely install the batteries in a location that is dry and well-ventilated. Wet-cell batteries should be secured in a battery box, while absorbed glass mat batteries do not need boxes but do require tie-downs or brackets. The positive terminals should be covered with non-conductive boots.

Wire the System:

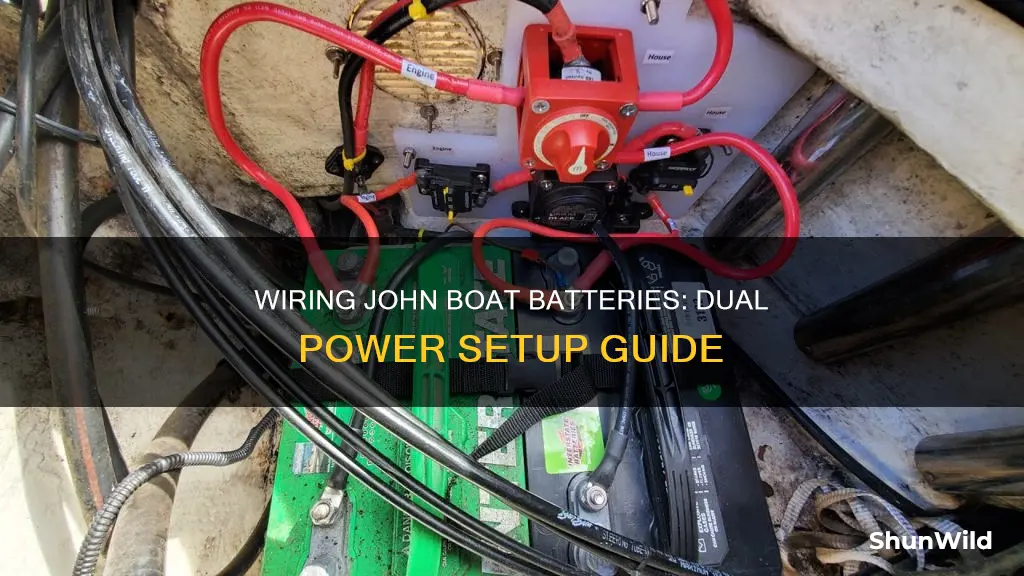

Connect the batteries to the switch and the boat's electrical system, respecting the polarity. For the positive cables, connect the positive terminals of both batteries to the corresponding posts on the back of the switch. Then, connect the positive cable from the engine to the output post of the switch, along with the positive accessory wire.

For the negative cables, a crossover cable between the negative terminals of the two batteries is necessary for the dual-battery system to operate properly. Connect the negative cable lug from the engine/ground and the negative accessory wire to either of the negative battery posts. Ensure all terminal nuts are tight, and consider replacing wing nuts with locking hex nuts for a smarter option.

Test Your Setup:

Once everything is connected, test the system to ensure it is functioning correctly.

Maintenance and Troubleshooting:

Regularly check your batteries for any wear, rust, or loose wires. Keep the battery terminals clean using a mixture of baking soda and water to prevent corrosion. Ensure all cables and connections are tight and secure, and check the water levels in lead-acid batteries, topping up with distilled water if needed.

If you encounter issues like a battery not holding a charge, electrical problems, or charging imbalances, refer to troubleshooting guides or seek professional help if needed.

The Boys in the Boat: Heroes of WWII?

You may want to see also

Cold cranking amps: the current a battery can provide in freezing temperatures

Cold cranking amps (CCA) refer to a battery's ability to crank an engine in freezing temperatures. CCA is a rating used to define the power needed to start an engine in cold weather. CCA is measured by the amount of current (in amps) a fully charged 12V battery can deliver for 30 seconds while maintaining 7.2V at 0°F (-18°C).

CCA is an important metric to understand when purchasing a battery, especially if you live in a colder climate. Cold temperatures cause batteries to operate less efficiently, and their reaction times slow down. A battery with a higher CCA rating will be better equipped to handle the impact of cold temperatures.

When selecting a battery, it is important to consider the size of your engine. As a rule of thumb, an engine will require about one amp per cubic inch of engine displacement. Most vehicles will need between 250 and 600 CCA, but this can vary depending on the size of the engine. For example, larger vehicles such as buses or RVs may require up to 1,000 CCA.

It is also worth noting that CCA is different from marine cranking amps (MCA), which are used to measure the amps produced at 32°F, the freezing temperature for water. MCA is relevant for boats used in water-based activities, as most boats will not be out on the water when temperatures are below 32°F.

When wiring two batteries on a John boat, it is recommended to have one battery in the front for the trolling motor and one in the rear for the sonar and backup for the trolling motor. The trolling motor should be wired directly to the battery, with a fuse or circuit breaker right at the battery. The length of the wire run to the trolling motor and the size of the motor will determine the size of the wire. A circuit breaker with a test button is recommended for safety and to act as a switch.

For the fish finder, you can use 2-conductor shielded cable and a fuse holder at the battery with a 3-amp fuse. The negative wire from the fish finder will connect directly to the negative terminal of the battery. It is important to use marine-grade wire and to ensure all connections are secure and properly insulated to prevent short circuits.

Cruiser Boats: Understanding Their Unique Design and Appeal

You may want to see also

Conductor gauge: must be compatible with battery size to avoid safety hazards

When wiring two batteries on a John boat, it is important to ensure that the conductor gauge is compatible with the battery size to avoid safety hazards. The conductor gauge, or wire gauge, refers to the thickness of the wire and is measured using a standardised system such as the American Wire Gauge (AWG) or British Standard Wire Gauge (SWG). Using the correct wire thickness is crucial as it determines the amount of electric current the wire can safely carry, as well as its electrical resistance and weight.

In the context of wiring two batteries on a John boat, the wire gauge needs to be appropriate for the electrical load and current-carrying capacity required by the batteries. If the wire gauge is too thin for the electrical load, it can lead to overheating, voltage drops, and potential safety hazards such as fires. Therefore, it is essential to select a wire gauge that can safely handle the amount of electric current generated by the batteries.

To determine the appropriate wire gauge, one must consider the size and type of the batteries, as well as the length of the wire run. For example, if you are using a trolling motor, the length of the wire run and the size of the motor will dictate the wire gauge required. A larger motor will require a thicker wire to handle the increased electrical load. Additionally, longer wire runs may result in a greater voltage drop, which can affect the performance of the batteries.

It is also important to follow safety guidelines when working with batteries and electrical systems. This includes wearing safety gear such as gloves and eye protection, and ensuring proper ventilation to prevent the buildup of hydrogen gas emitted during battery charging. By following these guidelines and selecting the appropriate conductor gauge, you can ensure a safe and effective wiring installation for your John boat's batteries.

Testing Boat Batteries: Are They Still Good?

You may want to see also

Circuit breaker sizing: use an overcurrent protection device to safeguard the boat's energy system

Circuit breakers are a type of overcurrent protection (OCP) device, along with fuses. OCPs are critical safety measures that protect wiring from overheating and potential fires. They work by sensing the amount of current and opening the circuit when it exceeds the capacity of the wires.

When wiring two batteries on a Jon boat, it is important to consider the following guidelines for OCPs:

- The American Boat and Yacht Council (ABYC) guidelines state that OCPs must be installed within 7 inches of the source of power, measured by wire length. However, there are exceptions to this rule, such as when the conductor is connected directly to the battery terminal and is enclosed, in which case the maximum distance can be up to 72 inches.

- The wire size or gauge is important as it determines the amount of voltage lost. Size 2/0 cable can handle most outboards and gasoline inboards.

- The OCP should be sized according to the wire ampacity and the load it needs to fuse. It should not exceed the ampacity of the wire unless the battery bank could be used to crank a motor.

- Breakers and fuses can be used interchangeably, but breakers have the advantage of being reusable, while fuses need to be replaced after they blow.

- It is recommended to have one battery in the front for the trolling motor and one in the rear for the sonar and backup for the trolling motor.

- A circuit breaker with a test button can be used to shut off the motor circuit and act as a safety measure.

- The negative wire from the trolling motor connects directly to the negative terminal of the battery, bypassing the breaker.

- A dual battery switch can be used to choose between the two batteries, combine them, or disconnect both.

- A crossover cable between the negative terminals of the two batteries is necessary for the dual-battery system to operate properly.

Starting Cold Boat Engines: A Step-by-Step Guide

You may want to see also

Wiring options: series wiring for large boats; parallel wiring for most other situations

When wiring two batteries on a John boat, there are two main wiring options to consider: series wiring, which is typically used for large boats, and parallel wiring, which is more common for smaller vessels.

Series Wiring for Large Boats

Series wiring is an option when you want to increase the voltage in your boat's electrical system. By connecting two batteries in series, you can double the voltage available, which can be beneficial for powering certain equipment or appliances. This setup is particularly useful for large boats with higher voltage requirements.

To wire two batteries in series, connect the positive terminal of one battery to the negative terminal of the other battery. This creates a path for current to flow, and the two batteries function as if they were a single battery with double the voltage.

However, it's important to note that the amperage, or current, remains the same in a series circuit. So, while series wiring increases voltage, it does not increase the overall power available.

Parallel Wiring for Most Other Situations

Parallel wiring is the more common configuration for boats, especially smaller vessels with lower voltage requirements. This type of wiring increases the overall power, or amperage, available by combining the capacities of both batteries while keeping the voltage the same.

To wire two batteries in parallel, connect the positive terminals of both batteries together, and do the same for the negative terminals. This creates a larger power source that can provide more current to your boat's electrical system.

Parallel wiring is generally a more versatile setup, as it allows you to power multiple devices or appliances simultaneously without overloading the circuit. It's also safer in terms of battery maintenance, as you don't have to worry about balancing the charge between the batteries.

Additional Considerations

When wiring two batteries, it's crucial to use the appropriate type of wire for your boat. Marine-grade wire is specifically designed to resist chafe and heat and typically has more copper conductor than automotive-grade wire, making it better suited for the marine environment.

Additionally, always follow safety precautions when working with batteries. Disconnect the positive battery cables from the terminals before beginning any electrical work to prevent short circuits and reduce the risk of electrocution.

Lastly, consult a professional marine electrician if you're unsure about the wiring process or have any specific questions regarding your boat's electrical system. They can provide guidance tailored to your boat's unique setup.

Keep Bugs Away: Boat Packing Essentials

You may want to see also

Frequently asked questions

The simplest way to wire two batteries is to buy a 1/2/both/off battery switch and connect both batteries to it. This will allow you to charge both batteries while the motor is running and then switch to the backup battery when you're stopped.

You should use a 1/2/both/off battery switch, also known as a dual battery switch or marine dual battery selector switch. This type of switch lets you choose one of the two batteries, combine them, or disconnect both.

Having two batteries gives you twice the battery capacity, which can be useful if you inadvertently drain one battery while the engine is off. You can also use the second battery as a backup in case the main battery fails.

You will need a second marine battery that meets your engine specifications, a battery selector switch, a battery box or bracket, marine-grade cables and cable lugs, heat-shrink tubing, terminal caps, a power drill, mounting screws, a crimper or soldering gun, and cable clamps.

First, connect the positive terminals of both batteries to the corresponding posts on the back of the switch. Then, connect the positive cable from the engine to the output post of the switch, along with the positive accessory wire. Finally, connect the negative cables, including a crossover cable between the negative terminals of the two batteries.

Yes, batteries contain a high amount of stored energy and can be dangerous. Always remove the positive battery cables from the terminals before working on the electrical system to eliminate the risk of short circuits and electrocution. Wear safety glasses and have a water hose available in case of battery acid spills.